Hydrogen storage materials standards and regulatory compliance assessment

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical component in the global transition towards clean energy systems, particularly as hydrogen gains prominence as a versatile energy carrier. The development of efficient, safe, and economically viable hydrogen storage materials represents one of the most significant challenges in realizing a hydrogen-based economy. Historically, hydrogen storage research began in the mid-20th century, with significant acceleration occurring in the 1970s following the oil crisis, which highlighted the need for alternative energy sources.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based solutions including metal hydrides, complex hydrides, chemical hydrogen carriers, and nanoporous materials. Each evolutionary step has aimed to address fundamental limitations in volumetric and gravimetric storage capacity, operating conditions, and system safety.

Current technological objectives in hydrogen storage materials development focus on meeting the stringent requirements established by international bodies such as the U.S. Department of Energy (DOE) and the International Energy Agency (IEA). These targets include achieving system-level gravimetric densities exceeding 6.5 wt% and volumetric densities above 50 g/L, while maintaining operating temperatures between -40°C and 60°C and pressures below 100 bar for practical applications.

Beyond performance metrics, modern hydrogen storage research aims to develop materials and systems that comply with increasingly rigorous safety standards and regulatory frameworks. This includes addressing challenges related to material stability, hydrogen embrittlement, thermal management during charging/discharging cycles, and compatibility with existing infrastructure.

The standardization landscape for hydrogen storage materials remains in active development, with organizations such as ISO, ASTM International, and national regulatory bodies working to establish comprehensive testing protocols, safety guidelines, and performance benchmarks. These standards are essential for facilitating commercial deployment and ensuring interoperability across different hydrogen technologies and applications.

Looking forward, the field is trending toward multifunctional storage materials that not only store hydrogen efficiently but also integrate catalytic properties for improved kinetics, self-healing capabilities for extended cycling, and enhanced thermal management features. Computational materials science and high-throughput experimental techniques are accelerating the discovery and optimization of novel storage materials with unprecedented properties.

The ultimate goal of hydrogen storage materials development is to enable widespread adoption of hydrogen as an energy carrier across multiple sectors, including transportation, stationary power generation, and industrial processes, thereby contributing significantly to global decarbonization efforts.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based solutions including metal hydrides, complex hydrides, chemical hydrogen carriers, and nanoporous materials. Each evolutionary step has aimed to address fundamental limitations in volumetric and gravimetric storage capacity, operating conditions, and system safety.

Current technological objectives in hydrogen storage materials development focus on meeting the stringent requirements established by international bodies such as the U.S. Department of Energy (DOE) and the International Energy Agency (IEA). These targets include achieving system-level gravimetric densities exceeding 6.5 wt% and volumetric densities above 50 g/L, while maintaining operating temperatures between -40°C and 60°C and pressures below 100 bar for practical applications.

Beyond performance metrics, modern hydrogen storage research aims to develop materials and systems that comply with increasingly rigorous safety standards and regulatory frameworks. This includes addressing challenges related to material stability, hydrogen embrittlement, thermal management during charging/discharging cycles, and compatibility with existing infrastructure.

The standardization landscape for hydrogen storage materials remains in active development, with organizations such as ISO, ASTM International, and national regulatory bodies working to establish comprehensive testing protocols, safety guidelines, and performance benchmarks. These standards are essential for facilitating commercial deployment and ensuring interoperability across different hydrogen technologies and applications.

Looking forward, the field is trending toward multifunctional storage materials that not only store hydrogen efficiently but also integrate catalytic properties for improved kinetics, self-healing capabilities for extended cycling, and enhanced thermal management features. Computational materials science and high-throughput experimental techniques are accelerating the discovery and optimization of novel storage materials with unprecedented properties.

The ultimate goal of hydrogen storage materials development is to enable widespread adoption of hydrogen as an energy carrier across multiple sectors, including transportation, stationary power generation, and industrial processes, thereby contributing significantly to global decarbonization efforts.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage materials market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition towards a hydrogen economy. Current market valuations indicate that the hydrogen storage market reached approximately 14.8 billion USD in 2022, with projections suggesting a compound annual growth rate of 5.8% through 2030. This growth trajectory is primarily fueled by governmental commitments to carbon neutrality and substantial investments in hydrogen infrastructure across major economies.

The market segmentation for hydrogen storage solutions reveals distinct categories based on storage methods: physical-based storage (compressed gas, liquid hydrogen, and cryogenic storage) and material-based storage (metal hydrides, chemical hydrides, and carbon-based materials). Currently, physical-based storage dominates the market share at roughly 70%, with compressed gas hydrogen being the most widely adopted solution due to its technological maturity and established infrastructure.

Regional analysis demonstrates that Asia-Pacific, particularly Japan, South Korea, and China, leads in hydrogen storage technology development and implementation, accounting for approximately 40% of the global market. Europe follows closely with a 35% market share, driven by aggressive decarbonization policies and substantial investments in hydrogen infrastructure. North America represents about 20% of the market, with growing momentum in both research and commercial applications.

Key market drivers include stringent emission regulations, increasing renewable energy integration requiring energy storage solutions, and the expanding application of hydrogen in transportation, particularly in fuel cell electric vehicles. The commercial vehicle segment, including buses and trucks, shows the highest growth potential for hydrogen storage solutions, with a projected market expansion of 12% annually.

Market challenges persist, primarily centered around cost factors. The levelized cost of hydrogen storage remains significantly higher than conventional energy storage methods, with material-based storage solutions still facing commercialization barriers due to performance limitations and manufacturing complexities. Additionally, the lack of standardized regulatory frameworks across regions creates market fragmentation and impedes global scale deployment.

Consumer adoption trends indicate growing acceptance of hydrogen technologies in industrial applications, with the power generation and transportation sectors showing the strongest demand growth. Market forecasts suggest that material-based storage solutions, particularly advanced metal hydrides and nanoporous materials, will gain substantial market share by 2030 as research breakthroughs address current limitations in storage capacity and operational efficiency.

The market segmentation for hydrogen storage solutions reveals distinct categories based on storage methods: physical-based storage (compressed gas, liquid hydrogen, and cryogenic storage) and material-based storage (metal hydrides, chemical hydrides, and carbon-based materials). Currently, physical-based storage dominates the market share at roughly 70%, with compressed gas hydrogen being the most widely adopted solution due to its technological maturity and established infrastructure.

Regional analysis demonstrates that Asia-Pacific, particularly Japan, South Korea, and China, leads in hydrogen storage technology development and implementation, accounting for approximately 40% of the global market. Europe follows closely with a 35% market share, driven by aggressive decarbonization policies and substantial investments in hydrogen infrastructure. North America represents about 20% of the market, with growing momentum in both research and commercial applications.

Key market drivers include stringent emission regulations, increasing renewable energy integration requiring energy storage solutions, and the expanding application of hydrogen in transportation, particularly in fuel cell electric vehicles. The commercial vehicle segment, including buses and trucks, shows the highest growth potential for hydrogen storage solutions, with a projected market expansion of 12% annually.

Market challenges persist, primarily centered around cost factors. The levelized cost of hydrogen storage remains significantly higher than conventional energy storage methods, with material-based storage solutions still facing commercialization barriers due to performance limitations and manufacturing complexities. Additionally, the lack of standardized regulatory frameworks across regions creates market fragmentation and impedes global scale deployment.

Consumer adoption trends indicate growing acceptance of hydrogen technologies in industrial applications, with the power generation and transportation sectors showing the strongest demand growth. Market forecasts suggest that material-based storage solutions, particularly advanced metal hydrides and nanoporous materials, will gain substantial market share by 2030 as research breakthroughs address current limitations in storage capacity and operational efficiency.

Current Technical Challenges in Hydrogen Storage Materials

Despite significant advancements in hydrogen storage technologies, several critical technical challenges persist that impede widespread adoption of hydrogen as a mainstream energy carrier. Material-based storage systems face fundamental limitations in achieving the U.S. Department of Energy's targets for volumetric and gravimetric capacity. Current high-pressure tanks typically achieve only 5.5 wt% hydrogen storage, falling short of the 6.5 wt% target for automotive applications, while maintaining system costs below $10/kWh remains elusive.

Durability and cycling stability represent major hurdles for practical implementation. Metal hydrides suffer from degradation after repeated hydrogen absorption-desorption cycles, with capacity losses of 20-30% observed after 1000 cycles in many materials. This degradation is often accompanied by pulverization and structural changes that compromise long-term performance. Additionally, many promising materials exhibit slow kinetics, requiring temperatures above 300°C for hydrogen release, which creates significant energy penalties and system integration challenges.

Thermal management during hydrogen charging and discharging presents another substantial obstacle. The exothermic nature of hydrogen absorption generates heat that must be efficiently removed, while endothermic desorption requires heat input. Current heat exchanger designs struggle to manage these thermal requirements without adding prohibitive weight and complexity to storage systems, particularly for mobile applications.

Safety concerns and material compatibility issues further complicate development efforts. Many storage materials are highly reactive with air and moisture, necessitating complex handling protocols and robust containment systems. The potential for uncontrolled hydrogen release during accidents or material failure requires sophisticated safety systems that add cost and complexity.

Characterization and standardization challenges hinder consistent evaluation of materials. The lack of universally accepted testing protocols leads to discrepancies in reported performance metrics across research groups. This inconsistency complicates comparative analysis and slows the identification of truly promising materials. Furthermore, the absence of accelerated aging tests makes lifetime predictions difficult, creating uncertainty for commercial deployment.

Manufacturing scalability remains problematic for many advanced materials. Laboratory-scale synthesis methods often involve complex processes that are difficult to scale industrially while maintaining material performance. The high cost of precursors and specialized processing equipment contributes to prohibitive system costs, currently estimated at $15-25/kWh for most advanced storage materials, significantly above commercial targets.

Durability and cycling stability represent major hurdles for practical implementation. Metal hydrides suffer from degradation after repeated hydrogen absorption-desorption cycles, with capacity losses of 20-30% observed after 1000 cycles in many materials. This degradation is often accompanied by pulverization and structural changes that compromise long-term performance. Additionally, many promising materials exhibit slow kinetics, requiring temperatures above 300°C for hydrogen release, which creates significant energy penalties and system integration challenges.

Thermal management during hydrogen charging and discharging presents another substantial obstacle. The exothermic nature of hydrogen absorption generates heat that must be efficiently removed, while endothermic desorption requires heat input. Current heat exchanger designs struggle to manage these thermal requirements without adding prohibitive weight and complexity to storage systems, particularly for mobile applications.

Safety concerns and material compatibility issues further complicate development efforts. Many storage materials are highly reactive with air and moisture, necessitating complex handling protocols and robust containment systems. The potential for uncontrolled hydrogen release during accidents or material failure requires sophisticated safety systems that add cost and complexity.

Characterization and standardization challenges hinder consistent evaluation of materials. The lack of universally accepted testing protocols leads to discrepancies in reported performance metrics across research groups. This inconsistency complicates comparative analysis and slows the identification of truly promising materials. Furthermore, the absence of accelerated aging tests makes lifetime predictions difficult, creating uncertainty for commercial deployment.

Manufacturing scalability remains problematic for many advanced materials. Laboratory-scale synthesis methods often involve complex processes that are difficult to scale industrially while maintaining material performance. The high cost of precursors and specialized processing equipment contributes to prohibitive system costs, currently estimated at $15-25/kWh for most advanced storage materials, significantly above commercial targets.

Current Hydrogen Storage Material Solutions

01 Safety standards for hydrogen storage materials

Safety standards are critical for hydrogen storage materials to ensure they meet regulatory requirements. These standards address the safe handling, storage, and transportation of hydrogen materials, including pressure vessel specifications, leak detection protocols, and material compatibility requirements. Compliance with these standards helps minimize risks associated with hydrogen storage and ensures the safety of both users and the environment.- Safety standards for hydrogen storage materials: Hydrogen storage materials must comply with specific safety standards to ensure safe handling, storage, and transportation. These standards address issues such as material stability, pressure resistance, leak prevention, and compatibility with containment systems. Regulatory frameworks require rigorous testing and certification to verify that hydrogen storage materials meet established safety criteria before commercial deployment.

- Environmental compliance requirements for hydrogen storage technologies: Hydrogen storage materials are subject to environmental regulations that govern their production, use, and disposal. These regulations focus on minimizing environmental impact, reducing carbon footprint, and ensuring sustainable practices throughout the material lifecycle. Compliance requirements include environmental impact assessments, emissions monitoring, and adherence to waste management protocols specific to hydrogen storage technologies.

- Certification and testing protocols for hydrogen storage systems: Standardized testing and certification protocols are essential for validating the performance and safety of hydrogen storage materials. These protocols include procedures for measuring storage capacity, cycling stability, thermal management, and response to extreme conditions. Certification bodies require comprehensive documentation and testing results to verify compliance with industry standards before issuing approvals for commercial applications.

- International standards harmonization for hydrogen storage: The global nature of hydrogen technology development necessitates harmonization of international standards for hydrogen storage materials. Various international organizations work to align technical specifications, safety requirements, and testing methodologies across different regions. This harmonization facilitates global trade, technology transfer, and consistent safety practices while reducing regulatory barriers for hydrogen storage technologies.

- Regulatory frameworks for emerging hydrogen storage technologies: As innovative hydrogen storage materials and technologies emerge, regulatory frameworks are evolving to address novel safety and performance considerations. These frameworks include provisional standards for experimental materials, risk assessment methodologies for new storage approaches, and adaptive regulatory pathways that accommodate technological advancement while maintaining safety and reliability standards. Regulatory bodies work with industry stakeholders to develop appropriate compliance requirements for these emerging technologies.

02 Certification and compliance tracking systems

Specialized systems have been developed to track and manage regulatory compliance for hydrogen storage materials. These systems help organizations monitor certification status, document compliance with relevant standards, and maintain records for auditing purposes. They often include features for automated alerts when certifications are approaching expiration or when regulatory requirements change, ensuring continuous compliance with evolving standards.Expand Specific Solutions03 International regulatory frameworks for hydrogen technologies

Hydrogen storage materials are subject to various international regulatory frameworks that govern their development, testing, and deployment. These frameworks include standards from organizations such as ISO, IEC, and regional bodies that establish requirements for material performance, safety testing, and environmental impact. Companies working with hydrogen storage materials must navigate these complex international regulations to ensure global market access for their products.Expand Specific Solutions04 Material testing and qualification protocols

Specific testing and qualification protocols have been established for hydrogen storage materials to verify their compliance with regulatory standards. These protocols include cyclic loading tests, environmental exposure assessments, and performance evaluations under various operating conditions. The testing procedures ensure that materials can safely contain hydrogen under specified pressure and temperature ranges while maintaining structural integrity over their intended service life.Expand Specific Solutions05 Blockchain-based compliance verification

Innovative blockchain technologies are being applied to verify and document compliance with hydrogen storage material standards. These systems create immutable records of material testing, certification, and regulatory approvals throughout the supply chain. By using distributed ledger technology, stakeholders can access verified compliance information, enhancing transparency and trust in the regulatory compliance process for hydrogen storage materials.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Hydrogen storage materials standards and regulatory compliance assessment is currently in a growth phase, with the market expanding due to increasing focus on hydrogen as a clean energy carrier. The global market is projected to reach significant scale as hydrogen economies develop worldwide. Technologically, the field shows varying maturity levels across different storage solutions. Leading players include research institutions like Fraunhofer-Gesellschaft and Southwest Research Institute advancing fundamental technologies, while major automotive companies Toyota and Nissan are developing practical applications for vehicles. Energy giants like China Petroleum & Chemical Corp are investing in infrastructure solutions. Materials specialists such as GRZ Technologies, Santoku Corp, and ULVAC are making breakthroughs in advanced storage materials, with academic institutions like Zhejiang University contributing significant research to improve efficiency and safety standards.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive hydrogen storage solutions focusing on regulatory-compliant underground storage facilities and material-based systems. Their approach includes modified metal-organic frameworks (MOFs) with enhanced gravimetric capacity (7-8 wt%) that meet ISO/TC 197 standards for hydrogen technologies. Sinopec has established large-scale hydrogen purification and storage facilities that comply with GB/T 34425 (China's national standard for hydrogen fuel quality) and international standards like SAE J2719. Their underground salt cavern storage technology can safely store thousands of tons of hydrogen while meeting stringent safety regulations including NFPA 2 and CGA G-5.5 guidelines. Sinopec has also developed specialized pipeline materials resistant to hydrogen embrittlement that conform to ASME B31.12 standards for hydrogen piping and pipelines, enabling safe transport at pressures up to 20 MPa.

Strengths: Extensive infrastructure capabilities allowing for large-scale implementation; integrated supply chain from production to storage; strong government backing for standardization efforts. Weaknesses: Technologies primarily optimized for industrial-scale applications rather than mobile or small-scale solutions; regulatory framework heavily influenced by domestic rather than international standards.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced metal hydride storage systems for hydrogen that comply with global safety standards. Their technology focuses on high-density storage materials that meet SAE J2579 and ISO 16111 requirements for vehicular applications. Toyota's proprietary metal alloys can store hydrogen at lower pressures (around 10 MPa) while achieving volumetric densities comparable to 70 MPa compressed gas systems. Their materials undergo rigorous cycling stability tests (1,000+ cycles) and thermal management validation to ensure compliance with UN GTR No. 13 regulations. Toyota has also pioneered standardized testing protocols for evaluating hydrogen embrittlement in storage materials, which have been incorporated into industry standards. Their systems include integrated sensors and safety mechanisms that meet IEC 62282 standards for fuel cell technologies.

Strengths: Industry-leading expertise in metal hydride storage systems with proven implementation in commercial vehicles; comprehensive testing infrastructure for regulatory compliance verification. Weaknesses: Higher production costs compared to conventional storage methods; weight penalties that affect overall vehicle efficiency despite volumetric advantages.

Critical Patents and Technical Literature Review

Hydrogen storage materials

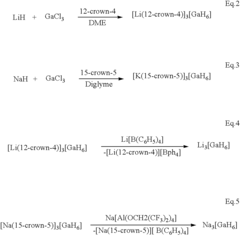

PatentInactiveUS7618611B2

Innovation

- A hydrogen storage material is developed using a liquid metal alloy that transitions from a solid in its charged state to a liquid in its discharged state, specifically utilizing gallium-based alloys like Li3Ga and Na3Ga, which can be hydrogenated to achieve high hydrogen content and facilitate efficient rehydrogenation, with methods including direct synthesis and a two-step process involving crown ether complexes.

Hydrogen storage materials containing liquid electrolytes

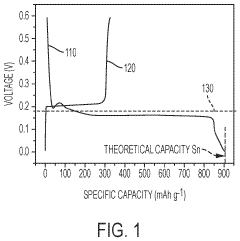

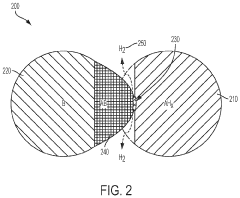

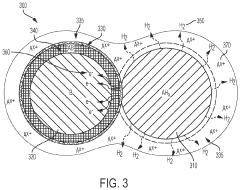

PatentActiveUS11050075B1

Innovation

- A hydrogen-storage material formulation comprising a solid hydrogen-storage material bonded ionically, covalently, or interstitially with a metal or metalloid, combined with a liquid electrolyte that is ionically conductive, enhancing hydrogen evolution rates and allowing for reversible dehydrogenation-hydrogenation cycles at practical temperatures and pressures.

Regulatory Framework and Compliance Requirements

The regulatory landscape for hydrogen storage materials is complex and multifaceted, spanning international, national, and regional frameworks. At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards like ISO 16111 for hydrogen absorbed in reversible metal hydride and ISO 19881 for gaseous hydrogen storage. These standards establish baseline requirements for safety, performance, and testing methodologies that manufacturers must adhere to globally.

In the United States, regulatory oversight is primarily managed by the Department of Energy (DOE) and the Department of Transportation (DOT). The DOE has established technical targets for hydrogen storage systems, including gravimetric capacity, volumetric capacity, and operational temperature ranges. Meanwhile, the DOT regulates the transportation of hydrogen storage materials through regulations like 49 CFR Parts 171-180, which address hazardous materials transportation requirements.

The European Union has implemented comprehensive regulations through directives such as the Pressure Equipment Directive (PED) 2014/68/EU and the Alternative Fuels Infrastructure Directive (AFID) 2014/94/EU. These frameworks establish safety requirements for pressure equipment and promote the development of alternative fuel infrastructure, including hydrogen refueling stations.

Compliance assessment for hydrogen storage materials involves rigorous testing protocols and certification processes. Materials must undergo extensive evaluation for mechanical properties, thermal stability, cycling durability, and safety characteristics. Third-party certification bodies like TÜV, UL, and DNV GL play crucial roles in verifying compliance with applicable standards and regulations.

Risk assessment methodologies form an integral part of the regulatory compliance process. Manufacturers must conduct Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) to identify potential failure modes and mitigate associated risks. These assessments must address concerns related to hydrogen embrittlement, pressure vessel integrity, and thermal management during charging and discharging cycles.

Emerging regulatory trends indicate a move toward harmonization of standards across different jurisdictions to facilitate global trade and technology deployment. Additionally, there is increasing focus on lifecycle assessment requirements, with regulations beginning to address end-of-life management and recyclability of hydrogen storage materials. This evolution reflects growing awareness of sustainability considerations in the hydrogen economy.

Navigating this complex regulatory landscape requires manufacturers to implement robust quality management systems and maintain comprehensive technical documentation demonstrating compliance with all applicable requirements. This documentation typically includes material specifications, test reports, risk assessments, and manufacturing process controls.

In the United States, regulatory oversight is primarily managed by the Department of Energy (DOE) and the Department of Transportation (DOT). The DOE has established technical targets for hydrogen storage systems, including gravimetric capacity, volumetric capacity, and operational temperature ranges. Meanwhile, the DOT regulates the transportation of hydrogen storage materials through regulations like 49 CFR Parts 171-180, which address hazardous materials transportation requirements.

The European Union has implemented comprehensive regulations through directives such as the Pressure Equipment Directive (PED) 2014/68/EU and the Alternative Fuels Infrastructure Directive (AFID) 2014/94/EU. These frameworks establish safety requirements for pressure equipment and promote the development of alternative fuel infrastructure, including hydrogen refueling stations.

Compliance assessment for hydrogen storage materials involves rigorous testing protocols and certification processes. Materials must undergo extensive evaluation for mechanical properties, thermal stability, cycling durability, and safety characteristics. Third-party certification bodies like TÜV, UL, and DNV GL play crucial roles in verifying compliance with applicable standards and regulations.

Risk assessment methodologies form an integral part of the regulatory compliance process. Manufacturers must conduct Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) to identify potential failure modes and mitigate associated risks. These assessments must address concerns related to hydrogen embrittlement, pressure vessel integrity, and thermal management during charging and discharging cycles.

Emerging regulatory trends indicate a move toward harmonization of standards across different jurisdictions to facilitate global trade and technology deployment. Additionally, there is increasing focus on lifecycle assessment requirements, with regulations beginning to address end-of-life management and recyclability of hydrogen storage materials. This evolution reflects growing awareness of sustainability considerations in the hydrogen economy.

Navigating this complex regulatory landscape requires manufacturers to implement robust quality management systems and maintain comprehensive technical documentation demonstrating compliance with all applicable requirements. This documentation typically includes material specifications, test reports, risk assessments, and manufacturing process controls.

Safety Standards and Risk Assessment Methodologies

The safety landscape for hydrogen storage materials is governed by a comprehensive framework of international and regional standards that address the unique hazards associated with hydrogen technologies. Key standards include ISO/TC 197 for hydrogen technologies, which provides specifications for safe hydrogen storage systems, and IEC 62282 series focusing on fuel cell technologies. These standards establish critical parameters for material performance, containment integrity, and operational safety across the hydrogen value chain.

Risk assessment methodologies for hydrogen storage materials have evolved significantly, incorporating both deterministic and probabilistic approaches. The Quantitative Risk Assessment (QRA) methodology has emerged as a predominant framework, enabling systematic identification of potential failure modes in storage systems. This approach integrates Failure Mode and Effects Analysis (FMEA) with consequence modeling to quantify risks associated with hydrogen release scenarios, including potential for fire, explosion, and asphyxiation hazards.

Material-specific safety protocols have been developed to address the unique challenges posed by different hydrogen storage technologies. For metal hydrides, standards focus on thermal management during hydrogenation/dehydrogenation cycles and potential pyrophoricity. Complex hydride materials require additional considerations regarding stability and decomposition products, while carbon-based materials are evaluated for dust explosion risks and structural integrity under cycling conditions.

Testing protocols for hydrogen storage materials have become increasingly sophisticated, incorporating accelerated aging tests, extreme condition exposure, and cyclic loading to validate long-term safety performance. These protocols typically evaluate parameters such as permeation rates, embrittlement resistance, and thermal stability under both normal and abnormal operating conditions.

Regulatory compliance frameworks vary significantly across jurisdictions, creating challenges for global deployment of hydrogen technologies. The European Union has established the most comprehensive regulatory environment through directives such as the Pressure Equipment Directive (PED) and ATEX for explosive atmospheres. In the United States, regulations are distributed across multiple agencies including DOT, EPA and OSHA, while Japan and South Korea have developed specialized hydrogen safety codes to support their hydrogen economy initiatives.

Emerging risk assessment methodologies are increasingly incorporating digital twins and AI-driven predictive analytics to enhance safety monitoring capabilities. These approaches enable real-time risk assessment and adaptive safety management, representing a significant advancement over traditional static risk assessment models. The integration of these technologies with standardized safety protocols promises to substantially improve the safety profile of next-generation hydrogen storage systems.

Risk assessment methodologies for hydrogen storage materials have evolved significantly, incorporating both deterministic and probabilistic approaches. The Quantitative Risk Assessment (QRA) methodology has emerged as a predominant framework, enabling systematic identification of potential failure modes in storage systems. This approach integrates Failure Mode and Effects Analysis (FMEA) with consequence modeling to quantify risks associated with hydrogen release scenarios, including potential for fire, explosion, and asphyxiation hazards.

Material-specific safety protocols have been developed to address the unique challenges posed by different hydrogen storage technologies. For metal hydrides, standards focus on thermal management during hydrogenation/dehydrogenation cycles and potential pyrophoricity. Complex hydride materials require additional considerations regarding stability and decomposition products, while carbon-based materials are evaluated for dust explosion risks and structural integrity under cycling conditions.

Testing protocols for hydrogen storage materials have become increasingly sophisticated, incorporating accelerated aging tests, extreme condition exposure, and cyclic loading to validate long-term safety performance. These protocols typically evaluate parameters such as permeation rates, embrittlement resistance, and thermal stability under both normal and abnormal operating conditions.

Regulatory compliance frameworks vary significantly across jurisdictions, creating challenges for global deployment of hydrogen technologies. The European Union has established the most comprehensive regulatory environment through directives such as the Pressure Equipment Directive (PED) and ATEX for explosive atmospheres. In the United States, regulations are distributed across multiple agencies including DOT, EPA and OSHA, while Japan and South Korea have developed specialized hydrogen safety codes to support their hydrogen economy initiatives.

Emerging risk assessment methodologies are increasingly incorporating digital twins and AI-driven predictive analytics to enhance safety monitoring capabilities. These approaches enable real-time risk assessment and adaptive safety management, representing a significant advancement over traditional static risk assessment models. The integration of these technologies with standardized safety protocols promises to substantially improve the safety profile of next-generation hydrogen storage systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!