Pintle Hitch Influence on Advanced Logistics Management Systems

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, playing a crucial role in the development of advanced logistics management systems. Initially designed as a simple coupling mechanism for towing trailers, the pintle hitch has transformed into a sophisticated component that integrates seamlessly with modern logistics technologies.

In its early stages, the pintle hitch was primarily used in military applications, providing a robust and reliable connection for heavy-duty vehicles and equipment. As commercial logistics operations expanded, the pintle hitch found its way into civilian use, becoming a standard feature in the trucking industry.

The evolution of the pintle hitch has been driven by the need for increased safety, efficiency, and compatibility with diverse vehicle types. Early designs focused on mechanical strength and durability, while later iterations incorporated advanced materials and engineering principles to enhance performance and reduce wear.

A significant milestone in pintle hitch evolution was the introduction of automated coupling systems. These innovations allowed for remote operation and monitoring of the hitching process, reducing the risk of human error and improving overall safety. This development aligned perfectly with the growing trend of automation in logistics management systems.

The integration of sensors and electronic components marked another leap forward in pintle hitch technology. These smart hitches could now communicate real-time data about the connection status, load distribution, and potential issues to the vehicle's onboard computer systems. This capability became instrumental in enhancing the efficiency and reliability of logistics operations.

As logistics management systems became more advanced, the pintle hitch evolved to accommodate new requirements. The introduction of standardized communication protocols allowed for seamless integration with fleet management software, enabling real-time tracking and optimization of trailer assignments and routes.

Recent developments in pintle hitch technology have focused on improving energy efficiency and reducing environmental impact. Innovations such as aerodynamic designs and lightweight materials have contributed to fuel savings and reduced emissions in long-haul transportation.

The future of pintle hitch evolution is closely tied to emerging trends in logistics, such as autonomous vehicles and platooning. Researchers are exploring concepts like self-aligning hitches and dynamic load balancing systems that can adapt to changing road conditions and vehicle configurations in real-time.

As logistics management systems continue to advance, the pintle hitch is expected to evolve further, incorporating artificial intelligence and predictive maintenance capabilities. These enhancements will not only improve operational efficiency but also contribute to the overall safety and sustainability of logistics operations.

In its early stages, the pintle hitch was primarily used in military applications, providing a robust and reliable connection for heavy-duty vehicles and equipment. As commercial logistics operations expanded, the pintle hitch found its way into civilian use, becoming a standard feature in the trucking industry.

The evolution of the pintle hitch has been driven by the need for increased safety, efficiency, and compatibility with diverse vehicle types. Early designs focused on mechanical strength and durability, while later iterations incorporated advanced materials and engineering principles to enhance performance and reduce wear.

A significant milestone in pintle hitch evolution was the introduction of automated coupling systems. These innovations allowed for remote operation and monitoring of the hitching process, reducing the risk of human error and improving overall safety. This development aligned perfectly with the growing trend of automation in logistics management systems.

The integration of sensors and electronic components marked another leap forward in pintle hitch technology. These smart hitches could now communicate real-time data about the connection status, load distribution, and potential issues to the vehicle's onboard computer systems. This capability became instrumental in enhancing the efficiency and reliability of logistics operations.

As logistics management systems became more advanced, the pintle hitch evolved to accommodate new requirements. The introduction of standardized communication protocols allowed for seamless integration with fleet management software, enabling real-time tracking and optimization of trailer assignments and routes.

Recent developments in pintle hitch technology have focused on improving energy efficiency and reducing environmental impact. Innovations such as aerodynamic designs and lightweight materials have contributed to fuel savings and reduced emissions in long-haul transportation.

The future of pintle hitch evolution is closely tied to emerging trends in logistics, such as autonomous vehicles and platooning. Researchers are exploring concepts like self-aligning hitches and dynamic load balancing systems that can adapt to changing road conditions and vehicle configurations in real-time.

As logistics management systems continue to advance, the pintle hitch is expected to evolve further, incorporating artificial intelligence and predictive maintenance capabilities. These enhancements will not only improve operational efficiency but also contribute to the overall safety and sustainability of logistics operations.

Logistics Market Demand

The logistics market has experienced significant growth and transformation in recent years, driven by the increasing complexity of supply chains, globalization, and the rise of e-commerce. The integration of advanced technologies, such as Pintle Hitch systems, into logistics management has become a crucial factor in meeting the evolving demands of this dynamic sector.

The global logistics market size was valued at $9.96 trillion in 2021 and is projected to reach $18.22 trillion by 2027, growing at a CAGR of 6.8% during the forecast period. This substantial growth is fueled by the increasing need for efficient transportation and warehousing solutions across various industries, including retail, manufacturing, healthcare, and automotive.

E-commerce has emerged as a major driver of logistics market demand, with online retail sales expected to reach $6.54 trillion by 2023. This rapid expansion has created a pressing need for advanced logistics management systems that can handle the complexities of last-mile delivery, reverse logistics, and inventory management.

The integration of Pintle Hitch technology in logistics vehicles has gained traction due to its ability to enhance load-carrying capacity, improve vehicle stability, and increase operational flexibility. This technology is particularly relevant in the context of intermodal transportation, where seamless transitions between different modes of transport are essential for optimizing supply chain efficiency.

In the automotive sector, the demand for Pintle Hitch-equipped vehicles is rising, driven by the need for versatile transportation solutions that can adapt to varying load requirements. The global commercial vehicle market, a key segment for Pintle Hitch applications, is expected to grow at a CAGR of 5.7% from 2021 to 2028, reaching a value of $1.67 trillion.

The adoption of advanced logistics management systems incorporating Pintle Hitch technology is also influenced by the increasing focus on sustainability and environmental regulations. These systems enable more efficient route planning, load optimization, and fuel consumption reduction, aligning with the growing demand for eco-friendly logistics solutions.

Furthermore, the rise of Industry 4.0 and the Internet of Things (IoT) has created new opportunities for integrating Pintle Hitch technology with smart logistics systems. This convergence allows for real-time tracking, predictive maintenance, and data-driven decision-making, addressing the market's demand for more responsive and agile supply chain solutions.

As global trade continues to expand and supply chains become increasingly complex, the demand for advanced logistics management systems that can leverage technologies like Pintle Hitch is expected to grow. This trend is further reinforced by the need for resilient supply chains capable of adapting to disruptions, as highlighted by recent global events such as the COVID-19 pandemic.

The global logistics market size was valued at $9.96 trillion in 2021 and is projected to reach $18.22 trillion by 2027, growing at a CAGR of 6.8% during the forecast period. This substantial growth is fueled by the increasing need for efficient transportation and warehousing solutions across various industries, including retail, manufacturing, healthcare, and automotive.

E-commerce has emerged as a major driver of logistics market demand, with online retail sales expected to reach $6.54 trillion by 2023. This rapid expansion has created a pressing need for advanced logistics management systems that can handle the complexities of last-mile delivery, reverse logistics, and inventory management.

The integration of Pintle Hitch technology in logistics vehicles has gained traction due to its ability to enhance load-carrying capacity, improve vehicle stability, and increase operational flexibility. This technology is particularly relevant in the context of intermodal transportation, where seamless transitions between different modes of transport are essential for optimizing supply chain efficiency.

In the automotive sector, the demand for Pintle Hitch-equipped vehicles is rising, driven by the need for versatile transportation solutions that can adapt to varying load requirements. The global commercial vehicle market, a key segment for Pintle Hitch applications, is expected to grow at a CAGR of 5.7% from 2021 to 2028, reaching a value of $1.67 trillion.

The adoption of advanced logistics management systems incorporating Pintle Hitch technology is also influenced by the increasing focus on sustainability and environmental regulations. These systems enable more efficient route planning, load optimization, and fuel consumption reduction, aligning with the growing demand for eco-friendly logistics solutions.

Furthermore, the rise of Industry 4.0 and the Internet of Things (IoT) has created new opportunities for integrating Pintle Hitch technology with smart logistics systems. This convergence allows for real-time tracking, predictive maintenance, and data-driven decision-making, addressing the market's demand for more responsive and agile supply chain solutions.

As global trade continues to expand and supply chains become increasingly complex, the demand for advanced logistics management systems that can leverage technologies like Pintle Hitch is expected to grow. This trend is further reinforced by the need for resilient supply chains capable of adapting to disruptions, as highlighted by recent global events such as the COVID-19 pandemic.

Pintle Tech Challenges

The integration of pintle hitch technology into advanced logistics management systems presents several significant technical challenges. One of the primary obstacles is the development of robust and reliable sensors capable of accurately detecting and monitoring the connection status between the pintle hook and the lunette eye. These sensors must operate reliably in harsh environments, including extreme temperatures, vibrations, and exposure to various weather conditions.

Another challenge lies in the real-time data transmission and processing capabilities required for effective integration with logistics management systems. The pintle hitch connection status, load weight, and other relevant parameters need to be continuously monitored and communicated to the central management system with minimal latency. This necessitates the implementation of high-speed, low-power wireless communication protocols that can function reliably in diverse operational environments.

The development of intelligent algorithms for predictive maintenance and failure detection poses an additional technical hurdle. These algorithms must analyze data from multiple sensors to identify potential issues before they lead to equipment failure or safety hazards. Machine learning and artificial intelligence techniques need to be adapted to process the unique data patterns associated with pintle hitch operations.

Ensuring the cybersecurity of the integrated system is another critical challenge. As pintle hitch data becomes an integral part of the logistics management system, protecting this information from unauthorized access or manipulation becomes paramount. Implementing robust encryption and authentication mechanisms without compromising system performance or introducing significant latency is a complex technical task.

Standardization and interoperability present further challenges. Different manufacturers may use varying sensor technologies and data formats, making it difficult to create a unified system that can seamlessly integrate with diverse equipment types. Developing industry-wide standards for data exchange and communication protocols is essential for widespread adoption and effective implementation.

Power management is another significant technical obstacle, particularly for mobile applications. Sensors and communication modules integrated into pintle hitches must operate on limited power sources, often relying on vehicle batteries or independent power systems. Designing ultra-low-power components and implementing efficient power management strategies are crucial for long-term, reliable operation.

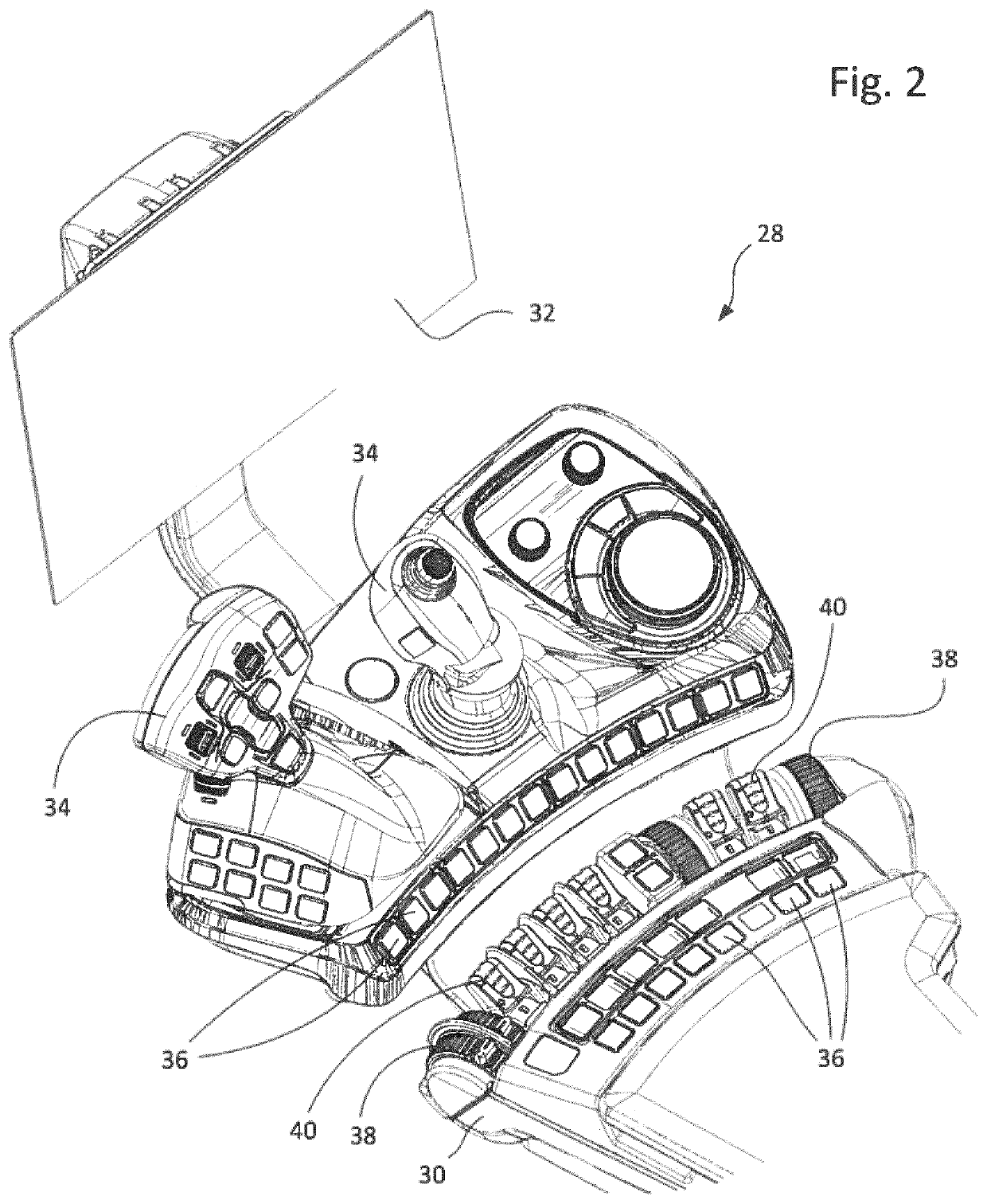

Lastly, the development of user-friendly interfaces that can effectively present complex pintle hitch data to logistics operators in an easily understandable format is a considerable challenge. These interfaces must provide real-time information and alerts while minimizing cognitive load on operators, who may be managing multiple vehicles or systems simultaneously.

Another challenge lies in the real-time data transmission and processing capabilities required for effective integration with logistics management systems. The pintle hitch connection status, load weight, and other relevant parameters need to be continuously monitored and communicated to the central management system with minimal latency. This necessitates the implementation of high-speed, low-power wireless communication protocols that can function reliably in diverse operational environments.

The development of intelligent algorithms for predictive maintenance and failure detection poses an additional technical hurdle. These algorithms must analyze data from multiple sensors to identify potential issues before they lead to equipment failure or safety hazards. Machine learning and artificial intelligence techniques need to be adapted to process the unique data patterns associated with pintle hitch operations.

Ensuring the cybersecurity of the integrated system is another critical challenge. As pintle hitch data becomes an integral part of the logistics management system, protecting this information from unauthorized access or manipulation becomes paramount. Implementing robust encryption and authentication mechanisms without compromising system performance or introducing significant latency is a complex technical task.

Standardization and interoperability present further challenges. Different manufacturers may use varying sensor technologies and data formats, making it difficult to create a unified system that can seamlessly integrate with diverse equipment types. Developing industry-wide standards for data exchange and communication protocols is essential for widespread adoption and effective implementation.

Power management is another significant technical obstacle, particularly for mobile applications. Sensors and communication modules integrated into pintle hitches must operate on limited power sources, often relying on vehicle batteries or independent power systems. Designing ultra-low-power components and implementing efficient power management strategies are crucial for long-term, reliable operation.

Lastly, the development of user-friendly interfaces that can effectively present complex pintle hitch data to logistics operators in an easily understandable format is a considerable challenge. These interfaces must provide real-time information and alerts while minimizing cognitive load on operators, who may be managing multiple vehicles or systems simultaneously.

Current Pintle Solutions

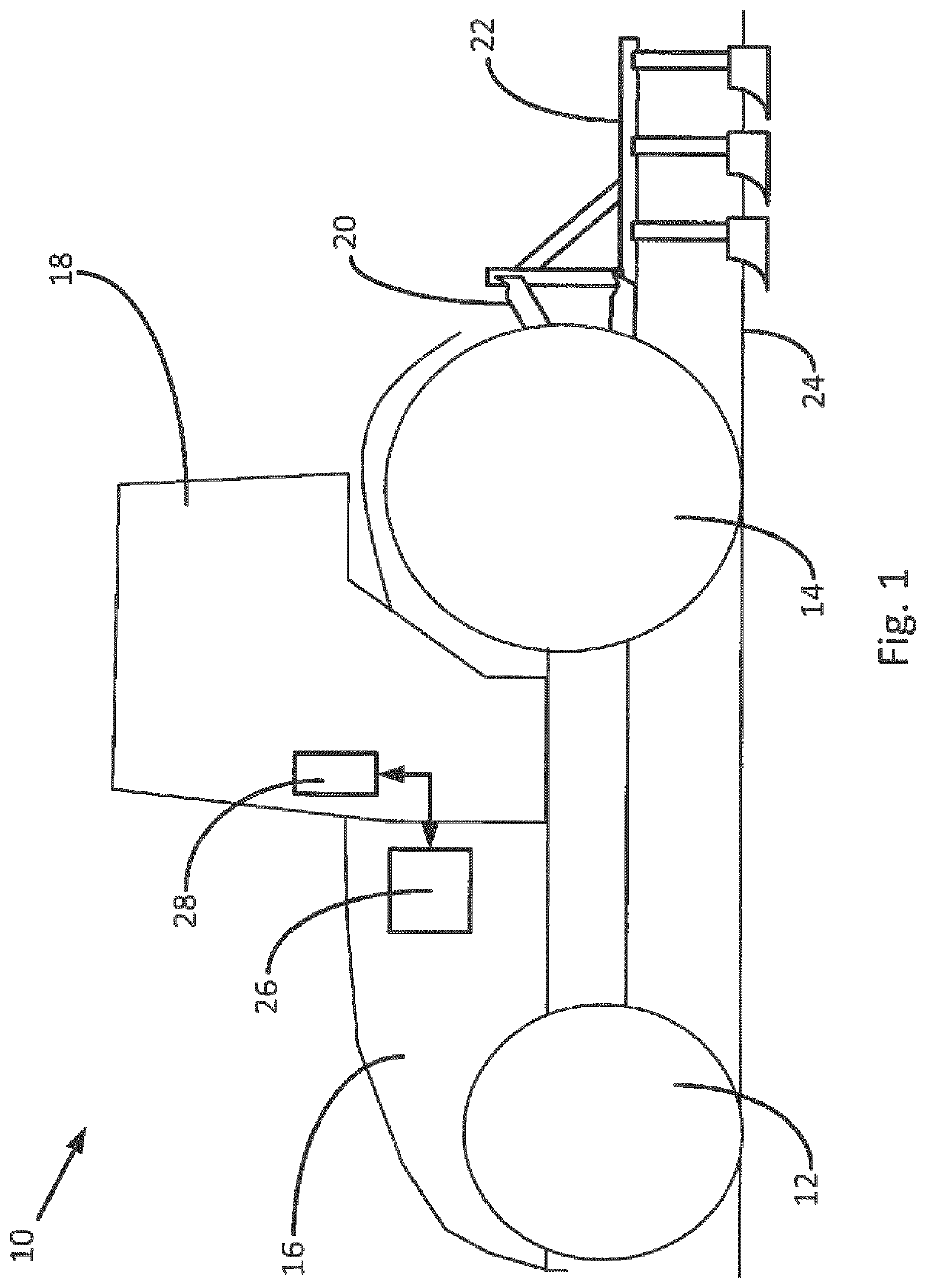

01 Pintle hitch design and structure

Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring on the trailer. The design typically includes a locking mechanism to ensure the connection remains secure during towing. Some designs incorporate adjustable features for improved versatility and compatibility with different trailer types.- Pintle hitch design and structure: Pintle hitches are designed with a hook-like structure that allows for secure coupling with a lunette ring on the trailer. The design typically includes a locking mechanism to ensure the connection remains secure during towing. Some designs incorporate adjustable features for improved versatility and compatibility with different trailer types.

- Safety features in pintle hitches: Modern pintle hitches often include advanced safety features such as secondary locking mechanisms, visual indicators for proper coupling, and integrated sensors for monitoring hitch status. These features aim to prevent accidental uncoupling and enhance overall towing safety.

- Combination pintle hitch and ball mount systems: Some designs incorporate both a pintle hook and a ball mount in a single unit, allowing for greater flexibility in towing different types of trailers. These combination systems often feature quick-change mechanisms for easy switching between pintle and ball hitch configurations.

- Adjustable and multi-position pintle hitches: Adjustable pintle hitches allow for customization of the hitch position to accommodate various trailer heights and towing vehicle configurations. Some designs feature multiple mounting positions or adjustable components to enhance versatility and improve towing performance across different applications.

- Integration of pintle hitches with vehicle systems: Advanced pintle hitch designs may incorporate integration with vehicle systems, such as electronic stability control, brake controllers, and backup cameras. This integration enhances overall towing performance, safety, and ease of use, particularly in commercial and heavy-duty applications.

02 Safety features in pintle hitches

Modern pintle hitches often include advanced safety features such as secondary locking mechanisms, visual indicators for proper coupling, and integrated safety chains. These features help prevent accidental uncoupling and enhance overall towing safety. Some designs also incorporate anti-theft measures to secure the trailer when not in use.Expand Specific Solutions03 Combination pintle hitch and ball mount systems

Some pintle hitch designs incorporate a combination of pintle hook and ball mount, allowing for greater versatility in towing different types of trailers. These systems often feature interchangeable or flip-over mechanisms to switch between pintle and ball hitch configurations, providing flexibility for various towing needs.Expand Specific Solutions04 Adjustable and multi-position pintle hitches

Adjustable pintle hitches allow for customization of the hitch position to accommodate different trailer heights and towing vehicle configurations. These designs may include features such as multiple mounting holes, sliding mechanisms, or pivoting components to achieve the desired towing position and improve overall towing performance.Expand Specific Solutions05 Integration of pintle hitches with vehicle systems

Advanced pintle hitch designs may incorporate integration with vehicle systems such as backup cameras, sensors, or electronic control units. These integrations can provide improved visibility, automated coupling assistance, or real-time monitoring of the hitch and trailer connection, enhancing safety and convenience for the user.Expand Specific Solutions

Key Industry Players

The pintle hitch technology in advanced logistics management systems is in a growth phase, with increasing market size driven by the expanding e-commerce and logistics sectors. The market is characterized by a mix of established players and innovative startups, indicating moderate technological maturity. Companies like Crown Equipment Corp. and Deere & Co. are leveraging their expertise in material handling and heavy machinery to develop advanced pintle hitch solutions. Emerging players such as Teleswivel LLC and INA Intelligent Technology are introducing novel approaches, while research institutions like the Naval Research Laboratory contribute to technological advancements. The involvement of diverse players, from automotive giants like Ford to specialized logistics companies, suggests a competitive landscape with potential for further innovation and market expansion.

Teleswivel LLC

Technical Solution: Teleswivel has developed a unique rotating pintle hitch system that integrates with advanced logistics management platforms. Their patented design allows for 360-degree rotation of the hitch, significantly improving maneuverability and reducing stress on both the towing vehicle and trailer[13]. The system incorporates smart sensors that monitor hitch position, load distribution, and stress levels in real-time. This data is transmitted to Teleswivel's cloud-based logistics management software, which uses AI algorithms to optimize route planning, predict maintenance needs, and improve overall fleet efficiency[14]. The company has also developed a mobile app that allows operators to remotely monitor and control the hitch position, enhancing safety during hitching and unhitching operations[15].

Strengths: Unique rotating design for improved maneuverability, remote monitoring and control capabilities, integration with existing logistics platforms. Weaknesses: May require additional training for operators, potentially higher initial cost compared to traditional fixed hitches.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced logistics management system that incorporates pintle hitch technology for improved trailer connectivity and control. Their system utilizes sensors and AI algorithms to optimize load distribution, enhance stability, and increase fuel efficiency. The pintle hitch design allows for greater articulation and maneuverability, especially in challenging terrains. Ford's system also integrates with their SYNC infotainment platform, providing real-time data on trailer status, weight distribution, and maintenance needs[1][3]. The company has implemented machine learning algorithms to predict potential issues and suggest preventive measures, reducing downtime and improving overall fleet management efficiency[5].

Strengths: Seamless integration with existing Ford vehicle systems, improved safety and stability, real-time data analytics. Weaknesses: May be limited to Ford vehicles, potentially higher initial implementation costs.

Pintle Hitch Innovations

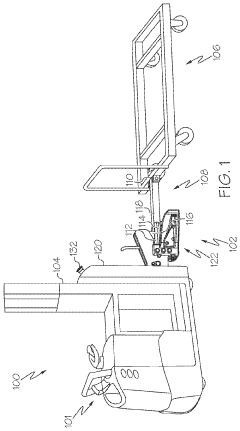

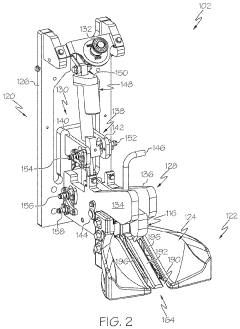

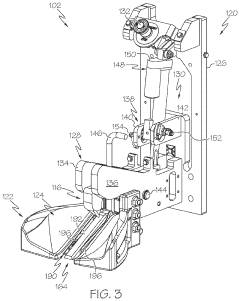

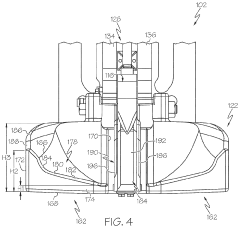

Hitches including latch actuators and sensors, and vehicles incorporating the same

PatentActiveUS11987084B2

Innovation

- A hitch system with a latch, sensors, and an actuator that automatically positions the latch between open and closed positions based on sensor signals, allowing for precise engagement and disengagement of the cart hook, enhancing the vehicle's ability to turn and maintain engagement while navigating.

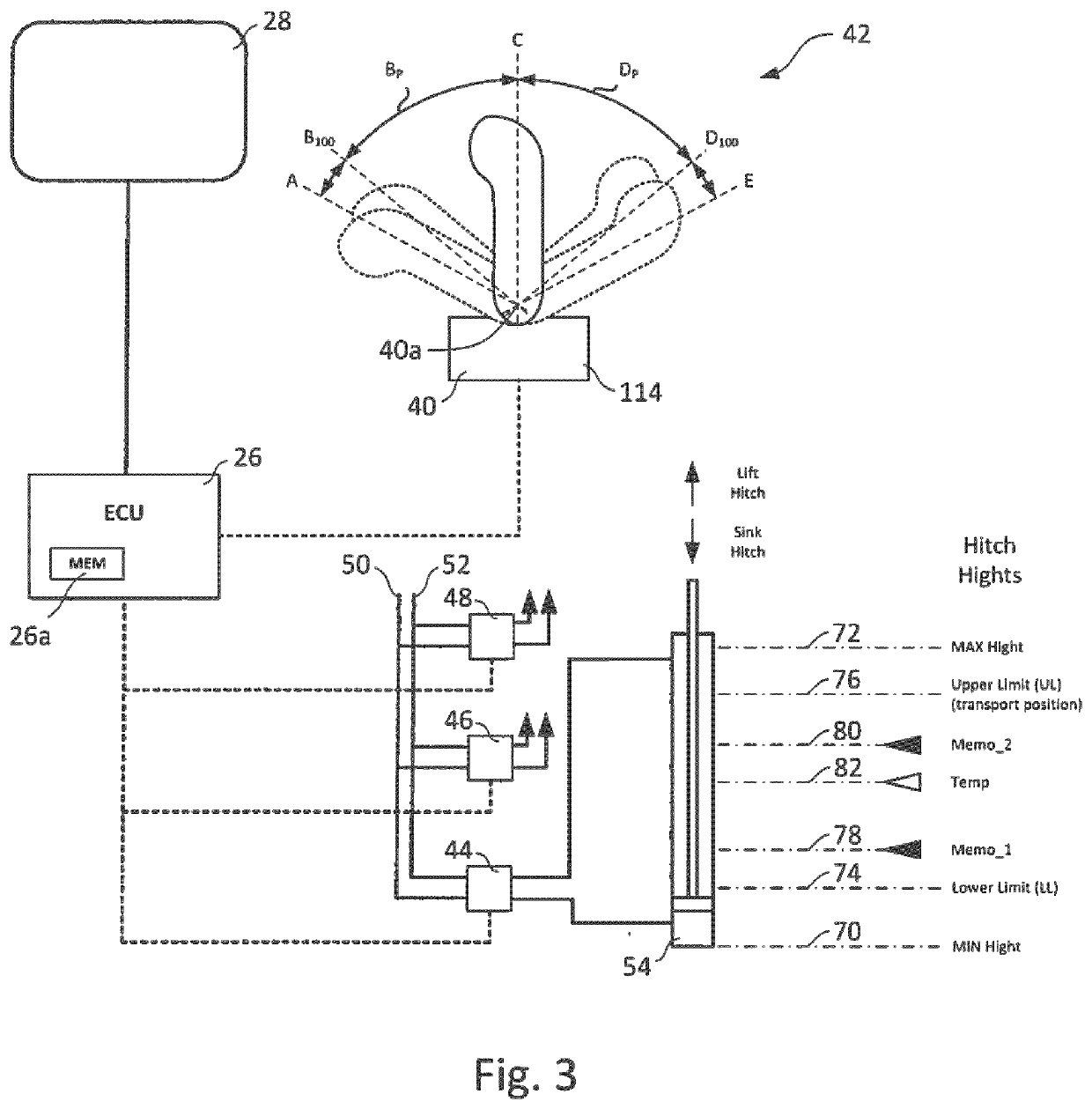

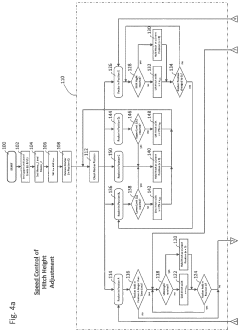

Implement hitch control system

PatentActiveUS20220240427A1

Innovation

- A control system that utilizes a single rocker control device to control the hitch's raising, lowering, and intermediate positioning, with an electronic control unit (ECU) capable of switching between modes without additional control elements, allowing the user to control the hitch's movement and position using the same device.

Regulatory Compliance

Regulatory compliance plays a crucial role in the integration of Pintle Hitch technology with Advanced Logistics Management Systems (ALMS). As these systems become more sophisticated and interconnected, adherence to various regulations becomes increasingly complex and vital for operational success.

The primary regulatory bodies overseeing Pintle Hitch and ALMS integration include the Department of Transportation (DOT), the Federal Motor Carrier Safety Administration (FMCSA), and the National Highway Traffic Safety Administration (NHTSA). These agencies establish and enforce standards for vehicle safety, load securement, and electronic logging devices (ELDs) used in logistics management.

One of the key regulatory considerations is the compliance with the Electronic Logging Device (ELD) mandate. ALMS incorporating Pintle Hitch data must ensure that the information collected and transmitted adheres to the FMCSA's ELD regulations. This includes accurate recording of driving hours, rest periods, and vehicle movement data.

Safety regulations also play a significant role in Pintle Hitch and ALMS integration. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) set specific requirements for trailer hitches, including Pintle Hitches. ALMS must incorporate these safety standards into their monitoring and management protocols to ensure compliance during operation.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA), impact how ALMS handle and protect the information collected through Pintle Hitch sensors and related systems. Compliance with these regulations requires robust data protection measures and transparent data handling practices.

Environmental regulations also influence the development and implementation of Pintle Hitch-enabled ALMS. The Environmental Protection Agency (EPA) and state-level environmental agencies set emissions standards that affect vehicle and equipment design. ALMS must account for these regulations when optimizing routes and managing fleet operations.

Compliance with international standards is essential for cross-border logistics operations. The International Organization for Standardization (ISO) provides guidelines for logistics management systems, including ISO 28000 for supply chain security management. ALMS integrating Pintle Hitch technology must align with these standards to ensure global interoperability and compliance.

As technology evolves, regulatory frameworks are likely to adapt. Companies implementing Pintle Hitch-enabled ALMS must stay informed about emerging regulations and proactively adjust their systems to maintain compliance. This may include participating in industry working groups, engaging with regulatory bodies, and investing in adaptable technology infrastructure.

The primary regulatory bodies overseeing Pintle Hitch and ALMS integration include the Department of Transportation (DOT), the Federal Motor Carrier Safety Administration (FMCSA), and the National Highway Traffic Safety Administration (NHTSA). These agencies establish and enforce standards for vehicle safety, load securement, and electronic logging devices (ELDs) used in logistics management.

One of the key regulatory considerations is the compliance with the Electronic Logging Device (ELD) mandate. ALMS incorporating Pintle Hitch data must ensure that the information collected and transmitted adheres to the FMCSA's ELD regulations. This includes accurate recording of driving hours, rest periods, and vehicle movement data.

Safety regulations also play a significant role in Pintle Hitch and ALMS integration. The NHTSA's Federal Motor Vehicle Safety Standards (FMVSS) set specific requirements for trailer hitches, including Pintle Hitches. ALMS must incorporate these safety standards into their monitoring and management protocols to ensure compliance during operation.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA), impact how ALMS handle and protect the information collected through Pintle Hitch sensors and related systems. Compliance with these regulations requires robust data protection measures and transparent data handling practices.

Environmental regulations also influence the development and implementation of Pintle Hitch-enabled ALMS. The Environmental Protection Agency (EPA) and state-level environmental agencies set emissions standards that affect vehicle and equipment design. ALMS must account for these regulations when optimizing routes and managing fleet operations.

Compliance with international standards is essential for cross-border logistics operations. The International Organization for Standardization (ISO) provides guidelines for logistics management systems, including ISO 28000 for supply chain security management. ALMS integrating Pintle Hitch technology must align with these standards to ensure global interoperability and compliance.

As technology evolves, regulatory frameworks are likely to adapt. Companies implementing Pintle Hitch-enabled ALMS must stay informed about emerging regulations and proactively adjust their systems to maintain compliance. This may include participating in industry working groups, engaging with regulatory bodies, and investing in adaptable technology infrastructure.

Environmental Impact

The environmental impact of Pintle Hitch systems in Advanced Logistics Management is a critical consideration for sustainable transportation practices. These systems, while enhancing operational efficiency, also contribute to various environmental factors that require careful assessment and mitigation strategies.

One of the primary environmental benefits of Pintle Hitch systems is their potential to reduce fuel consumption. By enabling more efficient coupling and uncoupling of trailers, these systems minimize idle time and optimize load distribution. This efficiency translates to reduced carbon emissions, as vehicles spend less time maneuvering and consume less fuel during transit.

However, the manufacturing process of Pintle Hitch components may have negative environmental implications. The production of steel and other materials used in these systems can contribute to resource depletion and energy-intensive processes. Additionally, the disposal of worn-out or obsolete Pintle Hitch components raises concerns about waste management and potential environmental contamination.

Noise pollution is another environmental factor associated with Pintle Hitch systems. The coupling and uncoupling processes can generate significant noise, particularly in urban areas or logistics hubs. This noise pollution may have adverse effects on local ecosystems and human populations, necessitating the development of noise-reduction technologies or operational guidelines.

The integration of Pintle Hitch systems with Advanced Logistics Management platforms offers opportunities for environmental optimization. Real-time data on vehicle performance, route efficiency, and load distribution can be leveraged to minimize environmental impact. For instance, intelligent routing algorithms can reduce overall mileage and emissions, while load optimization can maximize the utilization of each vehicle, reducing the number of trips required.

Maintenance practices for Pintle Hitch systems also play a role in their environmental impact. Regular maintenance can extend the lifespan of components, reducing the frequency of replacements and associated waste. Moreover, proper lubrication and adjustment of Pintle Hitch mechanisms can minimize friction and wear, leading to improved fuel efficiency and reduced emissions.

As logistics operations increasingly prioritize sustainability, the environmental performance of Pintle Hitch systems becomes a key differentiator. Manufacturers are exploring eco-friendly materials and production processes to reduce the carbon footprint of these components. Additionally, research into recyclable or biodegradable materials for non-critical parts of the Pintle Hitch system is gaining traction.

The integration of renewable energy sources in logistics operations further amplifies the environmental benefits of efficient Pintle Hitch systems. Electric and hybrid vehicles equipped with advanced hitching mechanisms can significantly reduce emissions, particularly in last-mile delivery scenarios. This synergy between clean energy and efficient coupling systems represents a promising direction for sustainable logistics management.

One of the primary environmental benefits of Pintle Hitch systems is their potential to reduce fuel consumption. By enabling more efficient coupling and uncoupling of trailers, these systems minimize idle time and optimize load distribution. This efficiency translates to reduced carbon emissions, as vehicles spend less time maneuvering and consume less fuel during transit.

However, the manufacturing process of Pintle Hitch components may have negative environmental implications. The production of steel and other materials used in these systems can contribute to resource depletion and energy-intensive processes. Additionally, the disposal of worn-out or obsolete Pintle Hitch components raises concerns about waste management and potential environmental contamination.

Noise pollution is another environmental factor associated with Pintle Hitch systems. The coupling and uncoupling processes can generate significant noise, particularly in urban areas or logistics hubs. This noise pollution may have adverse effects on local ecosystems and human populations, necessitating the development of noise-reduction technologies or operational guidelines.

The integration of Pintle Hitch systems with Advanced Logistics Management platforms offers opportunities for environmental optimization. Real-time data on vehicle performance, route efficiency, and load distribution can be leveraged to minimize environmental impact. For instance, intelligent routing algorithms can reduce overall mileage and emissions, while load optimization can maximize the utilization of each vehicle, reducing the number of trips required.

Maintenance practices for Pintle Hitch systems also play a role in their environmental impact. Regular maintenance can extend the lifespan of components, reducing the frequency of replacements and associated waste. Moreover, proper lubrication and adjustment of Pintle Hitch mechanisms can minimize friction and wear, leading to improved fuel efficiency and reduced emissions.

As logistics operations increasingly prioritize sustainability, the environmental performance of Pintle Hitch systems becomes a key differentiator. Manufacturers are exploring eco-friendly materials and production processes to reduce the carbon footprint of these components. Additionally, research into recyclable or biodegradable materials for non-critical parts of the Pintle Hitch system is gaining traction.

The integration of renewable energy sources in logistics operations further amplifies the environmental benefits of efficient Pintle Hitch systems. Electric and hybrid vehicles equipped with advanced hitching mechanisms can significantly reduce emissions, particularly in last-mile delivery scenarios. This synergy between clean energy and efficient coupling systems represents a promising direction for sustainable logistics management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!