Pintle Hitch in Vehicle Dynamics and Stability Analysis

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of the pintle hitch in vehicle dynamics and stability analysis has been a significant area of research and development in the automotive industry. Initially introduced as a simple coupling mechanism for towing, the pintle hitch has undergone substantial improvements to enhance vehicle stability and safety during towing operations.

In the early stages of its development, the pintle hitch was primarily designed for military applications, where ruggedness and simplicity were prioritized over refined performance. These early designs focused on providing a strong connection point between the towing vehicle and the trailer, with little consideration for the dynamic interactions between the two.

As civilian applications for towing became more prevalent, the limitations of the basic pintle hitch design became apparent. Issues such as trailer sway, jackknifing, and reduced stability at high speeds prompted researchers and engineers to investigate more sophisticated solutions. This led to the integration of advanced materials and design principles in pintle hitch construction.

The advent of computer-aided design and simulation technologies in the late 20th century marked a turning point in pintle hitch evolution. These tools allowed engineers to model and analyze the complex dynamics of vehicle-trailer systems with unprecedented accuracy. As a result, pintle hitch designs began to incorporate features that actively mitigated instability issues.

One significant development was the introduction of articulated pintle hitches, which allowed for greater flexibility in the connection between the vehicle and trailer. These designs reduced stress on the towing vehicle and improved maneuverability, particularly in off-road conditions. Concurrently, advancements in materials science led to the use of high-strength alloys and composites, enhancing the durability and weight characteristics of pintle hitches.

The integration of electronic systems marked another major milestone in pintle hitch evolution. Sensors and control units were incorporated to monitor trailer movement and automatically adjust vehicle systems to maintain stability. This led to the development of active sway control systems and electronic stability programs specifically designed for towing applications.

Recent years have seen a focus on improving the aerodynamics of pintle hitch systems to reduce fuel consumption and enhance overall vehicle efficiency. Additionally, research has been conducted on smart pintle hitches that can adapt to different load conditions and driving environments in real-time.

The ongoing evolution of pintle hitches continues to be driven by the need for improved safety, efficiency, and performance in towing applications. Current research is exploring the potential of AI and machine learning algorithms to further optimize vehicle-trailer dynamics and predict potential stability issues before they occur.

In the early stages of its development, the pintle hitch was primarily designed for military applications, where ruggedness and simplicity were prioritized over refined performance. These early designs focused on providing a strong connection point between the towing vehicle and the trailer, with little consideration for the dynamic interactions between the two.

As civilian applications for towing became more prevalent, the limitations of the basic pintle hitch design became apparent. Issues such as trailer sway, jackknifing, and reduced stability at high speeds prompted researchers and engineers to investigate more sophisticated solutions. This led to the integration of advanced materials and design principles in pintle hitch construction.

The advent of computer-aided design and simulation technologies in the late 20th century marked a turning point in pintle hitch evolution. These tools allowed engineers to model and analyze the complex dynamics of vehicle-trailer systems with unprecedented accuracy. As a result, pintle hitch designs began to incorporate features that actively mitigated instability issues.

One significant development was the introduction of articulated pintle hitches, which allowed for greater flexibility in the connection between the vehicle and trailer. These designs reduced stress on the towing vehicle and improved maneuverability, particularly in off-road conditions. Concurrently, advancements in materials science led to the use of high-strength alloys and composites, enhancing the durability and weight characteristics of pintle hitches.

The integration of electronic systems marked another major milestone in pintle hitch evolution. Sensors and control units were incorporated to monitor trailer movement and automatically adjust vehicle systems to maintain stability. This led to the development of active sway control systems and electronic stability programs specifically designed for towing applications.

Recent years have seen a focus on improving the aerodynamics of pintle hitch systems to reduce fuel consumption and enhance overall vehicle efficiency. Additionally, research has been conducted on smart pintle hitches that can adapt to different load conditions and driving environments in real-time.

The ongoing evolution of pintle hitches continues to be driven by the need for improved safety, efficiency, and performance in towing applications. Current research is exploring the potential of AI and machine learning algorithms to further optimize vehicle-trailer dynamics and predict potential stability issues before they occur.

Market Demand Analysis

The market demand for pintle hitch technology in vehicle dynamics and stability analysis has been steadily growing in recent years, driven by the increasing need for improved towing capabilities and enhanced safety features in both commercial and recreational vehicles. This demand is particularly pronounced in the automotive, agricultural, and construction sectors, where towing heavy loads is a common requirement.

In the automotive industry, there is a rising trend towards larger recreational vehicles and trailers, necessitating more robust and reliable towing systems. The pintle hitch, known for its durability and ability to handle heavy loads, has become a preferred choice for many manufacturers and consumers. This trend is further amplified by the growing popularity of outdoor activities and road trips, which has led to an increased demand for vehicles capable of towing boats, campers, and other recreational equipment.

The agricultural sector represents another significant market for pintle hitch technology. As farm equipment becomes larger and more sophisticated, the need for reliable and stable towing systems has intensified. Farmers require hitches that can withstand the rigors of daily use in challenging terrain while maintaining stability and safety. This has led to a surge in demand for advanced pintle hitch systems that can integrate with modern agricultural machinery and provide enhanced performance in various field conditions.

In the construction industry, the demand for pintle hitches is driven by the need for versatile and robust towing solutions for heavy machinery and equipment. Construction companies are increasingly looking for hitches that can improve efficiency and safety on job sites, leading to a growing market for innovative pintle hitch designs that offer improved stability and ease of use.

The market for pintle hitch technology is also being shaped by evolving safety regulations and standards. Governments and regulatory bodies worldwide are implementing stricter guidelines for towing safety, which is pushing manufacturers to develop more advanced and reliable hitch systems. This regulatory environment is creating opportunities for companies that can offer pintle hitch solutions with enhanced safety features and improved stability characteristics.

Furthermore, there is a growing demand for smart and connected towing systems. Consumers and businesses alike are showing interest in pintle hitches that can integrate with vehicle sensors and provide real-time data on towing performance, stability, and potential safety issues. This trend towards digitalization and connectivity in towing systems represents a significant growth opportunity for companies in the pintle hitch market.

As environmental concerns continue to shape the automotive industry, there is also an emerging demand for lightweight yet strong pintle hitch designs that can contribute to overall vehicle efficiency without compromising on towing capacity or safety. This presents both challenges and opportunities for manufacturers to innovate and develop new materials and designs that meet these evolving market needs.

In the automotive industry, there is a rising trend towards larger recreational vehicles and trailers, necessitating more robust and reliable towing systems. The pintle hitch, known for its durability and ability to handle heavy loads, has become a preferred choice for many manufacturers and consumers. This trend is further amplified by the growing popularity of outdoor activities and road trips, which has led to an increased demand for vehicles capable of towing boats, campers, and other recreational equipment.

The agricultural sector represents another significant market for pintle hitch technology. As farm equipment becomes larger and more sophisticated, the need for reliable and stable towing systems has intensified. Farmers require hitches that can withstand the rigors of daily use in challenging terrain while maintaining stability and safety. This has led to a surge in demand for advanced pintle hitch systems that can integrate with modern agricultural machinery and provide enhanced performance in various field conditions.

In the construction industry, the demand for pintle hitches is driven by the need for versatile and robust towing solutions for heavy machinery and equipment. Construction companies are increasingly looking for hitches that can improve efficiency and safety on job sites, leading to a growing market for innovative pintle hitch designs that offer improved stability and ease of use.

The market for pintle hitch technology is also being shaped by evolving safety regulations and standards. Governments and regulatory bodies worldwide are implementing stricter guidelines for towing safety, which is pushing manufacturers to develop more advanced and reliable hitch systems. This regulatory environment is creating opportunities for companies that can offer pintle hitch solutions with enhanced safety features and improved stability characteristics.

Furthermore, there is a growing demand for smart and connected towing systems. Consumers and businesses alike are showing interest in pintle hitches that can integrate with vehicle sensors and provide real-time data on towing performance, stability, and potential safety issues. This trend towards digitalization and connectivity in towing systems represents a significant growth opportunity for companies in the pintle hitch market.

As environmental concerns continue to shape the automotive industry, there is also an emerging demand for lightweight yet strong pintle hitch designs that can contribute to overall vehicle efficiency without compromising on towing capacity or safety. This presents both challenges and opportunities for manufacturers to innovate and develop new materials and designs that meet these evolving market needs.

Technical Challenges

The research on pintle hitch in vehicle dynamics and stability analysis faces several technical challenges that require innovative solutions. One of the primary obstacles is the complex nature of the pintle hitch's impact on vehicle behavior, particularly during towing operations. The dynamic interactions between the towing vehicle and the trailer create a multifaceted system that is difficult to model accurately.

Researchers struggle with developing comprehensive mathematical models that can precisely capture the intricate forces and moments acting on the pintle hitch connection. These models must account for various factors such as vehicle speed, road conditions, wind resistance, and load distribution. The non-linear nature of these interactions further complicates the analysis, making it challenging to predict system behavior under diverse operating conditions.

Another significant challenge lies in the real-time monitoring and control of pintle hitch dynamics. Current sensor technologies and data processing capabilities may not be sufficient to provide instantaneous feedback on the hitch's performance, especially in rapidly changing driving scenarios. This limitation hinders the development of advanced driver assistance systems and autonomous towing features that could enhance safety and stability.

The variability in trailer designs and load configurations presents an additional hurdle. Each combination of towing vehicle and trailer exhibits unique dynamic characteristics, making it difficult to establish standardized testing protocols and performance metrics. This diversity complicates the process of developing universal solutions for pintle hitch stability enhancement.

Furthermore, the integration of active control systems for pintle hitch stability poses technical challenges. Designing robust control algorithms that can effectively mitigate instabilities, such as trailer sway or jackknifing, without compromising the overall vehicle performance is a complex task. These systems must be capable of rapid response while maintaining smooth and predictable vehicle behavior.

Material science and structural engineering also face challenges in improving pintle hitch design. Developing lightweight yet durable materials that can withstand the high stresses and fatigue loads associated with towing operations is crucial. Simultaneously, these materials must maintain their performance characteristics across a wide range of environmental conditions, from extreme temperatures to corrosive environments.

Lastly, the validation and testing of pintle hitch systems present significant technical hurdles. Creating realistic simulation environments that accurately replicate real-world towing scenarios is essential for thorough analysis. However, the complexity of the system often necessitates extensive physical testing, which can be time-consuming and costly. Striking a balance between virtual simulations and practical experiments remains a challenge in the field of vehicle dynamics and stability analysis for pintle hitch systems.

Researchers struggle with developing comprehensive mathematical models that can precisely capture the intricate forces and moments acting on the pintle hitch connection. These models must account for various factors such as vehicle speed, road conditions, wind resistance, and load distribution. The non-linear nature of these interactions further complicates the analysis, making it challenging to predict system behavior under diverse operating conditions.

Another significant challenge lies in the real-time monitoring and control of pintle hitch dynamics. Current sensor technologies and data processing capabilities may not be sufficient to provide instantaneous feedback on the hitch's performance, especially in rapidly changing driving scenarios. This limitation hinders the development of advanced driver assistance systems and autonomous towing features that could enhance safety and stability.

The variability in trailer designs and load configurations presents an additional hurdle. Each combination of towing vehicle and trailer exhibits unique dynamic characteristics, making it difficult to establish standardized testing protocols and performance metrics. This diversity complicates the process of developing universal solutions for pintle hitch stability enhancement.

Furthermore, the integration of active control systems for pintle hitch stability poses technical challenges. Designing robust control algorithms that can effectively mitigate instabilities, such as trailer sway or jackknifing, without compromising the overall vehicle performance is a complex task. These systems must be capable of rapid response while maintaining smooth and predictable vehicle behavior.

Material science and structural engineering also face challenges in improving pintle hitch design. Developing lightweight yet durable materials that can withstand the high stresses and fatigue loads associated with towing operations is crucial. Simultaneously, these materials must maintain their performance characteristics across a wide range of environmental conditions, from extreme temperatures to corrosive environments.

Lastly, the validation and testing of pintle hitch systems present significant technical hurdles. Creating realistic simulation environments that accurately replicate real-world towing scenarios is essential for thorough analysis. However, the complexity of the system often necessitates extensive physical testing, which can be time-consuming and costly. Striking a balance between virtual simulations and practical experiments remains a challenge in the field of vehicle dynamics and stability analysis for pintle hitch systems.

Current Solutions

01 Pintle hitch design for improved stability

Various designs of pintle hitches aim to enhance vehicle stability during towing. These designs include features such as adjustable height mechanisms, shock-absorbing elements, and reinforced structures to minimize sway and improve overall towing performance.- Pintle hitch design for improved stability: Various designs of pintle hitches focus on enhancing vehicle stability during towing. These designs incorporate features such as adjustable height mechanisms, shock-absorbing elements, and reinforced structures to minimize swaying and improve overall towing performance.

- Anti-jackknifing mechanisms for pintle hitches: Innovations in pintle hitch systems include anti-jackknifing mechanisms that prevent excessive articulation between the towing vehicle and the trailer. These mechanisms utilize various techniques such as limiting pivot angles, employing friction-based systems, or incorporating electronic controls to maintain stability during turns and sudden maneuvers.

- Load distribution and weight transfer systems: Advanced pintle hitch designs incorporate load distribution and weight transfer systems to optimize vehicle dynamics. These systems help distribute the trailer's weight more evenly across the towing vehicle's axles, improving steering control, braking performance, and overall stability during towing operations.

- Integrated suspension and damping systems: Some pintle hitch designs feature integrated suspension and damping systems to enhance ride comfort and stability. These systems absorb shocks and vibrations, reducing stress on both the towing vehicle and the trailer, and improving overall handling characteristics, especially on uneven terrain or during sudden load shifts.

- Electronic stability control for pintle hitch systems: Advanced pintle hitch systems incorporate electronic stability control features to enhance vehicle dynamics and safety. These systems use sensors to monitor various parameters such as vehicle speed, yaw rate, and lateral acceleration, and can automatically apply brakes or adjust power distribution to maintain stability and prevent accidents during towing.

02 Anti-jackknifing mechanisms for pintle hitches

Innovations in pintle hitch designs incorporate anti-jackknifing mechanisms to prevent dangerous folding between the towing vehicle and trailer. These mechanisms may include pivoting components, locking systems, or specialized geometries that limit the angle between the vehicle and trailer.Expand Specific Solutions03 Suspension systems for improved ride quality

Integration of suspension systems within pintle hitch assemblies aims to enhance ride quality and stability. These systems may include air springs, hydraulic dampers, or other shock-absorbing elements to reduce vibration and improve overall towing comfort.Expand Specific Solutions04 Electronic stability control for pintle hitch systems

Advanced pintle hitch designs incorporate electronic stability control systems to monitor and adjust vehicle dynamics during towing. These systems may use sensors, actuators, and computerized control units to detect and mitigate instability, improving overall safety and performance.Expand Specific Solutions05 Weight distribution and load management

Pintle hitch designs focus on optimizing weight distribution and load management to enhance vehicle stability. These innovations may include adjustable weight distribution systems, load-sensing technologies, or specialized hitch geometries that help maintain proper balance between the towing vehicle and trailer.Expand Specific Solutions

Key Industry Players

The research on Pintle Hitch in Vehicle Dynamics and Stability Analysis is in a developing stage, with growing market potential due to increasing demand for towing solutions in various industries. The technology is moderately mature, with established players like ACPS Automotive GmbH and WESTFALIA-Automotive GmbH leading innovation. Major automotive manufacturers such as GM Global Technology Operations LLC, Ford Global Technologies LLC, and Hyundai Motor Co., Ltd. are also investing in this area, indicating its strategic importance. The market is expected to expand as vehicle manufacturers focus on improving towing capabilities and safety features, driven by consumer demand and regulatory requirements.

XCMG Construction Machinery Co., Ltd.

Technical Solution: XCMG has developed an advanced Pintle Hitch system for their construction vehicles, focusing on improving vehicle dynamics and stability. Their research incorporates a multi-link suspension system with an integrated pintle hitch, allowing for better load distribution and reduced stress on the vehicle frame[1]. The company has implemented advanced sensors and control algorithms to continuously monitor and adjust the hitch's position based on real-time road conditions and load characteristics[3]. This adaptive system enhances vehicle stability during turns and on uneven terrain, significantly reducing the risk of rollover incidents in heavy-duty construction machinery[5].

Strengths: Improved load distribution, enhanced stability on uneven terrain, and reduced rollover risk. Weaknesses: Potentially higher cost due to advanced sensor integration and complexity in maintenance.

GM Global Technology Operations LLC

Technical Solution: GM has developed a sophisticated Pintle Hitch system for their heavy-duty trucks and SUVs, focusing on enhancing towing capabilities while maintaining vehicle stability. Their research has led to the implementation of an electronically controlled pintle hitch that dynamically adjusts its position based on vehicle speed, acceleration, and road conditions[2]. The system incorporates advanced yaw control algorithms that work in conjunction with the vehicle's stability control system to minimize trailer sway and improve overall handling[4]. GM has also integrated a trailer recognition system that automatically detects the trailer's dimensions and weight, allowing for optimized hitch performance and vehicle dynamics adjustments[6].

Strengths: Enhanced towing capabilities, improved trailer sway control, and seamless integration with vehicle stability systems. Weaknesses: Increased complexity may lead to higher maintenance costs and potential reliability issues in extreme conditions.

Core Innovations

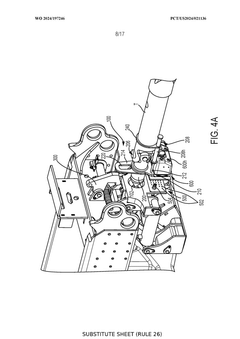

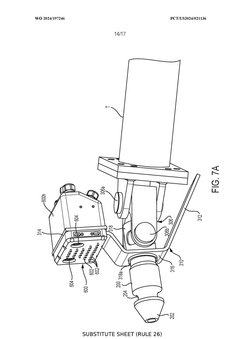

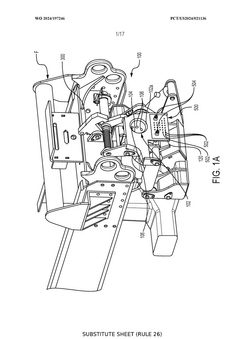

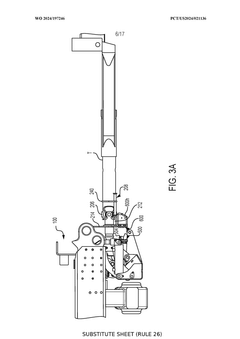

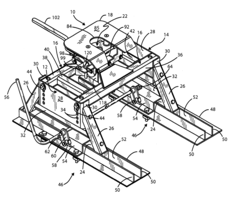

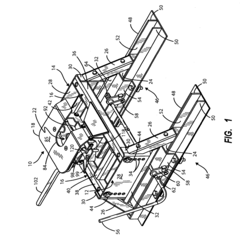

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

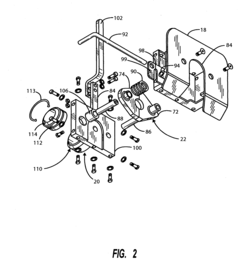

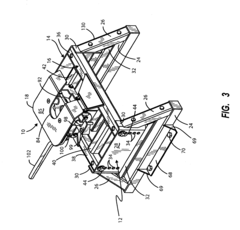

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Trailer Hitch

PatentInactiveUS20040145151A1

Innovation

- A fifth wheel hitch assembly with a support frame, spherical bearing for two degrees of movement, and a latch assembly with pivotable jaws and a cam follower mechanism that securely captures and adjusts the kingpin, allowing fore and aft and side-to-side movement, and is easily removable and adjustable along rails.

Safety Regulations

Safety regulations play a crucial role in the research and implementation of pintle hitch systems for vehicle dynamics and stability analysis. These regulations are designed to ensure the safe operation of vehicles equipped with pintle hitches, particularly in towing applications. The primary focus of safety regulations is to minimize the risk of accidents, injuries, and property damage associated with the use of pintle hitches.

One of the key aspects of safety regulations for pintle hitches is the standardization of design and manufacturing processes. Regulatory bodies such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) have established guidelines for the construction, testing, and performance of pintle hitches. These standards cover various aspects, including material specifications, load-bearing capacities, and durability requirements.

Safety regulations also address the proper installation and maintenance of pintle hitches. Manufacturers are required to provide detailed instructions for the correct mounting of the hitch to the vehicle, as well as guidelines for regular inspection and maintenance. This ensures that the hitch remains in optimal condition throughout its service life, reducing the risk of failure during operation.

Another important aspect of safety regulations is the specification of maximum towing capacities and weight distribution requirements. These regulations help prevent overloading and ensure proper weight distribution between the towing vehicle and the trailer. Compliance with these regulations is essential for maintaining vehicle stability and control, especially during cornering, braking, and acceleration.

Safety regulations also mandate the use of additional safety features in conjunction with pintle hitches. These may include safety chains, breakaway systems, and proper lighting and signaling equipment for towed vehicles. Such requirements are designed to provide redundancy and enhance overall safety in the event of a hitch failure or other unforeseen circumstances.

Furthermore, safety regulations often require comprehensive testing and certification processes for pintle hitch systems. This includes dynamic testing to evaluate the hitch's performance under various road conditions and load scenarios. Such testing helps identify potential weaknesses or design flaws that could compromise safety during real-world use.

In recent years, safety regulations have also begun to address the integration of advanced technologies with pintle hitch systems. This includes the development of standards for electronic stability control systems specifically designed for towing applications, as well as guidelines for the use of sensors and monitoring systems to enhance safety and performance.

As vehicle dynamics and stability analysis techniques continue to evolve, safety regulations for pintle hitches are likely to become increasingly sophisticated. Future regulations may incorporate more advanced simulation and modeling requirements, as well as provisions for emerging technologies such as autonomous towing systems and smart trailer connectivity.

One of the key aspects of safety regulations for pintle hitches is the standardization of design and manufacturing processes. Regulatory bodies such as the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO) have established guidelines for the construction, testing, and performance of pintle hitches. These standards cover various aspects, including material specifications, load-bearing capacities, and durability requirements.

Safety regulations also address the proper installation and maintenance of pintle hitches. Manufacturers are required to provide detailed instructions for the correct mounting of the hitch to the vehicle, as well as guidelines for regular inspection and maintenance. This ensures that the hitch remains in optimal condition throughout its service life, reducing the risk of failure during operation.

Another important aspect of safety regulations is the specification of maximum towing capacities and weight distribution requirements. These regulations help prevent overloading and ensure proper weight distribution between the towing vehicle and the trailer. Compliance with these regulations is essential for maintaining vehicle stability and control, especially during cornering, braking, and acceleration.

Safety regulations also mandate the use of additional safety features in conjunction with pintle hitches. These may include safety chains, breakaway systems, and proper lighting and signaling equipment for towed vehicles. Such requirements are designed to provide redundancy and enhance overall safety in the event of a hitch failure or other unforeseen circumstances.

Furthermore, safety regulations often require comprehensive testing and certification processes for pintle hitch systems. This includes dynamic testing to evaluate the hitch's performance under various road conditions and load scenarios. Such testing helps identify potential weaknesses or design flaws that could compromise safety during real-world use.

In recent years, safety regulations have also begun to address the integration of advanced technologies with pintle hitch systems. This includes the development of standards for electronic stability control systems specifically designed for towing applications, as well as guidelines for the use of sensors and monitoring systems to enhance safety and performance.

As vehicle dynamics and stability analysis techniques continue to evolve, safety regulations for pintle hitches are likely to become increasingly sophisticated. Future regulations may incorporate more advanced simulation and modeling requirements, as well as provisions for emerging technologies such as autonomous towing systems and smart trailer connectivity.

Simulation Techniques

Simulation techniques play a crucial role in the research on pintle hitch in vehicle dynamics and stability analysis. These techniques allow researchers and engineers to model and analyze complex vehicle systems without the need for extensive physical testing, saving time and resources while providing valuable insights.

One of the primary simulation methods used in this field is multi-body dynamics simulation. This approach treats the vehicle and trailer as a system of interconnected rigid bodies, allowing for the accurate representation of the pintle hitch connection. Multi-body dynamics simulations can capture the complex interactions between the towing vehicle and trailer, including the effects of articulation, weight distribution, and external forces.

Finite element analysis (FEA) is another essential simulation technique employed in pintle hitch research. FEA enables the detailed study of stress distributions and deformations in the hitch mechanism under various loading conditions. This method is particularly useful for optimizing the design of pintle hitches to improve their strength and durability.

Computational fluid dynamics (CFD) simulations are utilized to analyze the aerodynamic effects on vehicle-trailer combinations. These simulations can help researchers understand how air flow around the vehicles affects stability, particularly at high speeds or in crosswind conditions. CFD analysis can also be used to optimize the aerodynamic profile of both the towing vehicle and trailer to reduce drag and improve fuel efficiency.

Hardware-in-the-loop (HIL) simulation is an advanced technique that combines physical hardware with real-time software simulation. In the context of pintle hitch research, HIL can be used to test control systems and electronic stability programs under realistic conditions without the need for full-scale road tests.

Vehicle dynamics software packages, such as CarSim or TruckSim, are widely used for simulating the behavior of vehicle-trailer combinations. These specialized tools incorporate detailed vehicle models, tire dynamics, and road conditions to provide accurate predictions of vehicle performance and stability.

Monte Carlo simulations are employed to assess the robustness of pintle hitch designs and control systems under a wide range of operating conditions. By running numerous simulations with varying parameters, researchers can identify potential failure modes and optimize system performance across diverse scenarios.

As simulation techniques continue to advance, the integration of artificial intelligence and machine learning algorithms is becoming increasingly common. These methods can be used to process large amounts of simulation data, identify patterns, and optimize vehicle-trailer systems for improved stability and performance.

One of the primary simulation methods used in this field is multi-body dynamics simulation. This approach treats the vehicle and trailer as a system of interconnected rigid bodies, allowing for the accurate representation of the pintle hitch connection. Multi-body dynamics simulations can capture the complex interactions between the towing vehicle and trailer, including the effects of articulation, weight distribution, and external forces.

Finite element analysis (FEA) is another essential simulation technique employed in pintle hitch research. FEA enables the detailed study of stress distributions and deformations in the hitch mechanism under various loading conditions. This method is particularly useful for optimizing the design of pintle hitches to improve their strength and durability.

Computational fluid dynamics (CFD) simulations are utilized to analyze the aerodynamic effects on vehicle-trailer combinations. These simulations can help researchers understand how air flow around the vehicles affects stability, particularly at high speeds or in crosswind conditions. CFD analysis can also be used to optimize the aerodynamic profile of both the towing vehicle and trailer to reduce drag and improve fuel efficiency.

Hardware-in-the-loop (HIL) simulation is an advanced technique that combines physical hardware with real-time software simulation. In the context of pintle hitch research, HIL can be used to test control systems and electronic stability programs under realistic conditions without the need for full-scale road tests.

Vehicle dynamics software packages, such as CarSim or TruckSim, are widely used for simulating the behavior of vehicle-trailer combinations. These specialized tools incorporate detailed vehicle models, tire dynamics, and road conditions to provide accurate predictions of vehicle performance and stability.

Monte Carlo simulations are employed to assess the robustness of pintle hitch designs and control systems under a wide range of operating conditions. By running numerous simulations with varying parameters, researchers can identify potential failure modes and optimize system performance across diverse scenarios.

As simulation techniques continue to advance, the integration of artificial intelligence and machine learning algorithms is becoming increasingly common. These methods can be used to process large amounts of simulation data, identify patterns, and optimize vehicle-trailer systems for improved stability and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!