The Impact of Pintle Hitch on Overall Vehicular Towing Dynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution and Objectives

The pintle hitch has undergone significant evolution since its inception, driven by the need for more robust and versatile towing solutions. Originally developed for military applications, the pintle hitch has transitioned into civilian use, particularly in heavy-duty towing scenarios. Its design has progressed from simple hook-and-eye configurations to more sophisticated systems incorporating safety features and enhanced load-bearing capabilities.

The primary objective of pintle hitch development has been to improve overall vehicular towing dynamics. This includes enhancing stability during towing, increasing load capacity, and ensuring safer operation across various terrains and conditions. As vehicles have become more powerful and diverse in their towing needs, pintle hitches have adapted to meet these changing demands.

One key area of evolution has been the integration of advanced materials and manufacturing techniques. Modern pintle hitches often utilize high-strength alloys and precision engineering to achieve greater durability and performance. This has resulted in hitches capable of handling significantly higher gross trailer weights while maintaining a compact and efficient design.

Another important aspect of pintle hitch evolution has been the focus on reducing stress on both the towing vehicle and the trailer. Innovations in articulation and load distribution have aimed to minimize wear and tear on vehicle components, improve fuel efficiency, and enhance overall towing stability. This has led to the development of multi-axis pintle systems that allow for greater flexibility in movement while maintaining a secure connection.

Safety has been a paramount concern in the evolution of pintle hitches. Modern designs often incorporate features such as secondary locking mechanisms, integrated brake controllers, and compatibility with electronic stability control systems. These advancements aim to reduce the risk of trailer separation and improve overall control during towing operations.

The objectives for future pintle hitch development continue to focus on enhancing towing dynamics. This includes further improvements in weight distribution, the integration of smart technologies for real-time monitoring and adjustment of towing parameters, and the development of more environmentally friendly materials and manufacturing processes. Additionally, there is a growing emphasis on creating universal standards for pintle hitches to ensure compatibility across different vehicle types and towing applications.

As the automotive industry moves towards electrification and autonomous driving, pintle hitch technology is also adapting to these trends. Research is being conducted on how to optimize pintle hitches for electric vehicles, considering factors such as weight distribution and energy efficiency. Furthermore, the potential for automated hitching and unhitching systems is being explored, which could revolutionize the ease and safety of towing operations in the future.

The primary objective of pintle hitch development has been to improve overall vehicular towing dynamics. This includes enhancing stability during towing, increasing load capacity, and ensuring safer operation across various terrains and conditions. As vehicles have become more powerful and diverse in their towing needs, pintle hitches have adapted to meet these changing demands.

One key area of evolution has been the integration of advanced materials and manufacturing techniques. Modern pintle hitches often utilize high-strength alloys and precision engineering to achieve greater durability and performance. This has resulted in hitches capable of handling significantly higher gross trailer weights while maintaining a compact and efficient design.

Another important aspect of pintle hitch evolution has been the focus on reducing stress on both the towing vehicle and the trailer. Innovations in articulation and load distribution have aimed to minimize wear and tear on vehicle components, improve fuel efficiency, and enhance overall towing stability. This has led to the development of multi-axis pintle systems that allow for greater flexibility in movement while maintaining a secure connection.

Safety has been a paramount concern in the evolution of pintle hitches. Modern designs often incorporate features such as secondary locking mechanisms, integrated brake controllers, and compatibility with electronic stability control systems. These advancements aim to reduce the risk of trailer separation and improve overall control during towing operations.

The objectives for future pintle hitch development continue to focus on enhancing towing dynamics. This includes further improvements in weight distribution, the integration of smart technologies for real-time monitoring and adjustment of towing parameters, and the development of more environmentally friendly materials and manufacturing processes. Additionally, there is a growing emphasis on creating universal standards for pintle hitches to ensure compatibility across different vehicle types and towing applications.

As the automotive industry moves towards electrification and autonomous driving, pintle hitch technology is also adapting to these trends. Research is being conducted on how to optimize pintle hitches for electric vehicles, considering factors such as weight distribution and energy efficiency. Furthermore, the potential for automated hitching and unhitching systems is being explored, which could revolutionize the ease and safety of towing operations in the future.

Market Analysis for Pintle Hitch Systems

The pintle hitch system market has experienced significant growth in recent years, driven by the increasing demand for heavy-duty towing solutions across various industries. The global market for pintle hitch systems is projected to expand at a steady rate, with North America and Europe leading in terms of market share and technological advancements.

The construction and agriculture sectors are the primary drivers of pintle hitch system demand. As these industries continue to grow and modernize, the need for robust and versatile towing solutions has increased. The construction industry, in particular, relies heavily on pintle hitches for transporting heavy equipment and materials to job sites, contributing substantially to market growth.

Military and defense applications also play a crucial role in the pintle hitch market. The ability of pintle hitches to handle extreme conditions and heavy loads makes them ideal for military vehicles and equipment transport. This sector's demand is expected to remain strong, especially in regions with ongoing defense modernization programs.

The commercial transportation sector represents another significant market segment for pintle hitch systems. With the rise of e-commerce and the need for efficient logistics, there has been an increased demand for versatile towing solutions that can handle a variety of trailer types and loads. Pintle hitches offer the flexibility and durability required for diverse commercial applications.

In terms of product types, the market is segmented into fixed pintle hitches, combination pintle hitches, and receiver-style pintle hitches. Combination pintle hitches have gained popularity due to their versatility in accommodating both pintle hooks and ball mounts, catering to a wider range of towing needs.

Geographically, North America dominates the pintle hitch system market, followed by Europe and Asia-Pacific. The strong presence of major manufacturers, coupled with stringent safety regulations in these regions, has contributed to their market leadership. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by infrastructure development and industrialization.

Key market trends include the integration of advanced materials to reduce weight while maintaining strength, the development of smart pintle hitch systems with sensors for improved safety, and the increasing focus on eco-friendly manufacturing processes. These innovations are expected to drive market growth and differentiation among manufacturers.

The construction and agriculture sectors are the primary drivers of pintle hitch system demand. As these industries continue to grow and modernize, the need for robust and versatile towing solutions has increased. The construction industry, in particular, relies heavily on pintle hitches for transporting heavy equipment and materials to job sites, contributing substantially to market growth.

Military and defense applications also play a crucial role in the pintle hitch market. The ability of pintle hitches to handle extreme conditions and heavy loads makes them ideal for military vehicles and equipment transport. This sector's demand is expected to remain strong, especially in regions with ongoing defense modernization programs.

The commercial transportation sector represents another significant market segment for pintle hitch systems. With the rise of e-commerce and the need for efficient logistics, there has been an increased demand for versatile towing solutions that can handle a variety of trailer types and loads. Pintle hitches offer the flexibility and durability required for diverse commercial applications.

In terms of product types, the market is segmented into fixed pintle hitches, combination pintle hitches, and receiver-style pintle hitches. Combination pintle hitches have gained popularity due to their versatility in accommodating both pintle hooks and ball mounts, catering to a wider range of towing needs.

Geographically, North America dominates the pintle hitch system market, followed by Europe and Asia-Pacific. The strong presence of major manufacturers, coupled with stringent safety regulations in these regions, has contributed to their market leadership. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by infrastructure development and industrialization.

Key market trends include the integration of advanced materials to reduce weight while maintaining strength, the development of smart pintle hitch systems with sensors for improved safety, and the increasing focus on eco-friendly manufacturing processes. These innovations are expected to drive market growth and differentiation among manufacturers.

Current Challenges in Vehicular Towing

Vehicular towing dynamics present a complex set of challenges that continue to evolve with advancements in vehicle design and towing technologies. One of the primary issues facing the industry is the need for improved stability control systems specifically tailored for towing scenarios. Current systems often struggle to adequately compensate for the additional mass and altered center of gravity introduced by trailers, leading to potential instability during sudden maneuvers or adverse weather conditions.

Another significant challenge lies in the integration of advanced driver assistance systems (ADAS) with towing functionalities. While ADAS technologies have made significant strides in improving safety for standard vehicles, their effectiveness can be compromised when a trailer is attached. Adapting these systems to account for the presence and characteristics of various trailer types remains a complex task, requiring sophisticated sensor fusion and real-time data processing capabilities.

The increasing popularity of electric vehicles (EVs) has introduced new challenges in the realm of towing. EVs often have different weight distributions and power delivery characteristics compared to traditional internal combustion engine vehicles. This necessitates a reevaluation of towing capacities and the development of specialized towing systems that can effectively manage the unique properties of electric powertrains while maintaining optimal energy efficiency.

Aerodynamics continue to be a critical concern in vehicular towing. The interaction between the towing vehicle and the trailer can create significant drag, reducing fuel efficiency and potentially compromising stability at higher speeds. Developing more aerodynamic trailer designs and improving the integration between towing vehicles and trailers to minimize air resistance remains an ongoing challenge for manufacturers and engineers.

Weight distribution and load management present persistent challenges in towing dynamics. Improper loading can lead to trailer sway, reduced braking effectiveness, and increased wear on vehicle components. While advancements have been made in weight distribution hitches and sway control devices, there is still a need for more intelligent, adaptive systems that can automatically adjust to changing load conditions during travel.

The diversity of towing scenarios and trailer types further complicates the development of universal towing solutions. From light-duty recreational towing to heavy commercial applications, each situation presents unique challenges that require specialized approaches. Developing versatile towing systems that can adapt to a wide range of trailer sizes, weights, and configurations while maintaining optimal performance and safety remains a significant industry challenge.

Lastly, the integration of smart technologies and connectivity in towing systems presents both opportunities and challenges. While these technologies offer the potential for enhanced safety features, real-time monitoring, and improved user experience, they also introduce complexities in terms of data security, system reliability, and user interface design. Striking the right balance between technological advancement and practical, user-friendly implementation remains an ongoing challenge in the evolution of vehicular towing dynamics.

Another significant challenge lies in the integration of advanced driver assistance systems (ADAS) with towing functionalities. While ADAS technologies have made significant strides in improving safety for standard vehicles, their effectiveness can be compromised when a trailer is attached. Adapting these systems to account for the presence and characteristics of various trailer types remains a complex task, requiring sophisticated sensor fusion and real-time data processing capabilities.

The increasing popularity of electric vehicles (EVs) has introduced new challenges in the realm of towing. EVs often have different weight distributions and power delivery characteristics compared to traditional internal combustion engine vehicles. This necessitates a reevaluation of towing capacities and the development of specialized towing systems that can effectively manage the unique properties of electric powertrains while maintaining optimal energy efficiency.

Aerodynamics continue to be a critical concern in vehicular towing. The interaction between the towing vehicle and the trailer can create significant drag, reducing fuel efficiency and potentially compromising stability at higher speeds. Developing more aerodynamic trailer designs and improving the integration between towing vehicles and trailers to minimize air resistance remains an ongoing challenge for manufacturers and engineers.

Weight distribution and load management present persistent challenges in towing dynamics. Improper loading can lead to trailer sway, reduced braking effectiveness, and increased wear on vehicle components. While advancements have been made in weight distribution hitches and sway control devices, there is still a need for more intelligent, adaptive systems that can automatically adjust to changing load conditions during travel.

The diversity of towing scenarios and trailer types further complicates the development of universal towing solutions. From light-duty recreational towing to heavy commercial applications, each situation presents unique challenges that require specialized approaches. Developing versatile towing systems that can adapt to a wide range of trailer sizes, weights, and configurations while maintaining optimal performance and safety remains a significant industry challenge.

Lastly, the integration of smart technologies and connectivity in towing systems presents both opportunities and challenges. While these technologies offer the potential for enhanced safety features, real-time monitoring, and improved user experience, they also introduce complexities in terms of data security, system reliability, and user interface design. Striking the right balance between technological advancement and practical, user-friendly implementation remains an ongoing challenge in the evolution of vehicular towing dynamics.

Existing Pintle Hitch Solutions

01 Pintle hitch design and structure

Pintle hitches are designed with specific structural features to enhance towing dynamics. These designs may include adjustable components, reinforced materials, and specialized geometries to improve stability, weight distribution, and overall performance during towing operations.- Pintle hitch design and construction: Pintle hitches are designed for heavy-duty towing applications. They typically consist of a hook-like structure that connects to a lunette ring on the trailer. The design allows for greater articulation and flexibility in towing, making them suitable for off-road and rough terrain use. Innovations in pintle hitch design focus on improving strength, durability, and ease of use.

- Towing stability and control systems: Advanced towing dynamics systems are being developed to enhance stability and control during towing operations. These systems may include electronic sensors, hydraulic or pneumatic components, and computerized control units. They can adjust trailer alignment, manage weight distribution, and provide active sway control to improve overall towing safety and performance.

- Articulation and maneuverability improvements: Innovations in pintle hitch towing dynamics focus on enhancing articulation and maneuverability. This includes designs that allow for greater angular movement between the towing vehicle and trailer, as well as systems that improve turning radius and backing capabilities. These improvements aim to increase versatility in various towing scenarios, particularly in tight spaces or challenging terrain.

- Load distribution and weight management: Effective load distribution and weight management are crucial for safe and efficient towing. Innovations in this area include adjustable hitch systems, weight distribution hitches specifically designed for pintle configurations, and dynamic load sensing technologies. These advancements help to maintain proper tongue weight, reduce stress on the towing vehicle, and improve overall stability during transit.

- Integration of safety features and monitoring systems: Modern pintle hitch towing systems increasingly incorporate advanced safety features and monitoring capabilities. These may include integrated brake controllers, tire pressure monitoring systems for both towing vehicle and trailer, backup cameras with trailer view, and real-time monitoring of towing dynamics. Such features enhance overall safety, provide valuable feedback to the driver, and help prevent accidents or equipment damage during towing operations.

02 Articulation and pivot mechanisms

Advanced articulation and pivot mechanisms are incorporated into pintle hitch designs to allow for greater flexibility and maneuverability during towing. These mechanisms help reduce stress on the towing vehicle and trailer, improving overall stability and control, especially during turns and on uneven terrain.Expand Specific Solutions03 Shock absorption and vibration dampening

Pintle hitch systems often include shock absorption and vibration dampening features to enhance towing dynamics. These components help reduce the transfer of road vibrations and impacts between the towing vehicle and trailer, resulting in a smoother ride and reduced wear on both vehicles.Expand Specific Solutions04 Electronic monitoring and control systems

Integration of electronic monitoring and control systems in pintle hitch towing setups improves overall dynamics. These systems may include sensors, cameras, and computerized controls to monitor trailer sway, weight distribution, and other critical factors, allowing for real-time adjustments and enhanced safety during towing operations.Expand Specific Solutions05 Weight distribution and load management

Advanced pintle hitch designs incorporate features for improved weight distribution and load management. These may include adjustable components, specialized geometries, or integrated load-leveling systems to optimize the distribution of weight between the towing vehicle and trailer, enhancing stability and control during various towing conditions.Expand Specific Solutions

Key Manufacturers and Competitors

The impact of pintle hitch on vehicular towing dynamics is an evolving field within the automotive industry. The market is in a growth phase, driven by increasing demand for towing solutions in both commercial and recreational sectors. While the global towing equipment market is substantial, the pintle hitch segment represents a specialized niche. Technologically, pintle hitches are well-established, but ongoing innovations focus on improving safety, durability, and ease of use. Companies like Curt Manufacturing LLC and Horizon Global Americas, Inc. are at the forefront of developing advanced pintle hitch systems, while automotive giants such as Chery Automobile Co., Ltd. and Zhejiang Geely Holding Group Co., Ltd. are integrating these technologies into their vehicle designs to enhance towing capabilities.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has developed advanced pintle hitch systems that significantly impact vehicular towing dynamics. Their innovative designs incorporate a combination of high-strength steel construction and precision engineering to enhance overall towing stability and safety. The company's pintle hitches feature a unique locking mechanism that reduces play between the hitch and trailer, minimizing sway and improving control during towing operations[1]. Additionally, Curt has implemented a proprietary coating technology that increases corrosion resistance, extending the lifespan of their pintle hitches in various environmental conditions[2]. The company has also integrated smart sensors into their latest models, allowing real-time monitoring of hitch performance and early detection of potential issues[3].

Strengths: Enhanced stability, improved safety features, and integration of smart technology. Weaknesses: Potentially higher cost compared to standard hitches and may require specialized installation.

Horizon Global Americas, Inc.

Technical Solution: Horizon Global Americas, Inc. has made significant strides in pintle hitch technology, focusing on improving overall vehicular towing dynamics. Their approach involves the use of advanced computer-aided design and simulation techniques to optimize the hitch geometry for various towing scenarios[1]. The company has developed a patented load distribution system that effectively transfers weight across the towing vehicle's axles, enhancing stability and reducing wear on suspension components[2]. Horizon's pintle hitches also feature an innovative articulation joint that allows for greater flexibility in off-road conditions while maintaining rigidity during highway use[3]. Furthermore, they have incorporated lightweight, high-strength materials such as aircraft-grade aluminum in their designs, reducing overall vehicle weight without compromising towing capacity[4].

Strengths: Optimized weight distribution, versatility in various terrains, and use of lightweight materials. Weaknesses: May be more complex to install and potentially more expensive than traditional hitches.

Innovative Pintle Hitch Designs

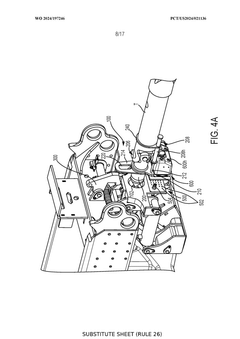

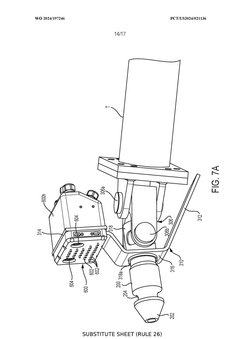

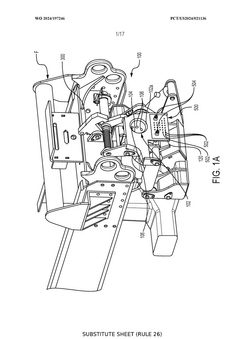

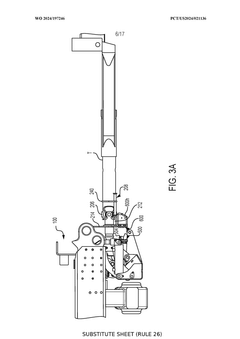

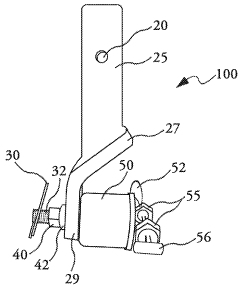

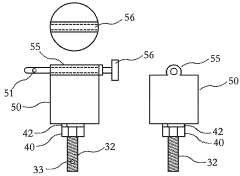

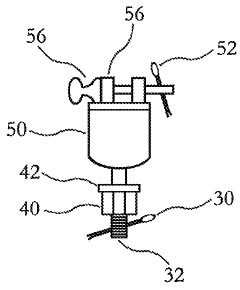

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Pintle hitch connector

PatentInactiveUS20180104998A1

Innovation

- A pintle hitch connector with a cylindrical trailer contact portion and a threaded portion featuring a locking mechanism and load securing pin, along with a universal connector design that includes a curved hitch bracket and connecting pin, simplifying attachment and reducing manufacturing costs.

Safety Regulations for Towing Systems

Safety regulations for towing systems play a crucial role in ensuring the safe operation of vehicles equipped with pintle hitches. These regulations are designed to address the unique challenges posed by the dynamic interactions between towing vehicles and their trailers. In the United States, the National Highway Traffic Safety Administration (NHTSA) is responsible for establishing and enforcing safety standards for towing systems, including those utilizing pintle hitches.

One of the primary safety regulations for pintle hitch towing systems is the requirement for proper weight distribution. This involves ensuring that the tongue weight of the trailer is within the recommended range, typically between 10-15% of the total trailer weight. Proper weight distribution helps maintain stability and control of the towing vehicle, reducing the risk of swaying or jackknifing during operation.

Another critical safety regulation pertains to the strength and durability of the pintle hitch itself. Manufacturers must adhere to strict guidelines regarding the materials used and the construction methods employed to ensure that the hitch can withstand the forces exerted during towing operations. These standards typically include requirements for minimum tensile strength, fatigue resistance, and corrosion protection.

Safety chains are also mandated by regulations to provide an additional layer of security in case of hitch failure. These chains must be properly rated for the weight of the trailer and securely attached to both the towing vehicle and the trailer. The length of the safety chains is also regulated to ensure they do not drag on the ground or interfere with turning maneuvers.

Lighting and signaling requirements form another essential aspect of towing safety regulations. Trailers must be equipped with functioning brake lights, turn signals, and marker lights that are compatible with the towing vehicle's electrical system. This ensures that other road users are aware of the towing vehicle's intentions and helps prevent accidents caused by poor visibility.

Brake system regulations are particularly important for towing safety. Depending on the weight of the trailer, electric or hydraulic brake systems may be required. These systems must be properly integrated with the towing vehicle's braking system to ensure coordinated and effective stopping power. Regular maintenance and inspection of brake systems are also mandated to maintain their reliability.

Regulations also address the need for proper driver training and licensing when operating vehicles with pintle hitch towing systems. Many jurisdictions require special endorsements or certifications for drivers towing heavy trailers, recognizing the additional skills and knowledge required for safe operation.

Lastly, safety regulations often include requirements for regular inspections and maintenance of towing systems. This includes checking for wear and tear on the pintle hitch, ensuring proper lubrication of moving parts, and verifying the integrity of all connections and safety features. These ongoing maintenance requirements help to prevent equipment failures that could lead to accidents on the road.

One of the primary safety regulations for pintle hitch towing systems is the requirement for proper weight distribution. This involves ensuring that the tongue weight of the trailer is within the recommended range, typically between 10-15% of the total trailer weight. Proper weight distribution helps maintain stability and control of the towing vehicle, reducing the risk of swaying or jackknifing during operation.

Another critical safety regulation pertains to the strength and durability of the pintle hitch itself. Manufacturers must adhere to strict guidelines regarding the materials used and the construction methods employed to ensure that the hitch can withstand the forces exerted during towing operations. These standards typically include requirements for minimum tensile strength, fatigue resistance, and corrosion protection.

Safety chains are also mandated by regulations to provide an additional layer of security in case of hitch failure. These chains must be properly rated for the weight of the trailer and securely attached to both the towing vehicle and the trailer. The length of the safety chains is also regulated to ensure they do not drag on the ground or interfere with turning maneuvers.

Lighting and signaling requirements form another essential aspect of towing safety regulations. Trailers must be equipped with functioning brake lights, turn signals, and marker lights that are compatible with the towing vehicle's electrical system. This ensures that other road users are aware of the towing vehicle's intentions and helps prevent accidents caused by poor visibility.

Brake system regulations are particularly important for towing safety. Depending on the weight of the trailer, electric or hydraulic brake systems may be required. These systems must be properly integrated with the towing vehicle's braking system to ensure coordinated and effective stopping power. Regular maintenance and inspection of brake systems are also mandated to maintain their reliability.

Regulations also address the need for proper driver training and licensing when operating vehicles with pintle hitch towing systems. Many jurisdictions require special endorsements or certifications for drivers towing heavy trailers, recognizing the additional skills and knowledge required for safe operation.

Lastly, safety regulations often include requirements for regular inspections and maintenance of towing systems. This includes checking for wear and tear on the pintle hitch, ensuring proper lubrication of moving parts, and verifying the integrity of all connections and safety features. These ongoing maintenance requirements help to prevent equipment failures that could lead to accidents on the road.

Environmental Impact of Towing Technologies

The environmental impact of towing technologies, particularly the pintle hitch system, is a crucial consideration in the broader context of vehicular towing dynamics. As the automotive industry continues to evolve, there is an increasing focus on sustainable practices and reducing the ecological footprint of transportation systems. The pintle hitch, while primarily designed for improved towing performance and safety, also has implications for environmental sustainability.

One of the key environmental benefits of the pintle hitch system is its potential to improve fuel efficiency during towing operations. The design of the pintle hitch allows for better weight distribution and reduced sway, which can lead to lower fuel consumption compared to traditional ball hitch systems. This improved efficiency translates to reduced carbon emissions over the lifetime of the vehicle, contributing to overall efforts to mitigate climate change.

Furthermore, the durability and longevity of pintle hitch systems can have positive environmental implications. These systems are typically more robust and resistant to wear and tear compared to conventional hitches, potentially reducing the need for frequent replacements. This longevity can lead to a decrease in the production and disposal of towing equipment, thereby reducing the associated environmental impacts of manufacturing and waste management.

The pintle hitch's ability to handle heavier loads more efficiently also has indirect environmental benefits. By enabling safer and more stable towing of larger loads, it can potentially reduce the number of trips required for transporting goods or equipment. This reduction in overall vehicle miles traveled can contribute to lower emissions and reduced road wear, which in turn decreases the environmental impact associated with road maintenance and construction.

However, it is important to note that the manufacturing process of pintle hitches may have its own environmental considerations. The production of these more complex and robust systems could potentially require more resources and energy compared to simpler hitch designs. This aspect necessitates a comprehensive life cycle assessment to fully understand the net environmental impact of adopting pintle hitch technology on a large scale.

In the context of noise pollution, pintle hitches may offer some advantages. Their design often results in a more secure connection between the towing vehicle and the trailer, potentially reducing the rattling and noise associated with looser connections in traditional hitching systems. This reduction in noise can contribute to improved environmental quality, particularly in urban areas or along frequently used towing routes.

As the automotive industry continues to prioritize environmental sustainability, future developments in pintle hitch technology are likely to focus on incorporating more eco-friendly materials and manufacturing processes. This could include the use of recycled materials, the development of lighter yet equally strong components to further improve fuel efficiency, and the integration of smart technologies to optimize towing performance and minimize environmental impact.

One of the key environmental benefits of the pintle hitch system is its potential to improve fuel efficiency during towing operations. The design of the pintle hitch allows for better weight distribution and reduced sway, which can lead to lower fuel consumption compared to traditional ball hitch systems. This improved efficiency translates to reduced carbon emissions over the lifetime of the vehicle, contributing to overall efforts to mitigate climate change.

Furthermore, the durability and longevity of pintle hitch systems can have positive environmental implications. These systems are typically more robust and resistant to wear and tear compared to conventional hitches, potentially reducing the need for frequent replacements. This longevity can lead to a decrease in the production and disposal of towing equipment, thereby reducing the associated environmental impacts of manufacturing and waste management.

The pintle hitch's ability to handle heavier loads more efficiently also has indirect environmental benefits. By enabling safer and more stable towing of larger loads, it can potentially reduce the number of trips required for transporting goods or equipment. This reduction in overall vehicle miles traveled can contribute to lower emissions and reduced road wear, which in turn decreases the environmental impact associated with road maintenance and construction.

However, it is important to note that the manufacturing process of pintle hitches may have its own environmental considerations. The production of these more complex and robust systems could potentially require more resources and energy compared to simpler hitch designs. This aspect necessitates a comprehensive life cycle assessment to fully understand the net environmental impact of adopting pintle hitch technology on a large scale.

In the context of noise pollution, pintle hitches may offer some advantages. Their design often results in a more secure connection between the towing vehicle and the trailer, potentially reducing the rattling and noise associated with looser connections in traditional hitching systems. This reduction in noise can contribute to improved environmental quality, particularly in urban areas or along frequently used towing routes.

As the automotive industry continues to prioritize environmental sustainability, future developments in pintle hitch technology are likely to focus on incorporating more eco-friendly materials and manufacturing processes. This could include the use of recycled materials, the development of lighter yet equally strong components to further improve fuel efficiency, and the integration of smart technologies to optimize towing performance and minimize environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!