The Role of Pintle Hitch in Heavy-Duty Freight Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution and Objectives

The pintle hitch has played a crucial role in heavy-duty freight systems since its inception in the early 20th century. Originally developed as a simple coupling mechanism for military vehicles, the pintle hitch has evolved significantly to meet the growing demands of the commercial trucking industry.

The evolution of the pintle hitch can be traced through several key stages. In its earliest form, the pintle hitch consisted of a basic hook and eye system, providing a robust but somewhat inflexible connection between vehicles. As the needs of the freight industry expanded, so did the capabilities of the pintle hitch. The introduction of the swivel pintle hitch in the mid-20th century marked a significant advancement, allowing for greater articulation and maneuverability of trailers.

Further developments led to the creation of combination pintle hitches, which incorporated both a pintle hook and a ball hitch, offering versatility in towing different types of trailers. This innovation greatly enhanced the adaptability of heavy-duty vehicles in various freight scenarios. The late 20th century saw the integration of advanced materials and engineering techniques, resulting in pintle hitches with higher weight capacities and improved durability.

The primary objectives driving the evolution of pintle hitches have remained consistent throughout its history. Foremost among these is the goal of increasing towing capacity to accommodate the ever-growing size and weight of freight loads. Equally important has been the aim to enhance safety features, reducing the risk of trailer separation and improving overall stability during transport.

Another key objective has been to improve the ease of use and efficiency in coupling and uncoupling operations. This has led to the development of automated and remote-controlled pintle hitches, significantly reducing the time and effort required for hitching processes. Additionally, there has been a continuous focus on reducing wear and tear, extending the lifespan of both the hitch and the connected vehicles.

In recent years, the objectives have expanded to include integration with smart technologies. Modern pintle hitches are being designed with sensors and connectivity features, allowing for real-time monitoring of hitch status, load distribution, and potential safety issues. This aligns with the broader trend of digitalization in the freight industry, aiming to enhance overall operational efficiency and safety.

Looking forward, the evolution of pintle hitches is likely to continue focusing on increased weight capacity, improved safety mechanisms, and further integration with smart technologies. There is also a growing emphasis on developing more environmentally friendly designs, in line with the industry's shift towards sustainable freight solutions. As heavy-duty freight systems continue to evolve, the pintle hitch remains a critical component, adapting to meet the changing needs of the industry while maintaining its core function of providing a secure and reliable connection for heavy-duty towing applications.

The evolution of the pintle hitch can be traced through several key stages. In its earliest form, the pintle hitch consisted of a basic hook and eye system, providing a robust but somewhat inflexible connection between vehicles. As the needs of the freight industry expanded, so did the capabilities of the pintle hitch. The introduction of the swivel pintle hitch in the mid-20th century marked a significant advancement, allowing for greater articulation and maneuverability of trailers.

Further developments led to the creation of combination pintle hitches, which incorporated both a pintle hook and a ball hitch, offering versatility in towing different types of trailers. This innovation greatly enhanced the adaptability of heavy-duty vehicles in various freight scenarios. The late 20th century saw the integration of advanced materials and engineering techniques, resulting in pintle hitches with higher weight capacities and improved durability.

The primary objectives driving the evolution of pintle hitches have remained consistent throughout its history. Foremost among these is the goal of increasing towing capacity to accommodate the ever-growing size and weight of freight loads. Equally important has been the aim to enhance safety features, reducing the risk of trailer separation and improving overall stability during transport.

Another key objective has been to improve the ease of use and efficiency in coupling and uncoupling operations. This has led to the development of automated and remote-controlled pintle hitches, significantly reducing the time and effort required for hitching processes. Additionally, there has been a continuous focus on reducing wear and tear, extending the lifespan of both the hitch and the connected vehicles.

In recent years, the objectives have expanded to include integration with smart technologies. Modern pintle hitches are being designed with sensors and connectivity features, allowing for real-time monitoring of hitch status, load distribution, and potential safety issues. This aligns with the broader trend of digitalization in the freight industry, aiming to enhance overall operational efficiency and safety.

Looking forward, the evolution of pintle hitches is likely to continue focusing on increased weight capacity, improved safety mechanisms, and further integration with smart technologies. There is also a growing emphasis on developing more environmentally friendly designs, in line with the industry's shift towards sustainable freight solutions. As heavy-duty freight systems continue to evolve, the pintle hitch remains a critical component, adapting to meet the changing needs of the industry while maintaining its core function of providing a secure and reliable connection for heavy-duty towing applications.

Market Demand Analysis for Heavy-Duty Freight Systems

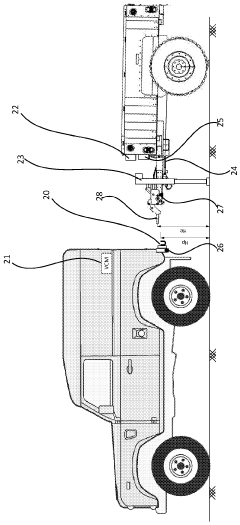

The market demand for heavy-duty freight systems incorporating pintle hitches has shown significant growth in recent years, driven by the increasing need for efficient and versatile transportation solutions. The global heavy-duty freight market is experiencing a steady expansion, with a particular emphasis on systems that can handle larger loads and provide enhanced flexibility in cargo handling.

Pintle hitches play a crucial role in this market, offering unique advantages that cater to the evolving needs of the transportation industry. These hitches are known for their robust design and ability to handle heavy loads, making them particularly suitable for industrial and military applications. The demand for pintle hitches in heavy-duty freight systems is closely tied to sectors such as construction, agriculture, and logistics, where the transportation of oversized and heavy equipment is common.

The construction industry, in particular, has been a major driver of demand for pintle hitch-equipped freight systems. As urbanization continues and infrastructure projects grow in scale and complexity, the need for transporting heavy machinery and materials efficiently has increased. Pintle hitches provide the necessary strength and maneuverability required for these challenging tasks, contributing to their rising popularity in this sector.

In the agricultural sector, the trend towards larger farm equipment has also fueled the demand for heavy-duty freight systems with pintle hitches. These systems allow for the safe and efficient transportation of large tractors, harvesters, and other agricultural machinery between fields or to different locations, supporting the needs of modern farming operations.

The logistics and transportation industry has seen a growing interest in pintle hitch systems due to their versatility in handling various types of trailers and loads. This flexibility is particularly valuable in intermodal transportation, where cargo may need to be transferred between different modes of transport. The ability of pintle hitches to accommodate diverse trailer configurations makes them an attractive option for companies seeking to optimize their freight operations.

Military and defense applications represent another significant market segment for pintle hitch-equipped heavy-duty freight systems. The robust nature of these hitches makes them ideal for transporting military vehicles, equipment, and supplies in challenging terrains and conditions. As global defense spending continues to rise, the demand for reliable and durable transportation solutions in this sector is expected to grow.

The market for heavy-duty freight systems with pintle hitches is also influenced by regulatory factors and safety considerations. Stricter regulations regarding load capacity and safety standards in many countries have led to increased adoption of more reliable and secure hitching systems, benefiting the pintle hitch market.

Pintle hitches play a crucial role in this market, offering unique advantages that cater to the evolving needs of the transportation industry. These hitches are known for their robust design and ability to handle heavy loads, making them particularly suitable for industrial and military applications. The demand for pintle hitches in heavy-duty freight systems is closely tied to sectors such as construction, agriculture, and logistics, where the transportation of oversized and heavy equipment is common.

The construction industry, in particular, has been a major driver of demand for pintle hitch-equipped freight systems. As urbanization continues and infrastructure projects grow in scale and complexity, the need for transporting heavy machinery and materials efficiently has increased. Pintle hitches provide the necessary strength and maneuverability required for these challenging tasks, contributing to their rising popularity in this sector.

In the agricultural sector, the trend towards larger farm equipment has also fueled the demand for heavy-duty freight systems with pintle hitches. These systems allow for the safe and efficient transportation of large tractors, harvesters, and other agricultural machinery between fields or to different locations, supporting the needs of modern farming operations.

The logistics and transportation industry has seen a growing interest in pintle hitch systems due to their versatility in handling various types of trailers and loads. This flexibility is particularly valuable in intermodal transportation, where cargo may need to be transferred between different modes of transport. The ability of pintle hitches to accommodate diverse trailer configurations makes them an attractive option for companies seeking to optimize their freight operations.

Military and defense applications represent another significant market segment for pintle hitch-equipped heavy-duty freight systems. The robust nature of these hitches makes them ideal for transporting military vehicles, equipment, and supplies in challenging terrains and conditions. As global defense spending continues to rise, the demand for reliable and durable transportation solutions in this sector is expected to grow.

The market for heavy-duty freight systems with pintle hitches is also influenced by regulatory factors and safety considerations. Stricter regulations regarding load capacity and safety standards in many countries have led to increased adoption of more reliable and secure hitching systems, benefiting the pintle hitch market.

Current State and Challenges of Pintle Hitch Technology

Pintle hitch technology has become a cornerstone in heavy-duty freight systems, offering robust coupling solutions for various industrial applications. The current state of pintle hitch technology reflects a mature yet evolving field, with ongoing advancements aimed at enhancing safety, efficiency, and versatility.

In the present landscape, pintle hitches are widely adopted across diverse sectors, including agriculture, construction, and military logistics. Their popularity stems from their ability to handle heavy loads and operate in challenging terrains. Modern pintle hitches typically feature high-strength steel construction, with load capacities ranging from 10,000 to 150,000 pounds, depending on the specific design and application.

Recent innovations have focused on improving the ease of use and safety features of pintle hitches. Automated coupling systems have been introduced, reducing the need for manual intervention and minimizing the risk of operator injury. These systems often incorporate sensors and electronic controls to ensure secure connections and provide real-time status updates to drivers.

Despite these advancements, the pintle hitch technology faces several challenges. One significant issue is the need for standardization across different manufacturers and industries. The lack of universal standards can lead to compatibility issues, especially when coupling equipment from different sources or regions.

Another challenge lies in the realm of weight distribution and stability. As freight loads become increasingly diverse and complex, there is a growing demand for pintle hitch systems that can dynamically adjust to varying load conditions. This requires the integration of sophisticated load-sensing technologies and adaptive coupling mechanisms.

Durability remains a critical concern, particularly in harsh operating environments. While current pintle hitches are designed for robustness, there is an ongoing push to develop materials and coatings that can better withstand extreme temperatures, corrosive substances, and high-impact forces without compromising performance or lifespan.

The integration of smart technologies presents both opportunities and challenges. There is a growing trend towards incorporating IoT (Internet of Things) capabilities into pintle hitch systems, enabling real-time monitoring, predictive maintenance, and enhanced fleet management. However, this also raises concerns about cybersecurity and the need for reliable connectivity in remote or challenging environments.

Environmental considerations are also shaping the evolution of pintle hitch technology. There is increasing pressure to develop more sustainable solutions, including the use of recycled materials, improved energy efficiency in manufacturing processes, and designs that facilitate easier end-of-life recycling.

As the freight industry continues to evolve, pintle hitch technology must adapt to meet new regulatory requirements, particularly those related to safety and emissions. This necessitates ongoing research and development to ensure compliance while maintaining or improving performance characteristics.

In the present landscape, pintle hitches are widely adopted across diverse sectors, including agriculture, construction, and military logistics. Their popularity stems from their ability to handle heavy loads and operate in challenging terrains. Modern pintle hitches typically feature high-strength steel construction, with load capacities ranging from 10,000 to 150,000 pounds, depending on the specific design and application.

Recent innovations have focused on improving the ease of use and safety features of pintle hitches. Automated coupling systems have been introduced, reducing the need for manual intervention and minimizing the risk of operator injury. These systems often incorporate sensors and electronic controls to ensure secure connections and provide real-time status updates to drivers.

Despite these advancements, the pintle hitch technology faces several challenges. One significant issue is the need for standardization across different manufacturers and industries. The lack of universal standards can lead to compatibility issues, especially when coupling equipment from different sources or regions.

Another challenge lies in the realm of weight distribution and stability. As freight loads become increasingly diverse and complex, there is a growing demand for pintle hitch systems that can dynamically adjust to varying load conditions. This requires the integration of sophisticated load-sensing technologies and adaptive coupling mechanisms.

Durability remains a critical concern, particularly in harsh operating environments. While current pintle hitches are designed for robustness, there is an ongoing push to develop materials and coatings that can better withstand extreme temperatures, corrosive substances, and high-impact forces without compromising performance or lifespan.

The integration of smart technologies presents both opportunities and challenges. There is a growing trend towards incorporating IoT (Internet of Things) capabilities into pintle hitch systems, enabling real-time monitoring, predictive maintenance, and enhanced fleet management. However, this also raises concerns about cybersecurity and the need for reliable connectivity in remote or challenging environments.

Environmental considerations are also shaping the evolution of pintle hitch technology. There is increasing pressure to develop more sustainable solutions, including the use of recycled materials, improved energy efficiency in manufacturing processes, and designs that facilitate easier end-of-life recycling.

As the freight industry continues to evolve, pintle hitch technology must adapt to meet new regulatory requirements, particularly those related to safety and emissions. This necessitates ongoing research and development to ensure compliance while maintaining or improving performance characteristics.

Existing Pintle Hitch Solutions for Freight Systems

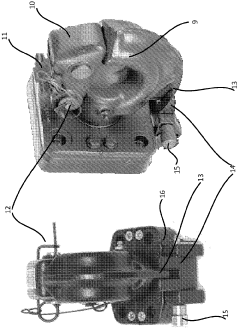

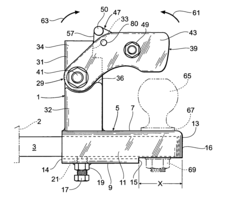

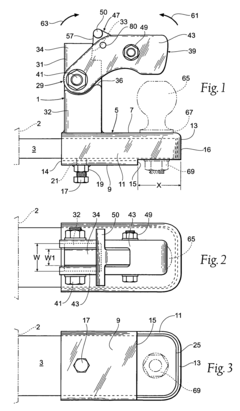

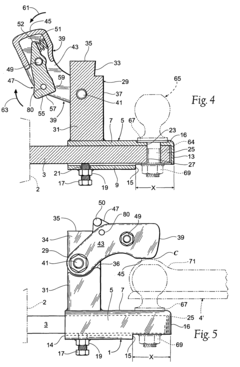

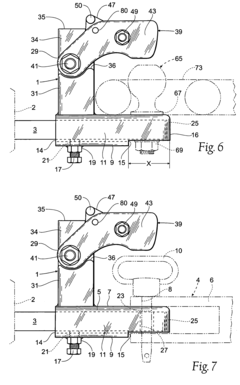

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring or eye. The design typically includes a locking mechanism to ensure the connection remains secure during towing. These hitches are known for their durability and ability to handle heavy loads, making them suitable for various towing applications.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling between a towing vehicle and a trailer. The design typically includes a robust hook mechanism that can withstand heavy loads and provide flexibility in various towing situations. Some designs incorporate additional features for improved safety and ease of use.

- Locking mechanisms for pintle hitches: Various locking mechanisms are employed in pintle hitches to ensure secure attachment and prevent accidental uncoupling during towing. These may include spring-loaded latches, safety pins, or automated locking systems that engage when the trailer is properly connected.

- Adjustable and multi-functional pintle hitches: Some pintle hitch designs offer adjustability to accommodate different trailer heights or towing requirements. These may include features such as adjustable mounting plates, multi-position hooks, or combination designs that can function as both a pintle hitch and a ball hitch.

- Integration of pintle hitches with vehicle systems: Advanced pintle hitch designs may incorporate integration with vehicle systems for improved functionality and safety. This can include electronic sensors for monitoring hitch status, compatibility with backup cameras, or integration with trailer brake controllers.

- Enhanced safety features for pintle hitches: Safety-focused improvements in pintle hitch design may include visual indicators for proper coupling, integrated safety chains, or secondary locking mechanisms. These features aim to reduce the risk of accidents due to improper hitching or unexpected disconnection during towing.

02 Safety features in pintle hitches

Modern pintle hitches incorporate various safety features to enhance towing security. These may include secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. Some designs also feature adjustable components to accommodate different towing heights and improve overall stability during use.Expand Specific Solutions03 Adaptability and versatility

Pintle hitches are designed to be adaptable to various towing scenarios. Some models feature interchangeable components or adjustable elements that allow for use with different types of trailers or towed equipment. This versatility makes pintle hitches suitable for a wide range of applications, from agricultural and construction use to military and heavy-duty industrial towing.Expand Specific Solutions04 Integration with vehicle systems

Advanced pintle hitch designs may incorporate integration with vehicle systems for improved functionality and safety. This can include electronic monitoring of the hitch status, connection to brake controllers, and compatibility with backup cameras or sensors. Such integrations enhance the overall towing experience and provide additional safety measures during operation.Expand Specific Solutions05 Innovative materials and manufacturing techniques

Manufacturers are exploring the use of innovative materials and manufacturing techniques to improve the performance and durability of pintle hitches. This may include the use of high-strength alloys, advanced coatings for corrosion resistance, or novel production methods such as 3D printing for complex geometries. These advancements aim to create lighter yet stronger hitches capable of handling increased loads and withstanding harsh environmental conditions.Expand Specific Solutions

Key Players in Pintle Hitch Manufacturing

The pintle hitch market in heavy-duty freight systems is in a growth phase, driven by increasing demand for robust towing solutions in commercial and industrial applications. The market size is expanding as logistics and transportation sectors evolve. Technologically, pintle hitches are mature but continue to see incremental improvements in design and materials. Key players like Curt Manufacturing, Horizon Global Americas, and ACPS Automotive are leading innovation, focusing on enhancing durability, safety features, and load capacity. Emerging trends include integration of smart technologies for improved monitoring and performance. Companies such as Deere & Co. and Caterpillar are incorporating advanced pintle hitch designs in their heavy equipment, further driving market growth and technological advancements.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has developed advanced pintle hitch systems for heavy-duty freight applications. Their technology incorporates a robust design with a high-strength steel construction, capable of handling loads up to 60,000 lbs[1]. The company's pintle hitches feature a unique locking mechanism that ensures secure coupling between the towing vehicle and trailer, reducing the risk of disconnection during transit[2]. Curt's pintle hitches also incorporate a self-lubricating design, which minimizes wear and extends the lifespan of the hitch[3]. Additionally, they have implemented a modular system that allows for easy customization and replacement of components, enhancing versatility and reducing maintenance costs for fleet operators[4].

Strengths: High load capacity, secure locking mechanism, and modular design for easy maintenance. Weaknesses: May be more expensive than simpler hitch designs, and the complex locking mechanism could require more frequent inspections.

Wabash National Corp.

Technical Solution: Wabash National Corp. has innovated in the field of pintle hitch technology for heavy-duty freight systems with their DuraPlate® AeroSkirt® CX system. This system integrates a reinforced pintle hitch connection point into their aerodynamic trailer skirts, providing a dual benefit of improved fuel efficiency and robust towing capability[1]. The company's pintle hitch design incorporates high-strength, lightweight materials that reduce overall vehicle weight while maintaining a towing capacity of up to 80,000 lbs[2]. Wabash has also developed a smart pintle hitch system that includes sensors for real-time monitoring of hitch stress and wear, allowing for predictive maintenance and enhanced safety[3]. Their pintle hitches are designed with a quick-release mechanism, facilitating faster coupling and uncoupling processes in freight yards[4].

Strengths: Integration with aerodynamic systems, high towing capacity, and smart monitoring capabilities. Weaknesses: The integrated design may make repairs more complex, and the advanced features could lead to higher initial costs.

Core Innovations in Pintle Hitch Design

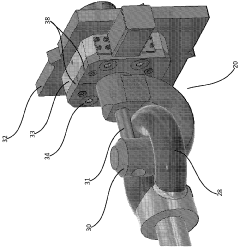

Military towed vehicle automatic hitching system

PatentActiveGB2591705A

Innovation

- An autonomous pintle hitch system that automatically locks or unlocks the pintle's rotation based on the type of towing eye using a controller and drive mechanism, including a locking pin and retaining pin, which can be moved between locked and unlocked positions to prevent or allow rotation, and includes a biasing mechanism and shear pin for safety, allowing for wireless identification of the trailer's eye type and ensuring secure engagement and disengagement.

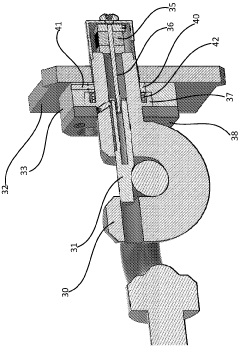

Pintle hitch adaptor for drawbar or DMI bumper

PatentInactiveUS7735848B2

Innovation

- A pintle hitch adaptor that fits over a drawbar, featuring a sleeve with a lock screw and a pivotable latch, allowing for the use of either a hitch ball or tow pin, providing versatility and strength by combining the benefits of both systems.

Safety Regulations for Heavy-Duty Towing Systems

Safety regulations for heavy-duty towing systems are critical in ensuring the secure operation of freight transportation involving pintle hitches. These regulations are designed to minimize risks associated with towing heavy loads and protect both operators and other road users.

The primary focus of safety regulations in this domain is on the structural integrity and load-bearing capacity of pintle hitches. Manufacturers are required to adhere to strict standards regarding the materials used, construction methods, and overall design of these components. These standards typically specify minimum strength requirements for various parts of the hitch, including the pintle hook, drawbar, and mounting hardware.

Load rating is another crucial aspect addressed by safety regulations. Pintle hitches must be clearly marked with their maximum gross trailer weight (GTW) and vertical load capacity. This information helps operators ensure that the hitch is appropriate for the intended load and prevents overloading, which can lead to catastrophic failures during transit.

Regulations also mandate regular inspection and maintenance protocols for pintle hitches. Operators are required to perform visual checks before each use, looking for signs of wear, damage, or deformation. More comprehensive inspections, often involving non-destructive testing methods, are typically required at specified intervals or after any incident that may have compromised the hitch's integrity.

The proper coupling and uncoupling procedures are outlined in safety guidelines to prevent accidents during these critical operations. These procedures include ensuring correct alignment, proper latching, and the use of safety chains or cables as secondary connections. Regulations often specify the minimum strength and configuration requirements for these safety chains.

Training and certification requirements for operators of heavy-duty towing systems are another key component of safety regulations. Drivers must demonstrate proficiency in handling vehicles with pintle hitches, understanding load dynamics, and performing pre-trip inspections. This helps to ensure that those responsible for operating these systems are fully aware of the potential risks and best practices for mitigating them.

Visibility and lighting requirements are also addressed in safety regulations for pintle hitch systems. Proper placement of reflectors, lights, and markers on both the towing vehicle and trailer is mandated to enhance visibility and communicate the vehicle's size and movements to other road users, especially during low-light conditions.

Lastly, safety regulations often include provisions for emergency procedures and equipment. This may include requirements for brake systems, including emergency breakaway systems, and guidelines for handling unexpected situations such as jackknifing or load shifts during transit.

The primary focus of safety regulations in this domain is on the structural integrity and load-bearing capacity of pintle hitches. Manufacturers are required to adhere to strict standards regarding the materials used, construction methods, and overall design of these components. These standards typically specify minimum strength requirements for various parts of the hitch, including the pintle hook, drawbar, and mounting hardware.

Load rating is another crucial aspect addressed by safety regulations. Pintle hitches must be clearly marked with their maximum gross trailer weight (GTW) and vertical load capacity. This information helps operators ensure that the hitch is appropriate for the intended load and prevents overloading, which can lead to catastrophic failures during transit.

Regulations also mandate regular inspection and maintenance protocols for pintle hitches. Operators are required to perform visual checks before each use, looking for signs of wear, damage, or deformation. More comprehensive inspections, often involving non-destructive testing methods, are typically required at specified intervals or after any incident that may have compromised the hitch's integrity.

The proper coupling and uncoupling procedures are outlined in safety guidelines to prevent accidents during these critical operations. These procedures include ensuring correct alignment, proper latching, and the use of safety chains or cables as secondary connections. Regulations often specify the minimum strength and configuration requirements for these safety chains.

Training and certification requirements for operators of heavy-duty towing systems are another key component of safety regulations. Drivers must demonstrate proficiency in handling vehicles with pintle hitches, understanding load dynamics, and performing pre-trip inspections. This helps to ensure that those responsible for operating these systems are fully aware of the potential risks and best practices for mitigating them.

Visibility and lighting requirements are also addressed in safety regulations for pintle hitch systems. Proper placement of reflectors, lights, and markers on both the towing vehicle and trailer is mandated to enhance visibility and communicate the vehicle's size and movements to other road users, especially during low-light conditions.

Lastly, safety regulations often include provisions for emergency procedures and equipment. This may include requirements for brake systems, including emergency breakaway systems, and guidelines for handling unexpected situations such as jackknifing or load shifts during transit.

Environmental Impact of Pintle Hitch Systems

The environmental impact of pintle hitch systems in heavy-duty freight transportation is a critical consideration as the industry strives for sustainability. These systems, while essential for towing and hauling large loads, contribute to various environmental concerns that warrant careful examination.

One of the primary environmental impacts of pintle hitch systems is their contribution to increased fuel consumption. The additional weight of the hitch mechanism, coupled with the aerodynamic drag created by the connection point between the towing vehicle and trailer, can lead to reduced fuel efficiency. This increased fuel consumption directly translates to higher carbon emissions, contributing to greenhouse gas levels and climate change.

Wear and tear on road surfaces is another significant environmental concern associated with pintle hitch systems. The concentrated load transfer at the hitch point can cause accelerated degradation of road infrastructure, particularly in areas with frequent heavy-duty freight traffic. This leads to more frequent road maintenance and reconstruction, resulting in increased resource consumption and associated environmental impacts from construction activities.

Noise pollution is an often-overlooked environmental impact of pintle hitch systems. The metal-on-metal contact at the hitch point can generate significant noise, especially during turning maneuvers or when traversing uneven surfaces. This noise pollution can have adverse effects on wildlife habitats near transportation routes and impact the quality of life in urban areas through which these freight systems operate.

The manufacturing process of pintle hitch systems also carries environmental implications. The production of steel and other materials used in these systems involves energy-intensive processes and resource extraction, contributing to industrial emissions and potential habitat disruption in mining areas.

However, it is important to note that pintle hitch systems also offer some environmental benefits. Their durability and reliability can lead to fewer breakdowns and accidents, reducing the need for emergency responses and the associated environmental impacts of such incidents. Additionally, the versatility of pintle hitches allows for more efficient load combinations, potentially reducing the number of trips required for freight transport.

As the freight industry evolves, there is growing interest in developing more environmentally friendly pintle hitch designs. Research into lightweight materials, improved aerodynamics, and advanced lubrication systems aims to mitigate some of the negative environmental impacts while maintaining the strength and reliability required for heavy-duty applications.

In conclusion, while pintle hitch systems play a crucial role in heavy-duty freight transportation, their environmental impact is significant and multifaceted. Balancing the operational necessities with environmental concerns remains a key challenge for the industry, driving ongoing innovation and research into more sustainable freight solutions.

One of the primary environmental impacts of pintle hitch systems is their contribution to increased fuel consumption. The additional weight of the hitch mechanism, coupled with the aerodynamic drag created by the connection point between the towing vehicle and trailer, can lead to reduced fuel efficiency. This increased fuel consumption directly translates to higher carbon emissions, contributing to greenhouse gas levels and climate change.

Wear and tear on road surfaces is another significant environmental concern associated with pintle hitch systems. The concentrated load transfer at the hitch point can cause accelerated degradation of road infrastructure, particularly in areas with frequent heavy-duty freight traffic. This leads to more frequent road maintenance and reconstruction, resulting in increased resource consumption and associated environmental impacts from construction activities.

Noise pollution is an often-overlooked environmental impact of pintle hitch systems. The metal-on-metal contact at the hitch point can generate significant noise, especially during turning maneuvers or when traversing uneven surfaces. This noise pollution can have adverse effects on wildlife habitats near transportation routes and impact the quality of life in urban areas through which these freight systems operate.

The manufacturing process of pintle hitch systems also carries environmental implications. The production of steel and other materials used in these systems involves energy-intensive processes and resource extraction, contributing to industrial emissions and potential habitat disruption in mining areas.

However, it is important to note that pintle hitch systems also offer some environmental benefits. Their durability and reliability can lead to fewer breakdowns and accidents, reducing the need for emergency responses and the associated environmental impacts of such incidents. Additionally, the versatility of pintle hitches allows for more efficient load combinations, potentially reducing the number of trips required for freight transport.

As the freight industry evolves, there is growing interest in developing more environmentally friendly pintle hitch designs. Research into lightweight materials, improved aerodynamics, and advanced lubrication systems aims to mitigate some of the negative environmental impacts while maintaining the strength and reliability required for heavy-duty applications.

In conclusion, while pintle hitch systems play a crucial role in heavy-duty freight transportation, their environmental impact is significant and multifaceted. Balancing the operational necessities with environmental concerns remains a key challenge for the industry, driving ongoing innovation and research into more sustainable freight solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!