Pintle Hitch Influence on Trailer Sway Prevention

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of the pintle hitch represents a significant advancement in trailer coupling technology, particularly in its role in preventing trailer sway. The pintle hitch, originally developed in the early 20th century, has undergone several iterations to enhance its performance and safety features.

In its earliest form, the pintle hitch consisted of a simple hook and ring system. This basic design provided a sturdy connection between the towing vehicle and the trailer but offered limited control over trailer movement. As transportation needs grew more complex, engineers recognized the need for a more sophisticated coupling mechanism.

The mid-20th century saw the introduction of the lunette ring, a circular eye that replaced the simple ring of earlier designs. This modification allowed for greater articulation between the towing vehicle and the trailer, improving maneuverability. However, the increased flexibility also highlighted the need for better sway control.

In response to this challenge, manufacturers began incorporating spring-loaded mechanisms into pintle hitches. These springs helped to dampen the lateral forces that contribute to trailer sway, marking a significant step forward in trailer stability. This innovation was particularly beneficial for heavy-duty applications in construction and military sectors.

The late 20th century brought further refinements to pintle hitch design. Engineers introduced adjustable pintle hooks that could be tightened or loosened to accommodate different trailer weights and road conditions. This adaptability greatly enhanced the hitch's versatility and effectiveness in preventing sway across various towing scenarios.

Recent decades have seen the integration of advanced materials and manufacturing techniques in pintle hitch production. High-strength alloys and precision engineering have resulted in hitches capable of handling greater loads while maintaining optimal sway prevention characteristics. Additionally, the incorporation of electronic sensors and control systems has allowed for real-time monitoring and adjustment of trailer behavior.

Modern pintle hitches often feature integrated sway control mechanisms. These systems use friction-based or hydraulic components to actively resist lateral movements of the trailer. Such innovations have significantly improved the stability and safety of towed vehicles, particularly in challenging driving conditions.

The ongoing evolution of pintle hitches continues to focus on enhancing their role in trailer sway prevention. Current research explores the use of smart materials and adaptive systems that can automatically adjust to changing road and load conditions. These developments promise to further refine the pintle hitch's capabilities in maintaining trailer stability and improving overall towing safety.

In its earliest form, the pintle hitch consisted of a simple hook and ring system. This basic design provided a sturdy connection between the towing vehicle and the trailer but offered limited control over trailer movement. As transportation needs grew more complex, engineers recognized the need for a more sophisticated coupling mechanism.

The mid-20th century saw the introduction of the lunette ring, a circular eye that replaced the simple ring of earlier designs. This modification allowed for greater articulation between the towing vehicle and the trailer, improving maneuverability. However, the increased flexibility also highlighted the need for better sway control.

In response to this challenge, manufacturers began incorporating spring-loaded mechanisms into pintle hitches. These springs helped to dampen the lateral forces that contribute to trailer sway, marking a significant step forward in trailer stability. This innovation was particularly beneficial for heavy-duty applications in construction and military sectors.

The late 20th century brought further refinements to pintle hitch design. Engineers introduced adjustable pintle hooks that could be tightened or loosened to accommodate different trailer weights and road conditions. This adaptability greatly enhanced the hitch's versatility and effectiveness in preventing sway across various towing scenarios.

Recent decades have seen the integration of advanced materials and manufacturing techniques in pintle hitch production. High-strength alloys and precision engineering have resulted in hitches capable of handling greater loads while maintaining optimal sway prevention characteristics. Additionally, the incorporation of electronic sensors and control systems has allowed for real-time monitoring and adjustment of trailer behavior.

Modern pintle hitches often feature integrated sway control mechanisms. These systems use friction-based or hydraulic components to actively resist lateral movements of the trailer. Such innovations have significantly improved the stability and safety of towed vehicles, particularly in challenging driving conditions.

The ongoing evolution of pintle hitches continues to focus on enhancing their role in trailer sway prevention. Current research explores the use of smart materials and adaptive systems that can automatically adjust to changing road and load conditions. These developments promise to further refine the pintle hitch's capabilities in maintaining trailer stability and improving overall towing safety.

Trailer Sway Market

The trailer sway market has experienced significant growth in recent years, driven by increasing concerns about road safety and the rising popularity of recreational vehicle (RV) travel. Trailer sway, a dangerous oscillation that can occur when towing a trailer, has become a critical focus for both manufacturers and consumers in the automotive and RV industries.

Market demand for trailer sway prevention solutions has been steadily increasing, particularly in North America and Europe, where RV ownership and usage are most prevalent. The COVID-19 pandemic has further accelerated this trend, as more people have turned to RV travel as a safer alternative to traditional vacations. This shift in consumer behavior has led to a surge in trailer sales and, consequently, a greater need for effective sway prevention technologies.

The market for trailer sway prevention solutions can be segmented into two main categories: active and passive systems. Active systems, such as electronic stability control (ESC) and trailer sway control (TSC), have seen rapid adoption in recent years. These systems use sensors and computer-controlled braking to detect and mitigate sway in real-time. Passive systems, including weight distribution hitches and sway control bars, continue to maintain a significant market share due to their lower cost and simplicity.

Key players in the trailer sway prevention market include major automotive manufacturers like Ford, General Motors, and Toyota, who have integrated sway control technologies into their towing-capable vehicles. Specialized aftermarket companies such as Husky Towing Products, Equal-i-zer Hitch, and Hensley Manufacturing also hold significant market share, offering a range of hitches and sway control devices.

The market size for trailer sway prevention solutions is estimated to be in the billions of dollars globally, with steady growth projected over the next five years. This growth is driven not only by increasing RV sales but also by stricter safety regulations and growing awareness among consumers about the importance of towing safety.

Emerging trends in the trailer sway market include the integration of artificial intelligence and machine learning algorithms to improve the effectiveness of active sway control systems. Additionally, there is a growing focus on developing lightweight, high-strength materials for passive sway control devices, addressing the need for fuel efficiency without compromising safety.

The pintle hitch, while traditionally used in heavy-duty towing applications, is gaining attention in the broader trailer sway prevention market. Its unique design, which allows for greater articulation and potentially reduced sway in certain conditions, is being researched for its applicability in a wider range of towing scenarios. This represents a potential shift in the market, as manufacturers explore innovative ways to combine the strength of pintle hitches with advanced sway prevention technologies.

Market demand for trailer sway prevention solutions has been steadily increasing, particularly in North America and Europe, where RV ownership and usage are most prevalent. The COVID-19 pandemic has further accelerated this trend, as more people have turned to RV travel as a safer alternative to traditional vacations. This shift in consumer behavior has led to a surge in trailer sales and, consequently, a greater need for effective sway prevention technologies.

The market for trailer sway prevention solutions can be segmented into two main categories: active and passive systems. Active systems, such as electronic stability control (ESC) and trailer sway control (TSC), have seen rapid adoption in recent years. These systems use sensors and computer-controlled braking to detect and mitigate sway in real-time. Passive systems, including weight distribution hitches and sway control bars, continue to maintain a significant market share due to their lower cost and simplicity.

Key players in the trailer sway prevention market include major automotive manufacturers like Ford, General Motors, and Toyota, who have integrated sway control technologies into their towing-capable vehicles. Specialized aftermarket companies such as Husky Towing Products, Equal-i-zer Hitch, and Hensley Manufacturing also hold significant market share, offering a range of hitches and sway control devices.

The market size for trailer sway prevention solutions is estimated to be in the billions of dollars globally, with steady growth projected over the next five years. This growth is driven not only by increasing RV sales but also by stricter safety regulations and growing awareness among consumers about the importance of towing safety.

Emerging trends in the trailer sway market include the integration of artificial intelligence and machine learning algorithms to improve the effectiveness of active sway control systems. Additionally, there is a growing focus on developing lightweight, high-strength materials for passive sway control devices, addressing the need for fuel efficiency without compromising safety.

The pintle hitch, while traditionally used in heavy-duty towing applications, is gaining attention in the broader trailer sway prevention market. Its unique design, which allows for greater articulation and potentially reduced sway in certain conditions, is being researched for its applicability in a wider range of towing scenarios. This represents a potential shift in the market, as manufacturers explore innovative ways to combine the strength of pintle hitches with advanced sway prevention technologies.

Sway Prevention Tech

Trailer sway prevention technology has evolved significantly over the years, with various solutions emerging to address this critical safety concern. The pintle hitch, a robust coupling mechanism traditionally used in heavy-duty applications, has gained attention for its potential role in mitigating trailer sway.

Pintle hitches consist of a hook-like device on the towing vehicle that connects to a lunette ring on the trailer. This design allows for greater articulation and flexibility compared to traditional ball hitches, potentially offering improved stability during towing. The influence of pintle hitches on trailer sway prevention stems from their unique mechanical properties and load distribution characteristics.

One of the primary advantages of pintle hitches in sway prevention is their ability to reduce the pivot point between the towing vehicle and the trailer. This reduction in the pivot point can help minimize the lateral forces that contribute to trailer sway, especially during sudden maneuvers or in adverse weather conditions. Additionally, the robust construction of pintle hitches often provides a more secure connection, reducing play and enhancing overall stability.

Recent advancements in pintle hitch design have focused on integrating electronic stability control systems. These systems use sensors to detect trailer sway and automatically apply brakes to individual wheels on both the towing vehicle and the trailer, helping to bring the combination back under control. Some manufacturers have developed "smart" pintle hitches that incorporate load cells and accelerometers to provide real-time data on trailer movement and weight distribution.

Another area of development is the use of adaptive damping systems in conjunction with pintle hitches. These systems can adjust the suspension characteristics of the towing vehicle based on the trailer's behavior, further enhancing stability and reducing the likelihood of sway. Some advanced designs also incorporate active steering assistance, which can help counteract the forces that initiate trailer sway.

Research into materials science has led to the development of high-strength, lightweight alloys for pintle hitch construction. These materials offer improved durability and performance while reducing the overall weight of the hitch assembly. This weight reduction can contribute to better fuel efficiency and handling characteristics of the towing vehicle.

Despite these advancements, challenges remain in optimizing pintle hitch design for sway prevention across a wide range of trailer types and towing conditions. Ongoing research is focused on developing more sophisticated computer models to simulate the complex dynamics of trailer sway and the influence of various hitch designs. These models aim to provide insights that can lead to further improvements in pintle hitch technology and its application in trailer sway prevention.

Pintle hitches consist of a hook-like device on the towing vehicle that connects to a lunette ring on the trailer. This design allows for greater articulation and flexibility compared to traditional ball hitches, potentially offering improved stability during towing. The influence of pintle hitches on trailer sway prevention stems from their unique mechanical properties and load distribution characteristics.

One of the primary advantages of pintle hitches in sway prevention is their ability to reduce the pivot point between the towing vehicle and the trailer. This reduction in the pivot point can help minimize the lateral forces that contribute to trailer sway, especially during sudden maneuvers or in adverse weather conditions. Additionally, the robust construction of pintle hitches often provides a more secure connection, reducing play and enhancing overall stability.

Recent advancements in pintle hitch design have focused on integrating electronic stability control systems. These systems use sensors to detect trailer sway and automatically apply brakes to individual wheels on both the towing vehicle and the trailer, helping to bring the combination back under control. Some manufacturers have developed "smart" pintle hitches that incorporate load cells and accelerometers to provide real-time data on trailer movement and weight distribution.

Another area of development is the use of adaptive damping systems in conjunction with pintle hitches. These systems can adjust the suspension characteristics of the towing vehicle based on the trailer's behavior, further enhancing stability and reducing the likelihood of sway. Some advanced designs also incorporate active steering assistance, which can help counteract the forces that initiate trailer sway.

Research into materials science has led to the development of high-strength, lightweight alloys for pintle hitch construction. These materials offer improved durability and performance while reducing the overall weight of the hitch assembly. This weight reduction can contribute to better fuel efficiency and handling characteristics of the towing vehicle.

Despite these advancements, challenges remain in optimizing pintle hitch design for sway prevention across a wide range of trailer types and towing conditions. Ongoing research is focused on developing more sophisticated computer models to simulate the complex dynamics of trailer sway and the influence of various hitch designs. These models aim to provide insights that can lead to further improvements in pintle hitch technology and its application in trailer sway prevention.

Current Sway Solutions

01 Anti-sway mechanisms for pintle hitch trailers

Various anti-sway mechanisms have been developed to reduce trailer sway in pintle hitch systems. These include friction-based devices, hydraulic dampers, and spring-loaded mechanisms that work to counteract the lateral forces causing sway. These systems can be integrated into the hitch design or added as separate components to improve trailer stability and safety during towing.- Anti-sway mechanisms for pintle hitch trailers: Various anti-sway mechanisms have been developed to reduce trailer sway in pintle hitch systems. These include damping devices, stabilizing bars, and friction-based systems that help maintain alignment between the towing vehicle and the trailer. Such mechanisms can significantly improve stability and safety during towing operations.

- Adjustable pintle hitch designs: Adjustable pintle hitch designs allow for customization of the hitch position and angle. These designs often incorporate multiple mounting points or adjustable components that can be tailored to different trailer configurations. This flexibility helps optimize weight distribution and reduce sway potential for various towing scenarios.

- Integration of electronic stability control: Advanced pintle hitch systems incorporate electronic stability control features. These systems use sensors to detect trailer sway and automatically apply brakes or adjust vehicle dynamics to counteract the sway. This technology enhances safety by providing real-time corrections to maintain trailer stability.

- Improved pintle hitch locking mechanisms: Enhanced locking mechanisms for pintle hitches have been developed to ensure secure coupling between the towing vehicle and the trailer. These designs often feature multiple locking points or fail-safe systems to prevent accidental disconnection and reduce play in the hitch, which can contribute to trailer sway.

- Weight distribution systems for pintle hitches: Weight distribution systems specifically designed for pintle hitches help to evenly distribute the trailer's weight across the towing vehicle's axles. These systems often include adjustable spring bars or air-assisted components that can be fine-tuned to different load conditions, reducing the likelihood of trailer sway and improving overall towing stability.

02 Adjustable pintle hitch designs

Adjustable pintle hitch designs allow for customization of the hitch position and angle, which can help reduce trailer sway. These designs may include features such as multiple mounting positions, adjustable height mechanisms, or pivoting components that allow the driver to optimize the hitch configuration based on the specific trailer and load characteristics.Expand Specific Solutions03 Electronic sway control systems

Advanced electronic sway control systems have been developed for pintle hitch trailers. These systems use sensors to detect trailer movement and can automatically apply brakes or adjust vehicle dynamics to counteract sway. Some systems integrate with the vehicle's existing electronic stability control to provide a comprehensive approach to trailer stability management.Expand Specific Solutions04 Improved hitch coupling designs

Innovative coupling designs for pintle hitches aim to reduce play and increase stability at the connection point between the tow vehicle and trailer. These designs may incorporate features such as double-locking mechanisms, self-aligning components, or specialized materials that absorb vibrations and reduce the potential for sway initiation.Expand Specific Solutions05 Weight distribution systems for pintle hitches

Weight distribution systems adapted for use with pintle hitches help to evenly distribute the trailer's tongue weight across the tow vehicle's axles. By improving weight distribution, these systems can significantly reduce the likelihood of trailer sway and improve overall towing stability. Some designs integrate sway control features directly into the weight distribution apparatus.Expand Specific Solutions

Towing Industry Players

The research on pintle hitch influence on trailer sway prevention is in a developing stage, with the market showing potential for growth as vehicle safety concerns increase. The technology's maturity varies among key players, with established automotive companies like BYD, Ford, GM, and Bosch leading in innovation. Specialized firms such as Tuson RV Brakes and ACPS Automotive are also making significant contributions. The competitive landscape is diverse, including major automakers, parts manufacturers, and niche trailer technology companies. As the importance of trailer stability gains recognition, we can expect increased investment and technological advancements in this field.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced Trailer Sway Control (TSC) system that works in conjunction with their AdvanceTrac with Roll Stability Control (RSC) technology. This system uses gyroscopic sensors to detect trailer sway and automatically applies precise braking pressure to individual wheels and reduces engine torque to help maintain control[1]. Ford's TSC system also incorporates a unique algorithm that considers the trailer's weight and length, which are input by the driver, to optimize its response[2]. Additionally, Ford has patented a proactive trailer sway mitigation system that uses cameras and sensors to predict potential sway conditions before they occur, allowing for preemptive corrective actions[3].

Strengths: Integrated with existing stability control systems, considers trailer-specific parameters, and includes predictive capabilities. Weaknesses: Requires driver input for optimal performance, may not be as effective for very large or irregularly shaped trailers.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a sophisticated Trailer Sway Control system across its vehicle lineup, particularly in its trucks and SUVs. The system uses StabiliTrak sensors to monitor trailer movement and vehicle yaw rate. When sway is detected, it automatically applies both vehicle and trailer brakes (if equipped with an integrated trailer brake controller) to bring the trailer back in line[4]. GM's system also incorporates a feature called Proactive Roll Avoidance, which can predict potential rollover situations and take preventive action. Furthermore, GM has developed a patent-pending hitch design that actively counteracts trailer sway forces using hydraulic actuators integrated into the hitch assembly[5].

Strengths: Comprehensive approach combining vehicle and trailer braking, proactive roll avoidance, and innovative hitch design. Weaknesses: Full functionality may require additional equipment (e.g., integrated trailer brake controller), potentially increasing cost.

Pintle Hitch Patents

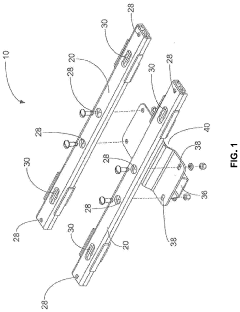

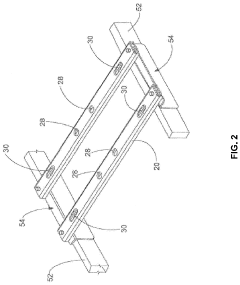

Fifth wheel conversion hitch mounting system

PatentActiveUS20200070905A1

Innovation

- A fifth wheel conversion hitch mounting system that selectively accommodates either a fifth wheel hitch or a gooseneck hitch, using an underbed hitch assembly with rails and a mid rail that includes a hitch ball socket, along with attachment points like a gooseneck collar and safety chain hold downs to prevent rotation, allowing for easy installation and removal without permanent modifications.

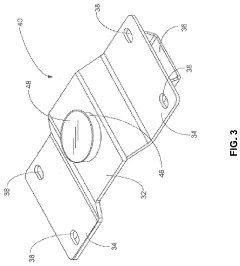

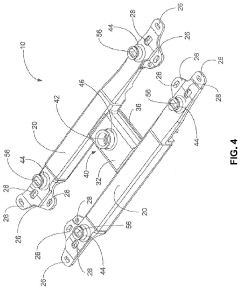

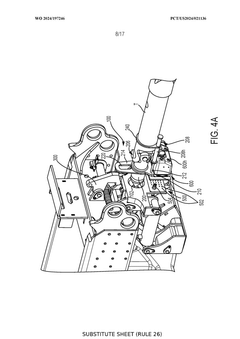

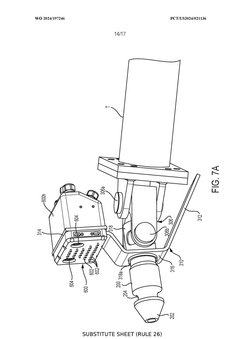

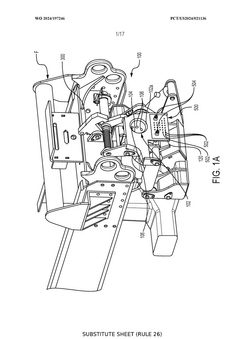

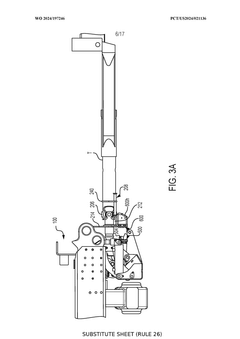

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Safety Regulations

Safety regulations play a crucial role in the research and implementation of pintle hitch systems for trailer sway prevention. These regulations are designed to ensure the safety of drivers, passengers, and other road users by establishing minimum standards for vehicle and trailer coupling systems.

In the United States, the National Highway Traffic Safety Administration (NHTSA) is responsible for developing and enforcing safety standards for motor vehicles and related equipment. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for trailer hitches and coupling devices. FMVSS No. 223 and 224 address rear impact guards for trailers, which indirectly affect the design and performance of pintle hitches.

The Society of Automotive Engineers (SAE) has also developed several standards relevant to pintle hitches and trailer sway prevention. SAE J684 provides guidelines for trailer couplings, hitches, and safety chains used in conjunction with trailers. This standard outlines performance requirements, test procedures, and design considerations for various types of hitches, including pintle hitches.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs mechanical coupling components between vehicles and trailers. This regulation specifies technical requirements and testing methods for coupling devices, including pintle hitches, to ensure their safety and reliability.

Australia and New Zealand follow the Australian Design Rules (ADR) for vehicle safety standards. ADR 62 specifically addresses mechanical connections between vehicles, including requirements for pintle hitches and other coupling systems used in trailer applications.

Compliance with these safety regulations is mandatory for manufacturers and importers of pintle hitches and related equipment. Regular testing and certification processes are required to ensure that products meet the established safety standards. These regulations are periodically reviewed and updated to address emerging safety concerns and technological advancements in trailer sway prevention.

Research on pintle hitch influence on trailer sway prevention must consider these safety regulations throughout the development and testing phases. Researchers and engineers need to design experiments and prototypes that not only demonstrate the effectiveness of pintle hitches in preventing trailer sway but also comply with the relevant safety standards.

Furthermore, safety regulations often drive innovation in the field of trailer sway prevention. As regulatory bodies identify new safety concerns or set more stringent requirements, manufacturers and researchers are compelled to develop advanced solutions that meet or exceed these standards. This regulatory pressure has led to the development of more sophisticated pintle hitch designs and integrated sway control systems.

In the United States, the National Highway Traffic Safety Administration (NHTSA) is responsible for developing and enforcing safety standards for motor vehicles and related equipment. The Federal Motor Vehicle Safety Standards (FMVSS) include specific requirements for trailer hitches and coupling devices. FMVSS No. 223 and 224 address rear impact guards for trailers, which indirectly affect the design and performance of pintle hitches.

The Society of Automotive Engineers (SAE) has also developed several standards relevant to pintle hitches and trailer sway prevention. SAE J684 provides guidelines for trailer couplings, hitches, and safety chains used in conjunction with trailers. This standard outlines performance requirements, test procedures, and design considerations for various types of hitches, including pintle hitches.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs mechanical coupling components between vehicles and trailers. This regulation specifies technical requirements and testing methods for coupling devices, including pintle hitches, to ensure their safety and reliability.

Australia and New Zealand follow the Australian Design Rules (ADR) for vehicle safety standards. ADR 62 specifically addresses mechanical connections between vehicles, including requirements for pintle hitches and other coupling systems used in trailer applications.

Compliance with these safety regulations is mandatory for manufacturers and importers of pintle hitches and related equipment. Regular testing and certification processes are required to ensure that products meet the established safety standards. These regulations are periodically reviewed and updated to address emerging safety concerns and technological advancements in trailer sway prevention.

Research on pintle hitch influence on trailer sway prevention must consider these safety regulations throughout the development and testing phases. Researchers and engineers need to design experiments and prototypes that not only demonstrate the effectiveness of pintle hitches in preventing trailer sway but also comply with the relevant safety standards.

Furthermore, safety regulations often drive innovation in the field of trailer sway prevention. As regulatory bodies identify new safety concerns or set more stringent requirements, manufacturers and researchers are compelled to develop advanced solutions that meet or exceed these standards. This regulatory pressure has led to the development of more sophisticated pintle hitch designs and integrated sway control systems.

Economic Impact

The economic impact of pintle hitch technology in trailer sway prevention extends far beyond the immediate safety benefits. The implementation of this technology has significant implications for various sectors of the economy, particularly in the transportation and logistics industries.

In the trucking sector, the adoption of pintle hitch systems for trailer sway prevention can lead to substantial cost savings. By reducing the likelihood of accidents caused by trailer sway, companies can minimize expenses related to vehicle repairs, cargo damage, and potential legal liabilities. This improved safety profile may also result in lower insurance premiums for fleet operators, contributing to overall operational cost reductions.

The manufacturing industry stands to benefit from increased demand for pintle hitch systems and related components. As awareness of the technology's effectiveness in preventing trailer sway grows, manufacturers specializing in these systems may experience heightened production volumes and revenue growth. This could stimulate job creation and economic activity within the automotive supply chain.

For the logistics and supply chain sector, the enhanced stability provided by pintle hitch technology can lead to more efficient and reliable transportation of goods. Reduced instances of trailer sway-related delays or accidents can improve delivery times and overall supply chain performance. This increased reliability may result in cost savings for businesses and potentially lower prices for consumers.

The tourism and recreational vehicle industry may also see positive economic impacts from the widespread adoption of pintle hitch technology. Improved safety features could encourage more people to engage in RV travel or towing activities, potentially boosting sales of trailers, campers, and related equipment. This could have ripple effects on tourism-dependent economies, particularly in areas popular for outdoor recreation.

From a broader economic perspective, the reduction in road accidents attributed to trailer sway can lead to decreased healthcare costs and reduced strain on emergency services. Additionally, fewer accidents mean less traffic congestion and associated productivity losses, contributing to overall economic efficiency.

The implementation of pintle hitch technology may also drive innovation and research in related fields, such as vehicle dynamics and control systems. This could lead to the development of new technologies and products, fostering economic growth in the research and development sector.

In the trucking sector, the adoption of pintle hitch systems for trailer sway prevention can lead to substantial cost savings. By reducing the likelihood of accidents caused by trailer sway, companies can minimize expenses related to vehicle repairs, cargo damage, and potential legal liabilities. This improved safety profile may also result in lower insurance premiums for fleet operators, contributing to overall operational cost reductions.

The manufacturing industry stands to benefit from increased demand for pintle hitch systems and related components. As awareness of the technology's effectiveness in preventing trailer sway grows, manufacturers specializing in these systems may experience heightened production volumes and revenue growth. This could stimulate job creation and economic activity within the automotive supply chain.

For the logistics and supply chain sector, the enhanced stability provided by pintle hitch technology can lead to more efficient and reliable transportation of goods. Reduced instances of trailer sway-related delays or accidents can improve delivery times and overall supply chain performance. This increased reliability may result in cost savings for businesses and potentially lower prices for consumers.

The tourism and recreational vehicle industry may also see positive economic impacts from the widespread adoption of pintle hitch technology. Improved safety features could encourage more people to engage in RV travel or towing activities, potentially boosting sales of trailers, campers, and related equipment. This could have ripple effects on tourism-dependent economies, particularly in areas popular for outdoor recreation.

From a broader economic perspective, the reduction in road accidents attributed to trailer sway can lead to decreased healthcare costs and reduced strain on emergency services. Additionally, fewer accidents mean less traffic congestion and associated productivity losses, contributing to overall economic efficiency.

The implementation of pintle hitch technology may also drive innovation and research in related fields, such as vehicle dynamics and control systems. This could lead to the development of new technologies and products, fostering economic growth in the research and development sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!