Pintle Hitch in Transport Resilience during Emergency Conditions

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution and Objectives

The pintle hitch has a rich history dating back to the early 20th century, evolving from simple towing mechanisms to sophisticated coupling systems. Initially developed for military applications, pintle hitches gained prominence during World War II for their ability to tow heavy artillery and equipment across challenging terrains. This robust design caught the attention of civilian industries, leading to its adaptation for commercial and agricultural use in the post-war era.

Throughout the 1950s and 1960s, pintle hitches underwent significant improvements in strength and durability. Manufacturers focused on enhancing the load-bearing capacity and introducing safety features such as locking mechanisms and reinforced mounting points. The 1970s saw the integration of standardized designs, facilitating compatibility across different vehicle types and trailer configurations.

The advent of computer-aided design in the 1980s and 1990s revolutionized pintle hitch development. Engineers could now optimize designs for specific applications, resulting in a diverse range of pintle hitches tailored to various industries. This period also marked the introduction of advanced materials, such as high-strength alloys, which further improved the hitch's performance under extreme conditions.

In recent years, the focus has shifted towards enhancing the pintle hitch's role in transport resilience, particularly during emergency conditions. The objective is to develop hitches that can withstand unpredictable stresses and maintain functionality in disaster-prone areas. This includes improving shock absorption capabilities, increasing articulation ranges, and incorporating smart technologies for real-time monitoring and adjustment.

Current research aims to address several key objectives in pintle hitch evolution. Firstly, there is a push to increase the weight capacity while reducing the overall mass of the hitch, utilizing advanced materials and innovative structural designs. Secondly, researchers are exploring ways to enhance the hitch's adaptability to various terrains and weather conditions, crucial for emergency response scenarios.

Another significant objective is the integration of smart technologies into pintle hitches. This includes sensors for load distribution monitoring, automated coupling systems, and predictive maintenance capabilities. These advancements aim to improve safety, efficiency, and reliability in challenging environments.

Furthermore, there is a growing emphasis on developing eco-friendly pintle hitches. This involves using sustainable materials, optimizing designs for fuel efficiency, and exploring ways to reduce wear and tear on both the hitch and the towing vehicle. These efforts align with broader sustainability goals in the transportation sector.

Throughout the 1950s and 1960s, pintle hitches underwent significant improvements in strength and durability. Manufacturers focused on enhancing the load-bearing capacity and introducing safety features such as locking mechanisms and reinforced mounting points. The 1970s saw the integration of standardized designs, facilitating compatibility across different vehicle types and trailer configurations.

The advent of computer-aided design in the 1980s and 1990s revolutionized pintle hitch development. Engineers could now optimize designs for specific applications, resulting in a diverse range of pintle hitches tailored to various industries. This period also marked the introduction of advanced materials, such as high-strength alloys, which further improved the hitch's performance under extreme conditions.

In recent years, the focus has shifted towards enhancing the pintle hitch's role in transport resilience, particularly during emergency conditions. The objective is to develop hitches that can withstand unpredictable stresses and maintain functionality in disaster-prone areas. This includes improving shock absorption capabilities, increasing articulation ranges, and incorporating smart technologies for real-time monitoring and adjustment.

Current research aims to address several key objectives in pintle hitch evolution. Firstly, there is a push to increase the weight capacity while reducing the overall mass of the hitch, utilizing advanced materials and innovative structural designs. Secondly, researchers are exploring ways to enhance the hitch's adaptability to various terrains and weather conditions, crucial for emergency response scenarios.

Another significant objective is the integration of smart technologies into pintle hitches. This includes sensors for load distribution monitoring, automated coupling systems, and predictive maintenance capabilities. These advancements aim to improve safety, efficiency, and reliability in challenging environments.

Furthermore, there is a growing emphasis on developing eco-friendly pintle hitches. This involves using sustainable materials, optimizing designs for fuel efficiency, and exploring ways to reduce wear and tear on both the hitch and the towing vehicle. These efforts align with broader sustainability goals in the transportation sector.

Emergency Transport Market Analysis

The emergency transport market has witnessed significant growth in recent years, driven by increasing natural disasters, man-made crises, and global health emergencies. The COVID-19 pandemic has further highlighted the critical importance of resilient transport systems during emergencies. In this context, the pintle hitch technology plays a crucial role in enhancing transport resilience and adaptability.

The global emergency transport market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising frequency and intensity of natural disasters, coupled with the growing awareness of the need for efficient emergency response systems. The market encompasses a wide range of vehicles and equipment, including ambulances, fire trucks, disaster response vehicles, and specialized trailers equipped with pintle hitches.

Pintle hitches have emerged as a key component in emergency transport systems due to their versatility and robustness. These hitches allow for quick and secure coupling of various types of trailers and equipment, enabling rapid deployment and reconfiguration of transport resources during emergencies. The demand for pintle hitch-equipped vehicles is particularly strong in regions prone to natural disasters, such as coastal areas vulnerable to hurricanes and flood-prone regions.

The North American market dominates the global emergency transport sector, accounting for approximately 35% of the total market share. This is largely due to well-established emergency response infrastructure and stringent regulations governing emergency preparedness. Europe follows closely, with a market share of around 30%, driven by increasing investments in disaster management and civil protection initiatives.

Emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth in the emergency transport market. Rapid urbanization, coupled with the increasing frequency of climate-related disasters, is driving the demand for advanced emergency transport solutions in these regions. The adoption of pintle hitch technology is gaining traction in these markets as governments and organizations seek to enhance their emergency response capabilities.

The competitive landscape of the emergency transport market is characterized by a mix of established players and innovative start-ups. Major vehicle manufacturers are increasingly incorporating pintle hitch technology into their emergency vehicle designs, recognizing its importance in enhancing operational flexibility. Specialized equipment manufacturers are also developing advanced pintle hitch systems with improved safety features and load-bearing capacities.

As the emergency transport market continues to evolve, several trends are shaping its future trajectory. There is a growing emphasis on the integration of smart technologies, such as IoT sensors and real-time tracking systems, with pintle hitch-equipped vehicles to enhance coordination and efficiency during emergency operations. Additionally, there is an increasing focus on developing lightweight yet durable materials for pintle hitches to improve fuel efficiency without compromising on strength and reliability.

The global emergency transport market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is primarily attributed to the rising frequency and intensity of natural disasters, coupled with the growing awareness of the need for efficient emergency response systems. The market encompasses a wide range of vehicles and equipment, including ambulances, fire trucks, disaster response vehicles, and specialized trailers equipped with pintle hitches.

Pintle hitches have emerged as a key component in emergency transport systems due to their versatility and robustness. These hitches allow for quick and secure coupling of various types of trailers and equipment, enabling rapid deployment and reconfiguration of transport resources during emergencies. The demand for pintle hitch-equipped vehicles is particularly strong in regions prone to natural disasters, such as coastal areas vulnerable to hurricanes and flood-prone regions.

The North American market dominates the global emergency transport sector, accounting for approximately 35% of the total market share. This is largely due to well-established emergency response infrastructure and stringent regulations governing emergency preparedness. Europe follows closely, with a market share of around 30%, driven by increasing investments in disaster management and civil protection initiatives.

Emerging economies in Asia-Pacific and Latin America are expected to witness the fastest growth in the emergency transport market. Rapid urbanization, coupled with the increasing frequency of climate-related disasters, is driving the demand for advanced emergency transport solutions in these regions. The adoption of pintle hitch technology is gaining traction in these markets as governments and organizations seek to enhance their emergency response capabilities.

The competitive landscape of the emergency transport market is characterized by a mix of established players and innovative start-ups. Major vehicle manufacturers are increasingly incorporating pintle hitch technology into their emergency vehicle designs, recognizing its importance in enhancing operational flexibility. Specialized equipment manufacturers are also developing advanced pintle hitch systems with improved safety features and load-bearing capacities.

As the emergency transport market continues to evolve, several trends are shaping its future trajectory. There is a growing emphasis on the integration of smart technologies, such as IoT sensors and real-time tracking systems, with pintle hitch-equipped vehicles to enhance coordination and efficiency during emergency operations. Additionally, there is an increasing focus on developing lightweight yet durable materials for pintle hitches to improve fuel efficiency without compromising on strength and reliability.

Pintle Hitch Technology Status

Pintle hitch technology has evolved significantly over the years, becoming an essential component in transport resilience during emergency conditions. Currently, the technology is widely used in military and emergency response vehicles, offering a robust and versatile coupling system for towing heavy loads in challenging environments.

The current state of pintle hitch technology is characterized by its simplicity, durability, and adaptability. Modern pintle hitches are typically made from high-strength steel or alloys, capable of withstanding extreme forces and environmental conditions. They feature a hook-like design that allows for quick and easy coupling with a lunette ring on the towed vehicle or equipment.

One of the primary advantages of current pintle hitch systems is their ability to accommodate vertical and horizontal movement between the towing and towed vehicles. This flexibility is crucial in off-road and emergency situations where terrain can be unpredictable. Many contemporary designs also incorporate safety features such as locking mechanisms and secondary retention systems to prevent accidental uncoupling.

Recent advancements in pintle hitch technology have focused on improving weight distribution and reducing wear. Some manufacturers have introduced articulating pintle hitches that can rotate on multiple axes, further enhancing maneuverability and reducing stress on both the hitch and the vehicles. Additionally, there has been a trend towards integrating electronic sensors and monitoring systems into pintle hitches, allowing for real-time tracking of coupling status and load distribution.

Despite these advancements, the technology still faces several challenges. One significant issue is the potential for excessive wear and tear due to the constant movement and high loads experienced by pintle hitches, especially in emergency and off-road conditions. This has led to ongoing research into more durable materials and improved lubrication systems.

Another area of concern is the standardization of pintle hitch designs across different industries and regions. While military applications often adhere to strict standards, there is less uniformity in civilian and emergency response sectors. This lack of standardization can sometimes lead to compatibility issues and increased complexity in emergency response scenarios.

The geographical distribution of pintle hitch technology development is primarily concentrated in countries with significant military and emergency response industries. The United States, European Union countries, and Russia are at the forefront of pintle hitch innovation, with emerging economies like China and India also making strides in this field.

In conclusion, while pintle hitch technology has proven its worth in enhancing transport resilience during emergency conditions, there is still room for improvement. Future developments are likely to focus on increasing durability, enhancing safety features, and improving integration with smart vehicle systems to meet the evolving demands of emergency response and military operations.

The current state of pintle hitch technology is characterized by its simplicity, durability, and adaptability. Modern pintle hitches are typically made from high-strength steel or alloys, capable of withstanding extreme forces and environmental conditions. They feature a hook-like design that allows for quick and easy coupling with a lunette ring on the towed vehicle or equipment.

One of the primary advantages of current pintle hitch systems is their ability to accommodate vertical and horizontal movement between the towing and towed vehicles. This flexibility is crucial in off-road and emergency situations where terrain can be unpredictable. Many contemporary designs also incorporate safety features such as locking mechanisms and secondary retention systems to prevent accidental uncoupling.

Recent advancements in pintle hitch technology have focused on improving weight distribution and reducing wear. Some manufacturers have introduced articulating pintle hitches that can rotate on multiple axes, further enhancing maneuverability and reducing stress on both the hitch and the vehicles. Additionally, there has been a trend towards integrating electronic sensors and monitoring systems into pintle hitches, allowing for real-time tracking of coupling status and load distribution.

Despite these advancements, the technology still faces several challenges. One significant issue is the potential for excessive wear and tear due to the constant movement and high loads experienced by pintle hitches, especially in emergency and off-road conditions. This has led to ongoing research into more durable materials and improved lubrication systems.

Another area of concern is the standardization of pintle hitch designs across different industries and regions. While military applications often adhere to strict standards, there is less uniformity in civilian and emergency response sectors. This lack of standardization can sometimes lead to compatibility issues and increased complexity in emergency response scenarios.

The geographical distribution of pintle hitch technology development is primarily concentrated in countries with significant military and emergency response industries. The United States, European Union countries, and Russia are at the forefront of pintle hitch innovation, with emerging economies like China and India also making strides in this field.

In conclusion, while pintle hitch technology has proven its worth in enhancing transport resilience during emergency conditions, there is still room for improvement. Future developments are likely to focus on increasing durability, enhancing safety features, and improving integration with smart vehicle systems to meet the evolving demands of emergency response and military operations.

Current Pintle Hitch Solutions

01 Pintle hitch design improvements

Various design improvements have been made to pintle hitches to enhance their transport resilience. These include modifications to the hitch structure, locking mechanisms, and overall geometry to increase stability, reduce wear, and improve safety during towing operations. Such improvements aim to enhance the durability and reliability of the hitch connection under various road conditions and load types.- Improved pintle hitch designs for enhanced stability: Various designs of pintle hitches have been developed to improve stability during transport. These designs include features such as reinforced structures, adjustable components, and locking mechanisms to reduce movement and increase resilience. The improved designs aim to enhance the overall safety and reliability of the towing connection.

- Shock-absorbing mechanisms for pintle hitches: Incorporating shock-absorbing elements into pintle hitch systems helps to reduce the impact of sudden movements and vibrations during transport. These mechanisms can include spring-loaded components, hydraulic dampers, or elastomeric materials that absorb and dissipate energy, thereby improving the overall resilience of the towing system.

- Integration of pintle hitches with vehicle suspension systems: Some designs focus on integrating pintle hitches with the vehicle's suspension system to improve overall transport resilience. This integration allows for better load distribution and enhanced shock absorption, resulting in a smoother and more stable towing experience. The combined system can adapt to various road conditions and load weights more effectively.

- Multi-functional pintle hitch assemblies: Advanced pintle hitch assemblies incorporate multiple functions to enhance transport resilience. These designs may include features such as adjustable height mechanisms, integrated weight distribution systems, or quick-release mechanisms. The multi-functional approach allows for greater adaptability to different towing scenarios and improves overall performance.

- Monitoring and control systems for pintle hitch performance: Implementing electronic monitoring and control systems in pintle hitch assemblies can significantly improve transport resilience. These systems may include sensors to detect stress, load, and movement, coupled with actuators to make real-time adjustments. Advanced control algorithms can optimize the hitch's performance based on various factors, enhancing safety and stability during transport.

02 Shock absorption and vibration damping

Incorporating shock absorption and vibration damping features into pintle hitch systems can significantly improve transport resilience. These features help to reduce the impact of road irregularities and sudden movements, protecting both the towing vehicle and the towed equipment. Various mechanisms, such as spring-loaded components or elastomeric materials, can be integrated into the hitch design to achieve this effect.Expand Specific Solutions03 Multi-functional pintle hitch systems

Developing multi-functional pintle hitch systems that can adapt to different towing requirements enhances transport resilience. These systems may include adjustable height mechanisms, interchangeable coupling components, or integrated stabilizers. Such versatility allows for better compatibility with various types of equipment and improves overall towing performance across different scenarios.Expand Specific Solutions04 Integration with vehicle systems

Integrating pintle hitch systems with other vehicle systems can enhance overall transport resilience. This may include connections to the vehicle's electronic control units for improved monitoring and control, integration with suspension systems for better load distribution, or compatibility with advanced driver assistance systems. Such integrations can lead to improved safety, efficiency, and performance during towing operations.Expand Specific Solutions05 Materials and manufacturing techniques

Advancements in materials science and manufacturing techniques contribute to improved pintle hitch transport resilience. The use of high-strength, lightweight materials can enhance durability while reducing overall weight. Additionally, advanced manufacturing processes, such as precision casting or additive manufacturing, can lead to more complex and efficient hitch designs that better withstand the stresses of towing.Expand Specific Solutions

Key Manufacturers and Competitors

The research on Pintle Hitch in Transport Resilience during Emergency Conditions is in its early development stage, with a growing market driven by increasing focus on emergency preparedness. The technology's maturity is still evolving, with key players like ACPS Automotive GmbH, Curt Manufacturing LLC, and B&W Trailer Hitches leading innovation. These companies are investing in R&D to enhance pintle hitch designs for improved resilience and safety. The market size is expanding as governments and organizations recognize the importance of robust transport solutions in crisis situations. However, the technology still requires further refinement and standardization to fully address the unique challenges posed by emergency conditions.

ACPS Automotive GmbH

Technical Solution: ACPS Automotive GmbH has developed advanced pintle hitch systems specifically designed for emergency transport resilience. Their technology incorporates a robust locking mechanism that ensures secure coupling even under extreme conditions. The company's pintle hitches feature a high-strength steel construction capable of withstanding severe stress and impact[1]. Additionally, ACPS has implemented a quick-release system that allows for rapid decoupling in emergency situations, enhancing overall operational efficiency[2]. The hitches are also equipped with integrated sensors that provide real-time monitoring of coupling status and load distribution, crucial for maintaining safety during emergency transport[3].

Strengths: Robust design for extreme conditions, quick-release system for emergencies, integrated sensor technology. Weaknesses: Potentially higher cost due to advanced features, may require specialized training for optimal use.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has focused on developing pintle hitches with enhanced durability and versatility for emergency transport scenarios. Their research has led to the creation of a multi-functional pintle hitch system that can adapt to various trailer types commonly used in emergency response[4]. The company has incorporated corrosion-resistant materials and treatments to ensure longevity in harsh environments[5]. Curt's pintle hitches also feature a patented shock-absorbing design that minimizes stress on both the towing vehicle and trailer during rough terrain navigation, which is particularly beneficial in disaster relief operations[6].

Strengths: Versatile design for multiple trailer types, corrosion-resistant materials, shock-absorbing technology. Weaknesses: May have limited compatibility with some specialized emergency vehicles, potential for higher maintenance requirements.

Innovative Pintle Hitch Designs

Method of converting a trailer configuration

PatentInactiveUS8151426B2

Innovation

- A convertible trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, enabling it to accommodate different hitch types by adjusting the position and securing the coupler support with pivot and slide locks.

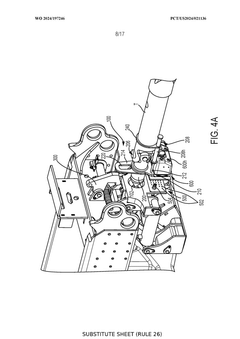

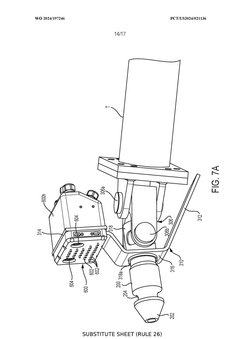

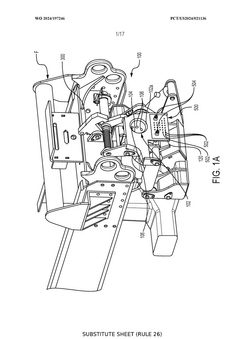

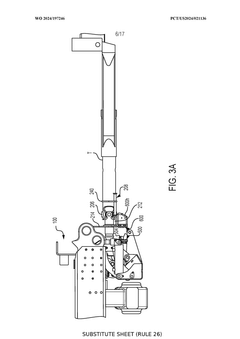

Apparatus, system, and method for connecting a towed vehicle to a towing vehicle

PatentWO2024197246A2

Innovation

- A hitch apparatus featuring a receiver tube with aligned apertures and ball bearings that secure an elongate shaft via a collar, allowing for remote activation and enabling roll rotation, while a manifold connects electrical and pneumatic systems between towing and towed vehicles, facilitating secure and automated coupling.

Emergency Response Regulations

Emergency response regulations play a crucial role in ensuring effective and coordinated actions during crisis situations, particularly in the context of transport resilience and the use of pintle hitches. These regulations are designed to provide a framework for preparedness, response, and recovery in emergency conditions.

At the federal level, the Federal Emergency Management Agency (FEMA) oversees the National Response Framework, which outlines the guiding principles for all response partners to prepare for and provide a unified national response to disasters and emergencies. This framework includes specific provisions for transportation systems and infrastructure, emphasizing the importance of maintaining operational capabilities during emergencies.

The Department of Transportation (DOT) has established regulations that directly impact the use of pintle hitches in emergency transport. These regulations cover aspects such as load capacity, safety requirements, and proper usage during emergency situations. The Federal Motor Carrier Safety Administration (FMCSA) provides guidelines for commercial motor vehicles, including those equipped with pintle hitches, to ensure safe operation during emergencies.

State and local governments also play a significant role in emergency response regulations. Many states have adopted their own emergency management acts, which often include specific provisions for transportation resilience. These regulations may address issues such as priority routes for emergency vehicles, temporary suspension of certain traffic laws, and the use of specialized equipment like pintle hitches for rapid deployment of resources.

The National Highway Traffic Safety Administration (NHTSA) has set standards for vehicle safety, including requirements for towing equipment such as pintle hitches. These standards become particularly relevant during emergency conditions when the reliability and safety of transport connections are paramount.

In the context of pintle hitches and transport resilience, emergency response regulations often focus on ensuring the compatibility and interoperability of equipment across different agencies and jurisdictions. This is crucial for facilitating rapid and efficient deployment of resources during large-scale emergencies that may require inter-agency cooperation.

Regulations also address the training and certification requirements for personnel operating vehicles equipped with pintle hitches during emergency situations. This ensures that responders are properly qualified to handle the unique challenges posed by emergency transport conditions.

Furthermore, emergency response regulations often include provisions for regular testing and maintenance of equipment, including pintle hitches, to ensure their reliability when needed most. This may involve scheduled inspections, stress tests, and replacement protocols to maintain the integrity of the transport system during emergencies.

At the federal level, the Federal Emergency Management Agency (FEMA) oversees the National Response Framework, which outlines the guiding principles for all response partners to prepare for and provide a unified national response to disasters and emergencies. This framework includes specific provisions for transportation systems and infrastructure, emphasizing the importance of maintaining operational capabilities during emergencies.

The Department of Transportation (DOT) has established regulations that directly impact the use of pintle hitches in emergency transport. These regulations cover aspects such as load capacity, safety requirements, and proper usage during emergency situations. The Federal Motor Carrier Safety Administration (FMCSA) provides guidelines for commercial motor vehicles, including those equipped with pintle hitches, to ensure safe operation during emergencies.

State and local governments also play a significant role in emergency response regulations. Many states have adopted their own emergency management acts, which often include specific provisions for transportation resilience. These regulations may address issues such as priority routes for emergency vehicles, temporary suspension of certain traffic laws, and the use of specialized equipment like pintle hitches for rapid deployment of resources.

The National Highway Traffic Safety Administration (NHTSA) has set standards for vehicle safety, including requirements for towing equipment such as pintle hitches. These standards become particularly relevant during emergency conditions when the reliability and safety of transport connections are paramount.

In the context of pintle hitches and transport resilience, emergency response regulations often focus on ensuring the compatibility and interoperability of equipment across different agencies and jurisdictions. This is crucial for facilitating rapid and efficient deployment of resources during large-scale emergencies that may require inter-agency cooperation.

Regulations also address the training and certification requirements for personnel operating vehicles equipped with pintle hitches during emergency situations. This ensures that responders are properly qualified to handle the unique challenges posed by emergency transport conditions.

Furthermore, emergency response regulations often include provisions for regular testing and maintenance of equipment, including pintle hitches, to ensure their reliability when needed most. This may involve scheduled inspections, stress tests, and replacement protocols to maintain the integrity of the transport system during emergencies.

Pintle Hitch Safety Standards

Pintle hitch safety standards play a crucial role in ensuring the resilience of transport systems during emergency conditions. These standards are designed to maintain the integrity of connections between towing vehicles and trailers, particularly in challenging situations where reliability is paramount.

The primary focus of pintle hitch safety standards is on the structural integrity and load-bearing capacity of the hitch mechanism. These standards typically specify minimum strength requirements for the pintle hook, drawbar eye, and associated components. The materials used in manufacturing these parts must meet stringent quality criteria to withstand the stresses encountered during emergency operations.

Safety standards also address the locking mechanisms of pintle hitches. These systems must be designed to prevent accidental disconnection, even under severe road conditions or sudden maneuvers. Many standards require redundant locking features, such as primary and secondary latches, to enhance security.

Corrosion resistance is another critical aspect covered by pintle hitch safety standards. Given the potential exposure to harsh environmental conditions during emergencies, the hitch components must maintain their structural integrity over time. Standards often specify corrosion-resistant coatings or materials to ensure long-term reliability.

The standards also encompass testing protocols to verify the performance of pintle hitches under various conditions. These may include static load tests, dynamic load tests, and environmental exposure tests. Such rigorous testing helps ensure that the hitches can withstand the demands of emergency transport scenarios.

Maintenance and inspection requirements form an integral part of pintle hitch safety standards. Regular checks for wear, damage, and proper functioning of locking mechanisms are typically mandated to maintain the hitch's reliability over its service life.

In the context of emergency conditions, pintle hitch safety standards often include provisions for quick coupling and uncoupling. This feature is crucial for rapid deployment and reconfiguration of transport resources during crisis situations.

Compatibility between different types of pintle hitches and drawbar eyes is also addressed in safety standards. This ensures interoperability between various vehicles and trailers, which is essential for coordinated emergency response efforts.

Some advanced safety standards incorporate requirements for electronic monitoring systems. These can provide real-time data on the hitch's status, including proper engagement and any potential issues, enhancing overall safety and operational efficiency during emergency transport.

The primary focus of pintle hitch safety standards is on the structural integrity and load-bearing capacity of the hitch mechanism. These standards typically specify minimum strength requirements for the pintle hook, drawbar eye, and associated components. The materials used in manufacturing these parts must meet stringent quality criteria to withstand the stresses encountered during emergency operations.

Safety standards also address the locking mechanisms of pintle hitches. These systems must be designed to prevent accidental disconnection, even under severe road conditions or sudden maneuvers. Many standards require redundant locking features, such as primary and secondary latches, to enhance security.

Corrosion resistance is another critical aspect covered by pintle hitch safety standards. Given the potential exposure to harsh environmental conditions during emergencies, the hitch components must maintain their structural integrity over time. Standards often specify corrosion-resistant coatings or materials to ensure long-term reliability.

The standards also encompass testing protocols to verify the performance of pintle hitches under various conditions. These may include static load tests, dynamic load tests, and environmental exposure tests. Such rigorous testing helps ensure that the hitches can withstand the demands of emergency transport scenarios.

Maintenance and inspection requirements form an integral part of pintle hitch safety standards. Regular checks for wear, damage, and proper functioning of locking mechanisms are typically mandated to maintain the hitch's reliability over its service life.

In the context of emergency conditions, pintle hitch safety standards often include provisions for quick coupling and uncoupling. This feature is crucial for rapid deployment and reconfiguration of transport resources during crisis situations.

Compatibility between different types of pintle hitches and drawbar eyes is also addressed in safety standards. This ensures interoperability between various vehicles and trailers, which is essential for coordinated emergency response efforts.

Some advanced safety standards incorporate requirements for electronic monitoring systems. These can provide real-time data on the hitch's status, including proper engagement and any potential issues, enhancing overall safety and operational efficiency during emergency transport.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!