Analyzing Pintle Hitch Role in Automated Cargo Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to the changing needs of the transportation industry and the advent of automated cargo systems. Initially developed as a simple coupling mechanism for towing trailers, the pintle hitch has transformed into a sophisticated component crucial for automated cargo handling.

In its early stages, the pintle hitch was primarily used in military applications, providing a robust and versatile coupling solution for heavy-duty vehicles. The basic design consisted of a hook-like protrusion (the pintle) that engaged with a ring or eye on the trailer. This simple yet effective mechanism allowed for quick coupling and decoupling, essential in military operations.

As commercial transportation needs grew, the pintle hitch found its way into civilian applications. The design was refined to accommodate heavier loads and improve safety features. Manufacturers introduced locking mechanisms to prevent accidental disconnection, enhancing the reliability of the hitch for long-haul transportation.

The advent of automated cargo systems marked a significant turning point in pintle hitch evolution. Engineers began to integrate electronic sensors and actuators into the hitch design, enabling remote monitoring and control. This integration allowed for automated coupling and uncoupling processes, reducing the need for manual intervention and improving operational efficiency.

Further advancements led to the development of "smart" pintle hitches. These incorporated advanced materials for increased durability and weight reduction, as well as integrated communication systems. The smart hitches could transmit real-time data about the connection status, load distribution, and potential issues, enhancing safety and enabling predictive maintenance.

Recent innovations have focused on improving the pintle hitch's role in fully automated cargo systems. Engineers have developed hitches with self-aligning capabilities, utilizing computer vision and AI algorithms to guide the coupling process. This technology significantly reduces the margin of error in automated docking procedures, a critical factor in unmanned logistics operations.

The latest generation of pintle hitches incorporates modular designs, allowing for easy customization and upgrades. This adaptability is crucial in the rapidly evolving field of automated cargo systems, where flexibility and scalability are key considerations. Additionally, efforts are being made to standardize pintle hitch interfaces across different manufacturers, facilitating seamless integration in diverse automated logistics ecosystems.

As automated cargo systems continue to advance, the pintle hitch is expected to evolve further. Future developments may include enhanced integration with autonomous vehicles, improved energy efficiency through optimized coupling dynamics, and the incorporation of advanced materials such as carbon composites for even greater strength-to-weight ratios.

In its early stages, the pintle hitch was primarily used in military applications, providing a robust and versatile coupling solution for heavy-duty vehicles. The basic design consisted of a hook-like protrusion (the pintle) that engaged with a ring or eye on the trailer. This simple yet effective mechanism allowed for quick coupling and decoupling, essential in military operations.

As commercial transportation needs grew, the pintle hitch found its way into civilian applications. The design was refined to accommodate heavier loads and improve safety features. Manufacturers introduced locking mechanisms to prevent accidental disconnection, enhancing the reliability of the hitch for long-haul transportation.

The advent of automated cargo systems marked a significant turning point in pintle hitch evolution. Engineers began to integrate electronic sensors and actuators into the hitch design, enabling remote monitoring and control. This integration allowed for automated coupling and uncoupling processes, reducing the need for manual intervention and improving operational efficiency.

Further advancements led to the development of "smart" pintle hitches. These incorporated advanced materials for increased durability and weight reduction, as well as integrated communication systems. The smart hitches could transmit real-time data about the connection status, load distribution, and potential issues, enhancing safety and enabling predictive maintenance.

Recent innovations have focused on improving the pintle hitch's role in fully automated cargo systems. Engineers have developed hitches with self-aligning capabilities, utilizing computer vision and AI algorithms to guide the coupling process. This technology significantly reduces the margin of error in automated docking procedures, a critical factor in unmanned logistics operations.

The latest generation of pintle hitches incorporates modular designs, allowing for easy customization and upgrades. This adaptability is crucial in the rapidly evolving field of automated cargo systems, where flexibility and scalability are key considerations. Additionally, efforts are being made to standardize pintle hitch interfaces across different manufacturers, facilitating seamless integration in diverse automated logistics ecosystems.

As automated cargo systems continue to advance, the pintle hitch is expected to evolve further. Future developments may include enhanced integration with autonomous vehicles, improved energy efficiency through optimized coupling dynamics, and the incorporation of advanced materials such as carbon composites for even greater strength-to-weight ratios.

Market Demand Analysis

The market demand for automated cargo systems incorporating pintle hitch technology has been steadily growing in recent years, driven by the increasing need for efficient and flexible logistics solutions across various industries. The global automated material handling equipment market, which includes automated cargo systems, is projected to reach $41.56 billion by 2027, with a compound annual growth rate (CAGR) of 7.8% from 2020 to 2027.

Pintle hitches play a crucial role in automated cargo systems by providing a robust and versatile coupling mechanism between vehicles and trailers. This technology enables seamless integration of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) with various cargo-carrying units, enhancing the overall efficiency and flexibility of logistics operations.

The e-commerce sector has been a significant driver of demand for automated cargo systems with pintle hitch technology. As online retail continues to expand, companies are seeking innovative solutions to streamline their warehouse operations and last-mile delivery processes. Pintle hitch-equipped automated systems offer the ability to quickly reconfigure cargo arrangements, adapt to changing load requirements, and optimize space utilization in distribution centers.

Manufacturing industries, particularly automotive and aerospace sectors, have also shown increased interest in automated cargo systems featuring pintle hitch technology. These industries require precise and efficient movement of heavy components and assemblies within their production facilities. The pintle hitch's ability to securely connect and disconnect cargo units allows for greater flexibility in production line layouts and material flow optimization.

The agriculture sector presents another growing market for automated cargo systems with pintle hitch technology. As precision agriculture practices become more widespread, there is a rising demand for autonomous vehicles and equipment that can efficiently transport harvested crops, fertilizers, and other agricultural inputs across large farm areas. Pintle hitches provide the necessary robustness and adaptability for these applications in challenging outdoor environments.

Port and terminal operations represent a significant potential market for automated cargo systems utilizing pintle hitch technology. With the increasing focus on port automation to improve efficiency and reduce operational costs, there is a growing need for flexible and reliable cargo handling solutions. Pintle hitch-equipped automated guided vehicles can efficiently move containers and other cargo units between ships, storage areas, and land transportation systems.

The market demand analysis also reveals a trend towards modular and scalable automated cargo systems. Pintle hitch technology aligns well with this trend, as it allows for easy reconfiguration and expansion of cargo handling systems to meet changing business needs. This flexibility is particularly valuable for small and medium-sized enterprises looking to gradually automate their logistics operations without significant upfront investments.

Pintle hitches play a crucial role in automated cargo systems by providing a robust and versatile coupling mechanism between vehicles and trailers. This technology enables seamless integration of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) with various cargo-carrying units, enhancing the overall efficiency and flexibility of logistics operations.

The e-commerce sector has been a significant driver of demand for automated cargo systems with pintle hitch technology. As online retail continues to expand, companies are seeking innovative solutions to streamline their warehouse operations and last-mile delivery processes. Pintle hitch-equipped automated systems offer the ability to quickly reconfigure cargo arrangements, adapt to changing load requirements, and optimize space utilization in distribution centers.

Manufacturing industries, particularly automotive and aerospace sectors, have also shown increased interest in automated cargo systems featuring pintle hitch technology. These industries require precise and efficient movement of heavy components and assemblies within their production facilities. The pintle hitch's ability to securely connect and disconnect cargo units allows for greater flexibility in production line layouts and material flow optimization.

The agriculture sector presents another growing market for automated cargo systems with pintle hitch technology. As precision agriculture practices become more widespread, there is a rising demand for autonomous vehicles and equipment that can efficiently transport harvested crops, fertilizers, and other agricultural inputs across large farm areas. Pintle hitches provide the necessary robustness and adaptability for these applications in challenging outdoor environments.

Port and terminal operations represent a significant potential market for automated cargo systems utilizing pintle hitch technology. With the increasing focus on port automation to improve efficiency and reduce operational costs, there is a growing need for flexible and reliable cargo handling solutions. Pintle hitch-equipped automated guided vehicles can efficiently move containers and other cargo units between ships, storage areas, and land transportation systems.

The market demand analysis also reveals a trend towards modular and scalable automated cargo systems. Pintle hitch technology aligns well with this trend, as it allows for easy reconfiguration and expansion of cargo handling systems to meet changing business needs. This flexibility is particularly valuable for small and medium-sized enterprises looking to gradually automate their logistics operations without significant upfront investments.

Technical Challenges

The integration of pintle hitches into automated cargo systems presents several significant technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the development of robust and reliable automated coupling mechanisms. These mechanisms must be capable of precisely aligning and securely connecting the pintle hitch to various trailer configurations under diverse environmental conditions, including uneven terrain and adverse weather.

Another critical challenge lies in the design of advanced sensor systems for accurate detection and positioning of the pintle hitch and trailer components. These sensors must provide real-time, high-precision data to guide the automated coupling process, while also being resilient to interference from dust, vibration, and electromagnetic fields commonly encountered in industrial environments.

The development of sophisticated control algorithms represents a further technical hurdle. These algorithms need to process sensor data, make real-time decisions, and control the movement of both the towing vehicle and the trailer during coupling and uncoupling operations. They must account for variables such as vehicle dynamics, load distribution, and potential obstacles in the surrounding area.

Ensuring the safety and reliability of automated pintle hitch systems is paramount and presents its own set of challenges. This includes implementing fail-safe mechanisms, redundancy systems, and comprehensive error detection and recovery protocols. Additionally, the system must be designed to handle unexpected scenarios, such as misalignment or mechanical failures, without compromising safety or operational efficiency.

Interoperability and standardization pose significant challenges in the development of automated pintle hitch systems. With various trailer designs and hitch configurations in use across different industries, creating a universally compatible system requires extensive collaboration and potentially the development of new industry standards.

Power management and energy efficiency are also important considerations, particularly for electric and autonomous vehicles. The automated pintle hitch system must be designed to minimize power consumption while maintaining optimal performance, which may require innovative energy recovery and storage solutions.

Lastly, the integration of automated pintle hitch systems with broader fleet management and logistics platforms presents complex data management and communication challenges. This includes developing secure, real-time data transmission protocols, implementing cloud-based monitoring and control systems, and ensuring seamless integration with existing transportation management software.

Another critical challenge lies in the design of advanced sensor systems for accurate detection and positioning of the pintle hitch and trailer components. These sensors must provide real-time, high-precision data to guide the automated coupling process, while also being resilient to interference from dust, vibration, and electromagnetic fields commonly encountered in industrial environments.

The development of sophisticated control algorithms represents a further technical hurdle. These algorithms need to process sensor data, make real-time decisions, and control the movement of both the towing vehicle and the trailer during coupling and uncoupling operations. They must account for variables such as vehicle dynamics, load distribution, and potential obstacles in the surrounding area.

Ensuring the safety and reliability of automated pintle hitch systems is paramount and presents its own set of challenges. This includes implementing fail-safe mechanisms, redundancy systems, and comprehensive error detection and recovery protocols. Additionally, the system must be designed to handle unexpected scenarios, such as misalignment or mechanical failures, without compromising safety or operational efficiency.

Interoperability and standardization pose significant challenges in the development of automated pintle hitch systems. With various trailer designs and hitch configurations in use across different industries, creating a universally compatible system requires extensive collaboration and potentially the development of new industry standards.

Power management and energy efficiency are also important considerations, particularly for electric and autonomous vehicles. The automated pintle hitch system must be designed to minimize power consumption while maintaining optimal performance, which may require innovative energy recovery and storage solutions.

Lastly, the integration of automated pintle hitch systems with broader fleet management and logistics platforms presents complex data management and communication challenges. This includes developing secure, real-time data transmission protocols, implementing cloud-based monitoring and control systems, and ensuring seamless integration with existing transportation management software.

Current Solutions

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism and a locking system to ensure safe towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.

- Safety features in pintle hitches: Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature anti-rattle systems to reduce noise and improve stability during towing.

- Adjustable and multi-functional pintle hitches: Innovative pintle hitch designs offer adjustability and multi-functionality. These hitches may feature adjustable height settings, interchangeable coupling components, or the ability to convert between different hitch types. Such versatility allows for compatibility with various towing vehicles and trailers.

- Integration with vehicle systems: Advanced pintle hitch designs incorporate integration with vehicle systems for improved functionality and safety. This may include electronic coupling sensors, compatibility with backup cameras, and connections to the vehicle's electrical system for trailer lighting and braking controls.

- Specialized pintle hitch applications: Pintle hitches are adapted for specialized applications, such as military vehicles, construction equipment, and off-road use. These designs may feature reinforced materials, enhanced corrosion resistance, or specific geometries to accommodate unique towing requirements in challenging environments.

02 Locking mechanisms for pintle hitches

Various locking mechanisms are employed in pintle hitches to secure the connection between the towing vehicle and the trailer. These can include spring-loaded latches, pin locks, or automated locking systems. The locking mechanisms are designed to prevent accidental disconnection during towing and to allow for easy coupling and uncoupling when needed.Expand Specific Solutions03 Adjustable and multi-functional pintle hitches

Some pintle hitches are designed to be adjustable or multi-functional, allowing for greater versatility in towing applications. These designs may include features such as adjustable height, interchangeable hitch balls, or the ability to convert between different hitch types. Such adaptability makes these hitches suitable for a wide range of vehicles and towing needs.Expand Specific Solutions04 Safety features in pintle hitches

Modern pintle hitches often incorporate various safety features to enhance towing security. These can include visual indicators for proper coupling, secondary locking mechanisms, or integrated brake controllers. Some designs also focus on reducing noise and vibration during towing, improving overall safety and comfort.Expand Specific Solutions05 Specialized pintle hitch designs

Certain pintle hitches are designed for specialized applications or to meet specific industry requirements. These may include heavy-duty designs for military or construction use, hitches with integrated swivel mechanisms for improved maneuverability, or designs that comply with particular safety standards or regulations. Such specialized designs cater to unique towing needs across various sectors.Expand Specific Solutions

Industry Players

The automated cargo systems market, including pintle hitch technology, is in a growth phase characterized by increasing demand for efficient logistics solutions. The market size is expanding, driven by e-commerce growth and the need for automated material handling. Technologically, the field is advancing rapidly, with companies like Zoomlion, XCMG, and Crown Equipment leading innovation in automated cargo handling. These firms are developing sophisticated pintle hitch systems integrated with AI and IoT for improved efficiency and safety. While the technology is maturing, there's still room for significant advancements, particularly in areas like autonomous vehicle integration and smart cargo management systems.

Waymo LLC

Technical Solution: Waymo has developed a cutting-edge automated cargo system that utilizes advanced pintle hitch technology to enhance autonomous trucking operations. Their system incorporates LiDAR and computer vision technologies to enable precise and autonomous hitching processes, even in challenging environmental conditions. Waymo's pintle hitch design features a self-aligning mechanism that can compensate for minor misalignments, crucial for fully autonomous operations. The system also includes a secure wireless communication protocol that allows for real-time data exchange between the truck and trailer, enabling advanced features such as remote monitoring and control[7]. Waymo has integrated this technology with their autonomous driving platform, creating a comprehensive solution for long-haul trucking that can operate with minimal human intervention. The system also incorporates machine learning algorithms that continuously improve hitching performance based on data collected from various operational scenarios[8].

Strengths: Seamless integration with autonomous driving technology, advanced self-aligning capabilities, and continuous improvement through machine learning. Weaknesses: May face regulatory challenges in some regions and require significant infrastructure adaptation for widespread implementation.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed an advanced automated cargo system utilizing pintle hitches for enhanced connectivity and flexibility in material handling. Their system incorporates smart sensors and machine learning algorithms to optimize coupling and uncoupling processes, reducing downtime and improving safety. The pintle hitch design allows for a wider range of motion and easier alignment, crucial for autonomous operations in varied terrains. Caterpillar's solution also features real-time load monitoring and predictive maintenance capabilities, ensuring optimal performance and reducing unexpected failures[1][3]. The system is designed to integrate seamlessly with Caterpillar's existing fleet management software, providing a comprehensive solution for automated cargo handling in construction and mining operations.

Strengths: Robust design suitable for heavy-duty applications, seamless integration with existing systems, and advanced predictive maintenance. Weaknesses: Potentially higher initial cost and may require specialized training for maintenance personnel.

Key Innovations

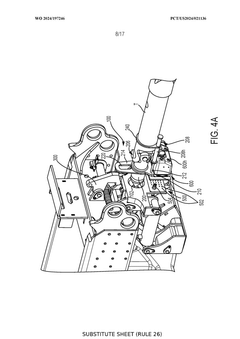

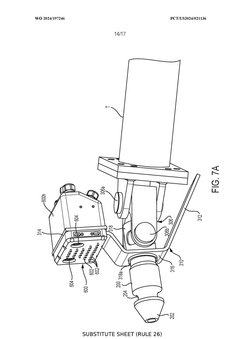

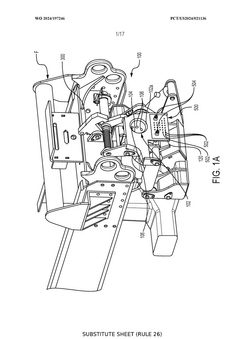

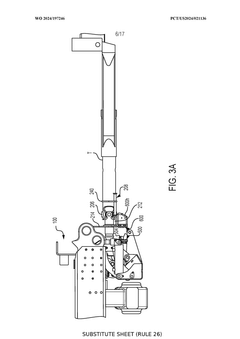

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

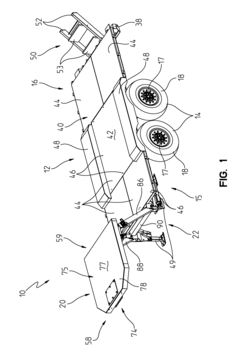

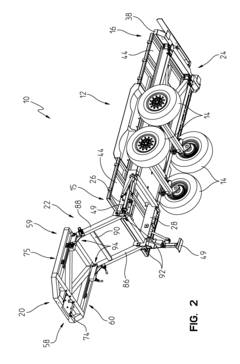

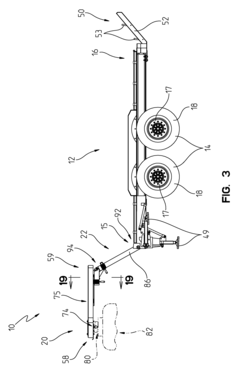

Convertible trailer

PatentInactiveUS8210557B2

Innovation

- A universal trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, enabling it to accommodate different hitch types by adjusting the position and securing the coupler support with pivot and slide locks.

Safety Regulations

Safety regulations play a crucial role in the implementation and operation of automated cargo systems utilizing pintle hitches. These regulations are designed to ensure the safe and efficient functioning of such systems, protecting both personnel and equipment involved in cargo handling operations.

The primary focus of safety regulations for pintle hitch-based automated cargo systems is on the structural integrity and reliability of the connection mechanism. Regulatory bodies typically require rigorous testing and certification processes to verify that pintle hitches can withstand the dynamic loads and stresses associated with automated cargo handling. This includes standards for material quality, manufacturing processes, and regular maintenance protocols.

Another key aspect of safety regulations is the integration of fail-safe mechanisms and emergency disconnection systems. These are essential to prevent accidents in case of system malfunctions or unexpected situations. Regulations often mandate the inclusion of redundant safety features, such as secondary locking mechanisms and automatic brake systems, to ensure that cargo remains secure even in the event of primary system failure.

Operational safety is also a significant concern addressed by regulations. This encompasses guidelines for the proper use of automated systems, including operator training requirements, safety protocols during coupling and uncoupling procedures, and the establishment of clear operational zones to minimize the risk of collisions or accidents involving personnel.

Environmental considerations are increasingly being incorporated into safety regulations for automated cargo systems. This includes standards for noise reduction, energy efficiency, and the use of environmentally friendly materials in the construction of pintle hitches and related components.

Regulatory bodies also focus on the cybersecurity aspects of automated cargo systems. With the increasing reliance on digital control systems, regulations are being developed to protect against potential cyber threats that could compromise the safety and integrity of cargo operations.

Compliance with international standards is another critical aspect of safety regulations. As automated cargo systems often operate across borders, harmonization of safety standards between different countries and regions is essential. This includes adherence to global standards such as those set by the International Organization for Standardization (ISO) and the International Maritime Organization (IMO).

Lastly, safety regulations typically require ongoing monitoring and reporting mechanisms. This ensures that automated cargo systems using pintle hitches are regularly assessed for compliance with current safety standards and that any incidents or near-misses are properly documented and analyzed to drive continuous improvement in safety protocols.

The primary focus of safety regulations for pintle hitch-based automated cargo systems is on the structural integrity and reliability of the connection mechanism. Regulatory bodies typically require rigorous testing and certification processes to verify that pintle hitches can withstand the dynamic loads and stresses associated with automated cargo handling. This includes standards for material quality, manufacturing processes, and regular maintenance protocols.

Another key aspect of safety regulations is the integration of fail-safe mechanisms and emergency disconnection systems. These are essential to prevent accidents in case of system malfunctions or unexpected situations. Regulations often mandate the inclusion of redundant safety features, such as secondary locking mechanisms and automatic brake systems, to ensure that cargo remains secure even in the event of primary system failure.

Operational safety is also a significant concern addressed by regulations. This encompasses guidelines for the proper use of automated systems, including operator training requirements, safety protocols during coupling and uncoupling procedures, and the establishment of clear operational zones to minimize the risk of collisions or accidents involving personnel.

Environmental considerations are increasingly being incorporated into safety regulations for automated cargo systems. This includes standards for noise reduction, energy efficiency, and the use of environmentally friendly materials in the construction of pintle hitches and related components.

Regulatory bodies also focus on the cybersecurity aspects of automated cargo systems. With the increasing reliance on digital control systems, regulations are being developed to protect against potential cyber threats that could compromise the safety and integrity of cargo operations.

Compliance with international standards is another critical aspect of safety regulations. As automated cargo systems often operate across borders, harmonization of safety standards between different countries and regions is essential. This includes adherence to global standards such as those set by the International Organization for Standardization (ISO) and the International Maritime Organization (IMO).

Lastly, safety regulations typically require ongoing monitoring and reporting mechanisms. This ensures that automated cargo systems using pintle hitches are regularly assessed for compliance with current safety standards and that any incidents or near-misses are properly documented and analyzed to drive continuous improvement in safety protocols.

Integration Strategies

The integration of pintle hitches into automated cargo systems requires a multifaceted approach that considers both the mechanical and digital aspects of the technology. One key strategy involves the development of standardized interfaces that allow for seamless communication between the pintle hitch mechanism and the automated control systems. This standardization ensures compatibility across different vehicle types and cargo configurations, facilitating widespread adoption in the logistics industry.

Another crucial integration strategy focuses on the incorporation of advanced sensors and actuators into the pintle hitch design. These components enable real-time monitoring of the connection status, load distribution, and potential safety issues. By integrating these sensors with the vehicle's central control unit, the system can automatically adjust towing parameters, optimize fuel efficiency, and enhance overall safety during transport operations.

The implementation of robust software algorithms is essential for effective integration. These algorithms must be capable of processing sensor data, making rapid decisions, and controlling the pintle hitch mechanism with precision. Machine learning techniques can be employed to continuously improve the system's performance, adapting to various road conditions, cargo types, and operational scenarios.

Modular design principles play a significant role in integration strategies. By developing modular pintle hitch components, manufacturers can offer scalable solutions that cater to different vehicle sizes and cargo requirements. This modularity also simplifies maintenance and upgrades, reducing downtime and operational costs for fleet operators.

Integration strategies must also address the human-machine interface aspect. User-friendly control panels and intuitive mobile applications can provide operators with easy access to system status, connection procedures, and troubleshooting guides. This ensures smooth adoption and operation of the automated cargo systems, even for users with limited technical expertise.

Collaboration between pintle hitch manufacturers, vehicle OEMs, and automation technology providers is crucial for successful integration. Joint development initiatives can lead to optimized designs that seamlessly blend the mechanical robustness of pintle hitches with the advanced capabilities of automated systems. This collaborative approach also helps in addressing potential compatibility issues early in the development process.

Lastly, integration strategies should include comprehensive testing and validation protocols. These protocols must cover a wide range of operational scenarios, environmental conditions, and potential failure modes. Rigorous testing ensures the reliability and safety of the integrated system, building trust among end-users and regulatory bodies.

Another crucial integration strategy focuses on the incorporation of advanced sensors and actuators into the pintle hitch design. These components enable real-time monitoring of the connection status, load distribution, and potential safety issues. By integrating these sensors with the vehicle's central control unit, the system can automatically adjust towing parameters, optimize fuel efficiency, and enhance overall safety during transport operations.

The implementation of robust software algorithms is essential for effective integration. These algorithms must be capable of processing sensor data, making rapid decisions, and controlling the pintle hitch mechanism with precision. Machine learning techniques can be employed to continuously improve the system's performance, adapting to various road conditions, cargo types, and operational scenarios.

Modular design principles play a significant role in integration strategies. By developing modular pintle hitch components, manufacturers can offer scalable solutions that cater to different vehicle sizes and cargo requirements. This modularity also simplifies maintenance and upgrades, reducing downtime and operational costs for fleet operators.

Integration strategies must also address the human-machine interface aspect. User-friendly control panels and intuitive mobile applications can provide operators with easy access to system status, connection procedures, and troubleshooting guides. This ensures smooth adoption and operation of the automated cargo systems, even for users with limited technical expertise.

Collaboration between pintle hitch manufacturers, vehicle OEMs, and automation technology providers is crucial for successful integration. Joint development initiatives can lead to optimized designs that seamlessly blend the mechanical robustness of pintle hitches with the advanced capabilities of automated systems. This collaborative approach also helps in addressing potential compatibility issues early in the development process.

Lastly, integration strategies should include comprehensive testing and validation protocols. These protocols must cover a wide range of operational scenarios, environmental conditions, and potential failure modes. Rigorous testing ensures the reliability and safety of the integrated system, building trust among end-users and regulatory bodies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!