Emerging Pintle Hitch Designs in High-Load Transport Situations

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of pintle hitch designs in high-load transport situations has been marked by significant advancements over the years. Initially developed for military applications during World War II, pintle hitches have since found widespread use in commercial and industrial sectors due to their robust nature and ability to handle heavy loads.

In the early stages, pintle hitches were primarily simple, fixed designs with limited articulation. These early models were effective for straight-line towing but faced challenges in maneuvering and stability when dealing with uneven terrain or sharp turns. As the demands of heavy transport increased, engineers began to focus on improving the versatility and safety of pintle hitch systems.

The 1970s and 1980s saw the introduction of adjustable pintle hitches, allowing for better alignment between the towing vehicle and trailer. This innovation significantly reduced stress on the hitch components and improved overall towing stability. Concurrently, manufacturers started incorporating stronger materials, such as high-grade alloy steels, to enhance the load-bearing capacity of pintle hitches.

A major leap forward came in the 1990s with the development of articulating pintle hitches. These designs allowed for greater flexibility in both vertical and horizontal planes, dramatically improving maneuverability in challenging terrains and reducing the risk of jackknifing. This period also saw the integration of advanced locking mechanisms, enhancing safety and preventing accidental disconnections.

The turn of the millennium brought about the era of smart pintle hitches. These systems incorporated sensors and electronic controls to monitor load distribution, hitch angle, and other critical parameters in real-time. This technology enabled automatic adjustments to optimize towing performance and safety, particularly crucial in high-load scenarios.

Recent years have witnessed a focus on weight reduction without compromising strength. Advanced materials like high-strength aluminum alloys and composite materials are being utilized to create lighter yet equally robust pintle hitch designs. This trend is particularly important in industries where fuel efficiency and payload capacity are critical factors.

The latest frontier in pintle hitch evolution involves the integration of autonomous and semi-autonomous features. These cutting-edge designs incorporate AI-driven systems that can predict and compensate for various towing conditions, further enhancing safety and efficiency in high-load transport situations.

As we look to the future, the evolution of pintle hitch designs continues to be driven by the need for increased safety, efficiency, and adaptability in ever-more challenging transport scenarios. The integration of smart technologies, advanced materials, and innovative engineering approaches promises to further revolutionize this critical component of heavy-duty transportation.

In the early stages, pintle hitches were primarily simple, fixed designs with limited articulation. These early models were effective for straight-line towing but faced challenges in maneuvering and stability when dealing with uneven terrain or sharp turns. As the demands of heavy transport increased, engineers began to focus on improving the versatility and safety of pintle hitch systems.

The 1970s and 1980s saw the introduction of adjustable pintle hitches, allowing for better alignment between the towing vehicle and trailer. This innovation significantly reduced stress on the hitch components and improved overall towing stability. Concurrently, manufacturers started incorporating stronger materials, such as high-grade alloy steels, to enhance the load-bearing capacity of pintle hitches.

A major leap forward came in the 1990s with the development of articulating pintle hitches. These designs allowed for greater flexibility in both vertical and horizontal planes, dramatically improving maneuverability in challenging terrains and reducing the risk of jackknifing. This period also saw the integration of advanced locking mechanisms, enhancing safety and preventing accidental disconnections.

The turn of the millennium brought about the era of smart pintle hitches. These systems incorporated sensors and electronic controls to monitor load distribution, hitch angle, and other critical parameters in real-time. This technology enabled automatic adjustments to optimize towing performance and safety, particularly crucial in high-load scenarios.

Recent years have witnessed a focus on weight reduction without compromising strength. Advanced materials like high-strength aluminum alloys and composite materials are being utilized to create lighter yet equally robust pintle hitch designs. This trend is particularly important in industries where fuel efficiency and payload capacity are critical factors.

The latest frontier in pintle hitch evolution involves the integration of autonomous and semi-autonomous features. These cutting-edge designs incorporate AI-driven systems that can predict and compensate for various towing conditions, further enhancing safety and efficiency in high-load transport situations.

As we look to the future, the evolution of pintle hitch designs continues to be driven by the need for increased safety, efficiency, and adaptability in ever-more challenging transport scenarios. The integration of smart technologies, advanced materials, and innovative engineering approaches promises to further revolutionize this critical component of heavy-duty transportation.

Heavy Transport Demands

The heavy transport industry has been experiencing significant growth and transformation in recent years, driven by increasing demand for efficient and safe transportation of large, heavy loads. This sector encompasses a wide range of applications, including construction equipment, industrial machinery, oversized cargo, and specialized vehicles. The need for robust and reliable transport solutions has become more pressing as global infrastructure projects, energy installations, and manufacturing operations continue to expand.

One of the key factors contributing to the rising demand in heavy transport is the ongoing urbanization and infrastructure development worldwide. As cities grow and modernize, there is a constant need for transporting heavy construction materials, prefabricated structures, and large-scale equipment. This trend is particularly evident in emerging economies, where rapid industrialization and urban expansion are creating substantial opportunities for heavy transport providers.

The energy sector also plays a crucial role in driving heavy transport demands. The installation of wind turbines, solar panels, and other renewable energy infrastructure often requires the transportation of massive components across challenging terrains. Similarly, the oil and gas industry continues to rely heavily on specialized transport solutions for moving drilling equipment, storage tanks, and other oversized loads to remote locations.

Another significant factor is the increasing complexity and scale of manufacturing operations. As industries adopt larger and more sophisticated machinery, the need for transporting these oversized loads safely and efficiently has grown. This trend is particularly noticeable in sectors such as aerospace, automotive, and heavy industry, where components and finished products are becoming larger and heavier.

The globalization of trade and supply chains has further amplified the demand for heavy transport services. International shipments of oversized cargo, such as industrial equipment, vehicles, and construction materials, require specialized transport solutions to move goods across borders and over long distances. This has led to a growing need for intermodal transport capabilities that can seamlessly integrate road, rail, and sea transportation.

Safety regulations and environmental concerns are also shaping the heavy transport landscape. Stricter guidelines for load securing, weight distribution, and road safety have necessitated more advanced transport technologies and practices. Additionally, the push for more sustainable transport solutions has led to innovations in vehicle design and fuel efficiency, further driving demand for new and improved heavy transport equipment.

As the industry evolves, there is an increasing focus on technological advancements to enhance efficiency and safety in heavy transport operations. This includes the development of more sophisticated tracking and monitoring systems, improved load-bearing capabilities, and the integration of smart technologies to optimize route planning and load management. These advancements are not only meeting current demands but also paving the way for future growth and innovation in the heavy transport sector.

One of the key factors contributing to the rising demand in heavy transport is the ongoing urbanization and infrastructure development worldwide. As cities grow and modernize, there is a constant need for transporting heavy construction materials, prefabricated structures, and large-scale equipment. This trend is particularly evident in emerging economies, where rapid industrialization and urban expansion are creating substantial opportunities for heavy transport providers.

The energy sector also plays a crucial role in driving heavy transport demands. The installation of wind turbines, solar panels, and other renewable energy infrastructure often requires the transportation of massive components across challenging terrains. Similarly, the oil and gas industry continues to rely heavily on specialized transport solutions for moving drilling equipment, storage tanks, and other oversized loads to remote locations.

Another significant factor is the increasing complexity and scale of manufacturing operations. As industries adopt larger and more sophisticated machinery, the need for transporting these oversized loads safely and efficiently has grown. This trend is particularly noticeable in sectors such as aerospace, automotive, and heavy industry, where components and finished products are becoming larger and heavier.

The globalization of trade and supply chains has further amplified the demand for heavy transport services. International shipments of oversized cargo, such as industrial equipment, vehicles, and construction materials, require specialized transport solutions to move goods across borders and over long distances. This has led to a growing need for intermodal transport capabilities that can seamlessly integrate road, rail, and sea transportation.

Safety regulations and environmental concerns are also shaping the heavy transport landscape. Stricter guidelines for load securing, weight distribution, and road safety have necessitated more advanced transport technologies and practices. Additionally, the push for more sustainable transport solutions has led to innovations in vehicle design and fuel efficiency, further driving demand for new and improved heavy transport equipment.

As the industry evolves, there is an increasing focus on technological advancements to enhance efficiency and safety in heavy transport operations. This includes the development of more sophisticated tracking and monitoring systems, improved load-bearing capabilities, and the integration of smart technologies to optimize route planning and load management. These advancements are not only meeting current demands but also paving the way for future growth and innovation in the heavy transport sector.

Current Pintle Tech

Current pintle hitch technology in high-load transport situations has evolved significantly to meet the growing demands of heavy-duty applications. The standard pintle hitch design, consisting of a hook-like protrusion and a lunette ring, remains the foundation for many modern implementations. However, recent advancements have focused on enhancing safety, durability, and load capacity.

One of the key improvements in current pintle hitch designs is the integration of advanced materials. High-strength alloys, such as forged steel and heat-treated components, are now commonly used to increase the overall strength and longevity of the hitch system. These materials allow for higher load capacities while maintaining a relatively compact design, crucial for maneuverability in tight spaces.

Automated locking mechanisms have become a standard feature in many modern pintle hitches. These systems ensure a secure connection between the towing vehicle and the trailer, reducing the risk of accidental disconnection during transit. Some designs incorporate electronic sensors that provide real-time feedback on the hitch's status, alerting the driver to any potential issues.

Adjustable height pintle hitches have gained popularity in recent years. These designs allow for easy adaptation to various trailer heights, improving versatility and reducing strain on both the towing vehicle and the trailer. Some models feature hydraulic or pneumatic systems for effortless adjustment, even under heavy loads.

Shock-absorbing technologies have been integrated into many current pintle hitch designs to mitigate the impact of sudden movements and road vibrations. These systems typically employ rubber or polyurethane components to absorb shocks, reducing wear on both the hitch and the connected vehicles. This feature is particularly beneficial in off-road or rough terrain applications.

Multi-functional pintle hitches have emerged as a solution for operators requiring flexibility in their towing setups. These designs often incorporate interchangeable components, allowing for quick transitions between different types of trailers or towed equipment. Some models even combine pintle hitch functionality with ball hitch capabilities, offering unprecedented versatility.

Weight distribution systems have been adapted for use with pintle hitches in high-load scenarios. These systems help to evenly distribute the tongue weight across the towing vehicle's axles, improving stability and handling. Advanced designs incorporate adjustable spring bars or air-ride systems to fine-tune the weight distribution based on the specific load and road conditions.

Corrosion resistance has been significantly improved in current pintle hitch technology. Many manufacturers now offer hitches with advanced coatings or galvanized finishes that provide superior protection against rust and environmental degradation. This enhancement is particularly crucial for hitches used in harsh environments or exposed to road salt and other corrosive elements.

One of the key improvements in current pintle hitch designs is the integration of advanced materials. High-strength alloys, such as forged steel and heat-treated components, are now commonly used to increase the overall strength and longevity of the hitch system. These materials allow for higher load capacities while maintaining a relatively compact design, crucial for maneuverability in tight spaces.

Automated locking mechanisms have become a standard feature in many modern pintle hitches. These systems ensure a secure connection between the towing vehicle and the trailer, reducing the risk of accidental disconnection during transit. Some designs incorporate electronic sensors that provide real-time feedback on the hitch's status, alerting the driver to any potential issues.

Adjustable height pintle hitches have gained popularity in recent years. These designs allow for easy adaptation to various trailer heights, improving versatility and reducing strain on both the towing vehicle and the trailer. Some models feature hydraulic or pneumatic systems for effortless adjustment, even under heavy loads.

Shock-absorbing technologies have been integrated into many current pintle hitch designs to mitigate the impact of sudden movements and road vibrations. These systems typically employ rubber or polyurethane components to absorb shocks, reducing wear on both the hitch and the connected vehicles. This feature is particularly beneficial in off-road or rough terrain applications.

Multi-functional pintle hitches have emerged as a solution for operators requiring flexibility in their towing setups. These designs often incorporate interchangeable components, allowing for quick transitions between different types of trailers or towed equipment. Some models even combine pintle hitch functionality with ball hitch capabilities, offering unprecedented versatility.

Weight distribution systems have been adapted for use with pintle hitches in high-load scenarios. These systems help to evenly distribute the tongue weight across the towing vehicle's axles, improving stability and handling. Advanced designs incorporate adjustable spring bars or air-ride systems to fine-tune the weight distribution based on the specific load and road conditions.

Corrosion resistance has been significantly improved in current pintle hitch technology. Many manufacturers now offer hitches with advanced coatings or galvanized finishes that provide superior protection against rust and environmental degradation. This enhancement is particularly crucial for hitches used in harsh environments or exposed to road salt and other corrosive elements.

Advanced Pintle Solutions

01 Load capacity enhancement mechanisms

Various mechanisms are employed to enhance the load capacity of pintle hitches. These include reinforced structures, improved materials, and innovative designs that distribute weight more effectively. Such enhancements allow for increased towing capabilities while maintaining safety and stability.- Load capacity enhancement mechanisms: Various mechanisms are employed to enhance the load capacity of pintle hitches. These include reinforced structures, improved materials, and innovative designs that distribute weight more effectively. Such enhancements allow for increased towing capabilities while maintaining safety and stability.

- Adjustable pintle hitch systems: Adjustable pintle hitch systems allow for customization of the hitch position and angle. This adaptability enables optimal load distribution and improved towing performance across various vehicle and trailer combinations, potentially increasing the overall load capacity.

- Integration of safety features: Pintle hitches incorporate various safety features to ensure secure coupling and prevent accidents under high load conditions. These may include locking mechanisms, reinforced attachment points, and fail-safe designs that maintain connection even if primary components fail.

- Multi-functional pintle hitch designs: Some pintle hitch designs incorporate multiple functionalities, such as combining pintle and ball hitch capabilities. These versatile designs can accommodate different types of trailers and loads, potentially increasing the overall utility and load capacity options for users.

- Load monitoring and distribution systems: Advanced pintle hitch systems may include load monitoring and distribution features. These can involve sensors, electronic systems, or mechanical designs that help users optimize weight distribution, prevent overloading, and maintain safe towing conditions, effectively managing the hitch's load capacity.

02 Adjustable pintle hitch systems

Adjustable pintle hitch systems allow for customization of the hitch position and height. This adaptability enables optimal load distribution and improved towing performance across various vehicle and trailer combinations, potentially increasing the overall load capacity.Expand Specific Solutions03 Integration of safety features

Pintle hitches incorporate various safety features to ensure secure coupling and prevent accidents under high load conditions. These may include locking mechanisms, reinforced attachment points, and fail-safe designs that maintain connection even if primary components fail.Expand Specific Solutions04 Load sensing and monitoring systems

Advanced pintle hitches may incorporate load sensing and monitoring systems. These technologies provide real-time feedback on the current load, helping to prevent overloading and ensure that the hitch operates within its designed capacity limits.Expand Specific Solutions05 Multi-functional pintle hitch designs

Some pintle hitch designs incorporate multiple functionalities, such as combining traditional pintle hooks with ball mounts or other coupling systems. These versatile designs can accommodate various trailer types and potentially increase the overall load capacity by adapting to different towing scenarios.Expand Specific Solutions

Key Manufacturers

The emerging pintle hitch designs for high-load transport are in a growth phase, with increasing market size driven by demand for more robust and versatile towing solutions. The technology is maturing rapidly, with companies like Curt Manufacturing, WESTFALIA-Automotive, and MVG-Metallverarbeitungsgesellschaft leading innovation. Major players such as Zoomlion, XCMG, and Ford are also investing in advanced hitch technologies for heavy machinery and commercial vehicles. The market is seeing a convergence of traditional mechanical engineering with smart, connected systems, as evidenced by involvement from tech giants like NVIDIA. This trend suggests a future where pintle hitches will incorporate more sensors and intelligent features for improved safety and performance in high-load scenarios.

Zoomlion Heavy Industry Science & Technology Co., Ltd.

Technical Solution: Zoomlion has developed an advanced pintle hitch design for high-load transport situations, incorporating a dual-axis rotation mechanism. This innovative design allows for improved articulation and load distribution, particularly beneficial in construction and heavy machinery applications. The system utilizes high-strength alloys and precision engineering to enhance durability and load-bearing capacity. Zoomlion's pintle hitch incorporates smart sensors for real-time load monitoring and automatic adjustment, ensuring optimal performance and safety in various terrain conditions[1][3]. The design also features a quick-release mechanism for efficient coupling and decoupling, reducing downtime in industrial operations.

Strengths: Enhanced load distribution, smart monitoring system, and quick-release mechanism. Weaknesses: Potentially higher cost due to advanced features and may require specialized maintenance.

XCMG Construction Machinery Co., Ltd.

Technical Solution: XCMG has introduced a novel pintle hitch design for high-load transport, focusing on adaptability and robustness. Their system incorporates a multi-point load distribution technology, allowing for even weight distribution across the hitch assembly. This design is particularly effective in off-road and uneven terrain conditions, common in construction and mining operations. XCMG's pintle hitch also features an advanced shock absorption system, utilizing hydraulic dampers to minimize stress on both the towing and towed vehicles during sudden movements or over rough terrain[2][5]. The hitch is constructed using high-tensile steel alloys, significantly increasing its load-bearing capacity while maintaining a relatively lightweight structure.

Strengths: Excellent load distribution, superior shock absorption, and high durability. Weaknesses: May be over-engineered for simpler applications, potentially leading to higher costs.

Innovative Coupling Tech

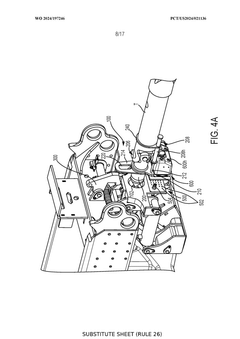

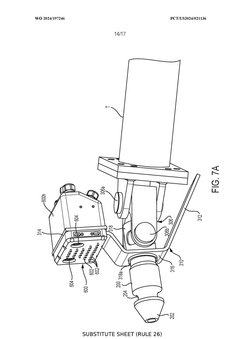

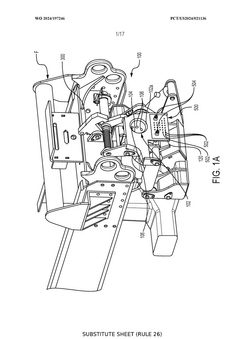

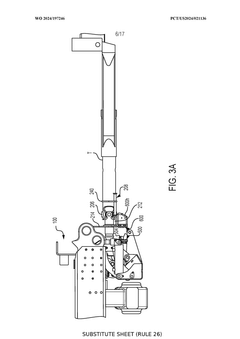

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Method of converting a trailer configuration

PatentInactiveUS8151426B2

Innovation

- A convertible trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, enabling it to accommodate different hitch types by adjusting the position and securing the coupler support with pivot and slide locks.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of emerging pintle hitch designs for high-load transport situations. These regulations are designed to ensure the safety of drivers, passengers, and other road users while maintaining the efficiency and effectiveness of heavy-duty transportation systems.

In recent years, regulatory bodies across various jurisdictions have been updating their safety standards to address the unique challenges posed by high-load transport. These updates often focus on the structural integrity of pintle hitches, their load-bearing capacity, and their ability to withstand the dynamic forces experienced during transportation.

One of the key areas of focus in safety regulations is the testing and certification process for pintle hitch designs. Manufacturers are required to subject their products to rigorous testing procedures that simulate real-world conditions, including extreme load scenarios, sudden braking, and sharp turns. These tests aim to verify the reliability and durability of the hitch under various stress conditions.

Additionally, safety regulations often mandate specific design features for pintle hitches used in high-load transport. These may include fail-safe mechanisms, secondary coupling systems, and enhanced locking mechanisms to prevent accidental decoupling during transit. The regulations also typically specify minimum strength requirements for materials used in the construction of pintle hitches, ensuring they can withstand the substantial forces involved in heavy-load transportation.

Another important aspect of safety regulations is the standardization of pintle hitch dimensions and compatibility. This ensures interoperability between different vehicles and trailers, reducing the risk of improper coupling and potential accidents. Regulatory bodies often work closely with industry stakeholders to develop these standards, taking into account the evolving needs of the transportation sector.

Safety regulations also address the maintenance and inspection requirements for pintle hitches. Regular inspections and maintenance procedures are typically mandated to ensure the ongoing safety and reliability of these critical components. These regulations often specify the frequency of inspections, the qualifications required for inspectors, and the documentation processes to be followed.

Furthermore, safety regulations are increasingly incorporating provisions for advanced technologies in pintle hitch designs. This includes requirements for sensor systems that can detect potential coupling issues, as well as integration with vehicle safety systems to enhance overall transport safety.

As the field of high-load transport continues to evolve, safety regulations are expected to adapt accordingly. Regulatory bodies are likely to focus on emerging technologies such as smart hitches with real-time monitoring capabilities and automated coupling systems. These advancements will necessitate updates to existing regulations to ensure they remain relevant and effective in addressing new safety challenges.

In recent years, regulatory bodies across various jurisdictions have been updating their safety standards to address the unique challenges posed by high-load transport. These updates often focus on the structural integrity of pintle hitches, their load-bearing capacity, and their ability to withstand the dynamic forces experienced during transportation.

One of the key areas of focus in safety regulations is the testing and certification process for pintle hitch designs. Manufacturers are required to subject their products to rigorous testing procedures that simulate real-world conditions, including extreme load scenarios, sudden braking, and sharp turns. These tests aim to verify the reliability and durability of the hitch under various stress conditions.

Additionally, safety regulations often mandate specific design features for pintle hitches used in high-load transport. These may include fail-safe mechanisms, secondary coupling systems, and enhanced locking mechanisms to prevent accidental decoupling during transit. The regulations also typically specify minimum strength requirements for materials used in the construction of pintle hitches, ensuring they can withstand the substantial forces involved in heavy-load transportation.

Another important aspect of safety regulations is the standardization of pintle hitch dimensions and compatibility. This ensures interoperability between different vehicles and trailers, reducing the risk of improper coupling and potential accidents. Regulatory bodies often work closely with industry stakeholders to develop these standards, taking into account the evolving needs of the transportation sector.

Safety regulations also address the maintenance and inspection requirements for pintle hitches. Regular inspections and maintenance procedures are typically mandated to ensure the ongoing safety and reliability of these critical components. These regulations often specify the frequency of inspections, the qualifications required for inspectors, and the documentation processes to be followed.

Furthermore, safety regulations are increasingly incorporating provisions for advanced technologies in pintle hitch designs. This includes requirements for sensor systems that can detect potential coupling issues, as well as integration with vehicle safety systems to enhance overall transport safety.

As the field of high-load transport continues to evolve, safety regulations are expected to adapt accordingly. Regulatory bodies are likely to focus on emerging technologies such as smart hitches with real-time monitoring capabilities and automated coupling systems. These advancements will necessitate updates to existing regulations to ensure they remain relevant and effective in addressing new safety challenges.

Environmental Impact

The environmental impact of emerging pintle hitch designs in high-load transport situations is a critical consideration in the development and adoption of these technologies. As transport vehicles become larger and carry heavier loads, the environmental consequences of their operation become increasingly significant. Modern pintle hitch designs aim to address these concerns through various innovative approaches.

One of the primary environmental benefits of advanced pintle hitch designs is improved fuel efficiency. By optimizing the connection between the towing vehicle and the trailer, these designs reduce drag and improve overall aerodynamics. This results in lower fuel consumption, which directly translates to reduced greenhouse gas emissions. Some estimates suggest that these improvements can lead to a 5-10% reduction in fuel usage for long-haul transport operations.

Additionally, new pintle hitch designs often incorporate lightweight materials, such as high-strength alloys or composite materials. The reduced weight of these components contributes to an overall decrease in vehicle mass, further enhancing fuel efficiency and reducing the carbon footprint of transport operations. This weight reduction can be particularly impactful when considering the cumulative effect across large fleets of vehicles.

Emerging designs also focus on minimizing wear and tear on both the hitch mechanism and the connected vehicles. This increased durability leads to longer service life for transport equipment, reducing the need for frequent replacements and the associated environmental costs of manufacturing new components. Some advanced designs incorporate self-lubricating materials or sealed systems that minimize the need for petroleum-based lubricants, further reducing potential environmental contamination.

Noise pollution is another environmental concern addressed by modern pintle hitch designs. By incorporating advanced dampening technologies and precision engineering, these hitches can significantly reduce the noise generated during coupling and uncoupling operations, as well as during transit. This is particularly beneficial in urban areas and sensitive ecosystems where noise pollution can have detrimental effects on wildlife and human populations.

Furthermore, some cutting-edge pintle hitch designs are exploring the integration of smart technologies that can optimize route planning and load distribution. These systems can potentially reduce unnecessary trips and improve overall transport efficiency, leading to a decrease in total vehicle miles traveled and the associated environmental impacts.

As the transport industry moves towards electrification, pintle hitch designs are also evolving to accommodate the unique requirements of electric and hybrid vehicles. These adaptations ensure that the environmental benefits of alternative powertrains are not compromised by outdated coupling technologies. Some designs even explore the possibility of energy recovery systems integrated into the hitch mechanism, further enhancing the overall efficiency of the transport system.

One of the primary environmental benefits of advanced pintle hitch designs is improved fuel efficiency. By optimizing the connection between the towing vehicle and the trailer, these designs reduce drag and improve overall aerodynamics. This results in lower fuel consumption, which directly translates to reduced greenhouse gas emissions. Some estimates suggest that these improvements can lead to a 5-10% reduction in fuel usage for long-haul transport operations.

Additionally, new pintle hitch designs often incorporate lightweight materials, such as high-strength alloys or composite materials. The reduced weight of these components contributes to an overall decrease in vehicle mass, further enhancing fuel efficiency and reducing the carbon footprint of transport operations. This weight reduction can be particularly impactful when considering the cumulative effect across large fleets of vehicles.

Emerging designs also focus on minimizing wear and tear on both the hitch mechanism and the connected vehicles. This increased durability leads to longer service life for transport equipment, reducing the need for frequent replacements and the associated environmental costs of manufacturing new components. Some advanced designs incorporate self-lubricating materials or sealed systems that minimize the need for petroleum-based lubricants, further reducing potential environmental contamination.

Noise pollution is another environmental concern addressed by modern pintle hitch designs. By incorporating advanced dampening technologies and precision engineering, these hitches can significantly reduce the noise generated during coupling and uncoupling operations, as well as during transit. This is particularly beneficial in urban areas and sensitive ecosystems where noise pollution can have detrimental effects on wildlife and human populations.

Furthermore, some cutting-edge pintle hitch designs are exploring the integration of smart technologies that can optimize route planning and load distribution. These systems can potentially reduce unnecessary trips and improve overall transport efficiency, leading to a decrease in total vehicle miles traveled and the associated environmental impacts.

As the transport industry moves towards electrification, pintle hitch designs are also evolving to accommodate the unique requirements of electric and hybrid vehicles. These adaptations ensure that the environmental benefits of alternative powertrains are not compromised by outdated coupling technologies. Some designs even explore the possibility of energy recovery systems integrated into the hitch mechanism, further enhancing the overall efficiency of the transport system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!