Stress Analysis of Pintle Hitch under Dynamic Loads

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Stress Analysis Background and Objectives

The stress analysis of pintle hitches under dynamic loads has become increasingly important in the field of vehicle engineering and transportation safety. This technical research aims to comprehensively examine the historical development of pintle hitch technology, explore current trends in stress analysis methodologies, and establish clear objectives for advancing this critical area of study.

Pintle hitches, widely used in heavy-duty towing applications, have evolved significantly since their inception. Originally designed for military use, these robust coupling devices have found extensive applications in commercial and industrial sectors. The growing demand for higher towing capacities and improved safety standards has driven continuous innovation in pintle hitch design and analysis techniques.

The primary goal of this research is to enhance our understanding of the complex stress distributions within pintle hitches when subjected to dynamic loads. This involves investigating the interplay between various factors such as material properties, geometric configurations, and loading conditions. By gaining deeper insights into these stress patterns, we aim to develop more reliable and efficient pintle hitch designs that can withstand increasingly demanding operational environments.

Recent advancements in computational modeling and simulation techniques have opened new avenues for stress analysis in pintle hitches. The integration of finite element analysis (FEA) with dynamic load simulation has enabled researchers to predict stress concentrations and potential failure modes with unprecedented accuracy. This research seeks to leverage these cutting-edge tools to develop more sophisticated analytical models that can account for the complex, time-dependent nature of dynamic loads experienced by pintle hitches during real-world operations.

Another crucial aspect of this study is to address the growing need for standardization in pintle hitch stress analysis methodologies. As the global transportation industry continues to expand, there is an increasing demand for harmonized testing and certification procedures. This research aims to contribute to the development of comprehensive guidelines that can be adopted across different regions and industries, ensuring consistent safety standards and facilitating international trade.

Furthermore, this technical investigation will explore emerging trends in materials science and their potential applications in pintle hitch design. Advanced materials with superior strength-to-weight ratios and enhanced fatigue resistance properties offer promising opportunities for improving the performance and durability of pintle hitches. By examining these innovative materials within the context of stress analysis, we aim to identify novel design solutions that can significantly enhance the safety and reliability of towing systems.

In conclusion, this research endeavors to push the boundaries of pintle hitch stress analysis, combining historical insights with cutting-edge technologies to pave the way for next-generation towing solutions. By addressing current challenges and anticipating future needs, we strive to contribute valuable knowledge that will shape the future of vehicle coupling systems and transportation safety.

Pintle hitches, widely used in heavy-duty towing applications, have evolved significantly since their inception. Originally designed for military use, these robust coupling devices have found extensive applications in commercial and industrial sectors. The growing demand for higher towing capacities and improved safety standards has driven continuous innovation in pintle hitch design and analysis techniques.

The primary goal of this research is to enhance our understanding of the complex stress distributions within pintle hitches when subjected to dynamic loads. This involves investigating the interplay between various factors such as material properties, geometric configurations, and loading conditions. By gaining deeper insights into these stress patterns, we aim to develop more reliable and efficient pintle hitch designs that can withstand increasingly demanding operational environments.

Recent advancements in computational modeling and simulation techniques have opened new avenues for stress analysis in pintle hitches. The integration of finite element analysis (FEA) with dynamic load simulation has enabled researchers to predict stress concentrations and potential failure modes with unprecedented accuracy. This research seeks to leverage these cutting-edge tools to develop more sophisticated analytical models that can account for the complex, time-dependent nature of dynamic loads experienced by pintle hitches during real-world operations.

Another crucial aspect of this study is to address the growing need for standardization in pintle hitch stress analysis methodologies. As the global transportation industry continues to expand, there is an increasing demand for harmonized testing and certification procedures. This research aims to contribute to the development of comprehensive guidelines that can be adopted across different regions and industries, ensuring consistent safety standards and facilitating international trade.

Furthermore, this technical investigation will explore emerging trends in materials science and their potential applications in pintle hitch design. Advanced materials with superior strength-to-weight ratios and enhanced fatigue resistance properties offer promising opportunities for improving the performance and durability of pintle hitches. By examining these innovative materials within the context of stress analysis, we aim to identify novel design solutions that can significantly enhance the safety and reliability of towing systems.

In conclusion, this research endeavors to push the boundaries of pintle hitch stress analysis, combining historical insights with cutting-edge technologies to pave the way for next-generation towing solutions. By addressing current challenges and anticipating future needs, we strive to contribute valuable knowledge that will shape the future of vehicle coupling systems and transportation safety.

Market Demand for Robust Towing Solutions

The market demand for robust towing solutions has been steadily increasing in recent years, driven by various factors across multiple industries. The automotive sector, particularly the recreational vehicle (RV) and trailer market, has seen significant growth as more people embrace outdoor activities and road trips. This trend has been further accelerated by the global pandemic, which has led to a surge in domestic travel and camping.

In the commercial transportation industry, there is a growing need for reliable and durable towing solutions to support the increasing volume of goods being transported by road. The rise of e-commerce and just-in-time delivery systems has put additional pressure on logistics companies to ensure their towing equipment can withstand frequent use and heavy loads.

The agricultural sector also contributes to the demand for robust towing solutions. As farms become larger and more mechanized, there is a need for towing equipment that can handle heavy machinery and trailers across various terrains. This includes the ability to withstand dynamic loads encountered during field operations and transportation between sites.

The construction industry is another significant driver of demand for robust towing solutions. Large-scale projects often require the transportation of heavy equipment and materials, necessitating towing systems that can handle substantial loads while maintaining safety and stability under dynamic conditions.

Market research indicates that consumers and businesses are increasingly prioritizing safety features and durability when selecting towing equipment. This has led to a growing interest in advanced towing solutions that incorporate stress analysis and dynamic load management capabilities. Manufacturers are responding to this demand by developing pintle hitches and other towing components that offer improved performance under varying load conditions.

The global market for towing equipment, including pintle hitches, is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of heavy-duty vehicles, the expansion of the logistics sector, and the rising popularity of recreational towing activities.

As environmental concerns gain prominence, there is also a growing demand for towing solutions that contribute to improved fuel efficiency and reduced emissions. This has led to the development of lightweight yet strong materials for towing components, as well as aerodynamic designs that minimize drag during towing operations.

In conclusion, the market demand for robust towing solutions, particularly those that can withstand dynamic loads, is strong and diverse. Industries ranging from automotive to agriculture are seeking advanced towing technologies that offer enhanced safety, durability, and performance. This demand is driving innovation in stress analysis and materials science, pushing manufacturers to develop more sophisticated and reliable towing systems.

In the commercial transportation industry, there is a growing need for reliable and durable towing solutions to support the increasing volume of goods being transported by road. The rise of e-commerce and just-in-time delivery systems has put additional pressure on logistics companies to ensure their towing equipment can withstand frequent use and heavy loads.

The agricultural sector also contributes to the demand for robust towing solutions. As farms become larger and more mechanized, there is a need for towing equipment that can handle heavy machinery and trailers across various terrains. This includes the ability to withstand dynamic loads encountered during field operations and transportation between sites.

The construction industry is another significant driver of demand for robust towing solutions. Large-scale projects often require the transportation of heavy equipment and materials, necessitating towing systems that can handle substantial loads while maintaining safety and stability under dynamic conditions.

Market research indicates that consumers and businesses are increasingly prioritizing safety features and durability when selecting towing equipment. This has led to a growing interest in advanced towing solutions that incorporate stress analysis and dynamic load management capabilities. Manufacturers are responding to this demand by developing pintle hitches and other towing components that offer improved performance under varying load conditions.

The global market for towing equipment, including pintle hitches, is projected to expand at a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the increasing adoption of heavy-duty vehicles, the expansion of the logistics sector, and the rising popularity of recreational towing activities.

As environmental concerns gain prominence, there is also a growing demand for towing solutions that contribute to improved fuel efficiency and reduced emissions. This has led to the development of lightweight yet strong materials for towing components, as well as aerodynamic designs that minimize drag during towing operations.

In conclusion, the market demand for robust towing solutions, particularly those that can withstand dynamic loads, is strong and diverse. Industries ranging from automotive to agriculture are seeking advanced towing technologies that offer enhanced safety, durability, and performance. This demand is driving innovation in stress analysis and materials science, pushing manufacturers to develop more sophisticated and reliable towing systems.

Current Challenges in Dynamic Load Stress Analysis

The dynamic load stress analysis of pintle hitches presents several significant challenges in the current technological landscape. One of the primary difficulties lies in accurately modeling the complex and variable nature of dynamic loads. Unlike static loads, dynamic loads fluctuate over time, making it challenging to capture the full spectrum of stress distributions and potential failure modes.

The non-linear behavior of materials under dynamic loading conditions further complicates the analysis. Traditional linear elastic models often fall short in predicting material responses to rapid load changes, necessitating more sophisticated constitutive models that can account for strain rate effects, plasticity, and material fatigue.

Another critical challenge is the accurate representation of boundary conditions and contact interfaces. Pintle hitches involve multiple components interacting under dynamic loads, and modeling these interactions, including friction and potential separation, requires advanced numerical techniques and significant computational resources.

The variability in loading scenarios poses yet another hurdle. Pintle hitches may experience a wide range of load conditions depending on factors such as vehicle speed, road conditions, and towing weight. Developing a comprehensive analysis that covers all possible scenarios while maintaining computational efficiency is a formidable task.

Furthermore, the integration of experimental validation with numerical simulations remains a challenge. While computational methods have advanced significantly, validating these models against real-world dynamic load conditions is crucial but often difficult to achieve due to the complexity of setting up representative experimental setups.

The multi-scale nature of stress analysis in pintle hitches also presents challenges. Stress concentrations at critical points may require very fine mesh resolutions, while the overall structure needs to be analyzed at a larger scale. Balancing these conflicting requirements while maintaining accuracy and computational efficiency is an ongoing challenge.

Lastly, the consideration of fatigue and wear under dynamic loading conditions adds another layer of complexity. Predicting the long-term performance and durability of pintle hitches requires sophisticated fatigue analysis methods that can account for variable amplitude loading and potential environmental factors.

Addressing these challenges requires a multidisciplinary approach, combining advanced numerical methods, material science, experimental techniques, and engineering expertise. As the demand for more robust and efficient pintle hitch designs grows, overcoming these obstacles in dynamic load stress analysis becomes increasingly critical for ensuring the safety and reliability of towing systems.

The non-linear behavior of materials under dynamic loading conditions further complicates the analysis. Traditional linear elastic models often fall short in predicting material responses to rapid load changes, necessitating more sophisticated constitutive models that can account for strain rate effects, plasticity, and material fatigue.

Another critical challenge is the accurate representation of boundary conditions and contact interfaces. Pintle hitches involve multiple components interacting under dynamic loads, and modeling these interactions, including friction and potential separation, requires advanced numerical techniques and significant computational resources.

The variability in loading scenarios poses yet another hurdle. Pintle hitches may experience a wide range of load conditions depending on factors such as vehicle speed, road conditions, and towing weight. Developing a comprehensive analysis that covers all possible scenarios while maintaining computational efficiency is a formidable task.

Furthermore, the integration of experimental validation with numerical simulations remains a challenge. While computational methods have advanced significantly, validating these models against real-world dynamic load conditions is crucial but often difficult to achieve due to the complexity of setting up representative experimental setups.

The multi-scale nature of stress analysis in pintle hitches also presents challenges. Stress concentrations at critical points may require very fine mesh resolutions, while the overall structure needs to be analyzed at a larger scale. Balancing these conflicting requirements while maintaining accuracy and computational efficiency is an ongoing challenge.

Lastly, the consideration of fatigue and wear under dynamic loading conditions adds another layer of complexity. Predicting the long-term performance and durability of pintle hitches requires sophisticated fatigue analysis methods that can account for variable amplitude loading and potential environmental factors.

Addressing these challenges requires a multidisciplinary approach, combining advanced numerical methods, material science, experimental techniques, and engineering expertise. As the demand for more robust and efficient pintle hitch designs grows, overcoming these obstacles in dynamic load stress analysis becomes increasingly critical for ensuring the safety and reliability of towing systems.

Existing Methodologies for Dynamic Stress Analysis

01 Stress reduction through design modifications

Various design modifications can be implemented to reduce stress on pintle hitches. These include reinforced structures, improved load distribution mechanisms, and optimized geometries that minimize stress concentrations. Such modifications aim to enhance the overall durability and performance of the hitch under different loading conditions.- Stress reduction through design modifications: Various design modifications can be implemented to reduce stress on pintle hitches. These include reinforced structures, improved weight distribution mechanisms, and optimized geometries that minimize stress concentrations. Such modifications aim to enhance the overall durability and performance of the hitch under different load conditions.

- Use of advanced materials for stress mitigation: Incorporating advanced materials in pintle hitch construction can significantly reduce stress. High-strength alloys, composite materials, and specialized coatings can be utilized to improve the hitch's resistance to wear, corrosion, and fatigue. These materials can enhance the hitch's load-bearing capacity while minimizing weight.

- Stress analysis and simulation techniques: Advanced stress analysis and simulation techniques are employed to optimize pintle hitch designs. Finite element analysis (FEA) and computer-aided engineering (CAE) tools are used to identify high-stress areas and evaluate the hitch's performance under various loading conditions. These methods help in developing more robust and efficient hitch designs.

- Innovative locking mechanisms for stress reduction: Novel locking mechanisms are developed to distribute stress more evenly across the pintle hitch assembly. These mechanisms can include advanced latching systems, adjustable components, and self-aligning features that minimize play and reduce stress concentrations during operation.

- Integration of shock-absorbing elements: Incorporating shock-absorbing elements into pintle hitch designs can significantly reduce stress caused by dynamic loads. These elements may include elastomeric materials, hydraulic or pneumatic dampers, or specially designed spring systems that absorb and dissipate energy from sudden movements or impacts.

02 Material selection for stress resistance

The choice of materials plays a crucial role in managing stress on pintle hitches. High-strength alloys, composite materials, or specially treated metals can be used to improve the hitch's ability to withstand stress and fatigue. These materials offer enhanced mechanical properties that contribute to the longevity and reliability of the hitch assembly.Expand Specific Solutions03 Stress analysis and testing methods

Advanced stress analysis techniques and rigorous testing methods are employed to evaluate and improve pintle hitch designs. These may include finite element analysis, strain gauge measurements, and accelerated life cycle testing. Such approaches help identify potential stress points and validate the effectiveness of stress reduction strategies.Expand Specific Solutions04 Adaptive and adjustable hitch mechanisms

Innovative pintle hitch designs incorporate adaptive or adjustable mechanisms that can respond to varying stress conditions. These may include shock-absorbing elements, self-aligning features, or load-sensing systems that automatically adjust the hitch configuration to minimize stress during operation.Expand Specific Solutions05 Integration of stress monitoring systems

Advanced pintle hitch designs may incorporate built-in stress monitoring systems. These can include sensors, data logging capabilities, and real-time feedback mechanisms that alert users to excessive stress conditions. Such systems enable proactive maintenance and help prevent stress-related failures during use.Expand Specific Solutions

Key Players in Towing Equipment Industry

The stress analysis of pintle hitches under dynamic loads is a critical area in the construction and automotive industries, currently in a mature development stage. The market for this technology is substantial, driven by the growing demand for heavy machinery and towing equipment. Companies like Zoomlion, XCMG, and NOV are at the forefront, leveraging their expertise in construction machinery and oil and gas equipment. The technology's maturity is evident in the involvement of academic institutions such as Wroclaw University of Science and Technology and Southeast University, indicating a strong foundation in research and development. However, there's still room for innovation, particularly in improving durability and efficiency under extreme dynamic loads.

Curt Manufacturing LLC

Technical Solution: Curt Manufacturing LLC has developed an advanced dynamic load analysis system for pintle hitches. Their approach utilizes finite element analysis (FEA) combined with real-time sensor data to accurately model stress distribution under various dynamic load conditions. The system incorporates a network of strain gauges strategically placed on critical points of the hitch structure, providing continuous feedback on stress levels[1]. This data is then processed through a proprietary algorithm that accounts for factors such as vehicle speed, road conditions, and cargo weight distribution. The result is a comprehensive stress map that allows for predictive maintenance and design optimization[3]. Additionally, Curt has implemented a novel material composition for their pintle hitches, featuring a high-strength steel alloy with improved fatigue resistance, enhancing the overall durability and lifespan of the hitch under repeated dynamic loads[5].

Strengths: Highly accurate real-time stress analysis, predictive maintenance capabilities, and improved material composition for enhanced durability. Weaknesses: Potentially higher cost due to advanced sensors and materials, may require more frequent calibration for optimal performance.

Deere & Co.

Technical Solution: Deere & Co. has pioneered a sophisticated approach to stress analysis of pintle hitches under dynamic loads, particularly for agricultural and construction equipment. Their method combines multi-body dynamics simulation with advanced finite element analysis to create a holistic model of the hitch-vehicle system[2]. This approach accounts for the complex interactions between the hitch, the towing vehicle, and the towed implement or trailer. Deere's system utilizes a network of accelerometers and load cells to capture real-world data, which is then fed into their proprietary simulation software. This software employs machine learning algorithms to continuously refine the stress prediction models based on accumulated data from various operating conditions[4]. Furthermore, Deere has developed a unique damping system integrated into their pintle hitch design, which actively mitigates stress peaks during sudden load changes, such as those experienced during rapid acceleration or braking[6].

Strengths: Comprehensive system-level analysis, adaptive modeling through machine learning, and active stress mitigation. Weaknesses: Complexity may lead to higher implementation costs, potential over-reliance on software predictions without sufficient physical validation.

Core Innovations in Pintle Hitch Stress Modeling

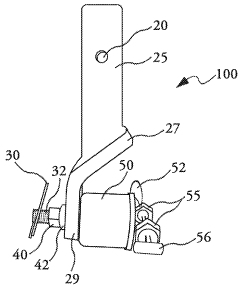

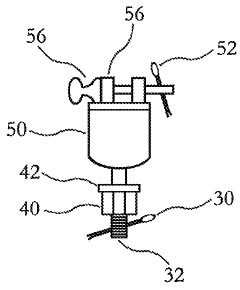

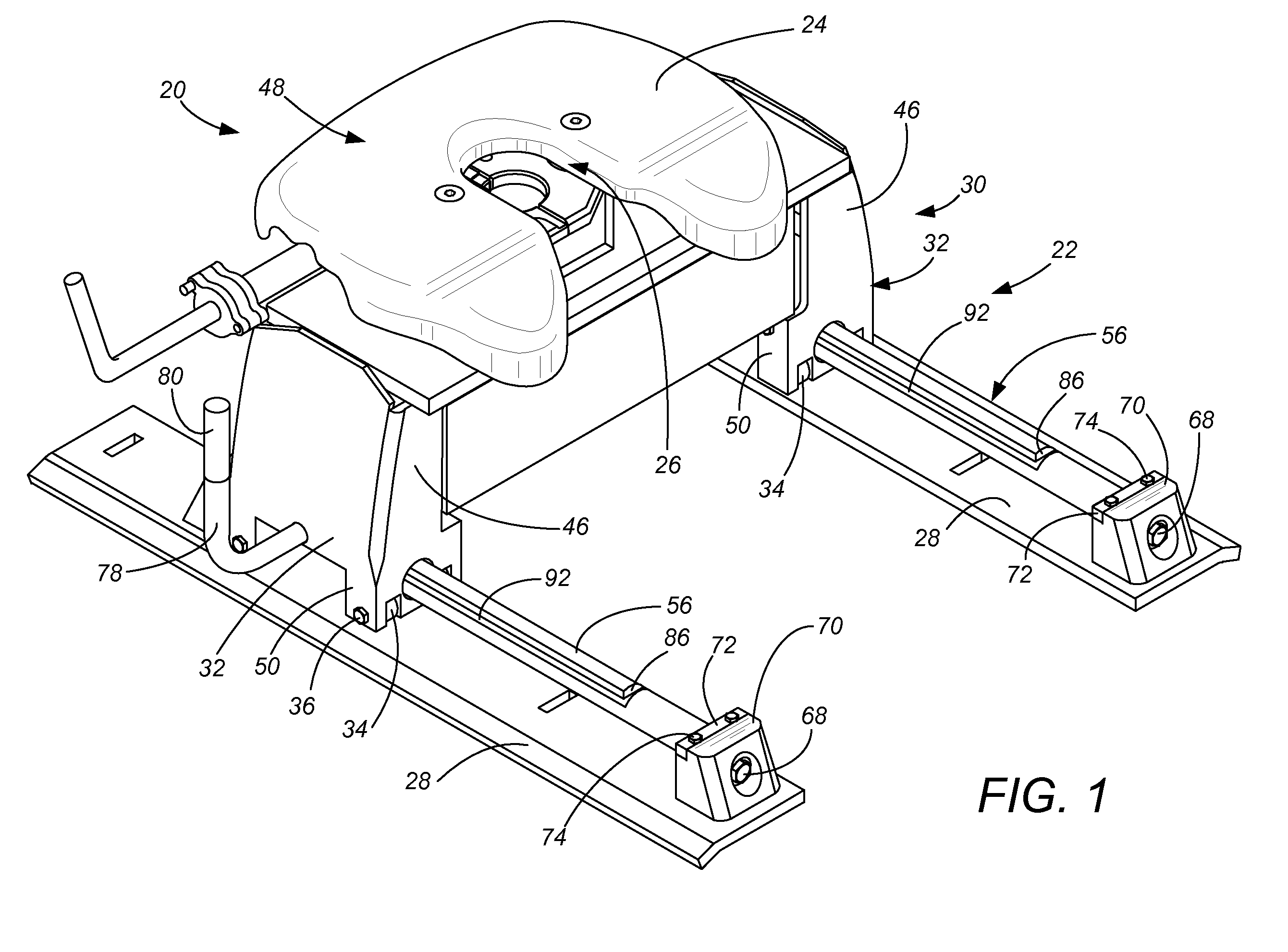

Pintle hitch connector

PatentInactiveUS20180104998A1

Innovation

- A pintle hitch connector with a cylindrical trailer contact portion and a threaded portion featuring a locking mechanism and load securing pin, along with a universal connector design that includes a curved hitch bracket and connecting pin, simplifying attachment and reducing manufacturing costs.

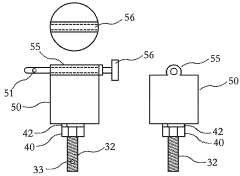

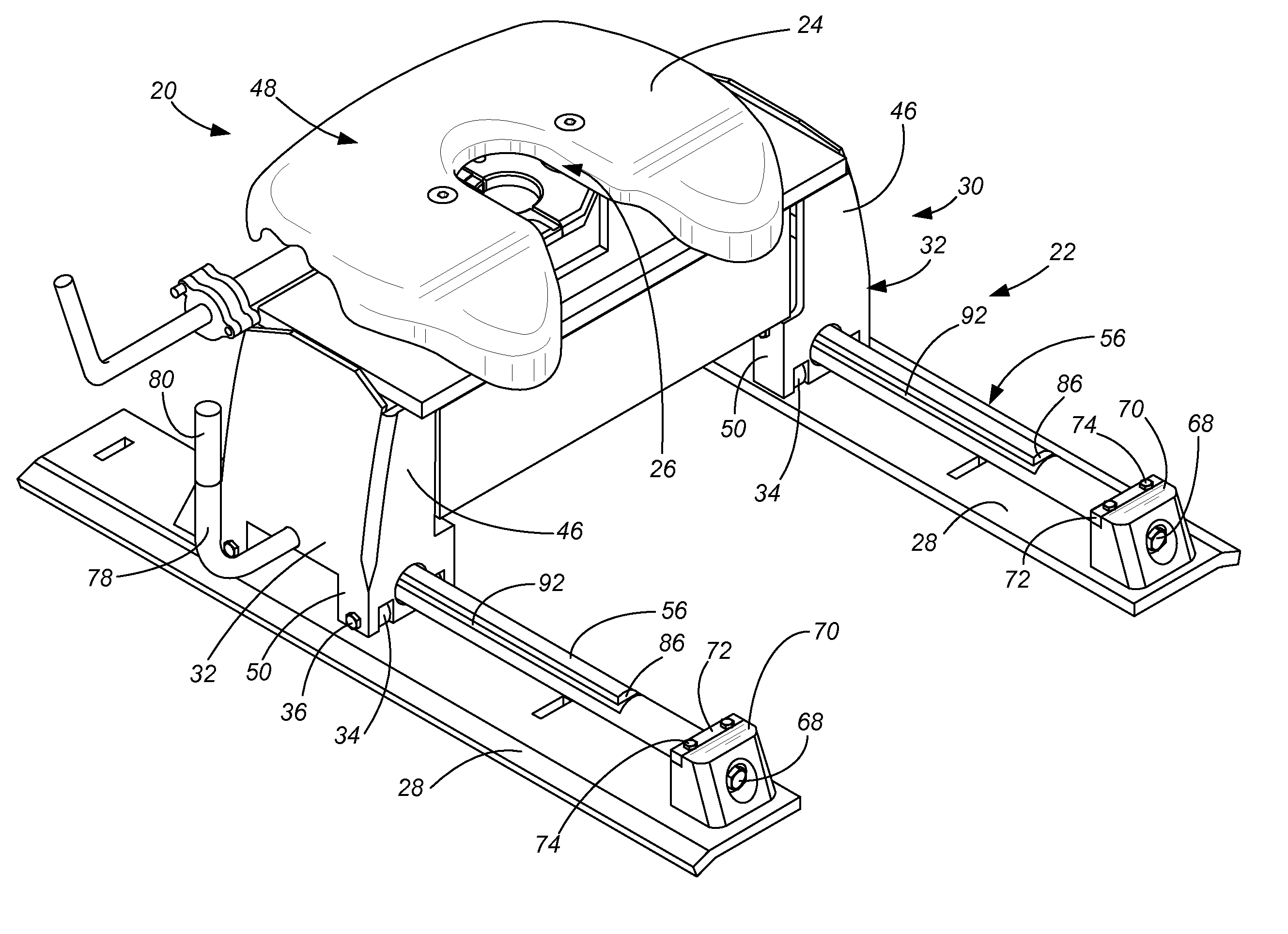

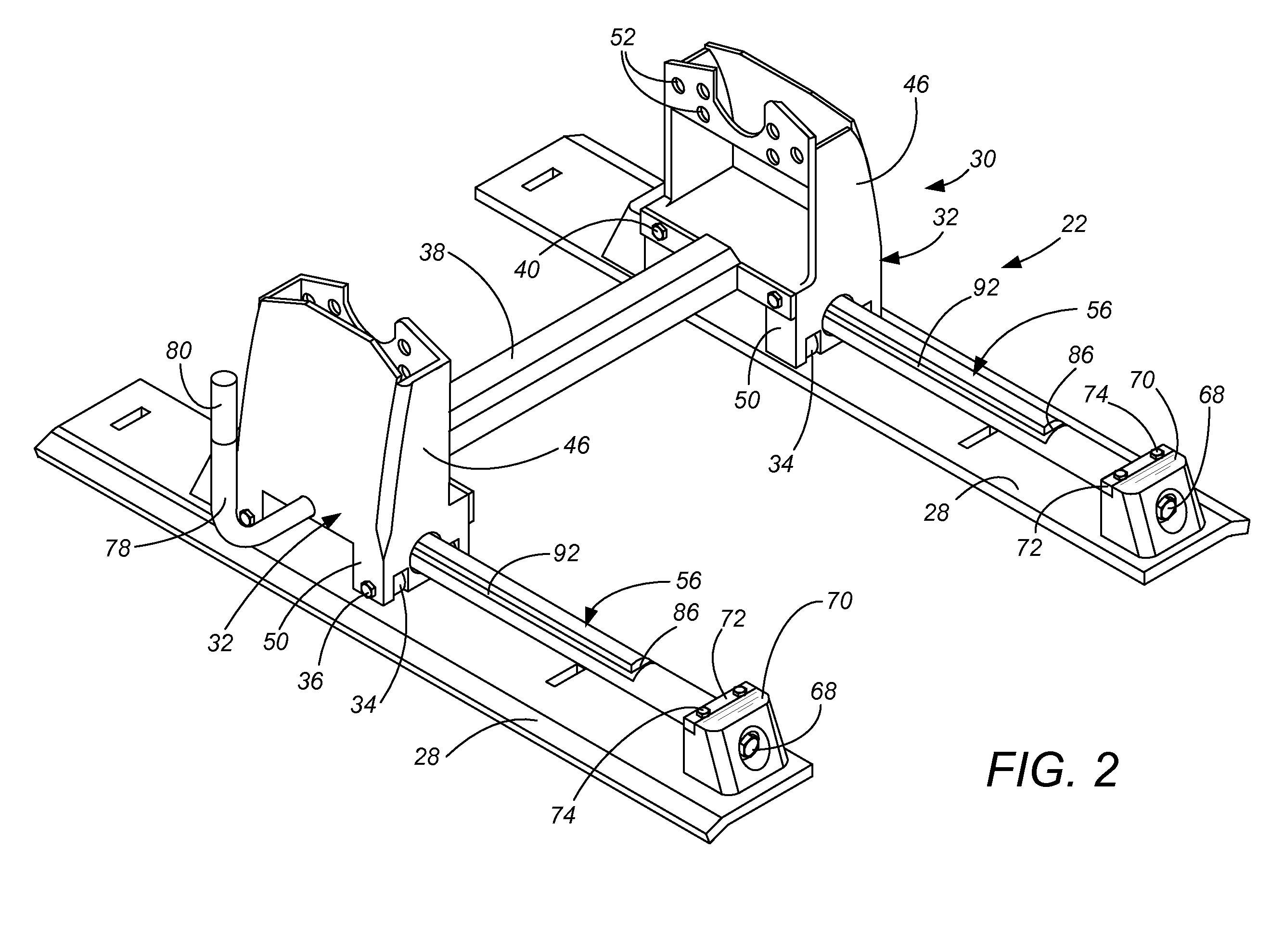

Moveable hitch with stress-free elevated bearing guide

PatentActiveUS7584982B2

Innovation

- A hitch design featuring a bearing guide with elevated guides and a locking key system that allows for lateral movement of the hitching point, utilizing rollers for smooth fore-and-aft repositioning and a locking mechanism that minimizes bending moments during braking and maneuvering, ensuring easy operation and durability.

Material Advancements for Pintle Hitch Durability

Material advancements play a crucial role in enhancing the durability and performance of pintle hitches under dynamic loads. Recent developments in metallurgy and composite materials have opened new avenues for improving the strength-to-weight ratio, corrosion resistance, and fatigue life of these critical components.

High-strength steels, such as ASTM A514 and HY-80, have gained popularity in pintle hitch manufacturing due to their superior tensile strength and yield strength compared to traditional carbon steels. These alloys offer improved resistance to deformation under high stress conditions, making them ideal for applications involving heavy loads and frequent coupling-uncoupling cycles.

Aluminum alloys, particularly the 7000 series, have emerged as viable alternatives for certain pintle hitch components. Their lightweight nature contributes to overall vehicle efficiency while maintaining adequate strength. However, careful consideration must be given to their lower fatigue resistance compared to steel, necessitating innovative design approaches to mitigate stress concentrations.

Advanced surface treatments and coatings have significantly enhanced the corrosion resistance of pintle hitches. Techniques such as plasma nitriding and physical vapor deposition (PVD) coatings have shown promising results in improving wear resistance and extending the service life of critical surfaces subjected to repeated contact and environmental exposure.

Composite materials, including carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), are being explored for non-load-bearing components of pintle hitches. These materials offer excellent strength-to-weight ratios and corrosion resistance, potentially reducing overall weight and maintenance requirements.

Nanotechnology-enhanced materials are at the forefront of pintle hitch material research. Nanoparticle reinforcement in metal matrices has demonstrated potential for improving mechanical properties without significant weight penalties. For instance, carbon nanotube-reinforced aluminum composites have shown enhanced strength and stiffness compared to conventional aluminum alloys.

Smart materials, such as shape memory alloys and piezoelectric materials, are being investigated for their potential in active stress management and real-time monitoring of pintle hitch conditions. These materials could enable adaptive responses to varying load conditions and provide valuable data for predictive maintenance strategies.

As research in material science continues to advance, the integration of these novel materials and treatments into pintle hitch design promises to significantly enhance their durability, safety, and performance under dynamic load conditions. However, careful consideration must be given to factors such as cost-effectiveness, manufacturability, and long-term reliability before widespread adoption in commercial applications.

High-strength steels, such as ASTM A514 and HY-80, have gained popularity in pintle hitch manufacturing due to their superior tensile strength and yield strength compared to traditional carbon steels. These alloys offer improved resistance to deformation under high stress conditions, making them ideal for applications involving heavy loads and frequent coupling-uncoupling cycles.

Aluminum alloys, particularly the 7000 series, have emerged as viable alternatives for certain pintle hitch components. Their lightweight nature contributes to overall vehicle efficiency while maintaining adequate strength. However, careful consideration must be given to their lower fatigue resistance compared to steel, necessitating innovative design approaches to mitigate stress concentrations.

Advanced surface treatments and coatings have significantly enhanced the corrosion resistance of pintle hitches. Techniques such as plasma nitriding and physical vapor deposition (PVD) coatings have shown promising results in improving wear resistance and extending the service life of critical surfaces subjected to repeated contact and environmental exposure.

Composite materials, including carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), are being explored for non-load-bearing components of pintle hitches. These materials offer excellent strength-to-weight ratios and corrosion resistance, potentially reducing overall weight and maintenance requirements.

Nanotechnology-enhanced materials are at the forefront of pintle hitch material research. Nanoparticle reinforcement in metal matrices has demonstrated potential for improving mechanical properties without significant weight penalties. For instance, carbon nanotube-reinforced aluminum composites have shown enhanced strength and stiffness compared to conventional aluminum alloys.

Smart materials, such as shape memory alloys and piezoelectric materials, are being investigated for their potential in active stress management and real-time monitoring of pintle hitch conditions. These materials could enable adaptive responses to varying load conditions and provide valuable data for predictive maintenance strategies.

As research in material science continues to advance, the integration of these novel materials and treatments into pintle hitch design promises to significantly enhance their durability, safety, and performance under dynamic load conditions. However, careful consideration must be given to factors such as cost-effectiveness, manufacturability, and long-term reliability before widespread adoption in commercial applications.

Safety Standards and Regulations for Towing Equipment

Safety standards and regulations for towing equipment play a crucial role in ensuring the safe operation of pintle hitches under dynamic loads. These standards are established by various regulatory bodies and industry organizations to minimize risks associated with towing operations.

The National Highway Traffic Safety Administration (NHTSA) in the United States sets federal motor vehicle safety standards that apply to towing equipment. These standards cover aspects such as strength requirements, durability testing, and performance criteria for pintle hitches and other towing components. The Society of Automotive Engineers (SAE) also provides industry standards and recommended practices for towing equipment, including specifications for pintle hitches and their stress analysis under dynamic loads.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs mechanical coupling components of motor vehicles and their trailers. This regulation outlines specific requirements for pintle hitches, including their design, testing procedures, and performance under various load conditions.

The International Organization for Standardization (ISO) has developed several standards relevant to towing equipment, such as ISO 7641 for trailer couplings and towed vehicles. These standards provide guidelines for the design, testing, and performance of pintle hitches and other coupling devices.

Many countries have adopted or adapted these international standards into their national regulations. For instance, Australia and New Zealand follow the Australian Design Rules (ADRs) and the New Zealand Transport Agency (NZTA) regulations, which incorporate elements from international standards while addressing specific regional requirements.

Compliance with these safety standards typically involves rigorous testing procedures to evaluate the stress distribution and fatigue resistance of pintle hitches under dynamic loads. These tests often include cyclic loading, impact testing, and simulated road conditions to ensure the hitch can withstand the forces encountered during normal towing operations and potential emergency situations.

Manufacturers of pintle hitches must demonstrate compliance with applicable safety standards through certification processes. This often involves third-party testing and documentation to verify that the equipment meets or exceeds the required performance criteria. Regular inspections and maintenance protocols are also typically mandated to ensure ongoing compliance and safety throughout the equipment's lifecycle.

As technology advances and new materials are introduced, safety standards and regulations for towing equipment continue to evolve. Regulatory bodies and industry organizations regularly review and update these standards to address emerging safety concerns and incorporate new testing methodologies. This ongoing process helps to ensure that pintle hitches and other towing components remain safe and reliable under increasingly demanding operational conditions.

The National Highway Traffic Safety Administration (NHTSA) in the United States sets federal motor vehicle safety standards that apply to towing equipment. These standards cover aspects such as strength requirements, durability testing, and performance criteria for pintle hitches and other towing components. The Society of Automotive Engineers (SAE) also provides industry standards and recommended practices for towing equipment, including specifications for pintle hitches and their stress analysis under dynamic loads.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs mechanical coupling components of motor vehicles and their trailers. This regulation outlines specific requirements for pintle hitches, including their design, testing procedures, and performance under various load conditions.

The International Organization for Standardization (ISO) has developed several standards relevant to towing equipment, such as ISO 7641 for trailer couplings and towed vehicles. These standards provide guidelines for the design, testing, and performance of pintle hitches and other coupling devices.

Many countries have adopted or adapted these international standards into their national regulations. For instance, Australia and New Zealand follow the Australian Design Rules (ADRs) and the New Zealand Transport Agency (NZTA) regulations, which incorporate elements from international standards while addressing specific regional requirements.

Compliance with these safety standards typically involves rigorous testing procedures to evaluate the stress distribution and fatigue resistance of pintle hitches under dynamic loads. These tests often include cyclic loading, impact testing, and simulated road conditions to ensure the hitch can withstand the forces encountered during normal towing operations and potential emergency situations.

Manufacturers of pintle hitches must demonstrate compliance with applicable safety standards through certification processes. This often involves third-party testing and documentation to verify that the equipment meets or exceeds the required performance criteria. Regular inspections and maintenance protocols are also typically mandated to ensure ongoing compliance and safety throughout the equipment's lifecycle.

As technology advances and new materials are introduced, safety standards and regulations for towing equipment continue to evolve. Regulatory bodies and industry organizations regularly review and update these standards to address emerging safety concerns and incorporate new testing methodologies. This ongoing process helps to ensure that pintle hitches and other towing components remain safe and reliable under increasingly demanding operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!