The Interaction of Pintle Hitch with High-Tech Trailer Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to meet the changing needs of towing and transportation industries. Initially developed as a simple coupling mechanism for military applications, the pintle hitch has transformed into a sophisticated component integral to modern high-tech trailer systems.

In its early stages, the pintle hitch was primarily used for heavy-duty towing in military and industrial settings. The basic design consisted of a hook-like protrusion on the towing vehicle that engaged with a ring or eye on the trailer. This simple yet robust design provided the necessary strength and flexibility for towing heavy loads over rough terrain.

As civilian applications for heavy-duty towing expanded, the pintle hitch design began to evolve. Manufacturers introduced improvements such as spring-loaded latches and safety chains to enhance security and prevent accidental disconnections. These advancements made pintle hitches more suitable for commercial trucking and construction industries.

The integration of electronic systems marked a significant milestone in pintle hitch evolution. Sensors and monitoring devices were incorporated to provide real-time data on hitch status, load distribution, and potential safety issues. This integration allowed for better control and management of towing operations, especially in challenging conditions.

Further advancements came with the introduction of air-ride suspension systems compatible with pintle hitches. These systems improved ride quality and load stability, making pintle hitches more versatile for a wider range of applications, including specialized transportation of sensitive equipment.

Recent years have seen the development of "smart" pintle hitches, which incorporate advanced materials, precision manufacturing techniques, and integrated electronic systems. These modern hitches feature automatic coupling and decoupling mechanisms, load sensing capabilities, and compatibility with vehicle telematics systems.

The evolution of pintle hitches has also been driven by regulatory changes and safety standards. Manufacturers have responded by developing hitches with improved weight ratings, enhanced durability, and advanced safety features such as breakaway systems and integrated brake controllers.

As trailer systems become increasingly high-tech, pintle hitches are evolving to seamlessly integrate with these advanced technologies. Modern pintle hitches now serve as a crucial interface between towing vehicles and smart trailers, facilitating communication between various onboard systems and enabling features such as autonomous backing and parking assistance.

The ongoing evolution of pintle hitches reflects the broader trends in vehicle technology, with a focus on enhancing safety, efficiency, and connectivity. As we look to the future, we can expect further innovations in pintle hitch design, potentially including AI-driven coupling systems, advanced materials for weight reduction and increased strength, and even more sophisticated integration with smart trailer technologies.

In its early stages, the pintle hitch was primarily used for heavy-duty towing in military and industrial settings. The basic design consisted of a hook-like protrusion on the towing vehicle that engaged with a ring or eye on the trailer. This simple yet robust design provided the necessary strength and flexibility for towing heavy loads over rough terrain.

As civilian applications for heavy-duty towing expanded, the pintle hitch design began to evolve. Manufacturers introduced improvements such as spring-loaded latches and safety chains to enhance security and prevent accidental disconnections. These advancements made pintle hitches more suitable for commercial trucking and construction industries.

The integration of electronic systems marked a significant milestone in pintle hitch evolution. Sensors and monitoring devices were incorporated to provide real-time data on hitch status, load distribution, and potential safety issues. This integration allowed for better control and management of towing operations, especially in challenging conditions.

Further advancements came with the introduction of air-ride suspension systems compatible with pintle hitches. These systems improved ride quality and load stability, making pintle hitches more versatile for a wider range of applications, including specialized transportation of sensitive equipment.

Recent years have seen the development of "smart" pintle hitches, which incorporate advanced materials, precision manufacturing techniques, and integrated electronic systems. These modern hitches feature automatic coupling and decoupling mechanisms, load sensing capabilities, and compatibility with vehicle telematics systems.

The evolution of pintle hitches has also been driven by regulatory changes and safety standards. Manufacturers have responded by developing hitches with improved weight ratings, enhanced durability, and advanced safety features such as breakaway systems and integrated brake controllers.

As trailer systems become increasingly high-tech, pintle hitches are evolving to seamlessly integrate with these advanced technologies. Modern pintle hitches now serve as a crucial interface between towing vehicles and smart trailers, facilitating communication between various onboard systems and enabling features such as autonomous backing and parking assistance.

The ongoing evolution of pintle hitches reflects the broader trends in vehicle technology, with a focus on enhancing safety, efficiency, and connectivity. As we look to the future, we can expect further innovations in pintle hitch design, potentially including AI-driven coupling systems, advanced materials for weight reduction and increased strength, and even more sophisticated integration with smart trailer technologies.

Market Demand Analysis

The market demand for advanced pintle hitch systems integrated with high-tech trailer solutions has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for enhanced safety, efficiency, and connectivity in the transportation and logistics sectors. As industries continue to embrace digital transformation, the integration of smart technologies into traditional towing mechanisms has become a focal point for innovation.

In the commercial trucking segment, fleet operators are actively seeking solutions that can provide real-time data on trailer status, load distribution, and overall performance. This demand is fueled by the desire to optimize route planning, reduce fuel consumption, and minimize maintenance costs. The integration of pintle hitches with high-tech trailer systems offers a comprehensive solution to these challenges, enabling better fleet management and operational efficiency.

The agricultural sector has also shown a growing interest in advanced pintle hitch technologies. Farmers and agricultural equipment manufacturers are looking for ways to improve the maneuverability and stability of heavy implements, especially in challenging terrain. High-tech trailer systems that can dynamically adjust to changing load conditions and provide precise control are becoming increasingly valuable in this market segment.

The construction industry represents another significant market for advanced pintle hitch and trailer systems. With the trend towards larger and more complex construction projects, there is a rising demand for towing solutions that can handle heavier loads while ensuring safety and compliance with regulations. Smart pintle hitch systems that can monitor stress levels, provide automated coupling assistance, and offer advanced safety features are gaining traction among construction companies.

The recreational vehicle (RV) market has also contributed to the growing demand for high-tech pintle hitch solutions. As more people embrace the RV lifestyle, there is an increasing need for user-friendly, safe, and reliable towing systems. Advanced pintle hitches that offer easy alignment, automatic coupling, and integrated stability control are becoming highly sought after by RV enthusiasts and manufacturers alike.

From a geographical perspective, North America and Europe currently lead the market demand for advanced pintle hitch and high-tech trailer systems. This is largely due to the presence of established automotive and transportation industries, stringent safety regulations, and higher adoption rates of new technologies. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand as their logistics and transportation sectors continue to modernize and expand.

The market trend indicates a shift towards more integrated and intelligent towing solutions. Customers are increasingly looking for systems that not only provide mechanical coupling but also offer advanced features such as wireless connectivity, autonomous hitching capabilities, and integration with vehicle telematics systems. This trend is likely to drive further innovation in the pintle hitch and high-tech trailer system market, creating opportunities for both established players and new entrants to develop cutting-edge solutions.

In the commercial trucking segment, fleet operators are actively seeking solutions that can provide real-time data on trailer status, load distribution, and overall performance. This demand is fueled by the desire to optimize route planning, reduce fuel consumption, and minimize maintenance costs. The integration of pintle hitches with high-tech trailer systems offers a comprehensive solution to these challenges, enabling better fleet management and operational efficiency.

The agricultural sector has also shown a growing interest in advanced pintle hitch technologies. Farmers and agricultural equipment manufacturers are looking for ways to improve the maneuverability and stability of heavy implements, especially in challenging terrain. High-tech trailer systems that can dynamically adjust to changing load conditions and provide precise control are becoming increasingly valuable in this market segment.

The construction industry represents another significant market for advanced pintle hitch and trailer systems. With the trend towards larger and more complex construction projects, there is a rising demand for towing solutions that can handle heavier loads while ensuring safety and compliance with regulations. Smart pintle hitch systems that can monitor stress levels, provide automated coupling assistance, and offer advanced safety features are gaining traction among construction companies.

The recreational vehicle (RV) market has also contributed to the growing demand for high-tech pintle hitch solutions. As more people embrace the RV lifestyle, there is an increasing need for user-friendly, safe, and reliable towing systems. Advanced pintle hitches that offer easy alignment, automatic coupling, and integrated stability control are becoming highly sought after by RV enthusiasts and manufacturers alike.

From a geographical perspective, North America and Europe currently lead the market demand for advanced pintle hitch and high-tech trailer systems. This is largely due to the presence of established automotive and transportation industries, stringent safety regulations, and higher adoption rates of new technologies. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand as their logistics and transportation sectors continue to modernize and expand.

The market trend indicates a shift towards more integrated and intelligent towing solutions. Customers are increasingly looking for systems that not only provide mechanical coupling but also offer advanced features such as wireless connectivity, autonomous hitching capabilities, and integration with vehicle telematics systems. This trend is likely to drive further innovation in the pintle hitch and high-tech trailer system market, creating opportunities for both established players and new entrants to develop cutting-edge solutions.

Technical Challenges

The integration of pintle hitch systems with advanced trailer technologies presents several significant technical challenges. One of the primary issues is ensuring compatibility between traditional mechanical coupling mechanisms and modern electronic systems. The pintle hitch, while robust and versatile, was not originally designed with high-tech integration in mind, leading to potential interface problems.

A major challenge lies in the development of reliable communication protocols between the towing vehicle and the trailer. Advanced trailer systems often incorporate sensors, control units, and actuators that require seamless data exchange. Establishing a standardized communication interface that can work across different manufacturers and vehicle models is crucial but technically complex.

Another significant hurdle is the power management and distribution system. High-tech trailers often require substantial electrical power for various functions, from lighting and climate control to advanced stability systems. The traditional pintle hitch design does not inherently support high-capacity power transmission, necessitating the development of new power coupling solutions that maintain the mechanical strength of the hitch while safely delivering the required electrical power.

Ensuring the durability and reliability of electronic components in the harsh environment of a pintle hitch connection poses another challenge. The connection point is subject to significant mechanical stress, vibration, and exposure to the elements. Designing ruggedized electronic systems that can withstand these conditions while maintaining consistent performance is a complex engineering task.

The integration of safety systems presents yet another technical challenge. Modern trailers often include advanced features such as electronic stability control, anti-lock braking systems, and tire pressure monitoring. Coordinating these systems with the towing vehicle through the pintle hitch connection requires sophisticated control algorithms and fail-safe mechanisms to ensure safe operation under all conditions.

Weight distribution and dynamic load management also present significant challenges when integrating high-tech systems with pintle hitches. The additional weight of electronic components and the potential for uneven load distribution can affect the trailer's stability and handling characteristics. Developing adaptive suspension systems that can work in conjunction with the pintle hitch to optimize weight distribution and maintain stability is a complex technical problem.

Lastly, the challenge of retrofitting existing pintle hitch systems with high-tech capabilities cannot be overlooked. Developing solutions that can be applied to the vast fleet of existing trailers and towing vehicles without requiring complete replacement of the hitch system is both economically important and technically demanding. This requires innovative approaches to modular design and plug-and-play technologies that can enhance functionality while maintaining compatibility with legacy systems.

A major challenge lies in the development of reliable communication protocols between the towing vehicle and the trailer. Advanced trailer systems often incorporate sensors, control units, and actuators that require seamless data exchange. Establishing a standardized communication interface that can work across different manufacturers and vehicle models is crucial but technically complex.

Another significant hurdle is the power management and distribution system. High-tech trailers often require substantial electrical power for various functions, from lighting and climate control to advanced stability systems. The traditional pintle hitch design does not inherently support high-capacity power transmission, necessitating the development of new power coupling solutions that maintain the mechanical strength of the hitch while safely delivering the required electrical power.

Ensuring the durability and reliability of electronic components in the harsh environment of a pintle hitch connection poses another challenge. The connection point is subject to significant mechanical stress, vibration, and exposure to the elements. Designing ruggedized electronic systems that can withstand these conditions while maintaining consistent performance is a complex engineering task.

The integration of safety systems presents yet another technical challenge. Modern trailers often include advanced features such as electronic stability control, anti-lock braking systems, and tire pressure monitoring. Coordinating these systems with the towing vehicle through the pintle hitch connection requires sophisticated control algorithms and fail-safe mechanisms to ensure safe operation under all conditions.

Weight distribution and dynamic load management also present significant challenges when integrating high-tech systems with pintle hitches. The additional weight of electronic components and the potential for uneven load distribution can affect the trailer's stability and handling characteristics. Developing adaptive suspension systems that can work in conjunction with the pintle hitch to optimize weight distribution and maintain stability is a complex technical problem.

Lastly, the challenge of retrofitting existing pintle hitch systems with high-tech capabilities cannot be overlooked. Developing solutions that can be applied to the vast fleet of existing trailers and towing vehicles without requiring complete replacement of the hitch system is both economically important and technically demanding. This requires innovative approaches to modular design and plug-and-play technologies that can enhance functionality while maintaining compatibility with legacy systems.

Current Solutions

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism that can withstand heavy loads and provide flexibility in towing various types of trailers. Some designs incorporate additional features for improved safety and ease of use.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance their reliability and prevent accidental uncoupling. These may include secondary locking mechanisms, visual indicators for proper engagement, and designs that minimize the risk of pinching or injury during operation. Some models also feature integrated sensors or electronic systems for monitoring hitch status.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality to accommodate different towing needs. These may include height-adjustable models, combination hitches that can work with both pintle and ball couplings, or hitches with interchangeable components for versatility. Such designs aim to provide greater flexibility for various towing scenarios.

- Integration with vehicle systems: Advanced pintle hitch systems are being developed to integrate more closely with vehicle systems. This may involve electronic connections for brake controllers, lighting systems, or even autonomous towing capabilities. Some designs also focus on improving aerodynamics or reducing noise and vibration during towing.

- Specialized pintle hitches for specific applications: Certain pintle hitch designs are tailored for specific industries or applications, such as military vehicles, construction equipment, or agricultural machinery. These specialized hitches may feature reinforced construction, additional attachment points, or compatibility with industry-specific accessories to meet the unique demands of their intended use.

02 Locking mechanisms for pintle hitches

Various locking mechanisms are employed in pintle hitches to ensure secure attachment and prevent accidental uncoupling during towing. These may include spring-loaded latches, safety pins, or automated locking systems that engage when the trailer is properly connected. Some designs incorporate multiple locking points for added security.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Adjustable pintle hitches allow for customization of the hitch height or position to accommodate different trailer configurations. Some designs incorporate multiple attachment points or interchangeable components to enable towing of various trailer types with a single hitch system. This versatility improves the utility of the towing vehicle.Expand Specific Solutions04 Integration of pintle hitches with other towing components

Some pintle hitch designs integrate additional towing components such as ball hitches, drawbars, or receiver systems. This integration allows for greater flexibility in towing different types of trailers without the need for separate hitch installations. These combination systems often feature quick-change mechanisms for easy switching between hitch types.Expand Specific Solutions05 Safety features and enhancements for pintle hitches

Modern pintle hitch designs incorporate various safety features to improve towing security and performance. These may include built-in shock absorbers to reduce stress on the towing vehicle, anti-rattle mechanisms to minimize noise and wear, and visual indicators to confirm proper coupling. Some designs also feature integrated brake controllers or electrical connections for trailer systems.Expand Specific Solutions

Key Industry Players

The interaction of pintle hitch with high-tech trailer systems represents an evolving niche in the automotive and transportation industry. This sector is in a growth phase, driven by increasing demand for advanced towing solutions in both commercial and recreational markets. The global market size for smart trailer technologies is expanding, with projections indicating significant growth over the next decade. Technologically, the field is rapidly advancing, with companies like Ford Global Technologies LLC, BYD Co., Ltd., and Magna International, Inc. leading innovation in integrating smart systems with traditional hitching mechanisms. These advancements are focusing on improving safety, efficiency, and connectivity in towing applications, reflecting a trend towards more sophisticated and automated trailer systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced pintle hitch system that integrates with high-tech trailer systems. Their solution incorporates smart sensors and connectivity features to enhance towing safety and efficiency. The system uses real-time data from both the vehicle and trailer to adjust braking, stability control, and power distribution[1]. It also includes a trailer sway control feature that detects and mitigates dangerous trailer oscillations. Ford's technology allows for seamless integration with their SYNC infotainment system, providing drivers with crucial information about trailer status, weight distribution, and potential issues[2].

Strengths: Seamless integration with Ford vehicles, comprehensive safety features, and user-friendly interface. Weaknesses: Limited compatibility with non-Ford vehicles and potential high cost for implementation.

WESTFALIA-Automotive GmbH

Technical Solution: WESTFALIA-Automotive has created an innovative pintle hitch system that integrates seamlessly with modern trailer technologies. Their solution focuses on modularity and adaptability, allowing for easy upgrades as trailer systems evolve. The system includes a smart control unit that communicates with the vehicle's onboard computer to optimize towing performance[5]. WESTFALIA's technology also incorporates a unique automatic coupling feature, which simplifies the hitching process and reduces the risk of improper attachment. Furthermore, they have developed a trailer assist function that aids in maneuvering and parking trailers of various sizes[6].

Strengths: Modular design for future upgrades, user-friendly automatic coupling, and advanced parking assistance. Weaknesses: May require specialized training for full utilization of features and potential compatibility issues with older vehicles.

Core Innovations

Powered trailer hitch

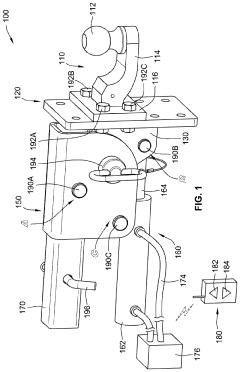

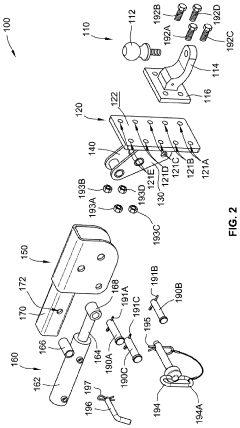

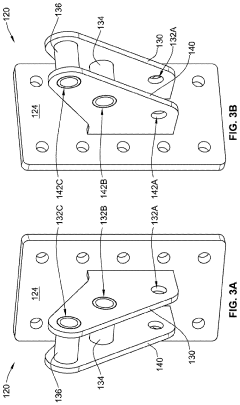

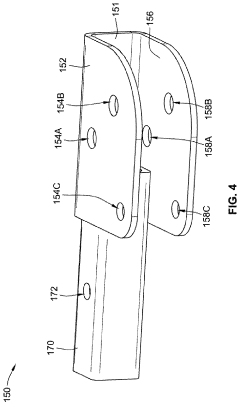

PatentActiveUS20210170817A1

Innovation

- A powered trailer hitch system with a housing, shaft, mounting plate, swing arms, and an actuator that allows for remote control operation, enabling automatic movement of the trailer ball to align and engage with the trailer tongue, reducing manual labor and enhancing safety.

hitch with a positioning drive assembly

PatentActiveEP2767417A2

Innovation

- A trailer hitch with a bearing arrangement providing pivoting and linear adjustment degrees of freedom, assisted by a positioning drive assembly, including motors and gears, to automatically position the coupling arm into the trailer receptacle, and a locking device for secure engagement, along with a sensor arrangement for position detection and control unit for automated operation.

Safety Regulations

The integration of pintle hitches with high-tech trailer systems necessitates a comprehensive understanding of safety regulations to ensure compliance and optimal performance. These regulations encompass a wide range of aspects, from design specifications to operational guidelines, aimed at minimizing risks associated with towing operations.

At the federal level in the United States, the National Highway Traffic Safety Administration (NHTSA) sets forth standards that directly impact pintle hitch and trailer system interactions. These include Federal Motor Vehicle Safety Standards (FMVSS) No. 108 for lighting and reflective devices, and No. 223 for rear impact guards on trailers. Additionally, the Society of Automotive Engineers (SAE) provides industry standards, such as SAE J684 for couplings, which influence pintle hitch design and compatibility with advanced trailer systems.

State-level regulations further complicate the regulatory landscape, as requirements for trailer brakes, weight distribution, and safety chains can vary. For instance, some states mandate electronic brake controllers for trailers exceeding certain weight thresholds, which must interface seamlessly with the towing vehicle's systems through the pintle hitch connection.

The emergence of high-tech trailer systems has introduced new safety considerations. Advanced features like trailer sway control, stability assist, and autonomous backing systems rely on sophisticated sensors and communication protocols. Safety regulations are evolving to address these technologies, with a focus on ensuring reliable data transmission between the towing vehicle and trailer through the pintle hitch interface.

Electromagnetic compatibility (EMC) regulations have gained prominence as electronic systems become more prevalent in trailer design. Pintle hitches must now be engineered to minimize electromagnetic interference that could disrupt critical safety systems or communication between the vehicle and trailer.

International harmonization efforts, such as those led by the United Nations Economic Commission for Europe (UNECE), are working to standardize safety requirements for towing equipment across borders. This global approach aims to facilitate trade while maintaining high safety standards for pintle hitch and trailer system interactions.

As autonomous and platooning technologies advance, regulatory bodies are developing frameworks to address the unique safety challenges posed by these systems. Future regulations may require pintle hitches to incorporate advanced sensing capabilities and fail-safe mechanisms to ensure safe operation in various autonomous towing scenarios.

Compliance with these multifaceted safety regulations requires ongoing vigilance and adaptation from manufacturers and operators alike. As technology continues to evolve, so too will the regulatory landscape, necessitating a proactive approach to safety in the design and implementation of pintle hitch and high-tech trailer system interactions.

At the federal level in the United States, the National Highway Traffic Safety Administration (NHTSA) sets forth standards that directly impact pintle hitch and trailer system interactions. These include Federal Motor Vehicle Safety Standards (FMVSS) No. 108 for lighting and reflective devices, and No. 223 for rear impact guards on trailers. Additionally, the Society of Automotive Engineers (SAE) provides industry standards, such as SAE J684 for couplings, which influence pintle hitch design and compatibility with advanced trailer systems.

State-level regulations further complicate the regulatory landscape, as requirements for trailer brakes, weight distribution, and safety chains can vary. For instance, some states mandate electronic brake controllers for trailers exceeding certain weight thresholds, which must interface seamlessly with the towing vehicle's systems through the pintle hitch connection.

The emergence of high-tech trailer systems has introduced new safety considerations. Advanced features like trailer sway control, stability assist, and autonomous backing systems rely on sophisticated sensors and communication protocols. Safety regulations are evolving to address these technologies, with a focus on ensuring reliable data transmission between the towing vehicle and trailer through the pintle hitch interface.

Electromagnetic compatibility (EMC) regulations have gained prominence as electronic systems become more prevalent in trailer design. Pintle hitches must now be engineered to minimize electromagnetic interference that could disrupt critical safety systems or communication between the vehicle and trailer.

International harmonization efforts, such as those led by the United Nations Economic Commission for Europe (UNECE), are working to standardize safety requirements for towing equipment across borders. This global approach aims to facilitate trade while maintaining high safety standards for pintle hitch and trailer system interactions.

As autonomous and platooning technologies advance, regulatory bodies are developing frameworks to address the unique safety challenges posed by these systems. Future regulations may require pintle hitches to incorporate advanced sensing capabilities and fail-safe mechanisms to ensure safe operation in various autonomous towing scenarios.

Compliance with these multifaceted safety regulations requires ongoing vigilance and adaptation from manufacturers and operators alike. As technology continues to evolve, so too will the regulatory landscape, necessitating a proactive approach to safety in the design and implementation of pintle hitch and high-tech trailer system interactions.

Integration Strategies

The integration of pintle hitch systems with high-tech trailer technologies requires a multifaceted approach to ensure seamless functionality and enhanced performance. One key strategy involves the development of smart coupling mechanisms that incorporate sensors and electronic controls. These advanced systems can automatically adjust the connection between the towing vehicle and trailer, optimizing stability and reducing wear.

Another crucial integration strategy focuses on the implementation of data communication protocols between the pintle hitch and the trailer's onboard systems. This allows for real-time monitoring of critical parameters such as load distribution, temperature, and stress levels. By establishing a robust data exchange network, operators can make informed decisions and preemptively address potential issues.

Modular design principles play a significant role in integration strategies. By creating standardized interfaces and connection points, manufacturers can ensure compatibility between various pintle hitch models and high-tech trailer systems. This approach not only simplifies installation and maintenance but also promotes flexibility in system configurations.

The incorporation of advanced materials in pintle hitch design is another vital strategy. Utilizing lightweight yet durable composites can significantly reduce the overall weight of the coupling system while maintaining or even improving its strength. This weight reduction contributes to improved fuel efficiency and increased payload capacity.

Integration strategies also extend to the development of user-friendly interfaces that bridge the gap between traditional towing methods and high-tech trailer systems. Intuitive control panels and mobile applications can provide drivers with comprehensive information about the hitch-trailer connection, enhancing safety and operational efficiency.

Lastly, the integration of pintle hitches with emerging autonomous vehicle technologies presents both challenges and opportunities. Strategies in this area focus on developing fail-safe mechanisms and redundant systems to ensure reliable operation in various driving scenarios. This includes the integration of advanced vision systems and AI-powered decision-making algorithms to manage complex towing situations autonomously.

Another crucial integration strategy focuses on the implementation of data communication protocols between the pintle hitch and the trailer's onboard systems. This allows for real-time monitoring of critical parameters such as load distribution, temperature, and stress levels. By establishing a robust data exchange network, operators can make informed decisions and preemptively address potential issues.

Modular design principles play a significant role in integration strategies. By creating standardized interfaces and connection points, manufacturers can ensure compatibility between various pintle hitch models and high-tech trailer systems. This approach not only simplifies installation and maintenance but also promotes flexibility in system configurations.

The incorporation of advanced materials in pintle hitch design is another vital strategy. Utilizing lightweight yet durable composites can significantly reduce the overall weight of the coupling system while maintaining or even improving its strength. This weight reduction contributes to improved fuel efficiency and increased payload capacity.

Integration strategies also extend to the development of user-friendly interfaces that bridge the gap between traditional towing methods and high-tech trailer systems. Intuitive control panels and mobile applications can provide drivers with comprehensive information about the hitch-trailer connection, enhancing safety and operational efficiency.

Lastly, the integration of pintle hitches with emerging autonomous vehicle technologies presents both challenges and opportunities. Strategies in this area focus on developing fail-safe mechanisms and redundant systems to ensure reliable operation in various driving scenarios. This includes the integration of advanced vision systems and AI-powered decision-making algorithms to manage complex towing situations autonomously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!