Pintle Hitch Integration Challenges in Small Vehicle Designs

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of the pintle hitch has been a significant journey in the realm of vehicle towing technology. Initially developed in the mid-20th century, the pintle hitch was primarily designed for heavy-duty military applications, offering a robust and versatile coupling system for towing large trailers and equipment. Its rugged construction and ability to handle severe articulation made it ideal for off-road and rough terrain use.

As civilian applications began to recognize the benefits of pintle hitches, adaptations were made to suit a wider range of vehicles and towing needs. The 1970s and 1980s saw the introduction of smaller, more refined pintle hitch designs that could be integrated into light commercial vehicles and even some larger passenger vehicles. This period marked a significant shift in the pintle hitch's evolution, as manufacturers sought to balance the strength and durability of the original military designs with the practicality required for everyday use.

The 1990s brought about further innovations in pintle hitch technology, with a focus on improving safety and ease of use. Automatic locking mechanisms were introduced, reducing the risk of accidental uncoupling during transit. Additionally, adjustable designs emerged, allowing for better compatibility with various trailer heights and improving overall towing stability.

In the early 2000s, the integration of pintle hitches into smaller vehicles became a growing trend. This shift presented new challenges, as designers had to contend with limited space and weight constraints while maintaining the hitch's core functionality. Advanced materials, such as high-strength alloys, were employed to reduce the overall weight of the hitch without compromising its load-bearing capacity.

Recent years have seen a focus on enhancing the aerodynamics of pintle hitch designs, particularly for small vehicle applications. Engineers have worked to create more streamlined profiles that minimize drag and improve fuel efficiency. This has led to the development of retractable and concealed pintle hitch systems, which can be tucked away when not in use, preserving the vehicle's aesthetics and aerodynamic properties.

The integration of smart technologies has been another notable trend in pintle hitch evolution. Modern designs often incorporate sensors and electronic systems that provide real-time feedback on hitch status, load distribution, and potential safety issues. This integration aligns with the broader trend of vehicle connectivity and aims to enhance overall towing safety and user experience.

As environmental concerns gain prominence, the latest developments in pintle hitch technology have also focused on sustainability. Manufacturers are exploring eco-friendly materials and production processes, as well as designs that contribute to overall vehicle efficiency when towing. These efforts reflect the industry's commitment to adapting traditional towing technologies to meet contemporary environmental standards and consumer expectations.

As civilian applications began to recognize the benefits of pintle hitches, adaptations were made to suit a wider range of vehicles and towing needs. The 1970s and 1980s saw the introduction of smaller, more refined pintle hitch designs that could be integrated into light commercial vehicles and even some larger passenger vehicles. This period marked a significant shift in the pintle hitch's evolution, as manufacturers sought to balance the strength and durability of the original military designs with the practicality required for everyday use.

The 1990s brought about further innovations in pintle hitch technology, with a focus on improving safety and ease of use. Automatic locking mechanisms were introduced, reducing the risk of accidental uncoupling during transit. Additionally, adjustable designs emerged, allowing for better compatibility with various trailer heights and improving overall towing stability.

In the early 2000s, the integration of pintle hitches into smaller vehicles became a growing trend. This shift presented new challenges, as designers had to contend with limited space and weight constraints while maintaining the hitch's core functionality. Advanced materials, such as high-strength alloys, were employed to reduce the overall weight of the hitch without compromising its load-bearing capacity.

Recent years have seen a focus on enhancing the aerodynamics of pintle hitch designs, particularly for small vehicle applications. Engineers have worked to create more streamlined profiles that minimize drag and improve fuel efficiency. This has led to the development of retractable and concealed pintle hitch systems, which can be tucked away when not in use, preserving the vehicle's aesthetics and aerodynamic properties.

The integration of smart technologies has been another notable trend in pintle hitch evolution. Modern designs often incorporate sensors and electronic systems that provide real-time feedback on hitch status, load distribution, and potential safety issues. This integration aligns with the broader trend of vehicle connectivity and aims to enhance overall towing safety and user experience.

As environmental concerns gain prominence, the latest developments in pintle hitch technology have also focused on sustainability. Manufacturers are exploring eco-friendly materials and production processes, as well as designs that contribute to overall vehicle efficiency when towing. These efforts reflect the industry's commitment to adapting traditional towing technologies to meet contemporary environmental standards and consumer expectations.

Market Demand Analysis

The market demand for pintle hitch integration in small vehicle designs has been steadily growing in recent years, driven by several key factors. Firstly, there's an increasing trend towards compact and versatile vehicles that can serve multiple purposes. Small vehicles equipped with pintle hitches offer enhanced towing capabilities without significantly compromising the vehicle's maneuverability or fuel efficiency. This versatility is particularly appealing to consumers who need occasional towing capacity but don't want to invest in larger, less fuel-efficient vehicles.

In the recreational sector, the rise of outdoor activities and adventure tourism has boosted the demand for small vehicles capable of towing lightweight trailers, boats, or camping equipment. The pintle hitch's robust design and ability to handle off-road conditions make it an attractive option for this market segment. Additionally, the growing popularity of tiny homes and mobile living solutions has created a niche market for small vehicles that can tow compact living spaces.

The commercial sector also shows significant potential for pintle hitch integration in small vehicles. Small businesses and service providers often require vehicles that can balance urban maneuverability with towing capacity. This is particularly relevant in industries such as landscaping, pest control, and mobile repair services, where equipment needs to be transported to various locations.

Urban development trends are another driving factor. As cities become more congested and parking spaces more limited, there's a growing preference for smaller vehicles. However, these vehicles still need to maintain functionality, including towing capabilities. Pintle hitch integration addresses this need, allowing small vehicles to remain practical in urban environments while retaining towing abilities.

The agricultural and construction sectors also contribute to the market demand, particularly in developing regions where smaller, more affordable vehicles with towing capabilities are preferred. These sectors often require vehicles that can navigate rough terrain while towing equipment or materials, making pintle hitch integration an attractive feature.

However, the market also faces challenges. The integration of pintle hitches into small vehicle designs presents engineering complexities, potentially increasing production costs. There's also a need for consumer education regarding the benefits and proper use of pintle hitches in small vehicles, as many are more familiar with traditional ball hitches.

Looking ahead, the market for pintle hitch integration in small vehicles is expected to continue growing. Advancements in materials science and engineering may lead to lighter, stronger hitch designs that are easier to integrate into smaller vehicles. Additionally, as electric vehicles gain market share, there may be new opportunities for innovative pintle hitch designs that complement the unique characteristics of electric powertrains.

In the recreational sector, the rise of outdoor activities and adventure tourism has boosted the demand for small vehicles capable of towing lightweight trailers, boats, or camping equipment. The pintle hitch's robust design and ability to handle off-road conditions make it an attractive option for this market segment. Additionally, the growing popularity of tiny homes and mobile living solutions has created a niche market for small vehicles that can tow compact living spaces.

The commercial sector also shows significant potential for pintle hitch integration in small vehicles. Small businesses and service providers often require vehicles that can balance urban maneuverability with towing capacity. This is particularly relevant in industries such as landscaping, pest control, and mobile repair services, where equipment needs to be transported to various locations.

Urban development trends are another driving factor. As cities become more congested and parking spaces more limited, there's a growing preference for smaller vehicles. However, these vehicles still need to maintain functionality, including towing capabilities. Pintle hitch integration addresses this need, allowing small vehicles to remain practical in urban environments while retaining towing abilities.

The agricultural and construction sectors also contribute to the market demand, particularly in developing regions where smaller, more affordable vehicles with towing capabilities are preferred. These sectors often require vehicles that can navigate rough terrain while towing equipment or materials, making pintle hitch integration an attractive feature.

However, the market also faces challenges. The integration of pintle hitches into small vehicle designs presents engineering complexities, potentially increasing production costs. There's also a need for consumer education regarding the benefits and proper use of pintle hitches in small vehicles, as many are more familiar with traditional ball hitches.

Looking ahead, the market for pintle hitch integration in small vehicles is expected to continue growing. Advancements in materials science and engineering may lead to lighter, stronger hitch designs that are easier to integrate into smaller vehicles. Additionally, as electric vehicles gain market share, there may be new opportunities for innovative pintle hitch designs that complement the unique characteristics of electric powertrains.

Technical Challenges

The integration of pintle hitches into small vehicle designs presents several significant technical challenges that require innovative solutions. One of the primary obstacles is the limited space available in compact vehicles, which constrains the placement and size of the hitch mechanism. This spatial restriction often leads to compromises in the hitch's strength and durability, potentially affecting its load-bearing capacity and overall performance.

Another critical challenge lies in maintaining the vehicle's structural integrity while incorporating the pintle hitch. The attachment point must be reinforced to withstand the substantial forces exerted during towing operations, which can be particularly demanding on smaller vehicles with lighter frames. This reinforcement needs to be achieved without significantly increasing the vehicle's weight or altering its center of gravity, both of which could negatively impact fuel efficiency and handling characteristics.

The integration of pintle hitches also raises concerns regarding safety and compliance with regulatory standards. Small vehicles must meet stringent safety requirements, and the addition of a towing mechanism introduces new variables that need to be carefully addressed. This includes ensuring proper load distribution, maintaining adequate braking performance, and implementing fail-safe mechanisms to prevent detachment during operation.

Furthermore, the electrical integration of the pintle hitch system poses its own set of challenges. Small vehicles often have limited electrical capacity, and the addition of trailer lighting and brake control systems can strain the existing electrical infrastructure. Engineers must devise efficient power management solutions and robust wiring systems that can withstand the rigors of towing without compromising other vehicle functions.

Aerodynamics and fuel efficiency are also significant considerations in small vehicle designs. The protrusion of a pintle hitch can disrupt airflow, potentially increasing drag and reducing fuel economy. Designers must find ways to minimize this impact, possibly through innovative hitch designs that can be partially or fully retracted when not in use.

Lastly, the challenge of user-friendliness and ease of operation cannot be overlooked. Small vehicle owners may not be as experienced with towing as drivers of larger vehicles, necessitating the development of intuitive and user-friendly hitch systems. This includes considerations for easy attachment and detachment, clear visual indicators for proper engagement, and potentially automated features to assist with alignment and coupling.

Another critical challenge lies in maintaining the vehicle's structural integrity while incorporating the pintle hitch. The attachment point must be reinforced to withstand the substantial forces exerted during towing operations, which can be particularly demanding on smaller vehicles with lighter frames. This reinforcement needs to be achieved without significantly increasing the vehicle's weight or altering its center of gravity, both of which could negatively impact fuel efficiency and handling characteristics.

The integration of pintle hitches also raises concerns regarding safety and compliance with regulatory standards. Small vehicles must meet stringent safety requirements, and the addition of a towing mechanism introduces new variables that need to be carefully addressed. This includes ensuring proper load distribution, maintaining adequate braking performance, and implementing fail-safe mechanisms to prevent detachment during operation.

Furthermore, the electrical integration of the pintle hitch system poses its own set of challenges. Small vehicles often have limited electrical capacity, and the addition of trailer lighting and brake control systems can strain the existing electrical infrastructure. Engineers must devise efficient power management solutions and robust wiring systems that can withstand the rigors of towing without compromising other vehicle functions.

Aerodynamics and fuel efficiency are also significant considerations in small vehicle designs. The protrusion of a pintle hitch can disrupt airflow, potentially increasing drag and reducing fuel economy. Designers must find ways to minimize this impact, possibly through innovative hitch designs that can be partially or fully retracted when not in use.

Lastly, the challenge of user-friendliness and ease of operation cannot be overlooked. Small vehicle owners may not be as experienced with towing as drivers of larger vehicles, necessitating the development of intuitive and user-friendly hitch systems. This includes considerations for easy attachment and detachment, clear visual indicators for proper engagement, and potentially automated features to assist with alignment and coupling.

Current Solutions

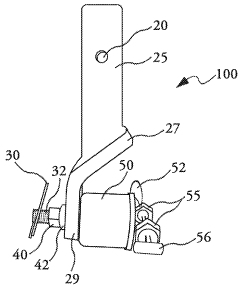

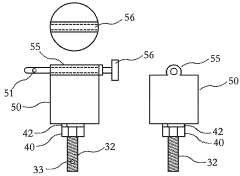

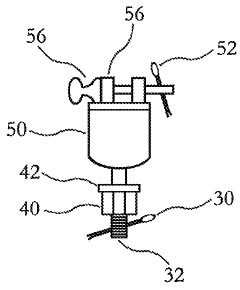

01 Pintle hitch design and structure

Various designs and structures of pintle hitches are presented, including improvements in the hitch mechanism, locking systems, and overall configuration to enhance safety and ease of use. These designs aim to provide secure coupling between vehicles and trailers while allowing for easy attachment and detachment.- Pintle hitch design and structure: Various designs and structures of pintle hitches are presented, focusing on improving the connection between the towing vehicle and the trailer. These designs aim to enhance stability, safety, and ease of use. Some innovations include adjustable components, locking mechanisms, and integrated safety features to prevent accidental disconnection during towing.

- Integration with vehicle frame: Methods for integrating pintle hitches with vehicle frames are explored. These approaches focus on secure attachment, load distribution, and compatibility with various vehicle types. Some designs incorporate reinforced mounting points, adjustable height mechanisms, and modular components to facilitate installation and customization for different vehicle models.

- Combination with other hitch types: Innovations in combining pintle hitches with other hitch types, such as ball hitches or gooseneck hitches, are presented. These hybrid designs aim to increase versatility and compatibility with various trailer types. Some solutions include interchangeable components, multi-functional hitch assemblies, and adaptable mounting systems to accommodate different towing needs.

- Safety and locking mechanisms: Advanced safety and locking mechanisms for pintle hitches are developed to prevent accidental disconnection and enhance overall towing security. These innovations include automatic locking systems, visual indicators for proper engagement, and fail-safe designs to ensure the hitch remains securely connected during transit. Some solutions also incorporate anti-theft features and electronic monitoring systems.

- Adjustability and adaptability: Designs focusing on the adjustability and adaptability of pintle hitches are presented. These innovations aim to accommodate various trailer heights, tongue weights, and towing conditions. Features include height-adjustable mounts, swivel mechanisms for improved maneuverability, and modular components that can be easily reconfigured or replaced to suit different towing requirements.

02 Integration with vehicle frame

Methods and systems for integrating pintle hitches with vehicle frames are discussed. This includes mounting techniques, reinforcement structures, and adaptations to different vehicle types. The integration aims to ensure a strong and stable connection between the hitch and the vehicle, improving overall towing performance and safety.Expand Specific Solutions03 Combination with other hitch types

Innovations in combining pintle hitches with other hitch types, such as ball hitches or gooseneck hitches, are presented. These combinations aim to increase versatility and compatibility with different trailer types, allowing for greater flexibility in towing applications.Expand Specific Solutions04 Security and locking mechanisms

Advanced security and locking mechanisms for pintle hitches are described, including anti-theft devices, improved latching systems, and fail-safe locking mechanisms. These innovations aim to enhance the safety and security of the hitch connection, preventing accidental disconnection and unauthorized use.Expand Specific Solutions05 Adjustable and multi-functional designs

Adjustable and multi-functional pintle hitch designs are presented, allowing for customization to different towing needs and vehicle configurations. These designs may include height-adjustable features, swivel mechanisms, or modular components that can be adapted to various towing situations.Expand Specific Solutions

Key Industry Players

The integration of pintle hitches in small vehicle designs presents a competitive landscape in a maturing industry. The market is experiencing moderate growth, driven by increasing demand for versatile towing solutions. While the technology is well-established, challenges persist in adapting it to compact vehicle platforms. Key players like WESTFALIA-Automotive GmbH and etrailer Corp. are leading innovation efforts, focusing on lightweight materials and compact designs. Companies such as Ford Global Technologies LLC and Honda Motor Co., Ltd. are exploring integration strategies to enhance small vehicle towing capabilities. The market is characterized by a mix of specialized hitch manufacturers and major automotive OEMs, indicating a growing recognition of pintle hitch potential in diverse vehicle segments.

WESTFALIA-Automotive GmbH

Technical Solution: WESTFALIA-Automotive GmbH has developed an innovative approach to integrating pintle hitches in small vehicle designs. Their solution involves a compact, retractable pintle hitch system that can be seamlessly integrated into the rear bumper of small vehicles. This design utilizes advanced materials such as high-strength steel and lightweight alloys to maintain structural integrity while minimizing weight impact. The system features a motorized deployment mechanism that allows the hitch to extend when needed and retract flush with the bumper when not in use, preserving the vehicle's aesthetics and aerodynamics[1]. Additionally, WESTFALIA has incorporated smart sensors and control systems to enhance safety, providing real-time feedback on hitch engagement and load distribution[2].

Strengths: Compact design suitable for small vehicles, preserves aesthetics when not in use, incorporates smart technology for enhanced safety. Weaknesses: Potentially higher cost due to complex mechanism, may require more maintenance than traditional fixed hitches.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has addressed the challenge of pintle hitch integration in small vehicles through a modular approach. Their system consists of a removable pintle hitch assembly that can be quickly installed and removed from a specially designed receiver integrated into the vehicle's frame. This solution utilizes advanced computer-aided design and finite element analysis to optimize the mounting points and load distribution, ensuring structural integrity without compromising the vehicle's overall design[3]. Ford has also developed a proprietary quick-connect system that allows for tool-free installation and removal, enhancing user convenience. To address weight concerns, the company has employed lightweight, high-strength materials such as aluminum alloys and advanced composites in the hitch assembly[4]. Furthermore, Ford has integrated their pintle hitch system with the vehicle's electronic stability control and trailer sway control systems to enhance towing safety in small vehicle applications[5].

Strengths: Modular design offers flexibility, optimized for small vehicle integration, enhanced safety features. Weaknesses: May require specific vehicle modifications for installation, potential for increased production costs.

Innovative Designs

Pintle hitch connector

PatentInactiveUS20180104998A1

Innovation

- A pintle hitch connector with a cylindrical trailer contact portion and a threaded portion featuring a locking mechanism and load securing pin, along with a universal connector design that includes a curved hitch bracket and connecting pin, simplifying attachment and reducing manufacturing costs.

Method of converting a trailer configuration

PatentInactiveUS8151426B2

Innovation

- A convertible trailer design featuring an adjustable neck with pivot and slide couplings that allows the trailer to be reconfigured between a pintle and a fifth-wheel configuration, enabling it to accommodate different hitch types by adjusting the position and securing the coupler support with pivot and slide locks.

Safety Regulations

Safety regulations play a crucial role in the integration of pintle hitches into small vehicle designs. These regulations are designed to ensure the safety of both the vehicle occupants and other road users. The primary focus of safety regulations in this context is on the structural integrity of the hitch, its attachment to the vehicle, and the overall impact on vehicle dynamics.

One of the key safety regulations pertains to the strength and durability of the pintle hitch itself. Manufacturers must adhere to strict standards regarding the materials used and the construction methods employed. These standards typically specify minimum load-bearing capacities and fatigue resistance requirements to ensure the hitch can withstand the stresses of towing under various conditions.

The attachment of the pintle hitch to the vehicle frame is another critical area addressed by safety regulations. Guidelines often dictate the number and type of mounting points, as well as the quality of fasteners used. This is to prevent the hitch from detaching from the vehicle during use, which could lead to catastrophic accidents.

Vehicle stability is a significant concern when integrating pintle hitches into small vehicle designs. Safety regulations often require manufacturers to conduct extensive testing to demonstrate that the addition of a pintle hitch does not adversely affect the vehicle's handling characteristics, braking performance, or overall stability. This may include specifying maximum tongue weights and trailer weights that can be safely towed.

Many safety regulations also address the electrical systems associated with pintle hitches. This includes requirements for proper wiring, lighting connections, and brake control interfaces. These systems are essential for ensuring that trailer lights and brakes function correctly, maintaining safety during towing operations.

Visibility is another aspect covered by safety regulations. The placement of the pintle hitch must not obstruct the driver's view or interfere with any existing safety features of the vehicle, such as backup cameras or proximity sensors. Additionally, regulations may specify requirements for the visibility of the hitch itself, particularly in low-light conditions.

Impact protection is an increasingly important area of focus in safety regulations for pintle hitch integration. This includes requirements for energy-absorbing designs that minimize damage to both vehicles in the event of a rear-end collision. Some regulations may also specify the need for quick-release mechanisms to allow for rapid decoupling in emergency situations.

Lastly, safety regulations often mandate clear labeling and user instructions. This includes visible markings on the hitch indicating its maximum capacities and proper usage guidelines. Manufacturers are typically required to provide comprehensive user manuals that detail proper installation, maintenance, and safe operation procedures for the pintle hitch system.

One of the key safety regulations pertains to the strength and durability of the pintle hitch itself. Manufacturers must adhere to strict standards regarding the materials used and the construction methods employed. These standards typically specify minimum load-bearing capacities and fatigue resistance requirements to ensure the hitch can withstand the stresses of towing under various conditions.

The attachment of the pintle hitch to the vehicle frame is another critical area addressed by safety regulations. Guidelines often dictate the number and type of mounting points, as well as the quality of fasteners used. This is to prevent the hitch from detaching from the vehicle during use, which could lead to catastrophic accidents.

Vehicle stability is a significant concern when integrating pintle hitches into small vehicle designs. Safety regulations often require manufacturers to conduct extensive testing to demonstrate that the addition of a pintle hitch does not adversely affect the vehicle's handling characteristics, braking performance, or overall stability. This may include specifying maximum tongue weights and trailer weights that can be safely towed.

Many safety regulations also address the electrical systems associated with pintle hitches. This includes requirements for proper wiring, lighting connections, and brake control interfaces. These systems are essential for ensuring that trailer lights and brakes function correctly, maintaining safety during towing operations.

Visibility is another aspect covered by safety regulations. The placement of the pintle hitch must not obstruct the driver's view or interfere with any existing safety features of the vehicle, such as backup cameras or proximity sensors. Additionally, regulations may specify requirements for the visibility of the hitch itself, particularly in low-light conditions.

Impact protection is an increasingly important area of focus in safety regulations for pintle hitch integration. This includes requirements for energy-absorbing designs that minimize damage to both vehicles in the event of a rear-end collision. Some regulations may also specify the need for quick-release mechanisms to allow for rapid decoupling in emergency situations.

Lastly, safety regulations often mandate clear labeling and user instructions. This includes visible markings on the hitch indicating its maximum capacities and proper usage guidelines. Manufacturers are typically required to provide comprehensive user manuals that detail proper installation, maintenance, and safe operation procedures for the pintle hitch system.

Weight Distribution

Weight distribution is a critical factor in the integration of pintle hitches into small vehicle designs. The addition of a pintle hitch to a compact vehicle can significantly alter its weight distribution, potentially affecting handling, stability, and overall performance. This challenge is particularly pronounced in smaller vehicles due to their limited size and weight capacity.

One of the primary concerns in weight distribution is the impact on the vehicle's center of gravity. The placement of a pintle hitch at the rear of a small vehicle can shift the center of gravity rearward, potentially leading to reduced front-wheel traction and compromised steering control. This shift can be exacerbated when towing, as the tongue weight of the trailer further increases the load on the rear axle.

To address these challenges, engineers must carefully consider the vehicle's suspension system. Modifications to the rear suspension, such as the addition of helper springs or air-assist systems, may be necessary to maintain proper ride height and load-bearing capacity. These adjustments help distribute the added weight more evenly across the vehicle's chassis, minimizing the impact on handling and stability.

Another crucial aspect of weight distribution is the impact on braking performance. The additional mass at the rear of the vehicle can alter the brake bias, potentially leading to longer stopping distances or increased risk of rear-wheel lockup during hard braking. To mitigate this, engineers may need to recalibrate the brake system or implement electronic brake force distribution systems to ensure optimal braking performance under various load conditions.

The integration of a pintle hitch also affects the vehicle's payload capacity. Small vehicles typically have limited payload capabilities, and the addition of a hitch and associated hardware can significantly reduce the available capacity for passengers and cargo. Engineers must carefully balance the desire for towing capability with the need to maintain adequate payload capacity for the vehicle's intended use.

To optimize weight distribution, designers may explore innovative materials and manufacturing techniques. The use of lightweight, high-strength materials for hitch components can help minimize the overall weight impact on the vehicle. Additionally, advanced computer-aided design and simulation tools can be employed to analyze and optimize the vehicle's weight distribution under various loading scenarios.

In conclusion, addressing weight distribution challenges in pintle hitch integration for small vehicles requires a multifaceted approach. Engineers must consider the impact on vehicle dynamics, suspension systems, braking performance, and payload capacity. By carefully balancing these factors and employing innovative design solutions, it is possible to successfully integrate pintle hitches into small vehicle designs while maintaining optimal performance and safety.

One of the primary concerns in weight distribution is the impact on the vehicle's center of gravity. The placement of a pintle hitch at the rear of a small vehicle can shift the center of gravity rearward, potentially leading to reduced front-wheel traction and compromised steering control. This shift can be exacerbated when towing, as the tongue weight of the trailer further increases the load on the rear axle.

To address these challenges, engineers must carefully consider the vehicle's suspension system. Modifications to the rear suspension, such as the addition of helper springs or air-assist systems, may be necessary to maintain proper ride height and load-bearing capacity. These adjustments help distribute the added weight more evenly across the vehicle's chassis, minimizing the impact on handling and stability.

Another crucial aspect of weight distribution is the impact on braking performance. The additional mass at the rear of the vehicle can alter the brake bias, potentially leading to longer stopping distances or increased risk of rear-wheel lockup during hard braking. To mitigate this, engineers may need to recalibrate the brake system or implement electronic brake force distribution systems to ensure optimal braking performance under various load conditions.

The integration of a pintle hitch also affects the vehicle's payload capacity. Small vehicles typically have limited payload capabilities, and the addition of a hitch and associated hardware can significantly reduce the available capacity for passengers and cargo. Engineers must carefully balance the desire for towing capability with the need to maintain adequate payload capacity for the vehicle's intended use.

To optimize weight distribution, designers may explore innovative materials and manufacturing techniques. The use of lightweight, high-strength materials for hitch components can help minimize the overall weight impact on the vehicle. Additionally, advanced computer-aided design and simulation tools can be employed to analyze and optimize the vehicle's weight distribution under various loading scenarios.

In conclusion, addressing weight distribution challenges in pintle hitch integration for small vehicles requires a multifaceted approach. Engineers must consider the impact on vehicle dynamics, suspension systems, braking performance, and payload capacity. By carefully balancing these factors and employing innovative design solutions, it is possible to successfully integrate pintle hitches into small vehicle designs while maintaining optimal performance and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!