Pintle Hitch and the Optimization of Towing Algorithms

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, reflecting the changing needs of towing applications and advancements in engineering. Initially developed as a simple coupling mechanism for military vehicles in the early 20th century, the pintle hitch has transformed into a sophisticated towing solution for various industries.

In its earliest form, the pintle hitch consisted of a basic hook-and-eye design, providing a robust connection point for towing heavy loads. This rudimentary design was favored for its simplicity and durability, particularly in rugged military environments. As civilian applications for heavy-duty towing grew, the pintle hitch began to see wider adoption in commercial and industrial sectors.

The mid-20th century marked a period of rapid advancement in pintle hitch technology. Engineers focused on improving the hitch's load-bearing capacity and stability. This led to the introduction of reinforced designs and the integration of safety features such as locking mechanisms to prevent accidental disconnection during towing operations.

The 1970s and 1980s saw a shift towards enhancing the versatility of pintle hitches. Manufacturers began developing adjustable pintle hitches that could accommodate various trailer heights and load distributions. This innovation significantly expanded the range of vehicles and trailers that could be safely towed using a single hitch system.

As computer-aided design and advanced materials became more prevalent in the automotive industry, pintle hitch design entered a new era of sophistication. The late 20th and early 21st centuries witnessed the integration of high-strength alloys and precision-engineered components, resulting in hitches with higher towing capacities and improved durability.

Recent developments in pintle hitch technology have focused on enhancing safety and ease of use. Modern designs often incorporate electronic sensors and monitoring systems that provide real-time feedback on hitch status, load distribution, and potential safety issues. These smart hitches represent a significant leap forward in towing technology, offering drivers unprecedented levels of control and peace of mind.

The evolution of pintle hitches has also been influenced by regulatory changes and industry standards. Stricter safety regulations have driven innovations in locking mechanisms, weight distribution systems, and compatibility with advanced trailer braking systems. This has resulted in pintle hitches that not only meet but often exceed current safety standards.

Looking ahead, the future of pintle hitch technology is likely to be shaped by trends in vehicle electrification and autonomous driving. As these technologies become more prevalent, we can expect to see pintle hitches that integrate seamlessly with electric powertrains and self-driving systems, potentially revolutionizing the towing industry once again.

In its earliest form, the pintle hitch consisted of a basic hook-and-eye design, providing a robust connection point for towing heavy loads. This rudimentary design was favored for its simplicity and durability, particularly in rugged military environments. As civilian applications for heavy-duty towing grew, the pintle hitch began to see wider adoption in commercial and industrial sectors.

The mid-20th century marked a period of rapid advancement in pintle hitch technology. Engineers focused on improving the hitch's load-bearing capacity and stability. This led to the introduction of reinforced designs and the integration of safety features such as locking mechanisms to prevent accidental disconnection during towing operations.

The 1970s and 1980s saw a shift towards enhancing the versatility of pintle hitches. Manufacturers began developing adjustable pintle hitches that could accommodate various trailer heights and load distributions. This innovation significantly expanded the range of vehicles and trailers that could be safely towed using a single hitch system.

As computer-aided design and advanced materials became more prevalent in the automotive industry, pintle hitch design entered a new era of sophistication. The late 20th and early 21st centuries witnessed the integration of high-strength alloys and precision-engineered components, resulting in hitches with higher towing capacities and improved durability.

Recent developments in pintle hitch technology have focused on enhancing safety and ease of use. Modern designs often incorporate electronic sensors and monitoring systems that provide real-time feedback on hitch status, load distribution, and potential safety issues. These smart hitches represent a significant leap forward in towing technology, offering drivers unprecedented levels of control and peace of mind.

The evolution of pintle hitches has also been influenced by regulatory changes and industry standards. Stricter safety regulations have driven innovations in locking mechanisms, weight distribution systems, and compatibility with advanced trailer braking systems. This has resulted in pintle hitches that not only meet but often exceed current safety standards.

Looking ahead, the future of pintle hitch technology is likely to be shaped by trends in vehicle electrification and autonomous driving. As these technologies become more prevalent, we can expect to see pintle hitches that integrate seamlessly with electric powertrains and self-driving systems, potentially revolutionizing the towing industry once again.

Towing Market Analysis

The towing market has experienced significant growth in recent years, driven by increasing demand across various sectors including automotive, construction, and logistics. The global towing equipment market size was valued at approximately $5.2 billion in 2020 and is projected to reach $7.8 billion by 2027, growing at a CAGR of 6.2% during the forecast period.

The automotive sector remains the largest consumer of towing equipment, accounting for over 40% of the market share. This is primarily due to the rising popularity of recreational vehicles (RVs) and the growing trend of outdoor activities. The RV industry has seen a surge in demand, particularly in North America and Europe, which has directly impacted the towing market.

Commercial transportation and logistics sectors are also significant contributors to market growth. With the expansion of e-commerce and the need for efficient goods transportation, the demand for towing solutions in the commercial vehicle segment has increased substantially. This trend is expected to continue as global trade and online retail activities expand further.

The construction industry is another key driver of the towing market. As infrastructure development projects continue to grow worldwide, the need for heavy-duty towing equipment has risen. This includes towing solutions for construction machinery, prefabricated structures, and large building materials.

Regionally, North America dominates the towing market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to its robust automotive industry and high adoption rate of recreational vehicles. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth in the coming years, driven by rapid industrialization and infrastructure development.

Technological advancements are playing a crucial role in shaping the towing market. The integration of smart technologies, such as IoT sensors and AI-powered towing algorithms, is enhancing the safety and efficiency of towing operations. This trend is particularly evident in the development of advanced driver assistance systems (ADAS) for towing vehicles, which is expected to be a major focus area for market players in the near future.

The market is characterized by intense competition, with several key players dominating the global landscape. These include Horizon Global Corporation, CURT Manufacturing LLC, and B&W Trailer Hitches, among others. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their market positions and capitalize on emerging opportunities.

The automotive sector remains the largest consumer of towing equipment, accounting for over 40% of the market share. This is primarily due to the rising popularity of recreational vehicles (RVs) and the growing trend of outdoor activities. The RV industry has seen a surge in demand, particularly in North America and Europe, which has directly impacted the towing market.

Commercial transportation and logistics sectors are also significant contributors to market growth. With the expansion of e-commerce and the need for efficient goods transportation, the demand for towing solutions in the commercial vehicle segment has increased substantially. This trend is expected to continue as global trade and online retail activities expand further.

The construction industry is another key driver of the towing market. As infrastructure development projects continue to grow worldwide, the need for heavy-duty towing equipment has risen. This includes towing solutions for construction machinery, prefabricated structures, and large building materials.

Regionally, North America dominates the towing market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to its robust automotive industry and high adoption rate of recreational vehicles. However, emerging economies in Asia-Pacific, such as China and India, are expected to witness the fastest growth in the coming years, driven by rapid industrialization and infrastructure development.

Technological advancements are playing a crucial role in shaping the towing market. The integration of smart technologies, such as IoT sensors and AI-powered towing algorithms, is enhancing the safety and efficiency of towing operations. This trend is particularly evident in the development of advanced driver assistance systems (ADAS) for towing vehicles, which is expected to be a major focus area for market players in the near future.

The market is characterized by intense competition, with several key players dominating the global landscape. These include Horizon Global Corporation, CURT Manufacturing LLC, and B&W Trailer Hitches, among others. These companies are focusing on product innovation, strategic partnerships, and geographical expansion to maintain their market positions and capitalize on emerging opportunities.

Pintle Hitch Challenges

Pintle hitches, while seemingly simple in design, present several significant challenges in both their construction and application. One of the primary issues is the high stress concentration at the connection point between the towing vehicle and the trailer. This stress can lead to accelerated wear and potential failure, especially under heavy loads or during sudden movements.

The dynamic nature of towing operations further complicates the design and use of pintle hitches. As vehicles navigate various terrains and road conditions, the hitch must withstand constant fluctuations in force and direction. This dynamic loading can cause fatigue in the materials over time, necessitating careful material selection and regular maintenance to ensure safety and longevity.

Another challenge lies in the precise alignment required for coupling and uncoupling operations. Misalignment during these processes can result in damage to the hitch components or, in severe cases, compromise the integrity of the connection. This issue is particularly pronounced in scenarios where visibility is limited or when dealing with heavy equipment that offers little maneuverability.

The diverse range of applications for pintle hitches also presents a challenge in terms of standardization. Different industries and vehicle types may require variations in hitch design, making it difficult to establish universal standards for manufacturing and testing. This lack of uniformity can lead to compatibility issues and potential safety risks when different systems are used interchangeably.

Environmental factors pose additional challenges for pintle hitch design and maintenance. Exposure to harsh weather conditions, corrosive substances, and extreme temperatures can accelerate wear and compromise the hitch's structural integrity. Engineers must consider these factors when selecting materials and designing protective measures to ensure long-term reliability.

From a regulatory perspective, pintle hitches must meet stringent safety standards across various jurisdictions. Compliance with these regulations, which may vary by region or application, adds complexity to the design and certification process. Manufacturers must navigate a complex landscape of requirements while still delivering products that are cost-effective and meet the practical needs of users.

The optimization of towing algorithms for vehicles equipped with pintle hitches presents its own set of challenges. These algorithms must account for the unique dynamics of pintle hitch connections, including the potential for increased sway and the need for precise control during backing maneuvers. Developing robust algorithms that can adapt to various trailer configurations and load distributions remains an ongoing area of research and development in the automotive industry.

The dynamic nature of towing operations further complicates the design and use of pintle hitches. As vehicles navigate various terrains and road conditions, the hitch must withstand constant fluctuations in force and direction. This dynamic loading can cause fatigue in the materials over time, necessitating careful material selection and regular maintenance to ensure safety and longevity.

Another challenge lies in the precise alignment required for coupling and uncoupling operations. Misalignment during these processes can result in damage to the hitch components or, in severe cases, compromise the integrity of the connection. This issue is particularly pronounced in scenarios where visibility is limited or when dealing with heavy equipment that offers little maneuverability.

The diverse range of applications for pintle hitches also presents a challenge in terms of standardization. Different industries and vehicle types may require variations in hitch design, making it difficult to establish universal standards for manufacturing and testing. This lack of uniformity can lead to compatibility issues and potential safety risks when different systems are used interchangeably.

Environmental factors pose additional challenges for pintle hitch design and maintenance. Exposure to harsh weather conditions, corrosive substances, and extreme temperatures can accelerate wear and compromise the hitch's structural integrity. Engineers must consider these factors when selecting materials and designing protective measures to ensure long-term reliability.

From a regulatory perspective, pintle hitches must meet stringent safety standards across various jurisdictions. Compliance with these regulations, which may vary by region or application, adds complexity to the design and certification process. Manufacturers must navigate a complex landscape of requirements while still delivering products that are cost-effective and meet the practical needs of users.

The optimization of towing algorithms for vehicles equipped with pintle hitches presents its own set of challenges. These algorithms must account for the unique dynamics of pintle hitch connections, including the potential for increased sway and the need for precise control during backing maneuvers. Developing robust algorithms that can adapt to various trailer configurations and load distributions remains an ongoing area of research and development in the automotive industry.

Current Towing Algos

01 Improved locking mechanisms

Optimization of pintle hitches through enhanced locking mechanisms, including automatic locking systems and improved safety latches. These innovations aim to increase security, prevent accidental disconnection, and simplify the coupling process between the towing vehicle and the trailer.- Improved locking mechanisms: Optimization of pintle hitches through enhanced locking mechanisms, including automatic locking systems and improved safety latches. These innovations aim to increase security, prevent accidental disconnection, and simplify the coupling process between the towing vehicle and the trailer.

- Adjustable and multi-functional designs: Development of adjustable and multi-functional pintle hitch designs that can accommodate various trailer types and sizes. These designs often include features such as height adjustment, multiple coupling options, and interchangeable components to enhance versatility and adaptability.

- Weight distribution and stability enhancements: Incorporation of weight distribution systems and stability-enhancing features in pintle hitch designs. These improvements aim to optimize load distribution, reduce sway, and enhance overall towing stability and safety, particularly for heavy-duty applications.

- Integration of advanced materials and manufacturing techniques: Utilization of advanced materials and manufacturing techniques to improve the strength, durability, and weight characteristics of pintle hitches. This includes the use of high-strength alloys, composite materials, and precision manufacturing processes to optimize performance and longevity.

- Enhanced safety features and monitoring systems: Integration of advanced safety features and monitoring systems into pintle hitch designs. This includes sensors for proper coupling, load monitoring, and real-time status indicators to improve overall safety and prevent accidents during towing operations.

02 Adjustable and multi-functional designs

Development of adjustable and multi-functional pintle hitch designs that can accommodate various trailer types and sizes. These designs often feature adjustable height, multiple coupling points, or interchangeable components to enhance versatility and adaptability for different towing scenarios.Expand Specific Solutions03 Enhanced weight distribution and stability

Optimization of pintle hitches to improve weight distribution and stability during towing. This includes designs that incorporate load-leveling features, anti-sway mechanisms, or improved structural support to enhance overall towing performance and safety.Expand Specific Solutions04 Integration of advanced materials and manufacturing techniques

Utilization of advanced materials and manufacturing techniques to optimize pintle hitch performance, durability, and weight. This may include the use of high-strength alloys, composite materials, or innovative production methods to create lighter yet stronger hitch components.Expand Specific Solutions05 Improved articulation and maneuverability

Optimization of pintle hitch designs to enhance articulation and maneuverability between the towing vehicle and trailer. This includes innovations in pivot points, swivel mechanisms, or flexible coupling systems that allow for greater range of motion and improved handling in various driving conditions.Expand Specific Solutions

Key Towing Players

The research on Pintle Hitch and optimization of towing algorithms is in a developing stage, with a growing market driven by increasing demand for advanced towing solutions. The technology is maturing, with companies like Curt Manufacturing LLC, Horizon Global Americas, Inc., and Lippert Components, Inc. leading the way in innovation. These firms are investing in R&D to enhance towing safety and efficiency. The competitive landscape is diverse, including traditional automotive manufacturers like GM Global Technology Operations LLC and Ford Global Technologies LLC, as well as specialized towing equipment providers. Academic institutions and research laboratories are also contributing to advancements in this field, indicating a collaborative approach to technology development.

Curt Manufacturing LLC

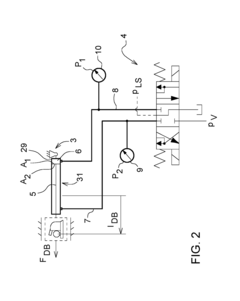

Technical Solution: Curt Manufacturing LLC has developed advanced pintle hitch systems with integrated load sensing and adaptive towing algorithms. Their technology utilizes strain gauges and accelerometers embedded in the hitch to continuously monitor trailer weight, tongue weight, and dynamic forces during towing [1]. This data is fed into a proprietary control algorithm that adjusts vehicle suspension, braking, and stability control systems in real-time to optimize towing performance and safety. The system also incorporates wireless communication between the hitch and vehicle to enable seamless integration and data sharing [3]. Additionally, Curt has implemented machine learning techniques to analyze historical towing data and improve algorithm performance over time.

Strengths: Comprehensive sensor integration, real-time adaptive control, and continuous improvement through machine learning. Weaknesses: Potential high cost and complexity, may require specialized vehicle integration.

Horizon Global Americas, Inc.

Technical Solution: Horizon Global Americas has developed a smart pintle hitch system that incorporates advanced materials and intelligent design to enhance towing capabilities. Their technology utilizes high-strength alloys and optimized geometries to increase load capacity while reducing overall weight [2]. The hitch incorporates an integrated electronic control unit that monitors towing conditions and communicates with the vehicle's onboard systems. This allows for dynamic adjustment of trailer brake controllers and stability systems based on real-time data [4]. Horizon's towing algorithm takes into account factors such as vehicle speed, acceleration, road conditions, and trailer characteristics to optimize performance and safety. The system also includes a smartphone app that provides the driver with real-time towing information and alerts.

Strengths: Advanced materials for improved strength-to-weight ratio, integrated electronic controls for enhanced safety. Weaknesses: May be limited to compatibility with specific vehicle models or trailer types.

Pintle Hitch Patents

Towing hitch

PatentActiveUS20190016184A1

Innovation

- A towing hitch with a longitudinally displaceable coupling member and actuator, combined with a guide element, allows for adjustable positioning of the coupling member to optimize load distribution and reduce the turning radius, facilitated by sensors and control devices for precise actuation.

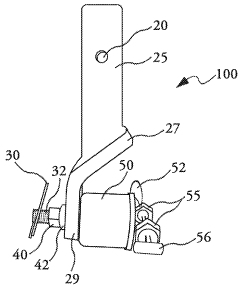

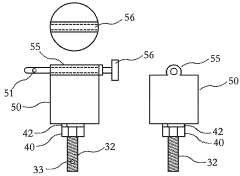

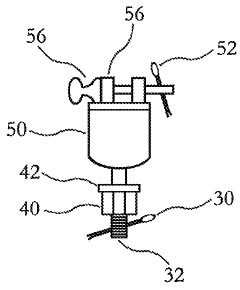

Pintle hitch connector

PatentInactiveUS20180104998A1

Innovation

- A pintle hitch connector with a cylindrical trailer contact portion and a threaded portion featuring a locking mechanism and load securing pin, along with a universal connector design that includes a curved hitch bracket and connecting pin, simplifying attachment and reducing manufacturing costs.

Safety Regulations

Safety regulations play a crucial role in the research and development of pintle hitch systems and towing algorithms. These regulations are designed to ensure the safety of both the towing vehicle and the towed trailer, as well as other road users. In the context of pintle hitch and towing algorithm optimization, safety regulations encompass a wide range of requirements and standards.

One of the primary safety concerns addressed by regulations is the structural integrity of the pintle hitch itself. Regulations typically specify minimum strength requirements for the hitch, including its ability to withstand various forces and loads encountered during towing operations. These requirements often include static and dynamic load testing to ensure the hitch can safely handle the weight of the trailer and resist sudden movements or impacts.

Towing capacity is another critical aspect covered by safety regulations. Manufacturers must clearly specify the maximum weight that can be safely towed using their pintle hitch systems. This information is essential for users to make informed decisions and avoid overloading, which can lead to dangerous situations on the road.

Safety regulations also address the connection between the towing vehicle and the trailer. This includes requirements for proper coupling mechanisms, safety chains, and breakaway systems. These components are designed to prevent complete separation of the trailer from the towing vehicle in case of a hitch failure, reducing the risk of accidents and injuries.

Visibility and lighting requirements are another important aspect of safety regulations for towing systems. Trailers must be equipped with proper lighting, including brake lights, turn signals, and reflectors, to ensure they are visible to other drivers, especially during low-light conditions or adverse weather.

In the realm of towing algorithms, safety regulations often focus on stability control systems. These algorithms are designed to detect and mitigate trailer sway, which can be a significant safety hazard. Regulations may specify performance criteria for these systems, such as response time and effectiveness in various driving conditions.

Braking systems are also subject to strict safety regulations in towing applications. This includes requirements for trailer brake controllers and their integration with the towing vehicle's braking system. Regulations often specify minimum braking performance standards to ensure safe stopping distances and stability during braking maneuvers.

As technology advances, safety regulations are evolving to address new features and capabilities in towing systems. For example, regulations are being developed or updated to cover advanced driver assistance systems (ADAS) specifically designed for towing applications, such as trailer backup assist and blind spot monitoring systems that account for the additional length of a trailer.

One of the primary safety concerns addressed by regulations is the structural integrity of the pintle hitch itself. Regulations typically specify minimum strength requirements for the hitch, including its ability to withstand various forces and loads encountered during towing operations. These requirements often include static and dynamic load testing to ensure the hitch can safely handle the weight of the trailer and resist sudden movements or impacts.

Towing capacity is another critical aspect covered by safety regulations. Manufacturers must clearly specify the maximum weight that can be safely towed using their pintle hitch systems. This information is essential for users to make informed decisions and avoid overloading, which can lead to dangerous situations on the road.

Safety regulations also address the connection between the towing vehicle and the trailer. This includes requirements for proper coupling mechanisms, safety chains, and breakaway systems. These components are designed to prevent complete separation of the trailer from the towing vehicle in case of a hitch failure, reducing the risk of accidents and injuries.

Visibility and lighting requirements are another important aspect of safety regulations for towing systems. Trailers must be equipped with proper lighting, including brake lights, turn signals, and reflectors, to ensure they are visible to other drivers, especially during low-light conditions or adverse weather.

In the realm of towing algorithms, safety regulations often focus on stability control systems. These algorithms are designed to detect and mitigate trailer sway, which can be a significant safety hazard. Regulations may specify performance criteria for these systems, such as response time and effectiveness in various driving conditions.

Braking systems are also subject to strict safety regulations in towing applications. This includes requirements for trailer brake controllers and their integration with the towing vehicle's braking system. Regulations often specify minimum braking performance standards to ensure safe stopping distances and stability during braking maneuvers.

As technology advances, safety regulations are evolving to address new features and capabilities in towing systems. For example, regulations are being developed or updated to cover advanced driver assistance systems (ADAS) specifically designed for towing applications, such as trailer backup assist and blind spot monitoring systems that account for the additional length of a trailer.

Environmental Impact

The environmental impact of pintle hitch systems and towing algorithms is a crucial consideration in the development and implementation of these technologies. As vehicles become more advanced and towing capabilities increase, it is essential to assess and mitigate the potential environmental consequences associated with their use.

One of the primary environmental concerns related to pintle hitch systems is the increased fuel consumption and emissions resulting from towing heavy loads. The additional weight and drag created by towed vehicles or trailers can significantly reduce fuel efficiency, leading to higher carbon dioxide emissions and other pollutants. This impact is particularly pronounced in urban areas where air quality is already a concern.

To address these issues, researchers and engineers are focusing on optimizing towing algorithms to improve fuel efficiency and reduce emissions. Advanced algorithms can analyze factors such as road conditions, vehicle weight, and aerodynamics to determine the most efficient towing strategies. These algorithms can adjust engine performance, transmission settings, and even route planning to minimize environmental impact while maintaining safe and effective towing operations.

Another environmental consideration is the production and disposal of pintle hitch components. The manufacturing process of these systems involves the use of various materials, including metals and plastics, which can have environmental implications in terms of resource extraction and energy consumption. Additionally, the disposal of worn-out or obsolete pintle hitch components at the end of their lifecycle presents challenges in terms of waste management and potential environmental contamination.

To mitigate these concerns, efforts are being made to develop more sustainable manufacturing processes and materials for pintle hitch systems. This includes the use of recycled materials, the implementation of more energy-efficient production techniques, and the design of components that are easier to recycle or repurpose at the end of their useful life.

The optimization of towing algorithms also has the potential to reduce wear and tear on both the towing vehicle and the towed equipment. By minimizing unnecessary stress on components, these algorithms can extend the lifespan of vehicles and trailers, reducing the frequency of replacements and the associated environmental impact of manufacturing new equipment.

Furthermore, the development of smart towing systems that incorporate environmental sensors and real-time data analysis can contribute to more eco-friendly towing practices. These systems can monitor and adjust towing parameters based on environmental conditions, such as air quality or noise levels, to minimize negative impacts in sensitive areas.

One of the primary environmental concerns related to pintle hitch systems is the increased fuel consumption and emissions resulting from towing heavy loads. The additional weight and drag created by towed vehicles or trailers can significantly reduce fuel efficiency, leading to higher carbon dioxide emissions and other pollutants. This impact is particularly pronounced in urban areas where air quality is already a concern.

To address these issues, researchers and engineers are focusing on optimizing towing algorithms to improve fuel efficiency and reduce emissions. Advanced algorithms can analyze factors such as road conditions, vehicle weight, and aerodynamics to determine the most efficient towing strategies. These algorithms can adjust engine performance, transmission settings, and even route planning to minimize environmental impact while maintaining safe and effective towing operations.

Another environmental consideration is the production and disposal of pintle hitch components. The manufacturing process of these systems involves the use of various materials, including metals and plastics, which can have environmental implications in terms of resource extraction and energy consumption. Additionally, the disposal of worn-out or obsolete pintle hitch components at the end of their lifecycle presents challenges in terms of waste management and potential environmental contamination.

To mitigate these concerns, efforts are being made to develop more sustainable manufacturing processes and materials for pintle hitch systems. This includes the use of recycled materials, the implementation of more energy-efficient production techniques, and the design of components that are easier to recycle or repurpose at the end of their useful life.

The optimization of towing algorithms also has the potential to reduce wear and tear on both the towing vehicle and the towed equipment. By minimizing unnecessary stress on components, these algorithms can extend the lifespan of vehicles and trailers, reducing the frequency of replacements and the associated environmental impact of manufacturing new equipment.

Furthermore, the development of smart towing systems that incorporate environmental sensors and real-time data analysis can contribute to more eco-friendly towing practices. These systems can monitor and adjust towing parameters based on environmental conditions, such as air quality or noise levels, to minimize negative impacts in sensitive areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!