Pintle Hitch Design Contributions to Fuel Optimization Strategies

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of the pintle hitch design has played a significant role in contributing to fuel optimization strategies in the transportation industry. This towing mechanism has undergone several transformations since its inception, each iteration aimed at improving efficiency and reducing fuel consumption.

In the early stages of pintle hitch development, the focus was primarily on strength and durability. The initial designs were robust but lacked consideration for aerodynamics and weight, two crucial factors in fuel efficiency. As the automotive industry began to prioritize fuel economy, engineers turned their attention to refining the pintle hitch design.

The first major breakthrough came with the introduction of lightweight materials. Manufacturers began replacing traditional steel components with high-strength aluminum alloys and advanced composites. This shift significantly reduced the overall weight of the hitch system, directly contributing to improved fuel efficiency for towing vehicles.

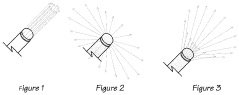

Aerodynamics became a key consideration in subsequent design iterations. Engineers recognized that the protruding nature of conventional pintle hitches created substantial drag, increasing fuel consumption. This led to the development of more streamlined designs, incorporating smooth contours and recessed mounting points to minimize air resistance.

Another pivotal advancement was the integration of adjustable height mechanisms. This feature allowed for optimal alignment between the towing vehicle and the trailer, reducing strain on the engine and improving overall fuel efficiency. The ability to fine-tune the hitch position also enhanced stability, further contributing to fuel savings by minimizing unnecessary corrections during transit.

The introduction of smart technologies marked a new era in pintle hitch evolution. Sensors and electronic systems were incorporated to monitor towing conditions in real-time. These innovations enabled dynamic adjustments to improve fuel efficiency, such as automatic load distribution and adaptive suspension settings.

Recent developments have focused on the integration of regenerative braking systems within the pintle hitch mechanism. This technology harnesses the energy typically lost during braking and converts it into usable power, further enhancing fuel economy. Additionally, some advanced designs now incorporate active aerodynamic elements that can adjust their shape based on speed and wind conditions to optimize fuel consumption.

The ongoing evolution of pintle hitch design continues to push the boundaries of fuel optimization. Current research is exploring the use of advanced materials like carbon nanotubes and graphene composites to further reduce weight while maintaining strength. Additionally, the integration of artificial intelligence and machine learning algorithms promises to deliver even more sophisticated fuel-saving strategies by predicting and adapting to various towing scenarios in real-time.

In the early stages of pintle hitch development, the focus was primarily on strength and durability. The initial designs were robust but lacked consideration for aerodynamics and weight, two crucial factors in fuel efficiency. As the automotive industry began to prioritize fuel economy, engineers turned their attention to refining the pintle hitch design.

The first major breakthrough came with the introduction of lightweight materials. Manufacturers began replacing traditional steel components with high-strength aluminum alloys and advanced composites. This shift significantly reduced the overall weight of the hitch system, directly contributing to improved fuel efficiency for towing vehicles.

Aerodynamics became a key consideration in subsequent design iterations. Engineers recognized that the protruding nature of conventional pintle hitches created substantial drag, increasing fuel consumption. This led to the development of more streamlined designs, incorporating smooth contours and recessed mounting points to minimize air resistance.

Another pivotal advancement was the integration of adjustable height mechanisms. This feature allowed for optimal alignment between the towing vehicle and the trailer, reducing strain on the engine and improving overall fuel efficiency. The ability to fine-tune the hitch position also enhanced stability, further contributing to fuel savings by minimizing unnecessary corrections during transit.

The introduction of smart technologies marked a new era in pintle hitch evolution. Sensors and electronic systems were incorporated to monitor towing conditions in real-time. These innovations enabled dynamic adjustments to improve fuel efficiency, such as automatic load distribution and adaptive suspension settings.

Recent developments have focused on the integration of regenerative braking systems within the pintle hitch mechanism. This technology harnesses the energy typically lost during braking and converts it into usable power, further enhancing fuel economy. Additionally, some advanced designs now incorporate active aerodynamic elements that can adjust their shape based on speed and wind conditions to optimize fuel consumption.

The ongoing evolution of pintle hitch design continues to push the boundaries of fuel optimization. Current research is exploring the use of advanced materials like carbon nanotubes and graphene composites to further reduce weight while maintaining strength. Additionally, the integration of artificial intelligence and machine learning algorithms promises to deliver even more sophisticated fuel-saving strategies by predicting and adapting to various towing scenarios in real-time.

Fuel Efficiency Demand

The demand for fuel efficiency in the transportation sector has become increasingly critical in recent years, driven by a combination of economic, environmental, and regulatory factors. As global concerns about climate change and air pollution intensify, governments worldwide have implemented stricter fuel economy standards and emissions regulations. These regulatory pressures have compelled automotive manufacturers to prioritize fuel efficiency in their vehicle designs, including the optimization of towing systems such as pintle hitches.

From an economic perspective, fuel costs represent a significant portion of operating expenses for both commercial fleets and individual vehicle owners. The volatility of fuel prices has further emphasized the need for improved fuel efficiency to reduce overall transportation costs. This economic incentive has created a strong market demand for vehicles and components that can contribute to fuel savings, particularly in heavy-duty applications where fuel consumption is typically higher.

The commercial transportation sector, in particular, has shown a growing interest in fuel-efficient technologies. Fleet operators are increasingly seeking ways to reduce their fuel consumption without compromising on performance or payload capacity. This demand has spurred innovation in various areas of vehicle design, including aerodynamics, powertrain efficiency, and towing systems. The pintle hitch, as a critical component in many towing applications, has become a focus area for optimization to contribute to overall fuel efficiency strategies.

Consumer awareness and preferences have also played a significant role in driving the demand for fuel-efficient vehicles. As environmental consciousness grows among the general public, there is an increasing preference for vehicles that offer better fuel economy. This trend extends to recreational vehicle owners and others who frequently engage in towing activities, creating a market for more efficient towing solutions.

The integration of fuel efficiency considerations into towing system design represents a response to these multifaceted demands. Manufacturers are exploring ways to optimize the pintle hitch design to reduce drag, improve weight distribution, and enhance overall vehicle aerodynamics during towing operations. This focus on fuel efficiency in towing applications aligns with broader industry efforts to meet regulatory requirements, reduce operating costs, and address consumer preferences for more environmentally friendly transportation options.

As the demand for fuel efficiency continues to grow, it is likely to drive further innovation in pintle hitch design and other towing components. The industry's response to this demand will play a crucial role in shaping the future of transportation, particularly in sectors that rely heavily on towing capabilities.

From an economic perspective, fuel costs represent a significant portion of operating expenses for both commercial fleets and individual vehicle owners. The volatility of fuel prices has further emphasized the need for improved fuel efficiency to reduce overall transportation costs. This economic incentive has created a strong market demand for vehicles and components that can contribute to fuel savings, particularly in heavy-duty applications where fuel consumption is typically higher.

The commercial transportation sector, in particular, has shown a growing interest in fuel-efficient technologies. Fleet operators are increasingly seeking ways to reduce their fuel consumption without compromising on performance or payload capacity. This demand has spurred innovation in various areas of vehicle design, including aerodynamics, powertrain efficiency, and towing systems. The pintle hitch, as a critical component in many towing applications, has become a focus area for optimization to contribute to overall fuel efficiency strategies.

Consumer awareness and preferences have also played a significant role in driving the demand for fuel-efficient vehicles. As environmental consciousness grows among the general public, there is an increasing preference for vehicles that offer better fuel economy. This trend extends to recreational vehicle owners and others who frequently engage in towing activities, creating a market for more efficient towing solutions.

The integration of fuel efficiency considerations into towing system design represents a response to these multifaceted demands. Manufacturers are exploring ways to optimize the pintle hitch design to reduce drag, improve weight distribution, and enhance overall vehicle aerodynamics during towing operations. This focus on fuel efficiency in towing applications aligns with broader industry efforts to meet regulatory requirements, reduce operating costs, and address consumer preferences for more environmentally friendly transportation options.

As the demand for fuel efficiency continues to grow, it is likely to drive further innovation in pintle hitch design and other towing components. The industry's response to this demand will play a crucial role in shaping the future of transportation, particularly in sectors that rely heavily on towing capabilities.

Current Challenges

The current challenges in Pintle Hitch Design Contributions to Fuel Optimization Strategies are multifaceted and complex. One of the primary issues is the trade-off between stability and fuel efficiency. Traditional pintle hitch designs often prioritize stability and towing capacity, which can lead to increased weight and aerodynamic drag, negatively impacting fuel consumption.

Another significant challenge is the integration of advanced materials and manufacturing techniques. While lightweight materials such as high-strength alloys and composites offer potential for weight reduction, their implementation in pintle hitch design is hindered by cost considerations and the need for extensive testing to ensure durability and safety standards are met.

The dynamic nature of towing scenarios presents a further challenge. Pintle hitch designs must account for various load distributions, road conditions, and vehicle speeds. Developing a system that can adapt to these changing conditions while maintaining optimal fuel efficiency remains a complex engineering problem.

Aerodynamics plays a crucial role in fuel optimization, yet current pintle hitch designs often create turbulence and increased drag. Engineers face the challenge of redesigning hitches to minimize air resistance without compromising their structural integrity and functionality.

The lack of standardization across different vehicle models and trailer types complicates the development of universally applicable fuel-optimized pintle hitch designs. This diversity in configurations makes it difficult to create a one-size-fits-all solution, necessitating customized approaches that can be costly and time-consuming to implement.

Additionally, the integration of smart technologies into pintle hitch systems for real-time monitoring and adjustment poses both opportunities and challenges. While such technologies could significantly contribute to fuel optimization, they introduce complexities in terms of power management, data processing, and system reliability.

Regulatory compliance and safety standards also present hurdles in innovating pintle hitch designs. Any new design must not only improve fuel efficiency but also meet or exceed existing safety regulations, which can sometimes conflict with aerodynamic or weight-saving goals.

Lastly, the challenge of consumer acceptance and market penetration cannot be overlooked. New, fuel-optimized pintle hitch designs may require changes in user behavior or additional maintenance, which could face resistance from consumers accustomed to traditional designs. Overcoming this barrier requires not only technical innovation but also effective marketing and education strategies.

Another significant challenge is the integration of advanced materials and manufacturing techniques. While lightweight materials such as high-strength alloys and composites offer potential for weight reduction, their implementation in pintle hitch design is hindered by cost considerations and the need for extensive testing to ensure durability and safety standards are met.

The dynamic nature of towing scenarios presents a further challenge. Pintle hitch designs must account for various load distributions, road conditions, and vehicle speeds. Developing a system that can adapt to these changing conditions while maintaining optimal fuel efficiency remains a complex engineering problem.

Aerodynamics plays a crucial role in fuel optimization, yet current pintle hitch designs often create turbulence and increased drag. Engineers face the challenge of redesigning hitches to minimize air resistance without compromising their structural integrity and functionality.

The lack of standardization across different vehicle models and trailer types complicates the development of universally applicable fuel-optimized pintle hitch designs. This diversity in configurations makes it difficult to create a one-size-fits-all solution, necessitating customized approaches that can be costly and time-consuming to implement.

Additionally, the integration of smart technologies into pintle hitch systems for real-time monitoring and adjustment poses both opportunities and challenges. While such technologies could significantly contribute to fuel optimization, they introduce complexities in terms of power management, data processing, and system reliability.

Regulatory compliance and safety standards also present hurdles in innovating pintle hitch designs. Any new design must not only improve fuel efficiency but also meet or exceed existing safety regulations, which can sometimes conflict with aerodynamic or weight-saving goals.

Lastly, the challenge of consumer acceptance and market penetration cannot be overlooked. New, fuel-optimized pintle hitch designs may require changes in user behavior or additional maintenance, which could face resistance from consumers accustomed to traditional designs. Overcoming this barrier requires not only technical innovation but also effective marketing and education strategies.

Existing Solutions

01 Aerodynamic improvements for fuel efficiency

Implementing aerodynamic enhancements to reduce drag and improve fuel efficiency in vehicles with pintle hitches. This includes designing streamlined fairings, air deflectors, and optimized shapes for the hitch and trailer connection to minimize air resistance during travel.- Aerodynamic improvements for fuel efficiency: Implementing aerodynamic enhancements to reduce drag and improve fuel efficiency in vehicles with pintle hitches. This includes designing streamlined fairings, air deflectors, and optimized hitch configurations to minimize air resistance and turbulence, resulting in better fuel economy for towing vehicles.

- Weight distribution and load management: Developing systems for optimal weight distribution and load management in pintle hitch configurations. This involves designing adjustable hitches, load-sensing technologies, and intelligent weight distribution systems to improve vehicle stability, reduce fuel consumption, and enhance overall towing efficiency.

- Fuel-efficient towing control systems: Integrating advanced control systems and algorithms to optimize fuel consumption during towing operations. This includes developing intelligent towing modes, adaptive cruise control for towing, and predictive powertrain management systems that adjust vehicle performance based on load and road conditions to maximize fuel efficiency.

- Innovative hitch designs for reduced friction: Creating novel pintle hitch designs that minimize friction and energy loss at the connection point. This involves developing low-friction materials, advanced lubrication systems, and optimized geometries to reduce wear and improve overall fuel efficiency in towing applications.

- Integration of alternative energy sources: Incorporating alternative energy sources and regenerative systems into pintle hitch configurations to supplement power and improve fuel efficiency. This includes integrating solar panels, regenerative braking systems, and energy recovery technologies to reduce the overall fuel consumption of towing vehicles.

02 Weight distribution and load management

Optimizing weight distribution and load management systems for vehicles with pintle hitches to improve fuel efficiency. This involves developing advanced weight sensing technologies, adjustable suspension systems, and intelligent load balancing mechanisms to reduce fuel consumption by minimizing unnecessary strain on the vehicle.Expand Specific Solutions03 Intelligent hitch control systems

Incorporating smart control systems and sensors into pintle hitches to optimize fuel consumption. These systems can automatically adjust hitch positioning, monitor trailer alignment, and provide real-time feedback to drivers for improved fuel efficiency during towing operations.Expand Specific Solutions04 Alternative fuel integration for towing vehicles

Developing pintle hitch systems compatible with alternative fuel technologies to enhance overall fuel efficiency. This includes designing hitches that work seamlessly with hybrid, electric, or hydrogen-powered towing vehicles, as well as integrating energy recovery systems to maximize fuel economy during towing operations.Expand Specific Solutions05 Lightweight materials and design optimization

Utilizing advanced lightweight materials and optimized designs for pintle hitches to reduce overall vehicle weight and improve fuel efficiency. This involves employing high-strength, low-weight alloys, composite materials, and innovative structural designs that maintain towing capacity while minimizing the impact on fuel consumption.Expand Specific Solutions

Industry Leaders

The competitive landscape for Pintle Hitch Design Contributions to Fuel Optimization Strategies is evolving as the industry enters a growth phase. The market is expanding due to increasing focus on fuel efficiency in transportation. While the technology is still developing, several key players are making significant advancements. Companies like Robert Bosch GmbH, Delphi Technology, and Woodward, Inc. are leading in innovation, leveraging their expertise in automotive and control systems. Siemens AG and RTX Corp. are also contributing with their advanced engineering capabilities. The involvement of major automotive manufacturers like Hyundai Motor Co. and Ford Global Technologies LLC indicates the technology's growing importance in the industry.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Pintle Hitch Design that contributes significantly to fuel optimization strategies. Their system incorporates a smart electronic control unit that dynamically adjusts the hitch position based on real-time driving conditions. This adaptive system uses sensors to monitor vehicle speed, load distribution, and road conditions, allowing for optimal trailer positioning[1]. The design includes a variable-geometry pintle that can alter its shape to reduce aerodynamic drag, particularly at higher speeds[3]. Bosch's solution also integrates with the vehicle's powertrain management system, enabling predictive control strategies that anticipate terrain changes and adjust engine output accordingly, further enhancing fuel efficiency[5].

Strengths: Highly integrated system with advanced electronic control, adaptable to various driving conditions, and seamless integration with vehicle systems. Weaknesses: Potentially higher cost due to complex components and may require more maintenance compared to traditional designs.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a Pintle Hitch Design that focuses on maximizing fuel efficiency through intelligent integration with the vehicle's powertrain and chassis systems. Their design features an electronically controlled, variable-height hitch system that automatically adjusts to optimize aerodynamics and weight distribution based on vehicle speed and load[8]. Hyundai's solution also incorporates an advanced trailer sway control system that works in conjunction with the vehicle's stability control, reducing unnecessary braking and acceleration events that can impact fuel economy[10]. The company has also implemented a predictive energy management system that uses GPS and topographical data to anticipate road conditions and adjust the powertrain output accordingly, further enhancing fuel efficiency during towing operations[12].

Strengths: Seamless integration with vehicle systems, advanced sway control for improved stability and efficiency, predictive energy management. Weaknesses: Reliance on complex electronic systems may increase maintenance requirements, potential for higher costs in entry-level vehicles.

Key Innovations

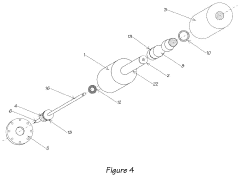

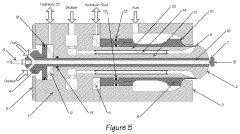

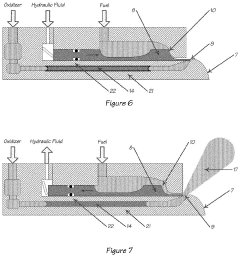

Liquid Combustion Concentric Injector and Ignitor

PatentActiveUS20200332744A1

Innovation

- The integration of a novel pintle injector design with a retractable coaxial ignitor and improved flow control sleeve that allows for efficient radial spoke jet spray and full face shutoff, ensuring stable combustion and throttleability through symmetrical hot gas ignition and recirculation patterns.

Fuel optimization algorithm for integration with navigation systems or direction generation software and fuel price databases

PatentInactiveUS20090271107A1

Innovation

- An algorithm integrating existing navigation systems, real-time fuel price databases, and vehicle fuel efficiency monitoring to suggest optimal fuel fill-up locations and quantities along a trip, adjusting in real-time based on vehicle performance and fuel price changes, transmitted via wireless means.

Environmental Impact

The environmental impact of Pintle Hitch Design in fuel optimization strategies is a crucial aspect to consider in the automotive industry. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, the design of towing components plays a significant role in achieving these goals.

Pintle hitch designs contribute to fuel optimization by reducing aerodynamic drag and improving overall vehicle stability during towing operations. The streamlined shape of modern pintle hitches minimizes air resistance, allowing vehicles to maintain better fuel economy even when towing heavy loads. This reduction in drag translates directly into lower fuel consumption and, consequently, decreased greenhouse gas emissions.

Furthermore, the weight optimization of pintle hitch designs contributes to improved fuel efficiency. Manufacturers are increasingly using lightweight materials such as high-strength steel alloys and advanced composites in hitch construction. These materials offer excellent strength-to-weight ratios, reducing the overall weight of the towing system without compromising safety or performance. The reduced weight results in less energy required to move the vehicle, leading to improved fuel economy and reduced carbon footprint.

The integration of smart technologies in pintle hitch designs also contributes to environmental benefits. Advanced sensors and control systems can optimize the towing process by adjusting vehicle dynamics in real-time. This intelligent adaptation helps maintain optimal fuel efficiency under various towing conditions, further reducing unnecessary fuel consumption and emissions.

Additionally, the durability and longevity of modern pintle hitch designs have positive environmental implications. High-quality materials and improved manufacturing processes result in hitches that last longer and require less frequent replacement. This reduction in the need for replacement parts and maintenance contributes to a decrease in resource consumption and waste generation over the lifetime of the vehicle.

The environmental impact of pintle hitch designs extends beyond fuel consumption to include considerations of material recyclability and end-of-life disposal. Many manufacturers are now focusing on designing hitches with easily recyclable materials and implementing take-back programs to ensure proper disposal and recycling of old components. This approach helps to minimize the environmental footprint of the product throughout its entire lifecycle.

In conclusion, the contributions of pintle hitch design to fuel optimization strategies have far-reaching environmental benefits. From improved aerodynamics and weight reduction to the integration of smart technologies and focus on recyclability, these design innovations play a crucial role in reducing the overall environmental impact of towing operations in the automotive industry.

Pintle hitch designs contribute to fuel optimization by reducing aerodynamic drag and improving overall vehicle stability during towing operations. The streamlined shape of modern pintle hitches minimizes air resistance, allowing vehicles to maintain better fuel economy even when towing heavy loads. This reduction in drag translates directly into lower fuel consumption and, consequently, decreased greenhouse gas emissions.

Furthermore, the weight optimization of pintle hitch designs contributes to improved fuel efficiency. Manufacturers are increasingly using lightweight materials such as high-strength steel alloys and advanced composites in hitch construction. These materials offer excellent strength-to-weight ratios, reducing the overall weight of the towing system without compromising safety or performance. The reduced weight results in less energy required to move the vehicle, leading to improved fuel economy and reduced carbon footprint.

The integration of smart technologies in pintle hitch designs also contributes to environmental benefits. Advanced sensors and control systems can optimize the towing process by adjusting vehicle dynamics in real-time. This intelligent adaptation helps maintain optimal fuel efficiency under various towing conditions, further reducing unnecessary fuel consumption and emissions.

Additionally, the durability and longevity of modern pintle hitch designs have positive environmental implications. High-quality materials and improved manufacturing processes result in hitches that last longer and require less frequent replacement. This reduction in the need for replacement parts and maintenance contributes to a decrease in resource consumption and waste generation over the lifetime of the vehicle.

The environmental impact of pintle hitch designs extends beyond fuel consumption to include considerations of material recyclability and end-of-life disposal. Many manufacturers are now focusing on designing hitches with easily recyclable materials and implementing take-back programs to ensure proper disposal and recycling of old components. This approach helps to minimize the environmental footprint of the product throughout its entire lifecycle.

In conclusion, the contributions of pintle hitch design to fuel optimization strategies have far-reaching environmental benefits. From improved aerodynamics and weight reduction to the integration of smart technologies and focus on recyclability, these design innovations play a crucial role in reducing the overall environmental impact of towing operations in the automotive industry.

Safety Regulations

Safety regulations play a crucial role in the design and implementation of Pintle Hitch systems for fuel optimization strategies in commercial vehicles. These regulations are established to ensure the safety of drivers, passengers, and other road users while maximizing fuel efficiency.

The primary safety concern for Pintle Hitch designs is the secure coupling between the towing vehicle and the trailer. Regulatory bodies, such as the National Highway Traffic Safety Administration (NHTSA) in the United States, have set specific standards for the strength and durability of Pintle Hitches. These standards typically include requirements for minimum breaking strength, fatigue resistance, and corrosion protection.

In the context of fuel optimization, safety regulations also address the aerodynamic properties of Pintle Hitch designs. Manufacturers must ensure that their designs not only improve fuel efficiency but also maintain stability and control of the vehicle-trailer combination at various speeds and under different weather conditions. This often involves wind tunnel testing and computer simulations to validate the safety of new aerodynamic features.

Weight distribution is another critical aspect covered by safety regulations. Proper weight distribution is essential for both fuel efficiency and vehicle stability. Regulations typically specify the maximum tongue weight and gross trailer weight that a Pintle Hitch can safely handle. Compliance with these weight limits is crucial for maintaining proper steering, braking, and overall vehicle control.

Safety regulations also extend to the integration of advanced technologies in Pintle Hitch designs. As manufacturers incorporate sensors, electronic stability control systems, and other smart features to optimize fuel consumption, these technologies must meet stringent safety standards. This includes requirements for electromagnetic compatibility, reliability under extreme conditions, and fail-safe mechanisms.

The visibility and lighting requirements for Pintle Hitch systems are also governed by safety regulations. This is particularly important for fuel optimization strategies that may alter the traditional shape or configuration of the hitch. Manufacturers must ensure that their designs do not obstruct required lighting or reflectors and that any additional features do not create confusion for other drivers.

Lastly, safety regulations often mandate regular inspection and maintenance procedures for Pintle Hitch systems. This is crucial for ensuring long-term safety and efficiency, as wear and tear can impact both the safety performance and fuel optimization capabilities of the hitch. Manufacturers are typically required to provide clear guidelines for inspection intervals and maintenance protocols as part of their compliance with safety regulations.

The primary safety concern for Pintle Hitch designs is the secure coupling between the towing vehicle and the trailer. Regulatory bodies, such as the National Highway Traffic Safety Administration (NHTSA) in the United States, have set specific standards for the strength and durability of Pintle Hitches. These standards typically include requirements for minimum breaking strength, fatigue resistance, and corrosion protection.

In the context of fuel optimization, safety regulations also address the aerodynamic properties of Pintle Hitch designs. Manufacturers must ensure that their designs not only improve fuel efficiency but also maintain stability and control of the vehicle-trailer combination at various speeds and under different weather conditions. This often involves wind tunnel testing and computer simulations to validate the safety of new aerodynamic features.

Weight distribution is another critical aspect covered by safety regulations. Proper weight distribution is essential for both fuel efficiency and vehicle stability. Regulations typically specify the maximum tongue weight and gross trailer weight that a Pintle Hitch can safely handle. Compliance with these weight limits is crucial for maintaining proper steering, braking, and overall vehicle control.

Safety regulations also extend to the integration of advanced technologies in Pintle Hitch designs. As manufacturers incorporate sensors, electronic stability control systems, and other smart features to optimize fuel consumption, these technologies must meet stringent safety standards. This includes requirements for electromagnetic compatibility, reliability under extreme conditions, and fail-safe mechanisms.

The visibility and lighting requirements for Pintle Hitch systems are also governed by safety regulations. This is particularly important for fuel optimization strategies that may alter the traditional shape or configuration of the hitch. Manufacturers must ensure that their designs do not obstruct required lighting or reflectors and that any additional features do not create confusion for other drivers.

Lastly, safety regulations often mandate regular inspection and maintenance procedures for Pintle Hitch systems. This is crucial for ensuring long-term safety and efficiency, as wear and tear can impact both the safety performance and fuel optimization capabilities of the hitch. Manufacturers are typically required to provide clear guidelines for inspection intervals and maintenance protocols as part of their compliance with safety regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!