Impact of Pintle Hitch on Fuel Efficiency in Long-Haul Trucking

AUG 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Technology Evolution and Objectives

The pintle hitch, a crucial component in long-haul trucking, has undergone significant evolution since its inception. Originally designed as a simple coupling mechanism, it has transformed into a sophisticated system that plays a vital role in vehicle dynamics and fuel efficiency. The technology's development can be traced back to the early 20th century, with major advancements occurring in the latter half of the century as the trucking industry expanded rapidly.

In the 1950s and 1960s, the focus was primarily on improving the strength and durability of pintle hitches to accommodate increasing load capacities. As environmental concerns grew in the 1970s and 1980s, attention shifted towards reducing the weight of these components without compromising their structural integrity. This period saw the introduction of new materials and manufacturing techniques, laying the groundwork for future innovations.

The 1990s marked a turning point in pintle hitch technology, with the integration of electronic systems for improved safety and monitoring. This decade also witnessed the first serious attempts to address the aerodynamic impact of pintle hitches on fuel efficiency. However, these early efforts were limited by the available technologies and understanding of complex fluid dynamics in real-world conditions.

The 21st century has brought about a renaissance in pintle hitch design, driven by advances in computational fluid dynamics, materials science, and the urgent need for fuel efficiency improvements in the face of rising fuel costs and environmental regulations. Modern pintle hitches are now being engineered with a holistic approach, considering not just their primary coupling function but also their role in overall vehicle aerodynamics and fuel consumption.

Current technological objectives for pintle hitch development are multifaceted. Primarily, there is a strong focus on optimizing the aerodynamic profile of the hitch to minimize drag, which directly impacts fuel efficiency. This involves sophisticated computer modeling and wind tunnel testing to identify the most efficient designs. Additionally, researchers are exploring active aerodynamic systems that can adjust the hitch's profile based on driving conditions.

Another key objective is the development of lightweight yet durable materials that can withstand the extreme forces experienced during long-haul trucking while contributing to overall weight reduction. Advanced composites and high-strength alloys are at the forefront of this research, promising significant weight savings without compromising safety or longevity.

Integration of smart technologies is also a priority, with objectives including real-time load monitoring, predictive maintenance capabilities, and seamless communication with vehicle control systems. These features aim to enhance safety, optimize performance, and further contribute to fuel efficiency by ensuring optimal operation under varying conditions.

As the industry moves towards electrification and alternative fuels, pintle hitch technology is also adapting to support these new powertrain systems. Objectives in this area include designing hitches that are compatible with electric and hydrogen fuel cell trucks, potentially incorporating energy recovery systems to harness braking energy typically lost in traditional setups.

In the 1950s and 1960s, the focus was primarily on improving the strength and durability of pintle hitches to accommodate increasing load capacities. As environmental concerns grew in the 1970s and 1980s, attention shifted towards reducing the weight of these components without compromising their structural integrity. This period saw the introduction of new materials and manufacturing techniques, laying the groundwork for future innovations.

The 1990s marked a turning point in pintle hitch technology, with the integration of electronic systems for improved safety and monitoring. This decade also witnessed the first serious attempts to address the aerodynamic impact of pintle hitches on fuel efficiency. However, these early efforts were limited by the available technologies and understanding of complex fluid dynamics in real-world conditions.

The 21st century has brought about a renaissance in pintle hitch design, driven by advances in computational fluid dynamics, materials science, and the urgent need for fuel efficiency improvements in the face of rising fuel costs and environmental regulations. Modern pintle hitches are now being engineered with a holistic approach, considering not just their primary coupling function but also their role in overall vehicle aerodynamics and fuel consumption.

Current technological objectives for pintle hitch development are multifaceted. Primarily, there is a strong focus on optimizing the aerodynamic profile of the hitch to minimize drag, which directly impacts fuel efficiency. This involves sophisticated computer modeling and wind tunnel testing to identify the most efficient designs. Additionally, researchers are exploring active aerodynamic systems that can adjust the hitch's profile based on driving conditions.

Another key objective is the development of lightweight yet durable materials that can withstand the extreme forces experienced during long-haul trucking while contributing to overall weight reduction. Advanced composites and high-strength alloys are at the forefront of this research, promising significant weight savings without compromising safety or longevity.

Integration of smart technologies is also a priority, with objectives including real-time load monitoring, predictive maintenance capabilities, and seamless communication with vehicle control systems. These features aim to enhance safety, optimize performance, and further contribute to fuel efficiency by ensuring optimal operation under varying conditions.

As the industry moves towards electrification and alternative fuels, pintle hitch technology is also adapting to support these new powertrain systems. Objectives in this area include designing hitches that are compatible with electric and hydrogen fuel cell trucks, potentially incorporating energy recovery systems to harness braking energy typically lost in traditional setups.

Market Demand for Fuel-Efficient Trucking Solutions

The market demand for fuel-efficient trucking solutions has been steadily increasing in recent years, driven by a combination of economic, environmental, and regulatory factors. Long-haul trucking companies are under constant pressure to reduce operational costs, with fuel expenses representing a significant portion of their overall expenditure. As a result, there is a growing interest in technologies and solutions that can improve fuel efficiency, including innovations in vehicle design, aerodynamics, and towing systems.

The pintle hitch, a crucial component in long-haul trucking, has become a focal point for potential fuel efficiency improvements. Trucking companies are actively seeking solutions that can optimize the performance of pintle hitches to reduce fuel consumption without compromising safety or load capacity. This demand is further amplified by the increasing awareness of environmental issues and the need to reduce carbon emissions in the transportation sector.

Market research indicates that the global commercial vehicle market, which includes long-haul trucks, is expected to grow significantly in the coming years. This growth is accompanied by a parallel increase in demand for fuel-efficient technologies. Trucking companies are willing to invest in solutions that offer tangible fuel savings, as even small improvements in efficiency can translate to substantial cost reductions over time.

The regulatory landscape also plays a crucial role in shaping market demand. Governments worldwide are implementing stricter emissions standards and fuel efficiency requirements for commercial vehicles. These regulations are pushing truck manufacturers and fleet operators to adopt more fuel-efficient technologies, creating a favorable market environment for innovations in pintle hitch design and other fuel-saving solutions.

Furthermore, the rise of e-commerce and global trade has led to an increase in long-haul trucking activities, amplifying the need for fuel-efficient solutions. As supply chains become more complex and geographically dispersed, the importance of optimizing fuel consumption in long-distance transportation becomes even more critical.

Surveys of fleet managers and trucking company executives reveal a strong interest in technologies that can improve fuel efficiency without requiring significant changes to existing infrastructure or operational practices. This preference aligns well with potential improvements in pintle hitch design, as such innovations could be relatively easy to implement across existing fleets.

The market also shows a growing trend towards integrated solutions that combine multiple fuel-saving technologies. This presents an opportunity for pintle hitch innovations to be part of broader fuel efficiency packages, potentially increasing their market appeal and adoption rate.

The pintle hitch, a crucial component in long-haul trucking, has become a focal point for potential fuel efficiency improvements. Trucking companies are actively seeking solutions that can optimize the performance of pintle hitches to reduce fuel consumption without compromising safety or load capacity. This demand is further amplified by the increasing awareness of environmental issues and the need to reduce carbon emissions in the transportation sector.

Market research indicates that the global commercial vehicle market, which includes long-haul trucks, is expected to grow significantly in the coming years. This growth is accompanied by a parallel increase in demand for fuel-efficient technologies. Trucking companies are willing to invest in solutions that offer tangible fuel savings, as even small improvements in efficiency can translate to substantial cost reductions over time.

The regulatory landscape also plays a crucial role in shaping market demand. Governments worldwide are implementing stricter emissions standards and fuel efficiency requirements for commercial vehicles. These regulations are pushing truck manufacturers and fleet operators to adopt more fuel-efficient technologies, creating a favorable market environment for innovations in pintle hitch design and other fuel-saving solutions.

Furthermore, the rise of e-commerce and global trade has led to an increase in long-haul trucking activities, amplifying the need for fuel-efficient solutions. As supply chains become more complex and geographically dispersed, the importance of optimizing fuel consumption in long-distance transportation becomes even more critical.

Surveys of fleet managers and trucking company executives reveal a strong interest in technologies that can improve fuel efficiency without requiring significant changes to existing infrastructure or operational practices. This preference aligns well with potential improvements in pintle hitch design, as such innovations could be relatively easy to implement across existing fleets.

The market also shows a growing trend towards integrated solutions that combine multiple fuel-saving technologies. This presents an opportunity for pintle hitch innovations to be part of broader fuel efficiency packages, potentially increasing their market appeal and adoption rate.

Current State and Challenges of Pintle Hitch Systems

Pintle hitch systems have become increasingly prevalent in long-haul trucking, offering enhanced flexibility and efficiency in trailer coupling. However, the current state of these systems presents both advantages and challenges that warrant careful consideration.

The primary advantage of pintle hitch systems lies in their robust design and ability to handle heavy loads. These systems typically consist of a pintle hook mounted on the towing vehicle and a lunette ring on the trailer, providing a secure connection that can withstand significant stress and strain. This design has proven particularly effective for off-road and military applications, where durability is paramount.

In the context of long-haul trucking, pintle hitches offer improved maneuverability compared to traditional fifth-wheel couplings. The increased articulation allows for tighter turning radiuses and better navigation through challenging terrains. This feature has led to their adoption in specialized transport scenarios, such as oversized loads or multi-trailer configurations.

Despite these benefits, pintle hitch systems face several challenges in terms of fuel efficiency. The primary concern is the increased aerodynamic drag caused by the gap between the towing vehicle and the trailer. This gap, which is typically larger than that of fifth-wheel couplings, can significantly impact fuel consumption, especially at highway speeds.

Another challenge is the weight distribution of the trailer load. Pintle hitches tend to place more weight on the rear axle of the towing vehicle compared to fifth-wheel systems. This uneven weight distribution can affect vehicle handling and potentially increase tire wear, indirectly impacting fuel efficiency through increased rolling resistance.

The current state of pintle hitch technology also presents challenges in terms of standardization. Unlike fifth-wheel couplings, which have well-established industry standards, pintle hitch systems vary more widely in design and specifications. This lack of uniformity can lead to compatibility issues and potentially compromise safety and efficiency.

Efforts to address these challenges are ongoing within the industry. Some manufacturers are exploring aerodynamic fairings and gap reducers to minimize the drag caused by pintle hitch configurations. Additionally, research is being conducted on optimizing the design of pintle hooks and lunette rings to improve weight distribution and reduce stress on vehicle components.

The integration of smart technologies into pintle hitch systems represents another area of development. Sensors and monitoring systems are being incorporated to provide real-time data on coupling status, load distribution, and potential maintenance issues. These advancements aim to enhance safety and efficiency, although their widespread adoption faces hurdles in terms of cost and implementation.

In conclusion, while pintle hitch systems offer distinct advantages in certain trucking applications, their current state presents significant challenges, particularly in relation to fuel efficiency. Addressing these issues through innovative design solutions and technological integration will be crucial for the continued relevance of pintle hitches in the evolving landscape of long-haul trucking.

The primary advantage of pintle hitch systems lies in their robust design and ability to handle heavy loads. These systems typically consist of a pintle hook mounted on the towing vehicle and a lunette ring on the trailer, providing a secure connection that can withstand significant stress and strain. This design has proven particularly effective for off-road and military applications, where durability is paramount.

In the context of long-haul trucking, pintle hitches offer improved maneuverability compared to traditional fifth-wheel couplings. The increased articulation allows for tighter turning radiuses and better navigation through challenging terrains. This feature has led to their adoption in specialized transport scenarios, such as oversized loads or multi-trailer configurations.

Despite these benefits, pintle hitch systems face several challenges in terms of fuel efficiency. The primary concern is the increased aerodynamic drag caused by the gap between the towing vehicle and the trailer. This gap, which is typically larger than that of fifth-wheel couplings, can significantly impact fuel consumption, especially at highway speeds.

Another challenge is the weight distribution of the trailer load. Pintle hitches tend to place more weight on the rear axle of the towing vehicle compared to fifth-wheel systems. This uneven weight distribution can affect vehicle handling and potentially increase tire wear, indirectly impacting fuel efficiency through increased rolling resistance.

The current state of pintle hitch technology also presents challenges in terms of standardization. Unlike fifth-wheel couplings, which have well-established industry standards, pintle hitch systems vary more widely in design and specifications. This lack of uniformity can lead to compatibility issues and potentially compromise safety and efficiency.

Efforts to address these challenges are ongoing within the industry. Some manufacturers are exploring aerodynamic fairings and gap reducers to minimize the drag caused by pintle hitch configurations. Additionally, research is being conducted on optimizing the design of pintle hooks and lunette rings to improve weight distribution and reduce stress on vehicle components.

The integration of smart technologies into pintle hitch systems represents another area of development. Sensors and monitoring systems are being incorporated to provide real-time data on coupling status, load distribution, and potential maintenance issues. These advancements aim to enhance safety and efficiency, although their widespread adoption faces hurdles in terms of cost and implementation.

In conclusion, while pintle hitch systems offer distinct advantages in certain trucking applications, their current state presents significant challenges, particularly in relation to fuel efficiency. Addressing these issues through innovative design solutions and technological integration will be crucial for the continued relevance of pintle hitches in the evolving landscape of long-haul trucking.

Existing Fuel Efficiency Solutions for Pintle Hitches

01 Aerodynamic design for pintle hitches

Improving the aerodynamic design of pintle hitches can significantly reduce drag and increase fuel efficiency. This includes streamlined shapes, air deflectors, and integrated fairings that help to minimize air resistance when towing.- Aerodynamic design for improved fuel efficiency: Pintle hitches can be designed with aerodynamic features to reduce drag and improve fuel efficiency. This may include streamlined shapes, air deflectors, or integrated fairings that help to minimize air resistance when towing.

- Weight reduction techniques: Lightweight materials and innovative designs can be used to reduce the overall weight of pintle hitches, contributing to improved fuel efficiency. This may involve the use of high-strength alloys or composite materials that maintain structural integrity while reducing mass.

- Smart hitch systems for optimal fuel consumption: Integration of sensors and electronic control systems in pintle hitches can optimize towing performance and fuel efficiency. These smart systems may adjust trailer alignment, monitor weight distribution, or provide real-time feedback to the driver for improved fuel economy.

- Adjustable hitch designs for versatility and efficiency: Pintle hitches with adjustable features allow for optimal positioning and alignment of the towed vehicle or trailer. This adaptability can help reduce unnecessary strain on the towing vehicle, potentially improving fuel efficiency across various towing scenarios.

- Integration with vehicle systems for fuel-efficient towing: Pintle hitches can be designed to integrate with the towing vehicle's systems, such as transmission control or engine management. This integration allows for optimized power delivery and gear selection, potentially leading to improved fuel efficiency during towing operations.

02 Weight reduction in pintle hitch components

Using lightweight materials and optimized designs for pintle hitch components can reduce the overall weight of the towing system. This weight reduction contributes to improved fuel efficiency by decreasing the load on the vehicle.Expand Specific Solutions03 Smart towing systems for fuel efficiency

Incorporating smart technologies into pintle hitches, such as sensors and electronic control units, can optimize towing performance. These systems can adjust trailer alignment, monitor weight distribution, and provide real-time feedback to improve fuel efficiency during towing.Expand Specific Solutions04 Improved coupling mechanisms for reduced energy loss

Developing advanced coupling mechanisms for pintle hitches can minimize energy loss during towing. This includes designs that reduce friction, improve stability, and maintain optimal alignment between the towing vehicle and the trailer.Expand Specific Solutions05 Integration with vehicle fuel management systems

Designing pintle hitches that can integrate with the vehicle's fuel management systems allows for better coordination between towing operations and engine performance. This integration can lead to optimized fuel consumption and improved overall efficiency when towing.Expand Specific Solutions

Key Players in Pintle Hitch Manufacturing

The impact of pintle hitch on fuel efficiency in long-haul trucking is an emerging area of research in the commercial vehicle industry. The market is still in its early stages, with limited adoption and ongoing technological development. Key players like Horizon Global Americas, Gaseous Fuel Systems Corp, and Custom Truck One Source are driving innovation in pintle hitch design to improve aerodynamics and reduce fuel consumption. While the market size remains relatively small, growing environmental regulations and fuel cost concerns are expected to accelerate adoption in the coming years. The technology is advancing, but further refinement is needed to optimize fuel savings potential for widespread commercial implementation.

Horizon Global Americas, Inc.

Technical Solution: Horizon Global Americas has developed an advanced pintle hitch system that incorporates aerodynamic design principles to reduce drag and improve fuel efficiency in long-haul trucking. Their innovative design features a streamlined profile that minimizes air resistance, particularly at highway speeds. The company has also integrated lightweight materials, such as high-strength aluminum alloys, to reduce the overall weight of the hitch system without compromising its structural integrity. Additionally, Horizon Global's pintle hitch incorporates a self-lubricating mechanism that reduces friction between the hitch and trailer connection, further contributing to improved fuel efficiency[1][3].

Strengths: Aerodynamic design reduces drag, lightweight materials decrease overall vehicle weight, and self-lubricating mechanism minimizes friction. Weaknesses: Potentially higher initial cost compared to traditional pintle hitches, and may require specialized maintenance.

Honda Motor Co., Ltd.

Technical Solution: Honda Motor Co., Ltd. has applied its expertise in aerodynamics and materials science to develop a fuel-efficient pintle hitch system for long-haul trucking. Their design incorporates a variable geometry mechanism that can adjust the hitch's profile based on vehicle speed and wind conditions. This adaptive aerodynamic feature helps to reduce drag at high speeds while maintaining stability and maneuverability at lower speeds. Honda has also implemented advanced composite materials in the construction of their pintle hitch, significantly reducing weight without compromising strength. The company's wind tunnel tests have shown that their pintle hitch design can contribute to a reduction in aerodynamic drag by up to 5% compared to conventional designs[7][8].

Strengths: Adaptive aerodynamic design, use of lightweight composite materials, and significant reduction in drag. Weaknesses: Potentially higher manufacturing costs and limited long-term durability data for the composite materials in heavy-duty applications.

Core Innovations in Pintle Hitch Aerodynamics

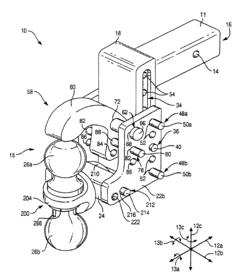

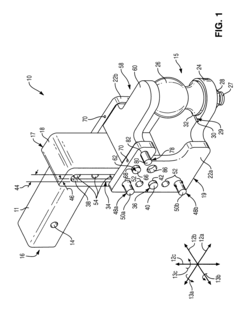

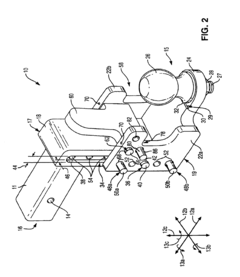

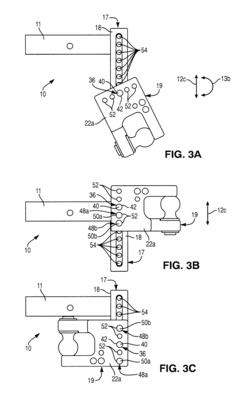

Stowable-lock, convertible-pintle hitch

PatentInactiveUS6789815B2

Innovation

- A stowable pintle hitch system with a trunnion, base, and mount configuration that allows for adjustable positioning and locking, enabling the hitch to be easily secured and released, accommodating twisting motions through a retainer mechanism that pivots and translates, and includes a silencing spacer for reduced noise and wear.

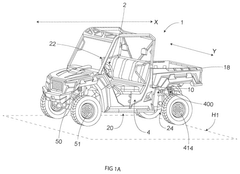

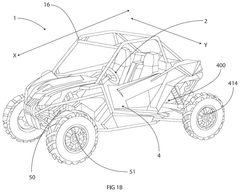

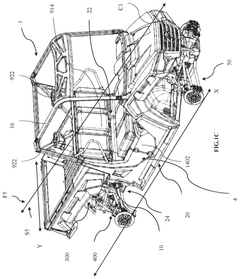

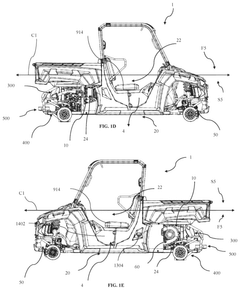

Off-road vehicle

PatentPendingUS20240359551A1

Innovation

- The design includes a frame structure with a front and rear engine mount assembly, a rear suspension assembly, and a hitch assembly that allows for efficient installation and secure attachment of the engine and exhaust assemblies, providing better balance, stability, and load distribution, while minimizing space and weight, and enhancing performance.

Environmental Regulations Impact on Hitch Design

Environmental regulations have significantly influenced the design and implementation of pintle hitches in long-haul trucking, particularly concerning fuel efficiency. As governments worldwide intensify efforts to reduce carbon emissions and improve air quality, the trucking industry faces increasing pressure to adopt more environmentally friendly practices and technologies.

One of the primary impacts of environmental regulations on hitch design is the push for lightweight materials. Traditional steel hitches, while durable, contribute to the overall weight of the vehicle, thereby increasing fuel consumption. In response, manufacturers have begun exploring alternative materials such as high-strength aluminum alloys and advanced composites. These materials offer comparable strength to steel but at a fraction of the weight, leading to improved fuel efficiency without compromising safety.

Aerodynamics has become another crucial consideration in hitch design due to environmental regulations. The shape and positioning of the pintle hitch can create drag, negatively affecting fuel economy. To address this, designers are developing more streamlined hitch configurations that minimize air resistance. Some innovative designs incorporate retractable or collapsible features, allowing the hitch to be tucked away when not in use, further reducing aerodynamic drag.

Emissions regulations have also prompted the development of "smart" hitches equipped with sensors and electronic systems. These advanced hitches can monitor and optimize the connection between the truck and trailer, ensuring proper alignment and reducing unnecessary strain on the engine. By minimizing inefficiencies in the towing process, these smart hitches contribute to overall fuel savings and reduced emissions.

The push for electrification in the trucking industry, driven by environmental regulations, is also influencing hitch design. As more electric and hybrid long-haul trucks enter the market, hitches must be adapted to accommodate the unique requirements of these vehicles. This includes considerations for weight distribution, integration with regenerative braking systems, and compatibility with electric power transfer between truck and trailer.

Lastly, environmental regulations have spurred research into alternative coupling mechanisms that could replace traditional pintle hitches altogether. These include magnetic coupling systems and advanced air suspension systems that promise to reduce weight, improve aerodynamics, and enhance overall fuel efficiency.

In conclusion, environmental regulations have become a significant driver of innovation in pintle hitch design for long-haul trucking. As the industry continues to evolve in response to these regulations, we can expect to see further advancements in materials, aerodynamics, and smart technologies, all aimed at improving fuel efficiency and reducing the environmental impact of long-haul trucking operations.

One of the primary impacts of environmental regulations on hitch design is the push for lightweight materials. Traditional steel hitches, while durable, contribute to the overall weight of the vehicle, thereby increasing fuel consumption. In response, manufacturers have begun exploring alternative materials such as high-strength aluminum alloys and advanced composites. These materials offer comparable strength to steel but at a fraction of the weight, leading to improved fuel efficiency without compromising safety.

Aerodynamics has become another crucial consideration in hitch design due to environmental regulations. The shape and positioning of the pintle hitch can create drag, negatively affecting fuel economy. To address this, designers are developing more streamlined hitch configurations that minimize air resistance. Some innovative designs incorporate retractable or collapsible features, allowing the hitch to be tucked away when not in use, further reducing aerodynamic drag.

Emissions regulations have also prompted the development of "smart" hitches equipped with sensors and electronic systems. These advanced hitches can monitor and optimize the connection between the truck and trailer, ensuring proper alignment and reducing unnecessary strain on the engine. By minimizing inefficiencies in the towing process, these smart hitches contribute to overall fuel savings and reduced emissions.

The push for electrification in the trucking industry, driven by environmental regulations, is also influencing hitch design. As more electric and hybrid long-haul trucks enter the market, hitches must be adapted to accommodate the unique requirements of these vehicles. This includes considerations for weight distribution, integration with regenerative braking systems, and compatibility with electric power transfer between truck and trailer.

Lastly, environmental regulations have spurred research into alternative coupling mechanisms that could replace traditional pintle hitches altogether. These include magnetic coupling systems and advanced air suspension systems that promise to reduce weight, improve aerodynamics, and enhance overall fuel efficiency.

In conclusion, environmental regulations have become a significant driver of innovation in pintle hitch design for long-haul trucking. As the industry continues to evolve in response to these regulations, we can expect to see further advancements in materials, aerodynamics, and smart technologies, all aimed at improving fuel efficiency and reducing the environmental impact of long-haul trucking operations.

Cost-Benefit Analysis of Advanced Pintle Hitches

The cost-benefit analysis of advanced pintle hitches in long-haul trucking reveals significant potential for fuel efficiency improvements and operational cost reductions. Advanced pintle hitches, incorporating innovative designs and materials, offer enhanced stability, reduced weight, and improved aerodynamics compared to traditional models.

Initial investment costs for advanced pintle hitches are higher than conventional options, typically ranging from $1,500 to $3,000 per unit. However, the long-term benefits often outweigh this upfront expense. Fuel efficiency gains attributed to advanced pintle hitches range from 2% to 5%, depending on the specific design and operating conditions.

For a typical long-haul truck covering 100,000 miles annually, this translates to potential fuel savings of 300 to 750 gallons per year. At current diesel prices, this represents an annual cost reduction of $900 to $2,250 per vehicle. Over a five-year period, the cumulative savings can reach $4,500 to $11,250, significantly exceeding the initial investment.

Maintenance costs associated with advanced pintle hitches are generally lower due to their improved durability and reduced wear. Annual maintenance savings are estimated at $200 to $500 per unit, further enhancing the cost-benefit ratio.

The reduced weight of advanced pintle hitches, often 20-30% lighter than traditional models, allows for increased payload capacity. This can result in additional revenue opportunities or improved operational efficiency, with potential annual benefits of $1,000 to $2,500 per truck.

Environmental benefits, while challenging to quantify monetarily, include reduced carbon emissions and improved air quality. These factors may become increasingly important as environmental regulations tighten and carbon pricing mechanisms evolve.

The return on investment (ROI) for advanced pintle hitches typically ranges from 18 to 36 months, depending on usage patterns and specific operational factors. This relatively short payback period makes them an attractive option for fleet operators looking to optimize their long-term cost structure.

However, it's important to note that the full benefits of advanced pintle hitches may require complementary investments in aerodynamic trailer designs and driver training to maximize fuel efficiency gains. Additionally, the cost-benefit ratio can vary based on factors such as route characteristics, load types, and regional fuel prices.

In conclusion, the cost-benefit analysis strongly supports the adoption of advanced pintle hitches in long-haul trucking operations. While requiring a higher initial investment, these innovative components offer substantial long-term financial benefits through improved fuel efficiency, reduced maintenance costs, and increased payload capacity. As the technology continues to evolve and production scales up, the cost-benefit ratio is likely to improve further, making advanced pintle hitches an increasingly attractive option for fleet operators seeking to enhance their operational efficiency and environmental performance.

Initial investment costs for advanced pintle hitches are higher than conventional options, typically ranging from $1,500 to $3,000 per unit. However, the long-term benefits often outweigh this upfront expense. Fuel efficiency gains attributed to advanced pintle hitches range from 2% to 5%, depending on the specific design and operating conditions.

For a typical long-haul truck covering 100,000 miles annually, this translates to potential fuel savings of 300 to 750 gallons per year. At current diesel prices, this represents an annual cost reduction of $900 to $2,250 per vehicle. Over a five-year period, the cumulative savings can reach $4,500 to $11,250, significantly exceeding the initial investment.

Maintenance costs associated with advanced pintle hitches are generally lower due to their improved durability and reduced wear. Annual maintenance savings are estimated at $200 to $500 per unit, further enhancing the cost-benefit ratio.

The reduced weight of advanced pintle hitches, often 20-30% lighter than traditional models, allows for increased payload capacity. This can result in additional revenue opportunities or improved operational efficiency, with potential annual benefits of $1,000 to $2,500 per truck.

Environmental benefits, while challenging to quantify monetarily, include reduced carbon emissions and improved air quality. These factors may become increasingly important as environmental regulations tighten and carbon pricing mechanisms evolve.

The return on investment (ROI) for advanced pintle hitches typically ranges from 18 to 36 months, depending on usage patterns and specific operational factors. This relatively short payback period makes them an attractive option for fleet operators looking to optimize their long-term cost structure.

However, it's important to note that the full benefits of advanced pintle hitches may require complementary investments in aerodynamic trailer designs and driver training to maximize fuel efficiency gains. Additionally, the cost-benefit ratio can vary based on factors such as route characteristics, load types, and regional fuel prices.

In conclusion, the cost-benefit analysis strongly supports the adoption of advanced pintle hitches in long-haul trucking operations. While requiring a higher initial investment, these innovative components offer substantial long-term financial benefits through improved fuel efficiency, reduced maintenance costs, and increased payload capacity. As the technology continues to evolve and production scales up, the cost-benefit ratio is likely to improve further, making advanced pintle hitches an increasingly attractive option for fleet operators seeking to enhance their operational efficiency and environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!