Analysis of Pintle Hitch in Transport Infrastructure Planning

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to the changing needs of transport infrastructure planning. Initially developed in the early 20th century, the pintle hitch was primarily used in military applications for towing artillery pieces and other heavy equipment. Its robust design and ability to handle heavy loads made it an ideal choice for military operations.

As transportation needs expanded beyond military use, the pintle hitch found its way into civilian applications. In the 1950s and 1960s, it began to be utilized in commercial trucking, particularly for heavy-duty towing and hauling operations. This transition marked a crucial point in its evolution, as manufacturers started to refine the design to meet the specific requirements of various industries.

The 1970s and 1980s saw further advancements in pintle hitch technology. Engineers focused on improving the hitch's durability and load-bearing capacity, incorporating stronger materials and more sophisticated manufacturing techniques. This period also witnessed the introduction of standardized pintle hitch designs, which facilitated greater compatibility between different vehicles and trailers.

In the 1990s, safety became a primary concern in transport infrastructure planning. As a result, pintle hitch designs were enhanced to include additional safety features such as secondary locking mechanisms and improved coupling systems. These innovations significantly reduced the risk of trailer separation during transit, a critical factor in ensuring road safety.

The turn of the millennium brought about a new era of technological integration. Smart pintle hitches began to emerge, incorporating sensors and electronic systems to monitor coupling status, load distribution, and wear. These advancements allowed for real-time data collection and analysis, contributing to more efficient fleet management and predictive maintenance strategies.

Recent years have seen a focus on sustainability and environmental considerations in transport infrastructure planning. This has led to the development of lightweight yet strong pintle hitch designs, utilizing advanced materials such as high-strength alloys and composites. These innovations have contributed to improved fuel efficiency and reduced emissions in heavy-duty transport operations.

Looking towards the future, the evolution of pintle hitches is likely to continue in line with broader trends in transportation technology. Integration with autonomous vehicle systems, further enhancements in smart monitoring capabilities, and adaptations for alternative fuel vehicles are all potential areas for development. As transport infrastructure planning becomes increasingly complex and data-driven, the pintle hitch will undoubtedly continue to evolve to meet the changing demands of the industry.

As transportation needs expanded beyond military use, the pintle hitch found its way into civilian applications. In the 1950s and 1960s, it began to be utilized in commercial trucking, particularly for heavy-duty towing and hauling operations. This transition marked a crucial point in its evolution, as manufacturers started to refine the design to meet the specific requirements of various industries.

The 1970s and 1980s saw further advancements in pintle hitch technology. Engineers focused on improving the hitch's durability and load-bearing capacity, incorporating stronger materials and more sophisticated manufacturing techniques. This period also witnessed the introduction of standardized pintle hitch designs, which facilitated greater compatibility between different vehicles and trailers.

In the 1990s, safety became a primary concern in transport infrastructure planning. As a result, pintle hitch designs were enhanced to include additional safety features such as secondary locking mechanisms and improved coupling systems. These innovations significantly reduced the risk of trailer separation during transit, a critical factor in ensuring road safety.

The turn of the millennium brought about a new era of technological integration. Smart pintle hitches began to emerge, incorporating sensors and electronic systems to monitor coupling status, load distribution, and wear. These advancements allowed for real-time data collection and analysis, contributing to more efficient fleet management and predictive maintenance strategies.

Recent years have seen a focus on sustainability and environmental considerations in transport infrastructure planning. This has led to the development of lightweight yet strong pintle hitch designs, utilizing advanced materials such as high-strength alloys and composites. These innovations have contributed to improved fuel efficiency and reduced emissions in heavy-duty transport operations.

Looking towards the future, the evolution of pintle hitches is likely to continue in line with broader trends in transportation technology. Integration with autonomous vehicle systems, further enhancements in smart monitoring capabilities, and adaptations for alternative fuel vehicles are all potential areas for development. As transport infrastructure planning becomes increasingly complex and data-driven, the pintle hitch will undoubtedly continue to evolve to meet the changing demands of the industry.

Market Demand Analysis

The market demand for pintle hitches in transport infrastructure planning has been steadily growing, driven by the increasing need for efficient and versatile towing solutions across various industries. The global pintle hitch market is experiencing significant expansion, particularly in sectors such as construction, agriculture, and logistics. This growth is attributed to the rising demand for heavy-duty towing capabilities and the versatility that pintle hitches offer in handling diverse load types.

In the construction industry, pintle hitches are becoming increasingly popular due to their ability to securely tow heavy equipment and materials across job sites. The ongoing urbanization and infrastructure development projects worldwide are fueling the demand for robust towing solutions, making pintle hitches an essential component in construction vehicle fleets. Similarly, in the agricultural sector, the trend towards larger and more powerful farming machinery has led to a greater need for reliable towing mechanisms, further boosting the market for pintle hitches.

The logistics and transportation industry is another key driver of pintle hitch demand. With the growth of e-commerce and the subsequent increase in freight movement, there is a rising need for versatile towing solutions that can handle a wide range of trailer types and load capacities. Pintle hitches, known for their durability and ability to withstand high tongue weights, are well-suited to meet these evolving requirements in the logistics sector.

Market analysis indicates that the adoption of pintle hitches is not uniform across regions. Developed economies in North America and Europe currently dominate the market, owing to their advanced transportation infrastructure and stringent safety regulations. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in pintle hitch adoption as they invest heavily in infrastructure development and modernize their transportation systems.

The market is also seeing a shift towards more advanced pintle hitch designs that offer enhanced safety features, improved load distribution, and easier coupling mechanisms. Manufacturers are focusing on developing innovative products that address specific industry needs, such as adjustable-height pintle hitches for improved versatility and combination pintle hook and ball mounts for greater flexibility in towing different trailer types.

Environmental considerations are increasingly influencing market trends, with a growing emphasis on lightweight yet durable materials that can improve fuel efficiency without compromising on towing capacity. This trend is likely to drive research and development efforts in the pintle hitch industry, potentially leading to new materials and design innovations in the coming years.

As transport infrastructure planning continues to evolve, the role of pintle hitches in ensuring efficient and safe towing operations is expected to grow. The market is projected to expand further as industries recognize the benefits of these versatile towing solutions in improving operational efficiency and meeting diverse towing requirements across various applications.

In the construction industry, pintle hitches are becoming increasingly popular due to their ability to securely tow heavy equipment and materials across job sites. The ongoing urbanization and infrastructure development projects worldwide are fueling the demand for robust towing solutions, making pintle hitches an essential component in construction vehicle fleets. Similarly, in the agricultural sector, the trend towards larger and more powerful farming machinery has led to a greater need for reliable towing mechanisms, further boosting the market for pintle hitches.

The logistics and transportation industry is another key driver of pintle hitch demand. With the growth of e-commerce and the subsequent increase in freight movement, there is a rising need for versatile towing solutions that can handle a wide range of trailer types and load capacities. Pintle hitches, known for their durability and ability to withstand high tongue weights, are well-suited to meet these evolving requirements in the logistics sector.

Market analysis indicates that the adoption of pintle hitches is not uniform across regions. Developed economies in North America and Europe currently dominate the market, owing to their advanced transportation infrastructure and stringent safety regulations. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in pintle hitch adoption as they invest heavily in infrastructure development and modernize their transportation systems.

The market is also seeing a shift towards more advanced pintle hitch designs that offer enhanced safety features, improved load distribution, and easier coupling mechanisms. Manufacturers are focusing on developing innovative products that address specific industry needs, such as adjustable-height pintle hitches for improved versatility and combination pintle hook and ball mounts for greater flexibility in towing different trailer types.

Environmental considerations are increasingly influencing market trends, with a growing emphasis on lightweight yet durable materials that can improve fuel efficiency without compromising on towing capacity. This trend is likely to drive research and development efforts in the pintle hitch industry, potentially leading to new materials and design innovations in the coming years.

As transport infrastructure planning continues to evolve, the role of pintle hitches in ensuring efficient and safe towing operations is expected to grow. The market is projected to expand further as industries recognize the benefits of these versatile towing solutions in improving operational efficiency and meeting diverse towing requirements across various applications.

Technical Challenges

The implementation of pintle hitches in transport infrastructure planning faces several significant technical challenges that require careful consideration and innovative solutions. One of the primary obstacles is the need for enhanced durability and strength to withstand the high stress and strain associated with heavy-duty towing applications. The constant exposure to varying load conditions, road vibrations, and environmental factors necessitates advanced materials and design techniques to ensure long-term reliability and safety.

Another critical challenge lies in the optimization of weight distribution and stability. As transport vehicles become larger and heavier, the pintle hitch must effectively manage the transfer of weight between the towing vehicle and the trailer. This requires sophisticated engineering to minimize sway, improve handling, and maintain overall vehicle stability, especially during high-speed travel or in adverse weather conditions.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While sensors and electronic systems can enhance safety and performance, their implementation must be robust enough to withstand harsh operating conditions. Ensuring the reliability of these electronic components in environments prone to dust, moisture, and extreme temperatures is a significant technical hurdle.

Standardization and compatibility across different vehicle types and manufacturers pose another challenge. As transport infrastructure becomes increasingly interconnected, there is a growing need for universal pintle hitch designs that can accommodate a wide range of vehicles and trailers. This requires extensive collaboration between industry stakeholders and regulatory bodies to develop and implement standardized specifications.

Environmental considerations also play a crucial role in pintle hitch design. The push for more fuel-efficient and environmentally friendly transportation solutions demands lighter yet stronger materials, as well as aerodynamic designs that reduce drag and improve overall vehicle efficiency. Balancing these requirements with the need for robust and reliable performance is a complex engineering challenge.

Maintenance and serviceability present additional technical hurdles. As pintle hitches become more sophisticated, incorporating advanced materials and electronic systems, ensuring ease of maintenance and repair becomes increasingly important. Designing components that are both highly durable and easily serviceable requires innovative approaches to modular design and materials selection.

Lastly, the adaptation of pintle hitch technology to emerging transport modes, such as autonomous vehicles and platooning systems, introduces new technical challenges. These advanced transport solutions require pintle hitches that can interface with complex control systems and potentially operate without human intervention, necessitating the development of new safety protocols and fail-safe mechanisms.

Another critical challenge lies in the optimization of weight distribution and stability. As transport vehicles become larger and heavier, the pintle hitch must effectively manage the transfer of weight between the towing vehicle and the trailer. This requires sophisticated engineering to minimize sway, improve handling, and maintain overall vehicle stability, especially during high-speed travel or in adverse weather conditions.

The integration of smart technologies into pintle hitch systems presents both opportunities and challenges. While sensors and electronic systems can enhance safety and performance, their implementation must be robust enough to withstand harsh operating conditions. Ensuring the reliability of these electronic components in environments prone to dust, moisture, and extreme temperatures is a significant technical hurdle.

Standardization and compatibility across different vehicle types and manufacturers pose another challenge. As transport infrastructure becomes increasingly interconnected, there is a growing need for universal pintle hitch designs that can accommodate a wide range of vehicles and trailers. This requires extensive collaboration between industry stakeholders and regulatory bodies to develop and implement standardized specifications.

Environmental considerations also play a crucial role in pintle hitch design. The push for more fuel-efficient and environmentally friendly transportation solutions demands lighter yet stronger materials, as well as aerodynamic designs that reduce drag and improve overall vehicle efficiency. Balancing these requirements with the need for robust and reliable performance is a complex engineering challenge.

Maintenance and serviceability present additional technical hurdles. As pintle hitches become more sophisticated, incorporating advanced materials and electronic systems, ensuring ease of maintenance and repair becomes increasingly important. Designing components that are both highly durable and easily serviceable requires innovative approaches to modular design and materials selection.

Lastly, the adaptation of pintle hitch technology to emerging transport modes, such as autonomous vehicles and platooning systems, introduces new technical challenges. These advanced transport solutions require pintle hitches that can interface with complex control systems and potentially operate without human intervention, necessitating the development of new safety protocols and fail-safe mechanisms.

Current Solutions

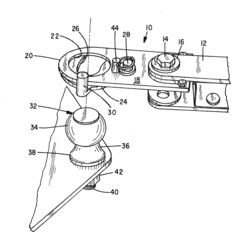

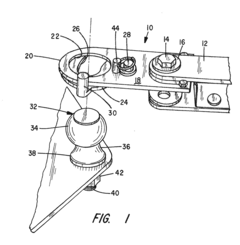

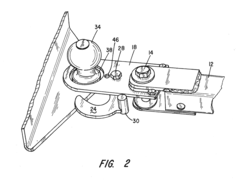

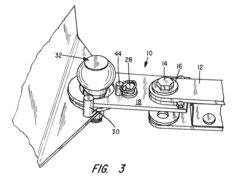

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism that can withstand heavy loads and provide flexibility in towing various types of trailers. Some designs incorporate additional features for improved safety and ease of use.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism and a locking system to ensure safe towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Locking mechanisms for pintle hitches: Various locking mechanisms are employed in pintle hitches to secure the connection between the towing vehicle and the trailer. These can include spring-loaded latches, pins, or other devices that prevent accidental disconnection during towing. Advanced locking systems may incorporate additional safety features or indicators to ensure proper engagement.

- Adjustable and multi-functional pintle hitches: Some pintle hitches are designed to be adjustable or multi-functional, allowing for greater versatility in towing applications. These may include features such as adjustable height, interchangeable coupling mechanisms, or the ability to accommodate different types of trailers. Such designs enhance the utility of the hitch for various towing needs.

- Integration of pintle hitches with other towing components: Pintle hitches can be integrated with other towing components to create more comprehensive towing systems. This may include combination designs that incorporate ball hitches, drawbars, or other attachment points. Such integrations can provide increased flexibility and functionality for diverse towing requirements.

- Safety features and enhancements for pintle hitches: Various safety features and enhancements have been developed for pintle hitches to improve their reliability and ease of use. These can include visual indicators for proper coupling, anti-rattle mechanisms, improved weight distribution systems, or enhanced corrosion resistance. Such features aim to increase the overall safety and performance of pintle hitch systems.

02 Locking mechanisms for pintle hitches

Various locking mechanisms are employed in pintle hitches to ensure secure attachment and prevent accidental disconnection during towing. These may include spring-loaded latches, safety pins, or automated locking systems that engage when the trailer is properly connected. Some designs incorporate multiple locking points for added security.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Adjustable pintle hitches allow for customization of the hitch height or position to accommodate different trailer configurations. Some designs incorporate multiple attachment points or interchangeable components to enable towing of various trailer types with a single hitch system. This versatility improves the utility of the towing vehicle.Expand Specific Solutions04 Integration of pintle hitches with other towing components

Some pintle hitch designs integrate additional towing components such as ball hitches, drawbars, or receiver systems. This integration allows for greater flexibility in towing different types of trailers without the need for separate hitch installations. These combination systems often feature quick-release mechanisms for easy switching between hitch types.Expand Specific Solutions05 Safety features and enhancements for pintle hitches

Modern pintle hitch designs incorporate various safety features to improve towing security and performance. These may include built-in shock absorbers to reduce stress on the towing vehicle, anti-rattle mechanisms to minimize noise and wear, and visual indicators to confirm proper coupling. Some designs also feature integrated brake controllers or electrical connections for trailer systems.Expand Specific Solutions

Key Industry Players

The analysis of Pintle Hitch in transport infrastructure planning reveals a competitive landscape in its early development stage. The market size is relatively small but growing, driven by increasing demand for efficient and versatile coupling systems in various transportation sectors. The technology's maturity is still evolving, with key players like Deere & Co., Ford Motor Co., and The Boeing Co. investing in research and development to enhance pintle hitch applications. These companies are leveraging their expertise in automotive and aerospace industries to adapt pintle hitch technology for diverse transport infrastructure needs, indicating a potential for significant market expansion and technological advancements in the near future.

Cisco Technology, Inc.

Technical Solution: Cisco Technology has applied its networking and IoT expertise to develop smart pintle hitch systems for improved transport infrastructure planning. Their approach focuses on creating a connected ecosystem of vehicles and infrastructure elements. Cisco's smart pintle hitch incorporates embedded sensors and communication modules that enable real-time data exchange between the towing vehicle, trailer, and surrounding infrastructure[12]. This system can monitor factors such as load distribution, wear patterns, and environmental conditions, providing valuable insights for infrastructure planning and maintenance. Cisco has also developed a cloud-based analytics platform that aggregates data from multiple vehicles and pintle hitches to identify trends and optimize transport routes[13]. The platform can integrate with existing traffic management systems to improve overall transportation efficiency and reduce congestion in urban areas.

Strengths: Strong focus on connectivity and data-driven insights, integration with existing smart city infrastructure. Weaknesses: Reliance on network connectivity, potential cybersecurity concerns.

The Boeing Co.

Technical Solution: Boeing has applied its aerospace engineering expertise to develop innovative pintle hitch solutions for ground transport applications. Their approach focuses on lightweight, high-strength materials and advanced load distribution techniques. Boeing's pintle hitch design incorporates composite materials and alloys typically used in aircraft construction, resulting in a significant weight reduction while maintaining exceptional strength[4]. The company has also implemented a dynamic load balancing system that uses hydraulic actuators to adjust the hitch's position in response to changing road conditions and vehicle dynamics[5]. This technology helps to minimize wear on both the towing vehicle and the trailer, potentially extending the lifespan of transport infrastructure[6].

Strengths: Lightweight yet durable construction, advanced load balancing capabilities. Weaknesses: Potentially high production costs, may require specialized training for maintenance personnel.

Core Innovations

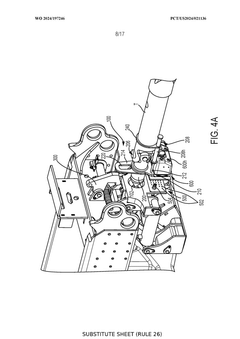

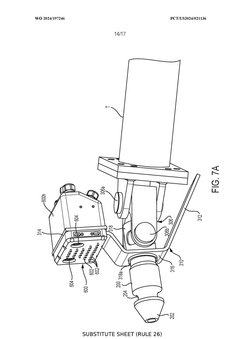

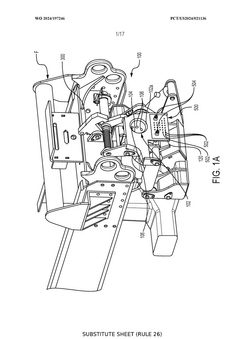

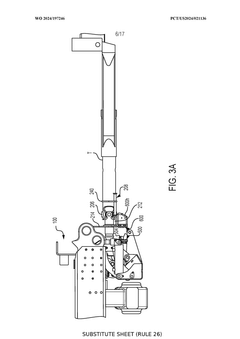

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Pintle Hitch For Coupling A Towed Implement To A Towing Vehicle

PatentInactiveUS20120139210A1

Innovation

- A pintle coupler design featuring a plate member with a first aperture and a pivotally connected retainer member with a U-shaped inset, which aligns with the aperture to securely capture a hitch ball using a spring-ball pin for locking, preventing unintended disengagement.

Safety Regulations

Safety regulations play a crucial role in the implementation and operation of pintle hitches in transport infrastructure planning. These regulations are designed to ensure the safe and efficient use of pintle hitches, which are essential components in connecting trailers to towing vehicles. The primary focus of safety regulations is to minimize the risk of accidents, injuries, and equipment damage associated with the use of pintle hitches.

One of the key aspects of safety regulations for pintle hitches is the establishment of standardized manufacturing and testing procedures. These standards ensure that all pintle hitches meet minimum safety requirements before they are approved for use in transport infrastructure. Regulatory bodies, such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO), have developed specific guidelines for the design, construction, and performance of pintle hitches.

Safety regulations also address the proper installation and maintenance of pintle hitches. This includes guidelines for the correct mounting of the hitch to the towing vehicle, as well as regular inspection and maintenance procedures to ensure the continued safe operation of the hitch. Proper lubrication, tightening of bolts, and checking for wear and tear are all essential aspects of maintaining pintle hitches in compliance with safety regulations.

Another important aspect of safety regulations is the specification of load capacities and towing limits for pintle hitches. These regulations define the maximum weight that can be safely towed using a particular pintle hitch, taking into account factors such as the strength of the hitch, the capacity of the towing vehicle, and the road conditions. Adhering to these weight limits is crucial for preventing accidents caused by overloading or improper load distribution.

Safety regulations also mandate the use of additional safety features in conjunction with pintle hitches. This includes the requirement for safety chains or cables as a secondary connection between the towing vehicle and the trailer. These safety devices are designed to prevent complete separation of the trailer from the towing vehicle in the event of a hitch failure, providing an additional layer of safety during transport operations.

Training and certification requirements for operators using pintle hitches are another important component of safety regulations. These regulations ensure that individuals responsible for coupling and uncoupling trailers, as well as those operating vehicles with pintle hitches, have the necessary knowledge and skills to do so safely. This may include formal training programs, practical assessments, and periodic recertification to maintain competency.

Lastly, safety regulations for pintle hitches often include provisions for reporting and investigating incidents or accidents involving these devices. This allows regulatory bodies and manufacturers to identify potential safety issues, implement corrective measures, and continuously improve the safety standards for pintle hitches in transport infrastructure planning.

One of the key aspects of safety regulations for pintle hitches is the establishment of standardized manufacturing and testing procedures. These standards ensure that all pintle hitches meet minimum safety requirements before they are approved for use in transport infrastructure. Regulatory bodies, such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO), have developed specific guidelines for the design, construction, and performance of pintle hitches.

Safety regulations also address the proper installation and maintenance of pintle hitches. This includes guidelines for the correct mounting of the hitch to the towing vehicle, as well as regular inspection and maintenance procedures to ensure the continued safe operation of the hitch. Proper lubrication, tightening of bolts, and checking for wear and tear are all essential aspects of maintaining pintle hitches in compliance with safety regulations.

Another important aspect of safety regulations is the specification of load capacities and towing limits for pintle hitches. These regulations define the maximum weight that can be safely towed using a particular pintle hitch, taking into account factors such as the strength of the hitch, the capacity of the towing vehicle, and the road conditions. Adhering to these weight limits is crucial for preventing accidents caused by overloading or improper load distribution.

Safety regulations also mandate the use of additional safety features in conjunction with pintle hitches. This includes the requirement for safety chains or cables as a secondary connection between the towing vehicle and the trailer. These safety devices are designed to prevent complete separation of the trailer from the towing vehicle in the event of a hitch failure, providing an additional layer of safety during transport operations.

Training and certification requirements for operators using pintle hitches are another important component of safety regulations. These regulations ensure that individuals responsible for coupling and uncoupling trailers, as well as those operating vehicles with pintle hitches, have the necessary knowledge and skills to do so safely. This may include formal training programs, practical assessments, and periodic recertification to maintain competency.

Lastly, safety regulations for pintle hitches often include provisions for reporting and investigating incidents or accidents involving these devices. This allows regulatory bodies and manufacturers to identify potential safety issues, implement corrective measures, and continuously improve the safety standards for pintle hitches in transport infrastructure planning.

Environmental Impact

The environmental impact of pintle hitches in transport infrastructure planning is a crucial consideration that extends beyond their immediate functional role. These coupling devices, while essential for connecting trailers to towing vehicles, have both direct and indirect effects on the environment throughout their lifecycle.

The manufacturing process of pintle hitches involves the extraction and processing of raw materials, primarily steel and other metals. This phase contributes to resource depletion and energy consumption, resulting in greenhouse gas emissions and potential pollution of air, water, and soil. The production facilities themselves may also have localized environmental impacts, including noise pollution and habitat disruption.

During the operational phase, pintle hitches play a significant role in the efficiency of transportation systems. Well-designed and properly maintained hitches can contribute to reduced fuel consumption by ensuring secure and stable connections between vehicles and trailers. This, in turn, leads to lower emissions of carbon dioxide and other pollutants associated with vehicle exhaust.

However, the use of pintle hitches also facilitates the movement of heavy loads and larger vehicles, which can have negative environmental consequences. Increased road wear from heavier vehicles may lead to more frequent road maintenance and reconstruction, resulting in additional resource consumption and emissions from construction activities.

The disposal and end-of-life management of pintle hitches present another set of environmental challenges. While many components can be recycled, the process requires energy and may produce waste materials. Improper disposal can lead to soil and water contamination, particularly if the hitches have been exposed to lubricants or other potentially harmful substances during their operational life.

In the context of transport infrastructure planning, the environmental impact of pintle hitches must be considered alongside their safety and efficiency benefits. Planners and engineers should focus on optimizing hitch designs to minimize material use, enhance durability, and improve recyclability. Additionally, the integration of pintle hitches into broader sustainable transportation strategies can help mitigate their environmental footprint.

Innovative approaches, such as the use of lightweight materials or the development of multi-functional hitch designs that reduce the need for additional components, can contribute to minimizing environmental impacts. Furthermore, the implementation of lifecycle assessment methodologies in the planning and design phases can provide valuable insights into the long-term environmental consequences of pintle hitch deployment in transport infrastructure.

The manufacturing process of pintle hitches involves the extraction and processing of raw materials, primarily steel and other metals. This phase contributes to resource depletion and energy consumption, resulting in greenhouse gas emissions and potential pollution of air, water, and soil. The production facilities themselves may also have localized environmental impacts, including noise pollution and habitat disruption.

During the operational phase, pintle hitches play a significant role in the efficiency of transportation systems. Well-designed and properly maintained hitches can contribute to reduced fuel consumption by ensuring secure and stable connections between vehicles and trailers. This, in turn, leads to lower emissions of carbon dioxide and other pollutants associated with vehicle exhaust.

However, the use of pintle hitches also facilitates the movement of heavy loads and larger vehicles, which can have negative environmental consequences. Increased road wear from heavier vehicles may lead to more frequent road maintenance and reconstruction, resulting in additional resource consumption and emissions from construction activities.

The disposal and end-of-life management of pintle hitches present another set of environmental challenges. While many components can be recycled, the process requires energy and may produce waste materials. Improper disposal can lead to soil and water contamination, particularly if the hitches have been exposed to lubricants or other potentially harmful substances during their operational life.

In the context of transport infrastructure planning, the environmental impact of pintle hitches must be considered alongside their safety and efficiency benefits. Planners and engineers should focus on optimizing hitch designs to minimize material use, enhance durability, and improve recyclability. Additionally, the integration of pintle hitches into broader sustainable transportation strategies can help mitigate their environmental footprint.

Innovative approaches, such as the use of lightweight materials or the development of multi-functional hitch designs that reduce the need for additional components, can contribute to minimizing environmental impacts. Furthermore, the implementation of lifecycle assessment methodologies in the planning and design phases can provide valuable insights into the long-term environmental consequences of pintle hitch deployment in transport infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!