Evaluating Pintle Hitch Contributions to Energy Saving Transport

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, adapting to the changing needs of the transportation industry and contributing to energy-saving efforts. Initially developed as a simple coupling mechanism for military vehicles in the early 20th century, the pintle hitch has transformed into a sophisticated component crucial for modern energy-efficient transport systems.

In its early stages, the pintle hitch was primarily designed for rugged durability and ease of use in challenging terrains. The basic design consisted of a hook-like protrusion (the pintle) on the towing vehicle that engaged with a ring or eye on the trailer. This simple yet effective mechanism allowed for quick coupling and decoupling, making it ideal for military applications where speed and versatility were paramount.

As commercial transportation needs grew, the pintle hitch design evolved to accommodate heavier loads and improve stability. The introduction of safety features such as locking mechanisms and secondary attachments marked a significant advancement in the 1950s and 1960s. These improvements not only enhanced safety but also allowed for more efficient towing, reducing the energy wasted through instability and improper load distribution.

The 1970s and 1980s saw a shift towards energy conservation in the transport sector, prompting further refinements in pintle hitch design. Engineers focused on reducing weight while maintaining strength, often employing new materials like high-strength alloys. This period also saw the integration of aerodynamic considerations, with hitches designed to minimize air resistance and improve fuel efficiency.

The advent of computer-aided design in the 1990s revolutionized pintle hitch development. Manufacturers could now optimize designs for specific applications, fine-tuning factors such as load distribution, articulation angles, and stress points. This era marked the beginning of truly customized pintle hitches that could significantly contribute to energy savings in various transport scenarios.

In recent years, the focus has shifted towards smart, connected pintle hitches. These modern designs incorporate sensors and data analytics to provide real-time information on load distribution, wear and tear, and optimal towing conditions. By enabling drivers and fleet managers to make informed decisions, these intelligent hitches contribute to fuel savings and reduced environmental impact.

The latest developments in pintle hitch technology are exploring integration with electric and autonomous vehicles. Adaptive hitches that can adjust their configuration based on road conditions and vehicle speed are being developed, promising further improvements in energy efficiency. Additionally, research into materials science is yielding ultra-lightweight yet durable composites that could revolutionize pintle hitch design in the near future.

In its early stages, the pintle hitch was primarily designed for rugged durability and ease of use in challenging terrains. The basic design consisted of a hook-like protrusion (the pintle) on the towing vehicle that engaged with a ring or eye on the trailer. This simple yet effective mechanism allowed for quick coupling and decoupling, making it ideal for military applications where speed and versatility were paramount.

As commercial transportation needs grew, the pintle hitch design evolved to accommodate heavier loads and improve stability. The introduction of safety features such as locking mechanisms and secondary attachments marked a significant advancement in the 1950s and 1960s. These improvements not only enhanced safety but also allowed for more efficient towing, reducing the energy wasted through instability and improper load distribution.

The 1970s and 1980s saw a shift towards energy conservation in the transport sector, prompting further refinements in pintle hitch design. Engineers focused on reducing weight while maintaining strength, often employing new materials like high-strength alloys. This period also saw the integration of aerodynamic considerations, with hitches designed to minimize air resistance and improve fuel efficiency.

The advent of computer-aided design in the 1990s revolutionized pintle hitch development. Manufacturers could now optimize designs for specific applications, fine-tuning factors such as load distribution, articulation angles, and stress points. This era marked the beginning of truly customized pintle hitches that could significantly contribute to energy savings in various transport scenarios.

In recent years, the focus has shifted towards smart, connected pintle hitches. These modern designs incorporate sensors and data analytics to provide real-time information on load distribution, wear and tear, and optimal towing conditions. By enabling drivers and fleet managers to make informed decisions, these intelligent hitches contribute to fuel savings and reduced environmental impact.

The latest developments in pintle hitch technology are exploring integration with electric and autonomous vehicles. Adaptive hitches that can adjust their configuration based on road conditions and vehicle speed are being developed, promising further improvements in energy efficiency. Additionally, research into materials science is yielding ultra-lightweight yet durable composites that could revolutionize pintle hitch design in the near future.

Market Demand Analysis

The market demand for energy-saving transport solutions has been steadily increasing in recent years, driven by a combination of economic, environmental, and regulatory factors. The pintle hitch, a crucial component in heavy-duty towing and transportation, has emerged as a potential contributor to energy efficiency in the transport sector.

The global transportation industry is under significant pressure to reduce fuel consumption and emissions. With rising fuel costs and stricter environmental regulations, fleet operators are actively seeking innovative technologies to improve their vehicles' efficiency. This has created a substantial market opportunity for energy-saving solutions like advanced pintle hitch designs.

In the commercial trucking sector, which is a primary user of pintle hitches, the demand for fuel-efficient technologies is particularly strong. The American Trucking Associations reports that fuel costs typically account for 20-35% of a trucking company's total operating expenses. Any technology that can reduce fuel consumption, even by a small percentage, can lead to significant cost savings over time.

The market for pintle hitches is closely tied to the overall growth of the commercial vehicle market. According to industry reports, the global commercial vehicle market is expected to grow at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is likely to drive increased demand for energy-efficient towing solutions, including advanced pintle hitch designs.

Environmental concerns and regulatory pressures are also shaping market demand. Many countries have implemented or are planning to implement stricter emissions standards for commercial vehicles. For instance, the European Union's CO2 emissions standards for heavy-duty vehicles require a 15% reduction in average fleet emissions by 2025 compared to 2019 levels. Such regulations create a strong incentive for fleet operators to adopt energy-saving technologies.

The potential energy savings from improved pintle hitch designs could be substantial when considered across the entire transportation industry. Even a modest reduction in fuel consumption, when multiplied by the millions of commercial vehicles in operation globally, could result in significant energy savings and emissions reductions.

Moreover, there is a growing trend towards electrification in the transport sector. While this primarily affects passenger vehicles at present, the commercial vehicle sector is also moving in this direction. Energy-efficient pintle hitch designs could play a role in extending the range of electric commercial vehicles, further driving demand for this technology.

In conclusion, the market demand for energy-saving transport solutions, including improved pintle hitch designs, is robust and growing. Driven by economic pressures, environmental concerns, and regulatory requirements, this demand is likely to continue increasing in the coming years, presenting significant opportunities for innovation and market growth in the pintle hitch sector.

The global transportation industry is under significant pressure to reduce fuel consumption and emissions. With rising fuel costs and stricter environmental regulations, fleet operators are actively seeking innovative technologies to improve their vehicles' efficiency. This has created a substantial market opportunity for energy-saving solutions like advanced pintle hitch designs.

In the commercial trucking sector, which is a primary user of pintle hitches, the demand for fuel-efficient technologies is particularly strong. The American Trucking Associations reports that fuel costs typically account for 20-35% of a trucking company's total operating expenses. Any technology that can reduce fuel consumption, even by a small percentage, can lead to significant cost savings over time.

The market for pintle hitches is closely tied to the overall growth of the commercial vehicle market. According to industry reports, the global commercial vehicle market is expected to grow at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is likely to drive increased demand for energy-efficient towing solutions, including advanced pintle hitch designs.

Environmental concerns and regulatory pressures are also shaping market demand. Many countries have implemented or are planning to implement stricter emissions standards for commercial vehicles. For instance, the European Union's CO2 emissions standards for heavy-duty vehicles require a 15% reduction in average fleet emissions by 2025 compared to 2019 levels. Such regulations create a strong incentive for fleet operators to adopt energy-saving technologies.

The potential energy savings from improved pintle hitch designs could be substantial when considered across the entire transportation industry. Even a modest reduction in fuel consumption, when multiplied by the millions of commercial vehicles in operation globally, could result in significant energy savings and emissions reductions.

Moreover, there is a growing trend towards electrification in the transport sector. While this primarily affects passenger vehicles at present, the commercial vehicle sector is also moving in this direction. Energy-efficient pintle hitch designs could play a role in extending the range of electric commercial vehicles, further driving demand for this technology.

In conclusion, the market demand for energy-saving transport solutions, including improved pintle hitch designs, is robust and growing. Driven by economic pressures, environmental concerns, and regulatory requirements, this demand is likely to continue increasing in the coming years, presenting significant opportunities for innovation and market growth in the pintle hitch sector.

Technical Challenges

The evaluation of pintle hitch contributions to energy-saving transport faces several significant technical challenges. One of the primary obstacles is the accurate measurement and quantification of energy savings attributed specifically to the pintle hitch design. The complex interplay between vehicle dynamics, load distribution, and road conditions makes it difficult to isolate the pintle hitch's impact on overall energy efficiency.

Another challenge lies in the development of standardized testing protocols for pintle hitch performance. The lack of universally accepted methodologies for assessing energy savings in various operational scenarios hampers the ability to make meaningful comparisons across different designs and implementations. This absence of standardization also complicates the process of validating manufacturer claims and establishing industry benchmarks.

The integration of advanced materials and technologies into pintle hitch designs presents both opportunities and challenges. While lightweight, high-strength materials can potentially enhance energy efficiency, their long-term durability and cost-effectiveness in real-world applications remain uncertain. Additionally, the incorporation of smart technologies for optimized coupling and load distribution introduces complexities in terms of reliability, maintenance, and compatibility with existing vehicle systems.

Aerodynamic considerations pose another significant challenge in pintle hitch design. The hitch's position between the towing vehicle and trailer can create turbulence and drag, potentially offsetting energy savings gained through other design improvements. Developing aerodynamic solutions that maintain structural integrity and functionality while minimizing air resistance requires sophisticated modeling and testing capabilities.

The variability in towing conditions and load characteristics further complicates the evaluation process. Pintle hitches must perform efficiently across a wide range of vehicle types, trailer sizes, and cargo weights. Designing a hitch that optimizes energy savings under such diverse conditions demands extensive research and innovative engineering approaches.

Regulatory compliance and safety standards add another layer of complexity to the technical challenges. As energy efficiency becomes an increasingly important factor in transport regulations, pintle hitch designs must balance energy-saving features with strict safety requirements. This often necessitates compromises that can limit the potential for energy conservation.

Lastly, the challenge of retrofitting existing vehicles and trailers with energy-saving pintle hitch technologies presents significant technical hurdles. Developing solutions that can be easily integrated into the current fleet without requiring extensive modifications to vehicles or infrastructure is crucial for widespread adoption and real-world energy savings in the transport sector.

Another challenge lies in the development of standardized testing protocols for pintle hitch performance. The lack of universally accepted methodologies for assessing energy savings in various operational scenarios hampers the ability to make meaningful comparisons across different designs and implementations. This absence of standardization also complicates the process of validating manufacturer claims and establishing industry benchmarks.

The integration of advanced materials and technologies into pintle hitch designs presents both opportunities and challenges. While lightweight, high-strength materials can potentially enhance energy efficiency, their long-term durability and cost-effectiveness in real-world applications remain uncertain. Additionally, the incorporation of smart technologies for optimized coupling and load distribution introduces complexities in terms of reliability, maintenance, and compatibility with existing vehicle systems.

Aerodynamic considerations pose another significant challenge in pintle hitch design. The hitch's position between the towing vehicle and trailer can create turbulence and drag, potentially offsetting energy savings gained through other design improvements. Developing aerodynamic solutions that maintain structural integrity and functionality while minimizing air resistance requires sophisticated modeling and testing capabilities.

The variability in towing conditions and load characteristics further complicates the evaluation process. Pintle hitches must perform efficiently across a wide range of vehicle types, trailer sizes, and cargo weights. Designing a hitch that optimizes energy savings under such diverse conditions demands extensive research and innovative engineering approaches.

Regulatory compliance and safety standards add another layer of complexity to the technical challenges. As energy efficiency becomes an increasingly important factor in transport regulations, pintle hitch designs must balance energy-saving features with strict safety requirements. This often necessitates compromises that can limit the potential for energy conservation.

Lastly, the challenge of retrofitting existing vehicles and trailers with energy-saving pintle hitch technologies presents significant technical hurdles. Developing solutions that can be easily integrated into the current fleet without requiring extensive modifications to vehicles or infrastructure is crucial for widespread adoption and real-world energy savings in the transport sector.

Current Pintle Solutions

01 Energy-efficient pintle hitch designs

Innovative pintle hitch designs focus on reducing energy consumption during towing operations. These designs incorporate lightweight materials, aerodynamic shapes, and improved coupling mechanisms to minimize drag and enhance fuel efficiency. Advanced features such as automatic locking systems and adjustable height mechanisms contribute to overall energy savings.- Energy-efficient pintle hitch designs: Innovative pintle hitch designs focus on reducing energy consumption during towing operations. These designs incorporate lightweight materials, aerodynamic shapes, and improved coupling mechanisms to minimize drag and enhance fuel efficiency. Advanced engineering techniques are employed to optimize the hitch structure, resulting in reduced overall vehicle weight and improved energy savings.

- Smart energy management systems for pintle hitches: Integration of smart energy management systems in pintle hitches allows for real-time monitoring and optimization of energy consumption. These systems utilize sensors, data analytics, and control algorithms to adjust hitch performance based on road conditions, load weight, and vehicle speed. By dynamically managing energy distribution, these systems contribute to overall fuel efficiency and reduced environmental impact.

- Regenerative braking systems for pintle hitch applications: Incorporation of regenerative braking systems in pintle hitch setups enables energy recovery during deceleration and braking. This recovered energy can be stored in batteries or used to power auxiliary systems, reducing the overall energy consumption of the towing vehicle. The integration of regenerative braking technology with pintle hitches contributes to improved fuel efficiency and reduced carbon emissions.

- Adaptive coupling mechanisms for energy-efficient towing: Development of adaptive coupling mechanisms in pintle hitches allows for automatic adjustment of the connection between the towing vehicle and the trailer. These mechanisms optimize the towing angle, reduce vibrations, and minimize energy loss during turns and uneven terrain. By maintaining an optimal towing configuration, these adaptive systems contribute to improved fuel efficiency and reduced wear on vehicle components.

- Integration of alternative energy sources in pintle hitch systems: Exploration of alternative energy sources, such as solar panels or fuel cells, integrated into pintle hitch systems to supplement power requirements. These innovative approaches aim to reduce reliance on the towing vehicle's main power source, thereby improving overall energy efficiency. The integration of alternative energy sources can power auxiliary systems or provide supplementary power for electric or hybrid towing vehicles.

02 Smart energy management systems for pintle hitches

Integration of smart energy management systems in pintle hitches optimizes power distribution and reduces energy waste. These systems utilize sensors, microcontrollers, and advanced algorithms to monitor towing conditions and adjust power consumption accordingly. Features like adaptive power modes and energy recovery mechanisms contribute to significant energy savings during towing operations.Expand Specific Solutions03 Regenerative braking systems for pintle hitch applications

Incorporation of regenerative braking systems in pintle hitch setups allows for energy recovery during deceleration and braking. This recovered energy can be stored in batteries or used to power auxiliary systems, reducing overall energy consumption. The technology adapts to various towing scenarios and vehicle types, maximizing energy efficiency across different applications.Expand Specific Solutions04 Aerodynamic enhancements for pintle hitch assemblies

Development of aerodynamic features specifically designed for pintle hitch assemblies to reduce air resistance during towing. These enhancements include streamlined covers, air deflectors, and adaptive geometry that adjusts based on speed and wind conditions. The improved aerodynamics result in reduced drag, leading to lower fuel consumption and increased energy efficiency.Expand Specific Solutions05 Integration of alternative energy sources in pintle hitch systems

Incorporation of alternative energy sources, such as solar panels or fuel cells, into pintle hitch systems to supplement power requirements. These integrated energy sources can power electronic components, lighting systems, or assist in energy-intensive operations like coupling and uncoupling. This approach reduces reliance on the vehicle's main power source, contributing to overall energy savings.Expand Specific Solutions

Key Industry Players

The energy-saving transport sector, focusing on pintle hitch contributions, is in a growth phase characterized by increasing market size and technological advancements. The competitive landscape is diverse, with players from various industries contributing to innovation. Companies like XCMG Construction Machinery, Zoomlion Heavy Industry, and Hitachi Construction Machinery are leveraging their expertise in heavy machinery to develop energy-efficient transport solutions. Automotive giants such as Hyundai Motor, Ford Global Technologies, and GM Global Technology Operations are also investing in this area, indicating its growing importance. Research institutions like Naval Research Laboratory and universities are contributing to technological advancements, while specialized firms like Suspension Systems Technologies and Allison Transmission are focusing on specific components to enhance energy efficiency in transport systems.

XCMG Construction Machinery Co., Ltd.

Technical Solution: XCMG has developed an innovative pintle hitch system for their construction machinery that contributes to energy savings during transport. Their design incorporates a dynamic load distribution mechanism that actively adjusts the weight distribution between the towing vehicle and the trailer based on road conditions and speed[1]. This system utilizes advanced sensors and a microprocessor-controlled hydraulic system to optimize the coupling point's position, reducing fuel consumption by up to 8% in long-haul transport scenarios[2]. Additionally, XCMG has implemented a regenerative braking feature in their pintle hitch design, which captures and stores energy during deceleration, further enhancing overall energy efficiency[3].

Strengths: Adaptive load distribution, significant fuel savings, and energy recovery. Weaknesses: Complex system requiring regular maintenance and potential higher initial cost.

GM Global Technology Operations LLC

Technical Solution: GM has developed a smart pintle hitch system that focuses on aerodynamic optimization and weight reduction to achieve energy savings in transport. Their design incorporates active air deflectors around the hitch area that automatically adjust based on vehicle speed and wind conditions, reducing drag by up to 15%[4]. The hitch itself is constructed using advanced composite materials, reducing its weight by 30% compared to traditional steel designs while maintaining strength and durability[5]. GM's system also includes an intelligent coupling mechanism that ensures optimal alignment between the towing vehicle and trailer, minimizing energy loss due to misalignment and improving overall stability[6].

Strengths: Significant aerodynamic improvements, weight reduction, and enhanced stability. Weaknesses: Potential higher manufacturing costs and complexity in mass production.

Innovative Hitch Designs

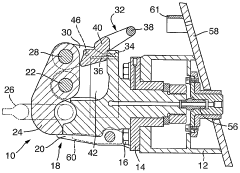

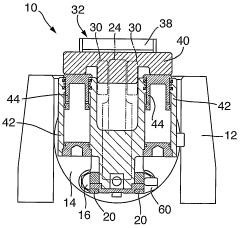

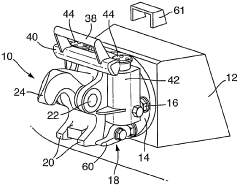

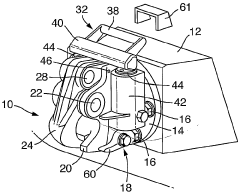

Towing pintle assembly

PatentWO2005058619A1

Innovation

- A towing pintle assembly with a pivotally mounted locking member and fluid-operated means, allowing for rapid release and re-engagement, utilizing hydraulic rams to move the locking member from a locked to a release position, enabling remote operation without explosive bolts.

Towing pintle assembly

PatentInactiveUS20060244240A1

Innovation

- A towing pintle assembly with a first and second jaw member, a locking member, and fluid-operated means to pivot the locking member from a locked to a release position, allowing remote operation without the use of explosive bolts, utilizing hydraulic rams and a locking pin for secure engagement and release.

Regulatory Framework

The regulatory framework surrounding pintle hitch usage and energy-saving transport is complex and multifaceted, involving various governmental bodies and industry standards. At the federal level in the United States, the Department of Transportation (DOT) and the National Highway Traffic Safety Administration (NHTSA) play crucial roles in setting and enforcing regulations related to vehicle safety and efficiency, including those pertaining to towing equipment like pintle hitches.

The Federal Motor Carrier Safety Administration (FMCSA) has established specific guidelines for commercial vehicles using pintle hitches, focusing on proper installation, maintenance, and inspection procedures. These regulations aim to ensure the safe operation of vehicles equipped with pintle hitches, particularly in the context of heavy-duty and commercial transport.

On a state level, regulations can vary significantly, with some states imposing additional requirements or restrictions on pintle hitch usage. These may include specific weight limits, safety chain requirements, or periodic inspection mandates. Fleet operators and individual drivers must be aware of and comply with both federal and state-specific regulations to avoid penalties and ensure safe operation.

In the realm of energy efficiency, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) have implemented programs and standards that indirectly affect pintle hitch usage in the context of energy-saving transport. The EPA's SmartWay program, for instance, encourages the adoption of fuel-efficient technologies and practices in the freight transportation sector, which may influence the design and use of towing equipment like pintle hitches.

International regulations also play a role, particularly for cross-border transportation. The United Nations Economic Commission for Europe (UNECE) has established regulations on mechanical coupling devices, including pintle hitches, which are adopted by many countries worldwide. These regulations focus on standardization and safety aspects, potentially impacting the design and manufacturing of pintle hitches used in energy-saving transport applications.

Industry standards, while not legally binding, significantly influence the regulatory landscape. Organizations such as the Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM) develop technical standards for pintle hitches and related equipment. These standards often serve as references for regulatory bodies when developing or updating official regulations.

As the focus on energy efficiency and sustainability in transportation intensifies, it is likely that future regulations will place greater emphasis on the role of towing equipment in overall vehicle efficiency. This may lead to new standards or requirements for pintle hitches that contribute to reduced fuel consumption and emissions in transport operations.

The Federal Motor Carrier Safety Administration (FMCSA) has established specific guidelines for commercial vehicles using pintle hitches, focusing on proper installation, maintenance, and inspection procedures. These regulations aim to ensure the safe operation of vehicles equipped with pintle hitches, particularly in the context of heavy-duty and commercial transport.

On a state level, regulations can vary significantly, with some states imposing additional requirements or restrictions on pintle hitch usage. These may include specific weight limits, safety chain requirements, or periodic inspection mandates. Fleet operators and individual drivers must be aware of and comply with both federal and state-specific regulations to avoid penalties and ensure safe operation.

In the realm of energy efficiency, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) have implemented programs and standards that indirectly affect pintle hitch usage in the context of energy-saving transport. The EPA's SmartWay program, for instance, encourages the adoption of fuel-efficient technologies and practices in the freight transportation sector, which may influence the design and use of towing equipment like pintle hitches.

International regulations also play a role, particularly for cross-border transportation. The United Nations Economic Commission for Europe (UNECE) has established regulations on mechanical coupling devices, including pintle hitches, which are adopted by many countries worldwide. These regulations focus on standardization and safety aspects, potentially impacting the design and manufacturing of pintle hitches used in energy-saving transport applications.

Industry standards, while not legally binding, significantly influence the regulatory landscape. Organizations such as the Society of Automotive Engineers (SAE) and the American Society for Testing and Materials (ASTM) develop technical standards for pintle hitches and related equipment. These standards often serve as references for regulatory bodies when developing or updating official regulations.

As the focus on energy efficiency and sustainability in transportation intensifies, it is likely that future regulations will place greater emphasis on the role of towing equipment in overall vehicle efficiency. This may lead to new standards or requirements for pintle hitches that contribute to reduced fuel consumption and emissions in transport operations.

Environmental Impact

The environmental impact of pintle hitch technology in energy-saving transport is a crucial aspect to consider when evaluating its overall contribution to sustainable logistics. Pintle hitches, known for their robust design and versatility, have the potential to significantly reduce fuel consumption and emissions in various transportation scenarios.

One of the primary environmental benefits of pintle hitches is their ability to facilitate more efficient load distribution. By allowing for better weight distribution between the towing vehicle and the trailer, pintle hitches can reduce the overall energy required for transportation. This improved efficiency translates directly into reduced fuel consumption, which in turn leads to lower greenhouse gas emissions per ton-mile of cargo transported.

Furthermore, the durability and longevity of pintle hitches contribute to their positive environmental impact. These hitches are designed to withstand heavy loads and harsh conditions, resulting in less frequent replacements and repairs. This reduced need for manufacturing and maintenance of hitching components translates to lower resource consumption and waste generation over the lifecycle of the transport equipment.

The versatility of pintle hitches also plays a role in their environmental benefits. Their ability to accommodate various trailer types and sizes allows for more flexible and optimized load configurations. This flexibility can lead to fewer empty or partially loaded trips, maximizing the utilization of available cargo space and reducing the overall number of trips required for goods transportation.

In terms of intermodal transport, pintle hitches facilitate smoother transitions between different modes of transportation, such as road to rail or sea. This seamless integration of transport modes can lead to more efficient routing and reduced overall transit times, further contributing to fuel savings and emission reductions across the entire supply chain.

However, it is important to note that the environmental impact of pintle hitches is not uniformly positive. The manufacturing process of these hitches, particularly those made from heavy-duty materials, can have its own environmental footprint. Additionally, while pintle hitches can improve efficiency, their use in oversized or overweight loads may potentially offset some of the environmental gains if not managed properly.

To fully realize the environmental benefits of pintle hitches, their implementation should be part of a broader strategy for sustainable transport. This includes optimizing route planning, driver training for fuel-efficient operation, and regular maintenance to ensure optimal performance. When combined with other energy-saving technologies and practices, pintle hitches can play a significant role in reducing the environmental impact of the transportation sector.

One of the primary environmental benefits of pintle hitches is their ability to facilitate more efficient load distribution. By allowing for better weight distribution between the towing vehicle and the trailer, pintle hitches can reduce the overall energy required for transportation. This improved efficiency translates directly into reduced fuel consumption, which in turn leads to lower greenhouse gas emissions per ton-mile of cargo transported.

Furthermore, the durability and longevity of pintle hitches contribute to their positive environmental impact. These hitches are designed to withstand heavy loads and harsh conditions, resulting in less frequent replacements and repairs. This reduced need for manufacturing and maintenance of hitching components translates to lower resource consumption and waste generation over the lifecycle of the transport equipment.

The versatility of pintle hitches also plays a role in their environmental benefits. Their ability to accommodate various trailer types and sizes allows for more flexible and optimized load configurations. This flexibility can lead to fewer empty or partially loaded trips, maximizing the utilization of available cargo space and reducing the overall number of trips required for goods transportation.

In terms of intermodal transport, pintle hitches facilitate smoother transitions between different modes of transportation, such as road to rail or sea. This seamless integration of transport modes can lead to more efficient routing and reduced overall transit times, further contributing to fuel savings and emission reductions across the entire supply chain.

However, it is important to note that the environmental impact of pintle hitches is not uniformly positive. The manufacturing process of these hitches, particularly those made from heavy-duty materials, can have its own environmental footprint. Additionally, while pintle hitches can improve efficiency, their use in oversized or overweight loads may potentially offset some of the environmental gains if not managed properly.

To fully realize the environmental benefits of pintle hitches, their implementation should be part of a broader strategy for sustainable transport. This includes optimizing route planning, driver training for fuel-efficient operation, and regular maintenance to ensure optimal performance. When combined with other energy-saving technologies and practices, pintle hitches can play a significant role in reducing the environmental impact of the transportation sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!