Pintle Hitch as a Factor in Noise Reduction Technologies

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Noise Reduction Background and Objectives

The pintle hitch, a crucial component in vehicle towing systems, has been a subject of increasing interest in noise reduction technologies. This research focuses on exploring the potential of pintle hitches as a factor in mitigating noise pollution associated with towing operations. The evolution of pintle hitch technology has been driven by the growing demand for more efficient and quieter towing solutions across various industries, including transportation, agriculture, and construction.

Historically, pintle hitches have been valued for their durability and versatility in heavy-duty towing applications. However, as environmental concerns and noise regulations have become more stringent, the need to address noise issues associated with towing has gained prominence. The primary sources of noise in pintle hitch systems include metal-on-metal contact, vibrations transmitted through the hitch assembly, and the dynamic interactions between the towing vehicle and the trailer.

Recent technological advancements have paved the way for innovative approaches to noise reduction in pintle hitch systems. These developments encompass a range of solutions, from improved materials and design modifications to the integration of smart technologies. The objective of this research is to comprehensively analyze the current state of pintle hitch noise reduction technologies and identify promising avenues for future development.

One of the key goals is to evaluate the effectiveness of various noise reduction strategies specifically tailored for pintle hitches. This includes examining the impact of material choices, such as high-density polymers and advanced alloys, on noise attenuation. Additionally, the research aims to explore the potential of novel design concepts, like adaptive damping systems and acoustic isolation techniques, in minimizing noise transmission through the hitch assembly.

Another critical aspect of this study is to investigate the role of pintle hitches in the broader context of vehicle noise reduction. This involves analyzing how improvements in pintle hitch design can contribute to overall noise reduction in towing operations, considering factors such as aerodynamics, load distribution, and the interaction between the towing vehicle and the trailer.

Furthermore, the research seeks to identify emerging trends and technologies that could revolutionize pintle hitch noise reduction. This includes exploring the potential of smart materials, active noise control systems, and predictive maintenance technologies in enhancing the acoustic performance of pintle hitches. By examining these cutting-edge approaches, the study aims to provide insights into the future direction of pintle hitch technology and its role in creating quieter, more environmentally friendly towing solutions.

Historically, pintle hitches have been valued for their durability and versatility in heavy-duty towing applications. However, as environmental concerns and noise regulations have become more stringent, the need to address noise issues associated with towing has gained prominence. The primary sources of noise in pintle hitch systems include metal-on-metal contact, vibrations transmitted through the hitch assembly, and the dynamic interactions between the towing vehicle and the trailer.

Recent technological advancements have paved the way for innovative approaches to noise reduction in pintle hitch systems. These developments encompass a range of solutions, from improved materials and design modifications to the integration of smart technologies. The objective of this research is to comprehensively analyze the current state of pintle hitch noise reduction technologies and identify promising avenues for future development.

One of the key goals is to evaluate the effectiveness of various noise reduction strategies specifically tailored for pintle hitches. This includes examining the impact of material choices, such as high-density polymers and advanced alloys, on noise attenuation. Additionally, the research aims to explore the potential of novel design concepts, like adaptive damping systems and acoustic isolation techniques, in minimizing noise transmission through the hitch assembly.

Another critical aspect of this study is to investigate the role of pintle hitches in the broader context of vehicle noise reduction. This involves analyzing how improvements in pintle hitch design can contribute to overall noise reduction in towing operations, considering factors such as aerodynamics, load distribution, and the interaction between the towing vehicle and the trailer.

Furthermore, the research seeks to identify emerging trends and technologies that could revolutionize pintle hitch noise reduction. This includes exploring the potential of smart materials, active noise control systems, and predictive maintenance technologies in enhancing the acoustic performance of pintle hitches. By examining these cutting-edge approaches, the study aims to provide insights into the future direction of pintle hitch technology and its role in creating quieter, more environmentally friendly towing solutions.

Market Analysis for Quiet Towing Solutions

The market for quiet towing solutions has been experiencing significant growth in recent years, driven by increasing awareness of noise pollution and stricter regulations on vehicle noise emissions. The pintle hitch, a crucial component in towing systems, has emerged as a focal point for noise reduction technologies in the towing industry.

The global towing equipment market, which includes pintle hitches, is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) of over 3% during the forecast period. This growth is attributed to the rising demand for recreational vehicles, increased commercial transportation activities, and the expansion of the construction and agriculture sectors.

Within this market, the demand for noise reduction technologies in towing systems has been steadily increasing. Consumers, particularly in developed countries, are becoming more conscious of environmental noise and are seeking quieter towing solutions for their vehicles. This trend is especially prominent in the recreational vehicle (RV) segment, where comfort and noise reduction are key factors influencing purchasing decisions.

The commercial transportation sector is another significant driver for quiet towing solutions. Fleet operators are increasingly recognizing the benefits of reduced noise in terms of driver comfort, improved fuel efficiency, and compliance with noise regulations in urban areas. This has led to a growing demand for advanced pintle hitch designs that incorporate noise reduction features.

Geographically, North America and Europe are the leading markets for quiet towing solutions, owing to stringent noise regulations and higher consumer awareness. However, emerging markets in Asia-Pacific and Latin America are expected to show rapid growth in the coming years, driven by increasing urbanization and rising disposable incomes.

The competitive landscape of the quiet towing solutions market is characterized by a mix of established players and innovative startups. Major towing equipment manufacturers are investing in research and development to improve their pintle hitch designs for noise reduction. Additionally, specialized acoustic engineering firms are entering the market with novel solutions targeting the noise issues associated with towing.

Customer preferences in the quiet towing solutions market are shifting towards integrated systems that offer both noise reduction and improved towing performance. This trend is driving manufacturers to develop multifunctional pintle hitches that address noise concerns while enhancing safety and ease of use.

In conclusion, the market analysis for quiet towing solutions, with a focus on pintle hitch technologies, reveals a growing and dynamic sector. The increasing demand for noise reduction in both consumer and commercial towing applications presents significant opportunities for innovation and market expansion in the coming years.

The global towing equipment market, which includes pintle hitches, is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) of over 3% during the forecast period. This growth is attributed to the rising demand for recreational vehicles, increased commercial transportation activities, and the expansion of the construction and agriculture sectors.

Within this market, the demand for noise reduction technologies in towing systems has been steadily increasing. Consumers, particularly in developed countries, are becoming more conscious of environmental noise and are seeking quieter towing solutions for their vehicles. This trend is especially prominent in the recreational vehicle (RV) segment, where comfort and noise reduction are key factors influencing purchasing decisions.

The commercial transportation sector is another significant driver for quiet towing solutions. Fleet operators are increasingly recognizing the benefits of reduced noise in terms of driver comfort, improved fuel efficiency, and compliance with noise regulations in urban areas. This has led to a growing demand for advanced pintle hitch designs that incorporate noise reduction features.

Geographically, North America and Europe are the leading markets for quiet towing solutions, owing to stringent noise regulations and higher consumer awareness. However, emerging markets in Asia-Pacific and Latin America are expected to show rapid growth in the coming years, driven by increasing urbanization and rising disposable incomes.

The competitive landscape of the quiet towing solutions market is characterized by a mix of established players and innovative startups. Major towing equipment manufacturers are investing in research and development to improve their pintle hitch designs for noise reduction. Additionally, specialized acoustic engineering firms are entering the market with novel solutions targeting the noise issues associated with towing.

Customer preferences in the quiet towing solutions market are shifting towards integrated systems that offer both noise reduction and improved towing performance. This trend is driving manufacturers to develop multifunctional pintle hitches that address noise concerns while enhancing safety and ease of use.

In conclusion, the market analysis for quiet towing solutions, with a focus on pintle hitch technologies, reveals a growing and dynamic sector. The increasing demand for noise reduction in both consumer and commercial towing applications presents significant opportunities for innovation and market expansion in the coming years.

Current Challenges in Pintle Hitch Noise Reduction

Despite significant advancements in vehicle engineering, noise reduction in pintle hitch systems remains a persistent challenge for manufacturers and users alike. The primary issue stems from the inherent design of the pintle hitch, which allows for a degree of movement between the towing vehicle and the trailer. This movement, while necessary for maneuverability, often results in unwanted noise during operation.

One of the main challenges is the metal-on-metal contact between the pintle hook and the lunette ring. As vehicles traverse uneven terrain or make sharp turns, this contact point experiences significant stress and movement, leading to rattling, clanking, and other disruptive noises. The intensity of these noises can vary depending on factors such as vehicle speed, road conditions, and load weight, making it difficult to develop a one-size-fits-all solution.

Another significant hurdle is the balance between noise reduction and maintaining the structural integrity and safety of the hitch system. Any modifications or additional components designed to dampen noise must not compromise the hitch's ability to securely connect the towing vehicle and trailer. This requirement often limits the range of potential solutions and materials that can be employed.

The diverse range of vehicles and trailers that utilize pintle hitches further complicates the noise reduction efforts. From military vehicles to construction equipment, each application presents unique challenges in terms of load capacity, operating conditions, and regulatory requirements. Developing a noise reduction solution that is universally applicable across this spectrum of use cases is a formidable task.

Environmental factors also play a crucial role in the noise reduction challenge. Pintle hitches are frequently exposed to harsh conditions, including extreme temperatures, moisture, and abrasive elements. Any noise reduction technology must be durable enough to withstand these conditions without degrading over time or requiring frequent maintenance.

Moreover, the cost-effectiveness of noise reduction solutions is a significant consideration. While high-end, specialized materials or complex dampening systems might offer superior noise reduction, they may not be economically viable for widespread implementation across various industries and vehicle types.

Lastly, the regulatory landscape surrounding vehicle noise emissions is becoming increasingly stringent. Manufacturers must not only address the practical aspects of noise reduction but also ensure compliance with evolving standards and regulations. This regulatory pressure adds another layer of complexity to the development of effective noise reduction technologies for pintle hitch systems.

One of the main challenges is the metal-on-metal contact between the pintle hook and the lunette ring. As vehicles traverse uneven terrain or make sharp turns, this contact point experiences significant stress and movement, leading to rattling, clanking, and other disruptive noises. The intensity of these noises can vary depending on factors such as vehicle speed, road conditions, and load weight, making it difficult to develop a one-size-fits-all solution.

Another significant hurdle is the balance between noise reduction and maintaining the structural integrity and safety of the hitch system. Any modifications or additional components designed to dampen noise must not compromise the hitch's ability to securely connect the towing vehicle and trailer. This requirement often limits the range of potential solutions and materials that can be employed.

The diverse range of vehicles and trailers that utilize pintle hitches further complicates the noise reduction efforts. From military vehicles to construction equipment, each application presents unique challenges in terms of load capacity, operating conditions, and regulatory requirements. Developing a noise reduction solution that is universally applicable across this spectrum of use cases is a formidable task.

Environmental factors also play a crucial role in the noise reduction challenge. Pintle hitches are frequently exposed to harsh conditions, including extreme temperatures, moisture, and abrasive elements. Any noise reduction technology must be durable enough to withstand these conditions without degrading over time or requiring frequent maintenance.

Moreover, the cost-effectiveness of noise reduction solutions is a significant consideration. While high-end, specialized materials or complex dampening systems might offer superior noise reduction, they may not be economically viable for widespread implementation across various industries and vehicle types.

Lastly, the regulatory landscape surrounding vehicle noise emissions is becoming increasingly stringent. Manufacturers must not only address the practical aspects of noise reduction but also ensure compliance with evolving standards and regulations. This regulatory pressure adds another layer of complexity to the development of effective noise reduction technologies for pintle hitch systems.

Existing Pintle Hitch Noise Reduction Solutions

01 Noise reduction through improved hitch design

Innovative pintle hitch designs can significantly reduce noise by minimizing metal-to-metal contact and incorporating noise-dampening materials. These designs often feature improved locking mechanisms and enhanced alignment systems to reduce rattling and vibration during towing.- Noise reduction through improved hitch design: Innovative pintle hitch designs can significantly reduce noise by incorporating features such as cushioning elements, dampeners, or flexible components. These designs aim to minimize metal-to-metal contact and absorb vibrations, resulting in quieter operation during towing.

- Lubrication systems for noise reduction: Implementing lubrication systems within the pintle hitch assembly can help reduce friction between moving parts, thereby minimizing noise. These systems may include self-lubricating materials, grease fittings, or automatic lubrication mechanisms to ensure smooth and quiet operation.

- Adjustable components for noise control: Incorporating adjustable components in pintle hitch designs allows for fine-tuning and customization to reduce noise. These may include adjustable tension mechanisms, variable-position locking systems, or adaptable cushioning elements that can be tailored to specific towing conditions.

- Noise-absorbing materials and coatings: Utilizing specialized noise-absorbing materials or applying noise-reducing coatings to key components of the pintle hitch can help dampen vibrations and minimize noise. These materials may include rubber compounds, polymers, or advanced composites designed to absorb sound and reduce resonance.

- Electronic noise cancellation systems: Implementing electronic noise cancellation systems in modern pintle hitch designs can actively reduce noise by generating counter-frequencies to cancel out unwanted sounds. These systems may use sensors to detect noise patterns and produce opposing sound waves to minimize perceived noise levels during towing operations.

02 Lubrication systems for noise reduction

Incorporating lubrication systems into pintle hitches can help reduce friction between moving parts, thereby minimizing noise. These systems may include self-lubricating materials, grease fittings, or automatic lubrication mechanisms to ensure smooth operation and reduced wear.Expand Specific Solutions03 Cushioning and damping elements

The integration of cushioning and damping elements in pintle hitch assemblies can effectively absorb vibrations and reduce noise. These elements may include rubber bushings, polyurethane inserts, or spring-loaded components that isolate the hitch from the vehicle frame.Expand Specific Solutions04 Adjustable tension mechanisms

Pintle hitches with adjustable tension mechanisms allow users to fine-tune the connection between the hitch and the trailer, reducing play and minimizing noise. These mechanisms may include threaded adjusters, cam-lock systems, or spring-loaded components that maintain proper tension during use.Expand Specific Solutions05 Advanced locking systems

Sophisticated locking systems in pintle hitches can help eliminate unwanted movement and reduce noise. These may include multi-point locking mechanisms, electronic locking systems, or self-adjusting locks that maintain a secure connection between the hitch and the trailer.Expand Specific Solutions

Key Players in Pintle Hitch Manufacturing

The research on Pintle Hitch as a factor in noise reduction technologies is currently in an emerging stage, with the market showing potential for growth as automotive and transportation industries increasingly focus on noise reduction solutions. The global market for noise reduction technologies is expanding, driven by stringent regulations and consumer demand for quieter vehicles. While the technology is still evolving, companies like Mitsubishi Electric Corp., Mercedes-Benz Group AG, and GM Global Technology Operations LLC are likely at the forefront of developing and implementing advanced noise reduction solutions, including those related to Pintle Hitch systems. The involvement of these major players suggests a growing recognition of the importance of this technology in enhancing vehicle performance and comfort.

The Yokohama Rubber Co., Ltd.

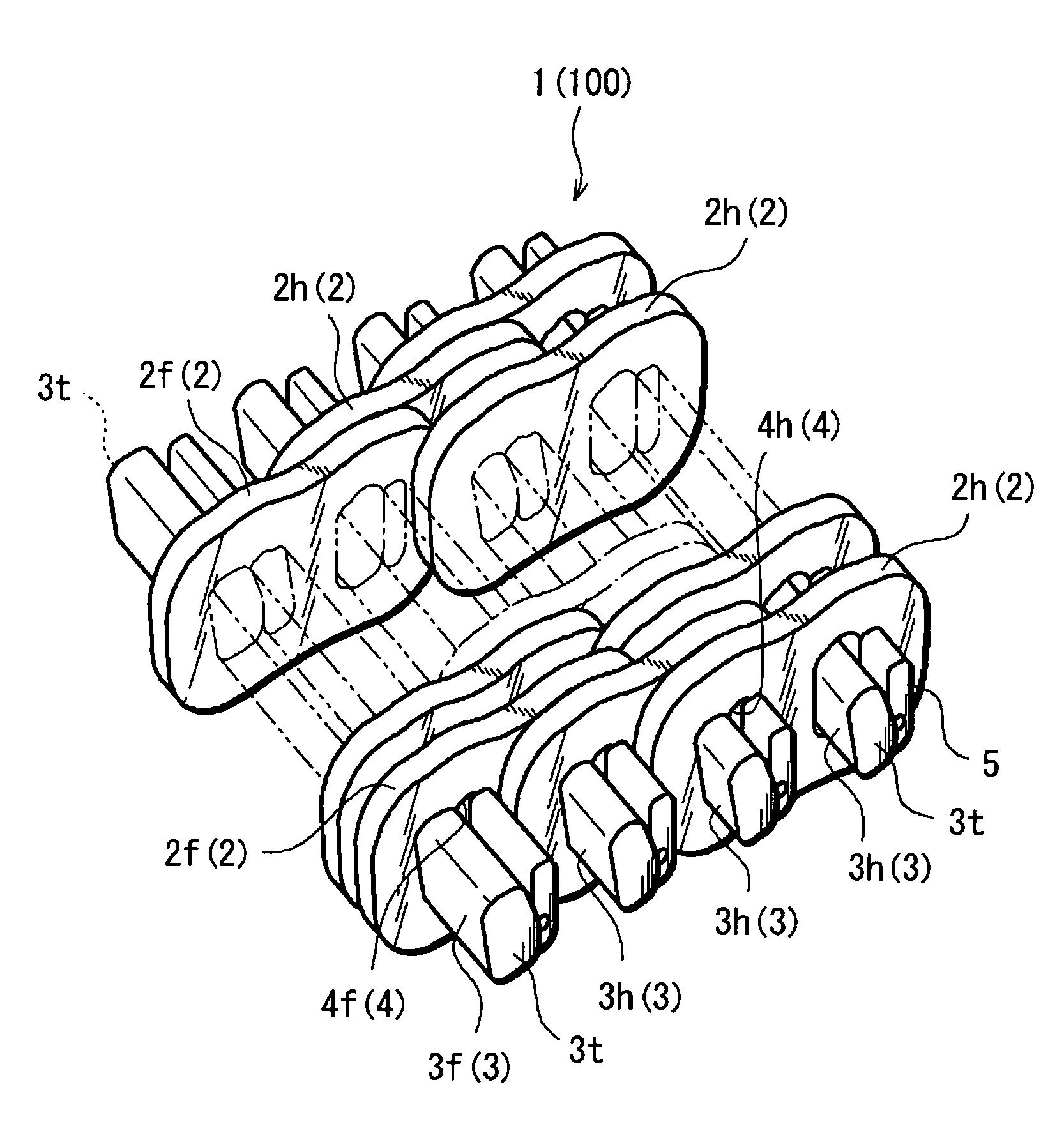

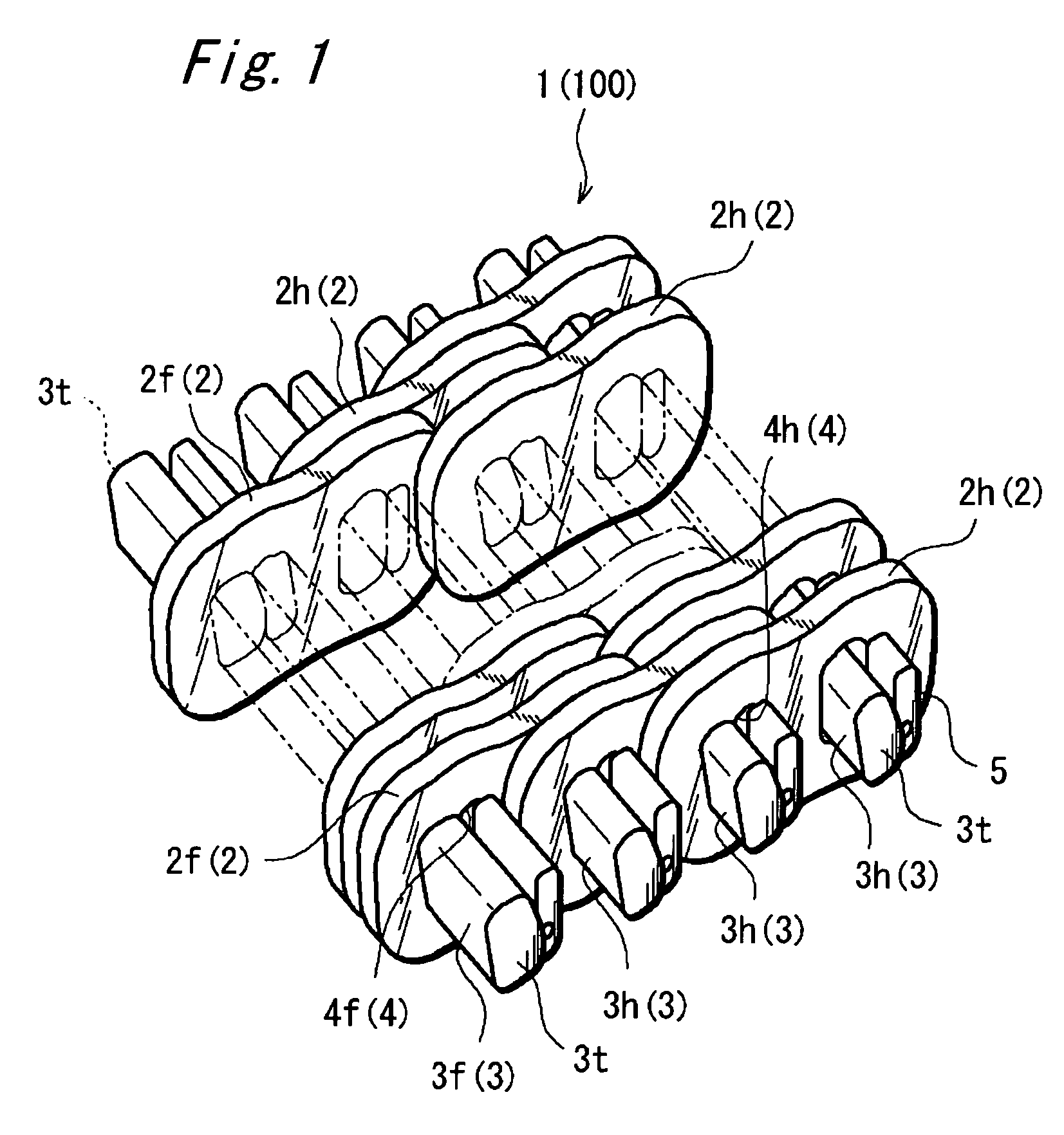

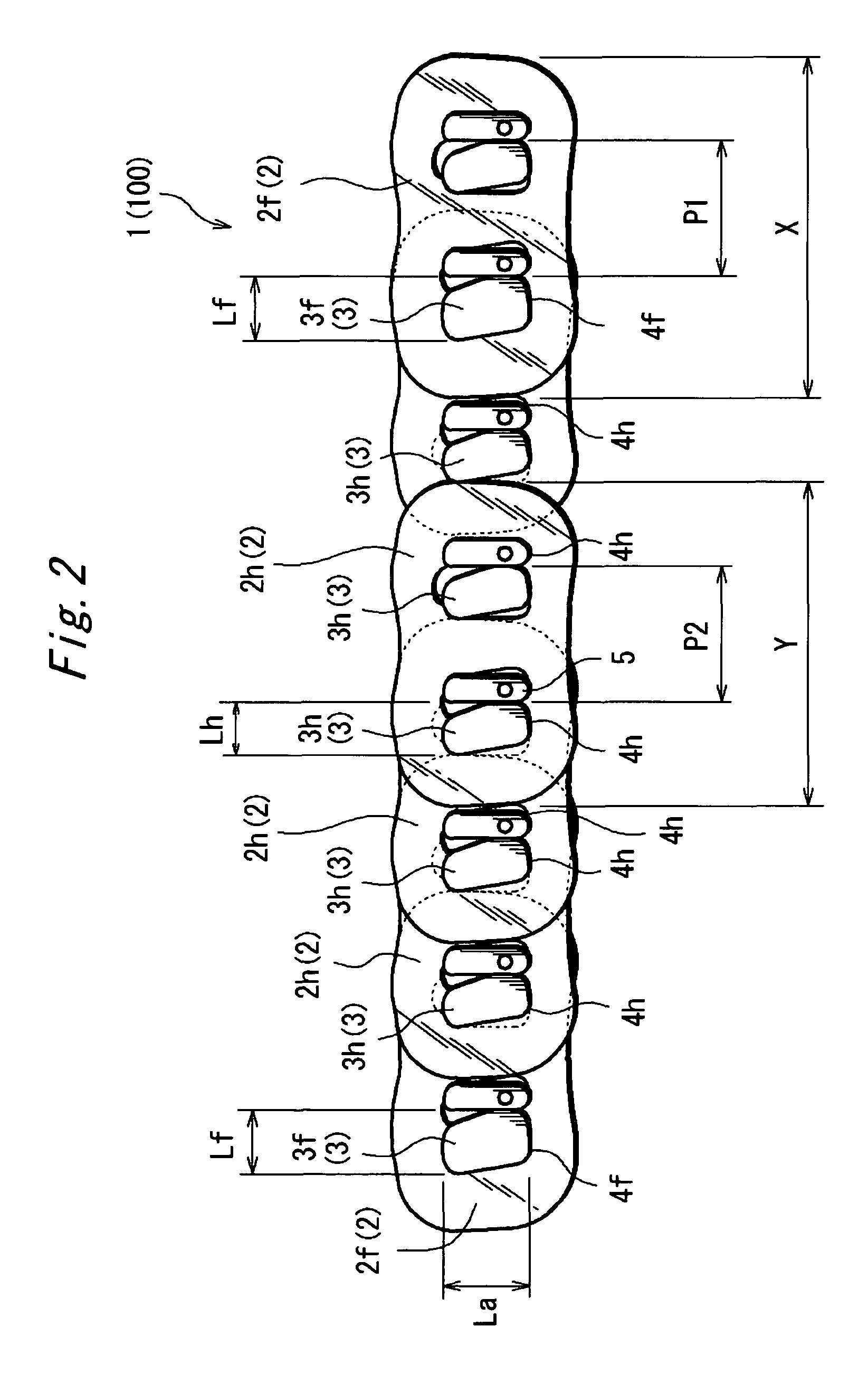

Technical Solution: Yokohama Rubber has developed innovative noise reduction technologies for pintle hitches, focusing on advanced rubber compounds and design optimization. Their approach involves using specially formulated rubber materials with high damping properties to absorb vibrations and reduce noise transmission. The company has implemented a multi-layer design for pintle hitch components, incorporating different rubber compounds with varying densities to target specific frequency ranges[1]. Additionally, they have developed a unique surface texture pattern for the rubber components, which helps to break up sound waves and further reduce noise[2].

Strengths: Expertise in rubber technology, innovative material formulations, and advanced design techniques. Weaknesses: Potential higher cost due to specialized materials and complex manufacturing processes.

Sumitomo Rubber Industries, Ltd.

Technical Solution: Sumitomo Rubber Industries has developed a proprietary noise reduction technology for pintle hitches called "Silent Core." This technology utilizes a specially designed inner layer within the hitch components, made from a high-performance polymer that effectively absorbs vibrations and reduces noise transmission. The Silent Core technology is complemented by an advanced outer rubber compound that provides durability and weather resistance. Sumitomo has also implemented computer-aided design and simulation techniques to optimize the shape and structure of pintle hitch components for maximum noise reduction efficiency[3].

Strengths: Proprietary Silent Core technology, integration of advanced materials and design optimization. Weaknesses: Potentially limited to specific hitch designs, may require adaptation for different vehicle types.

Core Innovations in Quiet Pintle Hitch Design

Power transmission chain and power transmission assembly using the same

PatentInactiveUS7993229B2

Innovation

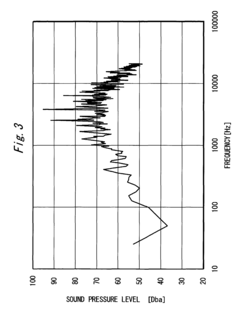

- A power transmission chain with pins of varying sectional areas but similar lengths, and chain friction transmission members with different rigidities, arranged to disperse noise frequencies and reduce polygonal vibrations, thereby lowering sound pressure levels.

Noise reduction method with self-controlling interference frequency

PatentInactiveUS7020291B2

Innovation

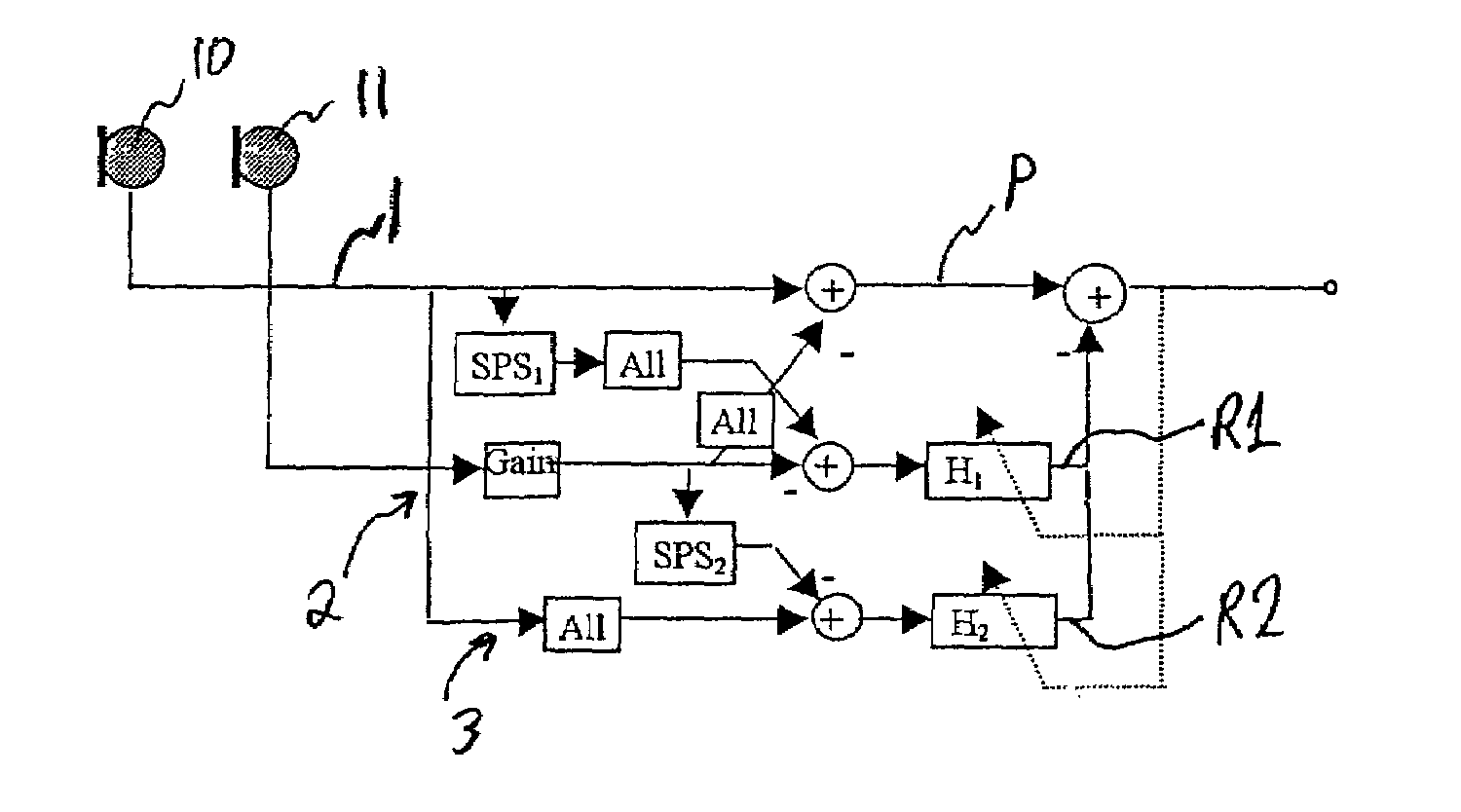

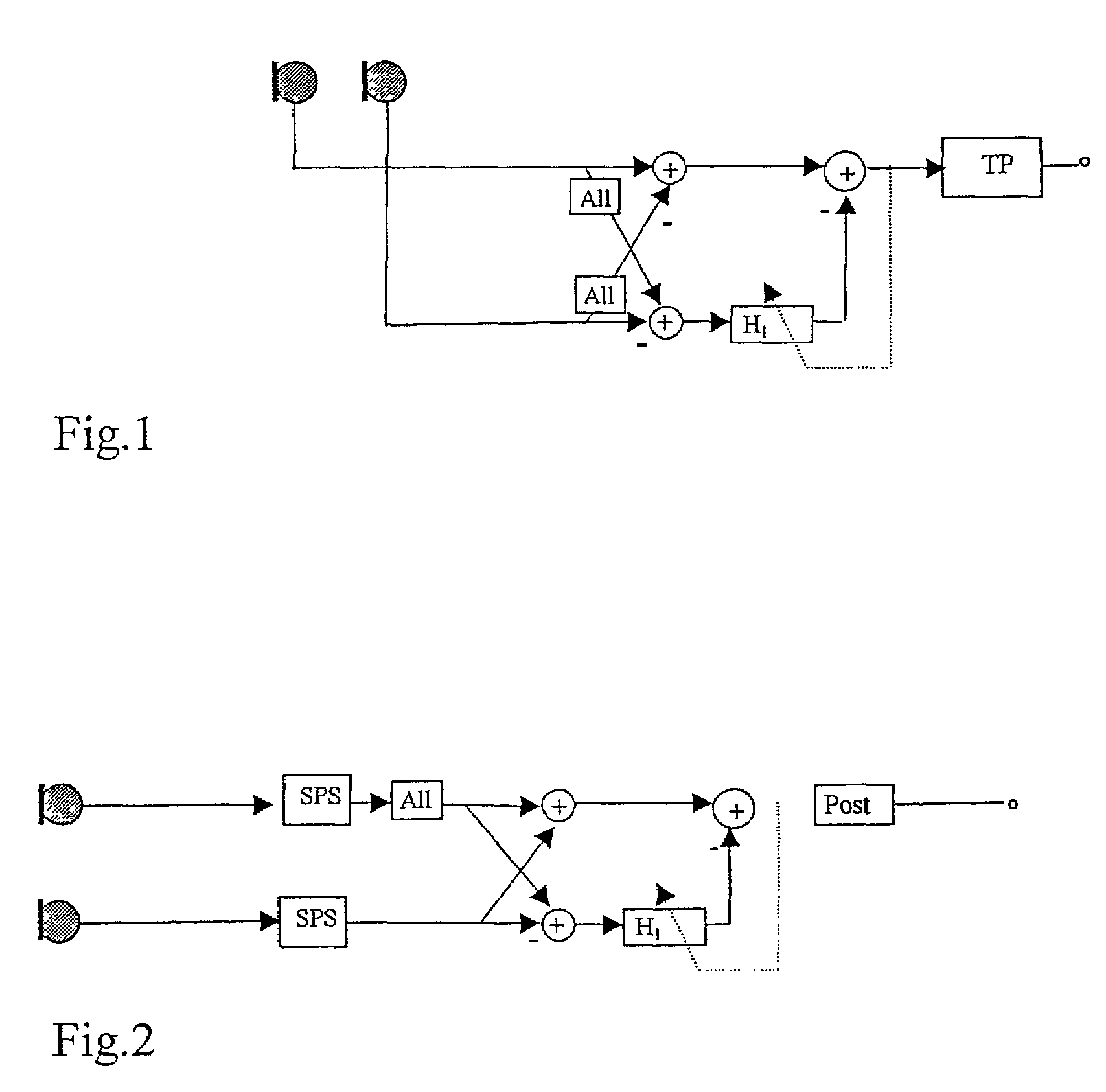

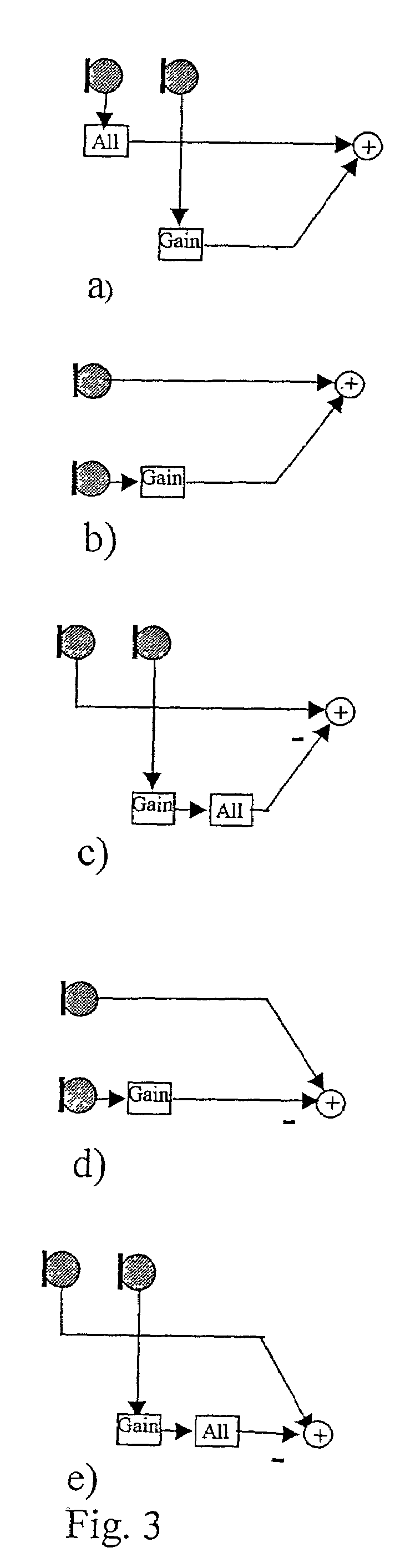

- A noise reduction method utilizing unilateral spectral subtraction to minimize unwanted signal components in the interference reference signal, allowing for effective noise reduction in multi-channel systems by producing an interference reference signal through differential or sum-and-difference arrays, and adapting filters using the LMS algorithm, with continuous adjustment of spectral subtraction effectiveness via a parameter.

Environmental Impact of Towing Noise

The environmental impact of towing noise is a significant concern in the context of pintle hitch research and noise reduction technologies. Towing vehicles, particularly those using pintle hitches, can generate substantial noise pollution, affecting both urban and rural environments. This noise contributes to overall environmental degradation and can have far-reaching consequences on ecosystems and human health.

One of the primary environmental impacts of towing noise is its effect on wildlife. Excessive noise from towing vehicles can disrupt animal communication, mating patterns, and migration routes. Studies have shown that prolonged exposure to traffic noise, including that from towing vehicles, can lead to reduced biodiversity in affected areas. Birds, in particular, are susceptible to noise pollution, with some species altering their song patterns or abandoning nesting sites in noisy environments.

In urban settings, towing noise contributes to the overall problem of noise pollution, which is increasingly recognized as a public health issue. Continuous exposure to high levels of noise can lead to stress, sleep disturbances, and cardiovascular problems in humans. The World Health Organization has identified traffic noise as a significant environmental stressor, with towing vehicles being a notable contributor, especially in areas with frequent heavy vehicle movement.

The impact of towing noise on air quality is another environmental concern. While noise itself does not directly affect air quality, the measures taken to reduce noise can have indirect effects. For instance, the use of noise barriers along highways to mitigate towing and traffic noise can alter air flow patterns, potentially leading to localized increases in air pollution concentration.

Furthermore, the environmental impact of towing noise extends to property values and land use planning. Areas affected by high levels of towing noise may see decreased property values, leading to changes in land use patterns and potentially contributing to urban sprawl as residents seek quieter environments.

The development of noise reduction technologies for pintle hitches and towing vehicles is crucial in mitigating these environmental impacts. Innovations in this field can lead to significant reductions in noise pollution, benefiting both urban and natural environments. Improved pintle hitch designs that minimize vibration and noise transmission can play a key role in creating more environmentally friendly transportation systems.

In conclusion, addressing the environmental impact of towing noise through research on pintle hitches and noise reduction technologies is essential for sustainable development and environmental protection. As urban areas continue to expand and transportation needs grow, the importance of mitigating towing noise will only increase, making this research area critical for future environmental management strategies.

One of the primary environmental impacts of towing noise is its effect on wildlife. Excessive noise from towing vehicles can disrupt animal communication, mating patterns, and migration routes. Studies have shown that prolonged exposure to traffic noise, including that from towing vehicles, can lead to reduced biodiversity in affected areas. Birds, in particular, are susceptible to noise pollution, with some species altering their song patterns or abandoning nesting sites in noisy environments.

In urban settings, towing noise contributes to the overall problem of noise pollution, which is increasingly recognized as a public health issue. Continuous exposure to high levels of noise can lead to stress, sleep disturbances, and cardiovascular problems in humans. The World Health Organization has identified traffic noise as a significant environmental stressor, with towing vehicles being a notable contributor, especially in areas with frequent heavy vehicle movement.

The impact of towing noise on air quality is another environmental concern. While noise itself does not directly affect air quality, the measures taken to reduce noise can have indirect effects. For instance, the use of noise barriers along highways to mitigate towing and traffic noise can alter air flow patterns, potentially leading to localized increases in air pollution concentration.

Furthermore, the environmental impact of towing noise extends to property values and land use planning. Areas affected by high levels of towing noise may see decreased property values, leading to changes in land use patterns and potentially contributing to urban sprawl as residents seek quieter environments.

The development of noise reduction technologies for pintle hitches and towing vehicles is crucial in mitigating these environmental impacts. Innovations in this field can lead to significant reductions in noise pollution, benefiting both urban and natural environments. Improved pintle hitch designs that minimize vibration and noise transmission can play a key role in creating more environmentally friendly transportation systems.

In conclusion, addressing the environmental impact of towing noise through research on pintle hitches and noise reduction technologies is essential for sustainable development and environmental protection. As urban areas continue to expand and transportation needs grow, the importance of mitigating towing noise will only increase, making this research area critical for future environmental management strategies.

Safety Considerations in Pintle Hitch Design

Safety considerations in pintle hitch design are paramount to ensure the secure coupling of trailers and towing vehicles. The primary focus is on preventing accidental disconnection, which could lead to catastrophic accidents on the road. Manufacturers must adhere to strict engineering standards and regulatory requirements to design pintle hitches that can withstand the dynamic forces encountered during towing operations.

One of the key safety features in modern pintle hitch designs is the incorporation of redundant locking mechanisms. These typically include a primary locking pin and a secondary safety latch or clip. The dual-locking system significantly reduces the risk of unintended decoupling, even under severe road conditions or sudden maneuvers.

Material selection plays a crucial role in the safety of pintle hitches. High-strength alloys are commonly used to ensure durability and resistance to wear, corrosion, and fatigue. The choice of materials must balance weight considerations with the need for robust performance, as excessive weight can negatively impact vehicle handling and fuel efficiency.

Proper load distribution is another critical safety aspect in pintle hitch design. Engineers must consider the vertical and horizontal forces exerted on the hitch during various driving scenarios. The hitch should be designed to maintain stability and minimize swaying or jackknifing, which can occur when the trailer's weight is not properly balanced.

Regular maintenance and inspection protocols are essential for ensuring the ongoing safety of pintle hitches. Designers must incorporate features that facilitate easy visual inspection of critical components, such as wear indicators or color-coded markings that signal when parts need replacement.

Ergonomics also play a role in pintle hitch safety. The design should allow for easy and secure coupling and uncoupling operations, reducing the risk of operator error or injury. This may include features like ergonomic handles, clear visual alignment guides, and audible locking indicators.

Advanced safety features in modern pintle hitch designs may include integrated sensors that monitor coupling status, load distribution, and potential wear. These systems can provide real-time feedback to the driver, alerting them to any safety concerns during operation.

Compatibility with a wide range of trailer types and sizes is another important safety consideration. Pintle hitches must be designed to accommodate various drawbar configurations while maintaining secure connections across different load capacities.

In conclusion, safety considerations in pintle hitch design encompass a wide range of factors, from material selection and structural integrity to user-friendly operation and advanced monitoring systems. As towing requirements evolve, ongoing research and development in this area will continue to enhance the safety and reliability of pintle hitch systems.

One of the key safety features in modern pintle hitch designs is the incorporation of redundant locking mechanisms. These typically include a primary locking pin and a secondary safety latch or clip. The dual-locking system significantly reduces the risk of unintended decoupling, even under severe road conditions or sudden maneuvers.

Material selection plays a crucial role in the safety of pintle hitches. High-strength alloys are commonly used to ensure durability and resistance to wear, corrosion, and fatigue. The choice of materials must balance weight considerations with the need for robust performance, as excessive weight can negatively impact vehicle handling and fuel efficiency.

Proper load distribution is another critical safety aspect in pintle hitch design. Engineers must consider the vertical and horizontal forces exerted on the hitch during various driving scenarios. The hitch should be designed to maintain stability and minimize swaying or jackknifing, which can occur when the trailer's weight is not properly balanced.

Regular maintenance and inspection protocols are essential for ensuring the ongoing safety of pintle hitches. Designers must incorporate features that facilitate easy visual inspection of critical components, such as wear indicators or color-coded markings that signal when parts need replacement.

Ergonomics also play a role in pintle hitch safety. The design should allow for easy and secure coupling and uncoupling operations, reducing the risk of operator error or injury. This may include features like ergonomic handles, clear visual alignment guides, and audible locking indicators.

Advanced safety features in modern pintle hitch designs may include integrated sensors that monitor coupling status, load distribution, and potential wear. These systems can provide real-time feedback to the driver, alerting them to any safety concerns during operation.

Compatibility with a wide range of trailer types and sizes is another important safety consideration. Pintle hitches must be designed to accommodate various drawbar configurations while maintaining secure connections across different load capacities.

In conclusion, safety considerations in pintle hitch design encompass a wide range of factors, from material selection and structural integrity to user-friendly operation and advanced monitoring systems. As towing requirements evolve, ongoing research and development in this area will continue to enhance the safety and reliability of pintle hitch systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!