Innovations in Pintle Hitch for Faster Coupling Processes

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The pintle hitch has undergone significant evolution since its inception, driven by the need for faster, safer, and more efficient coupling processes in various industries. Initially developed for military applications, the pintle hitch has found widespread use in commercial and agricultural sectors due to its robust design and versatility.

In the early stages, pintle hitches were simple, manually operated devices consisting of a hook-like protrusion (the pintle) and a lunette ring. These basic designs required considerable physical effort and time for coupling and uncoupling, often necessitating multiple attempts to align the vehicles properly.

As industrial and agricultural demands grew, manufacturers began to focus on improving the ease of use and safety features of pintle hitches. The introduction of adjustable height pintles in the mid-20th century marked a significant advancement, allowing for better compatibility between different vehicle heights and reducing the risk of misalignment during coupling.

The late 20th century saw the integration of hydraulic and pneumatic systems into pintle hitch designs. These innovations greatly reduced the manual effort required for coupling and uncoupling, particularly for heavy-duty applications. Automated locking mechanisms were also introduced, enhancing safety by ensuring secure connections and minimizing the risk of accidental uncoupling during transit.

In recent years, the focus has shifted towards developing "smart" pintle hitches incorporating sensors and electronic systems. These advanced designs offer features such as automatic coupling detection, real-time monitoring of connection status, and integration with vehicle telematics systems. Such innovations not only improve operational efficiency but also contribute to enhanced safety through continuous monitoring and early warning systems.

The advent of computer-aided design and advanced manufacturing techniques has allowed for the creation of more precise and durable pintle hitch components. Materials science advancements have led to the use of high-strength, lightweight alloys that offer improved performance and longevity while reducing overall vehicle weight.

Current trends in pintle hitch evolution are centered around further automation and integration with autonomous vehicle systems. Research is ongoing into self-aligning pintles that can automatically adjust their position to facilitate coupling, potentially eliminating the need for precise vehicle positioning. Additionally, there is growing interest in developing pintles with built-in power and data transfer capabilities, enabling seamless integration of trailer systems with the towing vehicle's electronics and power supply.

In the early stages, pintle hitches were simple, manually operated devices consisting of a hook-like protrusion (the pintle) and a lunette ring. These basic designs required considerable physical effort and time for coupling and uncoupling, often necessitating multiple attempts to align the vehicles properly.

As industrial and agricultural demands grew, manufacturers began to focus on improving the ease of use and safety features of pintle hitches. The introduction of adjustable height pintles in the mid-20th century marked a significant advancement, allowing for better compatibility between different vehicle heights and reducing the risk of misalignment during coupling.

The late 20th century saw the integration of hydraulic and pneumatic systems into pintle hitch designs. These innovations greatly reduced the manual effort required for coupling and uncoupling, particularly for heavy-duty applications. Automated locking mechanisms were also introduced, enhancing safety by ensuring secure connections and minimizing the risk of accidental uncoupling during transit.

In recent years, the focus has shifted towards developing "smart" pintle hitches incorporating sensors and electronic systems. These advanced designs offer features such as automatic coupling detection, real-time monitoring of connection status, and integration with vehicle telematics systems. Such innovations not only improve operational efficiency but also contribute to enhanced safety through continuous monitoring and early warning systems.

The advent of computer-aided design and advanced manufacturing techniques has allowed for the creation of more precise and durable pintle hitch components. Materials science advancements have led to the use of high-strength, lightweight alloys that offer improved performance and longevity while reducing overall vehicle weight.

Current trends in pintle hitch evolution are centered around further automation and integration with autonomous vehicle systems. Research is ongoing into self-aligning pintles that can automatically adjust their position to facilitate coupling, potentially eliminating the need for precise vehicle positioning. Additionally, there is growing interest in developing pintles with built-in power and data transfer capabilities, enabling seamless integration of trailer systems with the towing vehicle's electronics and power supply.

Market Demand Analysis

The market demand for innovations in pintle hitch for faster coupling processes has been steadily growing, driven by the increasing need for efficiency and safety in various industries. The transportation and logistics sector, in particular, has shown a significant interest in advanced pintle hitch technologies that can reduce coupling time and improve overall operational productivity.

In the commercial trucking industry, where time is a critical factor, faster coupling processes can lead to substantial cost savings and improved fleet utilization. Fleet managers are actively seeking solutions that can minimize the time spent on hitching and unhitching trailers, as even small time savings per operation can translate into significant economic benefits when multiplied across large fleets.

The agricultural sector has also emerged as a key market for innovative pintle hitch solutions. As farms grow larger and more mechanized, the ability to quickly switch between different implements becomes crucial for maximizing productivity during short planting and harvesting windows. Farmers are increasingly demanding hitching systems that allow for rapid equipment changes without compromising safety or stability.

The construction industry represents another substantial market for advanced pintle hitch technologies. On construction sites, where multiple pieces of equipment need to be moved and reconfigured frequently, faster coupling processes can significantly reduce downtime and improve project timelines. Construction companies are willing to invest in hitching systems that offer both speed and reliability.

Military and defense applications have also contributed to the growing demand for innovative pintle hitch solutions. The ability to quickly couple and decouple vehicles and equipment in challenging environments is crucial for military logistics and tactical operations. This sector often drives technological advancements that later find their way into civilian applications.

Market analysis indicates that the global pintle hitch market is expected to grow at a steady rate over the next five years. This growth is fueled not only by the demand for faster coupling processes but also by the integration of smart technologies. There is an increasing interest in pintle hitches equipped with sensors and connectivity features that can provide real-time data on coupling status, load distribution, and potential safety issues.

Safety considerations continue to play a crucial role in shaping market demand. While speed is important, end-users are equally concerned with ensuring that faster coupling processes do not compromise the security of the connection. This has led to a focus on developing pintle hitch innovations that incorporate advanced locking mechanisms and fail-safe features.

The aftermarket segment for pintle hitch upgrades also presents a significant opportunity. Many fleet operators and equipment owners are looking to retrofit their existing vehicles with more advanced hitching systems, creating a substantial market for retrofit solutions that offer improved coupling speed and efficiency.

In the commercial trucking industry, where time is a critical factor, faster coupling processes can lead to substantial cost savings and improved fleet utilization. Fleet managers are actively seeking solutions that can minimize the time spent on hitching and unhitching trailers, as even small time savings per operation can translate into significant economic benefits when multiplied across large fleets.

The agricultural sector has also emerged as a key market for innovative pintle hitch solutions. As farms grow larger and more mechanized, the ability to quickly switch between different implements becomes crucial for maximizing productivity during short planting and harvesting windows. Farmers are increasingly demanding hitching systems that allow for rapid equipment changes without compromising safety or stability.

The construction industry represents another substantial market for advanced pintle hitch technologies. On construction sites, where multiple pieces of equipment need to be moved and reconfigured frequently, faster coupling processes can significantly reduce downtime and improve project timelines. Construction companies are willing to invest in hitching systems that offer both speed and reliability.

Military and defense applications have also contributed to the growing demand for innovative pintle hitch solutions. The ability to quickly couple and decouple vehicles and equipment in challenging environments is crucial for military logistics and tactical operations. This sector often drives technological advancements that later find their way into civilian applications.

Market analysis indicates that the global pintle hitch market is expected to grow at a steady rate over the next five years. This growth is fueled not only by the demand for faster coupling processes but also by the integration of smart technologies. There is an increasing interest in pintle hitches equipped with sensors and connectivity features that can provide real-time data on coupling status, load distribution, and potential safety issues.

Safety considerations continue to play a crucial role in shaping market demand. While speed is important, end-users are equally concerned with ensuring that faster coupling processes do not compromise the security of the connection. This has led to a focus on developing pintle hitch innovations that incorporate advanced locking mechanisms and fail-safe features.

The aftermarket segment for pintle hitch upgrades also presents a significant opportunity. Many fleet operators and equipment owners are looking to retrofit their existing vehicles with more advanced hitching systems, creating a substantial market for retrofit solutions that offer improved coupling speed and efficiency.

Current Challenges

The current challenges in pintle hitch technology for faster coupling processes are multifaceted and require innovative solutions to enhance efficiency and safety. One of the primary obstacles is the alignment issue during the coupling process. Traditional pintle hitches often require precise positioning of the towing vehicle, which can be time-consuming and frustrating for operators, especially in low-visibility conditions or confined spaces.

Another significant challenge is the manual effort required for coupling and uncoupling. Many existing systems still rely on operators to physically lift and maneuver heavy components, leading to potential safety risks and increased coupling time. This manual intervention also introduces the possibility of human error, which can result in improper connections and subsequent safety hazards during transportation.

The locking mechanism in conventional pintle hitches presents another area of concern. Current designs may not provide sufficient feedback to operators regarding the secure engagement of the hitch, leading to uncertainty and the need for additional visual checks. This lack of clear indication can slow down the coupling process and potentially compromise safety if overlooked.

Durability and maintenance issues also pose challenges in pintle hitch technology. The constant stress and wear experienced by these components in various environmental conditions can lead to premature failure or reduced performance over time. This necessitates frequent inspections and maintenance, which can impact operational efficiency and increase downtime.

Furthermore, the adaptability of pintle hitches to different trailer types and load configurations remains a challenge. Many existing systems are designed for specific applications, limiting their versatility across various industries and use cases. This lack of flexibility can result in the need for multiple hitch systems or frequent changeovers, impacting overall operational efficiency.

The integration of smart technologies into pintle hitch systems is another area facing challenges. While there is a growing demand for automated and sensor-driven solutions, implementing these technologies in a robust, reliable, and cost-effective manner presents significant engineering hurdles. Ensuring the seamless operation of electronic components in harsh environments and maintaining their long-term reliability are key concerns.

Lastly, regulatory compliance and standardization across different regions and industries present ongoing challenges. As safety standards evolve and new regulations are introduced, pintle hitch manufacturers must continuously adapt their designs to meet these requirements while maintaining performance and efficiency. This balancing act between innovation, safety, and regulatory compliance adds complexity to the development of new pintle hitch technologies.

Another significant challenge is the manual effort required for coupling and uncoupling. Many existing systems still rely on operators to physically lift and maneuver heavy components, leading to potential safety risks and increased coupling time. This manual intervention also introduces the possibility of human error, which can result in improper connections and subsequent safety hazards during transportation.

The locking mechanism in conventional pintle hitches presents another area of concern. Current designs may not provide sufficient feedback to operators regarding the secure engagement of the hitch, leading to uncertainty and the need for additional visual checks. This lack of clear indication can slow down the coupling process and potentially compromise safety if overlooked.

Durability and maintenance issues also pose challenges in pintle hitch technology. The constant stress and wear experienced by these components in various environmental conditions can lead to premature failure or reduced performance over time. This necessitates frequent inspections and maintenance, which can impact operational efficiency and increase downtime.

Furthermore, the adaptability of pintle hitches to different trailer types and load configurations remains a challenge. Many existing systems are designed for specific applications, limiting their versatility across various industries and use cases. This lack of flexibility can result in the need for multiple hitch systems or frequent changeovers, impacting overall operational efficiency.

The integration of smart technologies into pintle hitch systems is another area facing challenges. While there is a growing demand for automated and sensor-driven solutions, implementing these technologies in a robust, reliable, and cost-effective manner presents significant engineering hurdles. Ensuring the seamless operation of electronic components in harsh environments and maintaining their long-term reliability are key concerns.

Lastly, regulatory compliance and standardization across different regions and industries present ongoing challenges. As safety standards evolve and new regulations are introduced, pintle hitch manufacturers must continuously adapt their designs to meet these requirements while maintaining performance and efficiency. This balancing act between innovation, safety, and regulatory compliance adds complexity to the development of new pintle hitch technologies.

Existing Solutions

01 Improved coupling mechanisms for pintle hitches

Various designs have been developed to enhance the coupling mechanism of pintle hitches, focusing on improving the speed and ease of connection. These improvements include automatic locking systems, quick-release mechanisms, and ergonomic designs that allow for faster and more efficient coupling and uncoupling of trailers.- Pintle hitch coupling mechanisms: Various designs of pintle hitch coupling mechanisms are used to improve the connection between a towing vehicle and a trailer. These mechanisms often include features for secure locking, easy alignment, and quick coupling/uncoupling. Some designs incorporate safety features to prevent accidental disconnection during travel.

- Speed-related safety features: Some pintle hitch coupling systems incorporate speed-related safety features. These may include sensors or mechanisms that monitor the speed of the vehicle and adjust the coupling or provide warnings to ensure safe operation at various speeds. Such features can help prevent accidents or damage caused by excessive speed while towing.

- Automated coupling systems: Advanced pintle hitch coupling systems may include automated features to assist with coupling and uncoupling. These systems can use sensors, actuators, and control mechanisms to align the hitch, engage the coupling, and secure the connection, potentially improving efficiency and safety during the hitching process.

- Adjustable coupling mechanisms: Some pintle hitch designs incorporate adjustable components to accommodate different vehicle heights or towing configurations. These adjustable mechanisms can help maintain proper alignment and weight distribution across various speeds and road conditions, enhancing stability and safety during towing operations.

- Wear-resistant and low-maintenance designs: Certain pintle hitch coupling designs focus on durability and low maintenance requirements. These may include features such as self-lubricating components, corrosion-resistant materials, or simplified designs that reduce wear and tear. Such designs can help maintain consistent performance and safety across a wide range of speeds and usage conditions.

02 Safety features for pintle hitch couplings

Safety is a crucial aspect of pintle hitch couplings, especially when considering coupling speed. Innovations in this area include sensors and indicators to ensure proper coupling, fail-safe locking mechanisms, and designs that prevent accidental uncoupling during transit. These features aim to maintain safety while allowing for quick and efficient hitching.Expand Specific Solutions03 Adjustable and versatile pintle hitch designs

To accommodate various coupling speeds and vehicle configurations, adjustable and versatile pintle hitch designs have been developed. These include height-adjustable hitches, multi-position couplings, and adaptable systems that can work with different trailer types, allowing for faster and more flexible coupling across diverse applications.Expand Specific Solutions04 Integration of electronic and hydraulic systems

Advanced pintle hitch coupling systems incorporate electronic and hydraulic components to enhance coupling speed and efficiency. These systems may include power-assisted coupling mechanisms, electronic alignment guides, and automated coupling processes that reduce the time and effort required for hitching.Expand Specific Solutions05 Lightweight and durable materials for faster handling

The use of lightweight yet durable materials in pintle hitch construction contributes to easier handling and faster coupling speeds. Advanced alloys and composite materials are employed to reduce the weight of coupling components while maintaining strength and reliability, allowing for quicker manual operations and reduced wear over time.Expand Specific Solutions

Key Industry Players

The market for pintle hitch innovations is in a growth phase, driven by increasing demand for faster and more efficient coupling processes in various industries. The global market size for trailer hitches, including pintle hitches, is projected to expand significantly in the coming years. While the technology is relatively mature, there is ongoing innovation to improve coupling speed and safety. Key players like Deere & Co., Caterpillar, Inc., and J.C. Bamford Excavators Ltd. are likely investing in R&D to enhance their product offerings. Smaller specialized companies such as V.ORLANDI SpA and Colder Products Co. may also be contributing to advancements in this field, leveraging their expertise in coupling technologies.

Deere & Co.

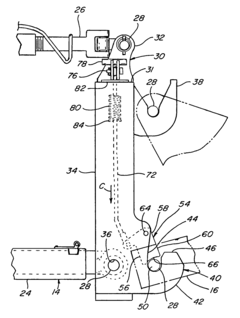

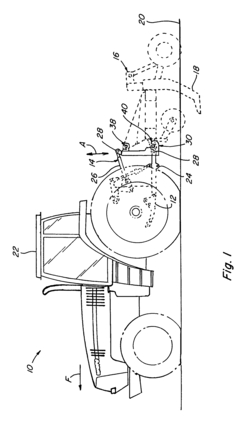

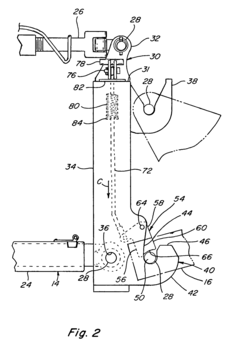

Technical Solution: Deere & Co. has developed an innovative pintle hitch system that significantly improves coupling processes. Their design incorporates a self-aligning mechanism that guides the implement into the correct position, reducing the need for precise alignment by the operator[1]. The system utilizes advanced sensors and hydraulic controls to automatically adjust the hitch height and angle, facilitating faster and more efficient coupling[3]. Additionally, Deere's pintle hitch features a quick-release mechanism that allows for rapid decoupling when needed, enhancing overall operational efficiency on the farm or construction site[5].

Strengths: Improved alignment accuracy, reduced coupling time, and enhanced operator safety. Weaknesses: May require more complex maintenance and potentially higher initial cost compared to traditional systems.

J.C. Bamford Excavators Ltd.

Technical Solution: J.C. Bamford Excavators Ltd. (JCB) has introduced a revolutionary pintle hitch design for their construction and agricultural equipment. Their system features a hydraulically-assisted coupling mechanism that allows for easy connection even when the towing vehicle and implement are not perfectly aligned[2]. JCB's pintle hitch incorporates a unique locking system that provides audible and visual confirmation of secure coupling, enhancing safety and reducing the risk of accidents[4]. The company has also integrated their pintle hitch with a smart telematics system, allowing operators to monitor hitch status and receive maintenance alerts remotely[6].

Strengths: Enhanced safety features, compatibility with telematics systems, and improved ease of use. Weaknesses: May be more expensive than traditional hitches and could require specialized training for operators.

Core Innovations

Rapid action coupling on the three-point hitch of agricultural machines

PatentInactiveEP0081221A1

Innovation

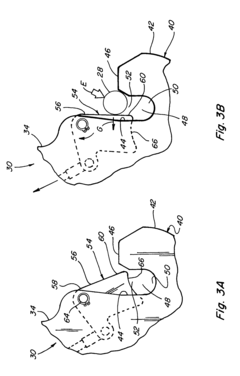

- The coupling element features a cylindrical outer surface and a hollow spherical inner surface, accommodating a spherically thickened socket, which reduces wear by minimizing surface contact and pressure, with a hollow-cylindrical hook mouth and a pivoting locking device to further minimize wear on the hook and attachment pin.

Coupler with self-latching and self-locking latching mechanism for a quick hitch

PatentActiveUS7404448B2

Innovation

- A self-latching and self-locking coupler design featuring a latch with a concave pin engaging surface and a projecting portion that securely holds the pin in place, even when the machine encounters forces and rotations that would otherwise open the latch, using a resilient biasing member for easy latching and unlatching, and a handle or servo device for manual operation.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of innovations in pintle hitch systems for faster coupling processes. These regulations are designed to ensure the safety of operators, vehicles, and cargo during the coupling and uncoupling procedures, as well as during transportation.

In the United States, the Federal Motor Carrier Safety Administration (FMCSA) sets the standards for commercial vehicle safety, including regulations pertaining to pintle hitches. These regulations cover aspects such as the strength and durability of the hitch components, the maximum allowable load capacity, and the proper installation and maintenance procedures.

The Society of Automotive Engineers (SAE) has also established industry standards for pintle hitches, including SAE J847, which specifies the performance requirements for pintle hooks and drawbars. These standards ensure that pintle hitches meet minimum safety and performance criteria across different manufacturers and applications.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs the mechanical coupling components of motor vehicles and their trailers. This regulation provides detailed specifications for the design, testing, and approval of coupling devices, including pintle hitches.

Innovations in pintle hitch systems must comply with these safety regulations while also improving the speed and efficiency of the coupling process. This often involves the integration of advanced sensors and electronic systems to enhance safety features. For example, some modern pintle hitch designs incorporate proximity sensors and automatic locking mechanisms to prevent accidental uncoupling during operation.

Another important aspect of safety regulations for pintle hitches is the requirement for regular inspections and maintenance. Many jurisdictions mandate periodic safety checks to ensure that the coupling devices remain in good working condition. These inspections typically include visual examinations for wear, damage, or corrosion, as well as functional tests of locking mechanisms and safety features.

As innovations in pintle hitch technology continue to evolve, safety regulations are likely to adapt to address new challenges and opportunities. For instance, the development of autonomous coupling systems may necessitate new safety standards to ensure reliable operation without human intervention. Additionally, the increasing use of lightweight materials in hitch construction may require updated testing protocols to verify their long-term durability and safety performance.

Manufacturers and developers of innovative pintle hitch systems must work closely with regulatory bodies to ensure that their products meet or exceed current safety standards. This collaboration often involves extensive testing and certification processes to demonstrate compliance with relevant regulations before new products can be brought to market.

In the United States, the Federal Motor Carrier Safety Administration (FMCSA) sets the standards for commercial vehicle safety, including regulations pertaining to pintle hitches. These regulations cover aspects such as the strength and durability of the hitch components, the maximum allowable load capacity, and the proper installation and maintenance procedures.

The Society of Automotive Engineers (SAE) has also established industry standards for pintle hitches, including SAE J847, which specifies the performance requirements for pintle hooks and drawbars. These standards ensure that pintle hitches meet minimum safety and performance criteria across different manufacturers and applications.

In Europe, the United Nations Economic Commission for Europe (UNECE) Regulation No. 55 governs the mechanical coupling components of motor vehicles and their trailers. This regulation provides detailed specifications for the design, testing, and approval of coupling devices, including pintle hitches.

Innovations in pintle hitch systems must comply with these safety regulations while also improving the speed and efficiency of the coupling process. This often involves the integration of advanced sensors and electronic systems to enhance safety features. For example, some modern pintle hitch designs incorporate proximity sensors and automatic locking mechanisms to prevent accidental uncoupling during operation.

Another important aspect of safety regulations for pintle hitches is the requirement for regular inspections and maintenance. Many jurisdictions mandate periodic safety checks to ensure that the coupling devices remain in good working condition. These inspections typically include visual examinations for wear, damage, or corrosion, as well as functional tests of locking mechanisms and safety features.

As innovations in pintle hitch technology continue to evolve, safety regulations are likely to adapt to address new challenges and opportunities. For instance, the development of autonomous coupling systems may necessitate new safety standards to ensure reliable operation without human intervention. Additionally, the increasing use of lightweight materials in hitch construction may require updated testing protocols to verify their long-term durability and safety performance.

Manufacturers and developers of innovative pintle hitch systems must work closely with regulatory bodies to ensure that their products meet or exceed current safety standards. This collaboration often involves extensive testing and certification processes to demonstrate compliance with relevant regulations before new products can be brought to market.

Environmental Impact

The environmental impact of innovations in pintle hitch for faster coupling processes is a crucial aspect to consider in the development and implementation of these technologies. As the transportation industry seeks to improve efficiency and reduce operational time, the environmental implications of these advancements must be carefully evaluated.

One of the primary environmental benefits of faster coupling processes is the potential reduction in fuel consumption and emissions. By minimizing the time vehicles spend idling during the coupling process, there is a direct decrease in unnecessary fuel burn and exhaust emissions. This improvement can lead to significant reductions in greenhouse gas emissions, particularly in large-scale operations where multiple couplings occur throughout the day.

Furthermore, innovations in pintle hitch design may contribute to improved aerodynamics of the coupled vehicles. Streamlined designs that facilitate quicker coupling can also reduce air resistance during transit, leading to better fuel efficiency and lower overall emissions during transport. This dual benefit of faster coupling and improved aerodynamics can have a substantial positive impact on the environmental footprint of transportation operations.

The materials used in advanced pintle hitch designs also play a role in their environmental impact. Manufacturers are increasingly focusing on lightweight yet durable materials that can withstand the stresses of faster coupling processes while reducing the overall weight of the vehicle. This weight reduction translates to improved fuel efficiency and reduced tire wear, both of which have positive environmental implications.

Additionally, faster coupling processes can lead to more efficient use of transportation infrastructure. By reducing the time vehicles spend in loading and unloading areas, there is potential for decreased congestion and improved traffic flow. This efficiency can result in lower overall emissions from vehicles waiting in queues and reduce the need for expansion of infrastructure, which often comes with its own environmental costs.

However, it is important to consider potential negative environmental impacts as well. The production of new, advanced pintle hitch systems may require energy-intensive manufacturing processes or the use of materials with high environmental footprints. The lifecycle analysis of these innovations must be carefully evaluated to ensure that the environmental benefits of their use outweigh the costs of their production and eventual disposal.

Lastly, the longevity and durability of these innovative coupling systems are crucial factors in their overall environmental impact. Systems designed for faster coupling must maintain their integrity over time to prevent premature replacement, which would negate any environmental benefits through increased waste and resource consumption. Manufacturers must strike a balance between speed, durability, and environmental sustainability in their designs.

One of the primary environmental benefits of faster coupling processes is the potential reduction in fuel consumption and emissions. By minimizing the time vehicles spend idling during the coupling process, there is a direct decrease in unnecessary fuel burn and exhaust emissions. This improvement can lead to significant reductions in greenhouse gas emissions, particularly in large-scale operations where multiple couplings occur throughout the day.

Furthermore, innovations in pintle hitch design may contribute to improved aerodynamics of the coupled vehicles. Streamlined designs that facilitate quicker coupling can also reduce air resistance during transit, leading to better fuel efficiency and lower overall emissions during transport. This dual benefit of faster coupling and improved aerodynamics can have a substantial positive impact on the environmental footprint of transportation operations.

The materials used in advanced pintle hitch designs also play a role in their environmental impact. Manufacturers are increasingly focusing on lightweight yet durable materials that can withstand the stresses of faster coupling processes while reducing the overall weight of the vehicle. This weight reduction translates to improved fuel efficiency and reduced tire wear, both of which have positive environmental implications.

Additionally, faster coupling processes can lead to more efficient use of transportation infrastructure. By reducing the time vehicles spend in loading and unloading areas, there is potential for decreased congestion and improved traffic flow. This efficiency can result in lower overall emissions from vehicles waiting in queues and reduce the need for expansion of infrastructure, which often comes with its own environmental costs.

However, it is important to consider potential negative environmental impacts as well. The production of new, advanced pintle hitch systems may require energy-intensive manufacturing processes or the use of materials with high environmental footprints. The lifecycle analysis of these innovations must be carefully evaluated to ensure that the environmental benefits of their use outweigh the costs of their production and eventual disposal.

Lastly, the longevity and durability of these innovative coupling systems are crucial factors in their overall environmental impact. Systems designed for faster coupling must maintain their integrity over time to prevent premature replacement, which would negate any environmental benefits through increased waste and resource consumption. Manufacturers must strike a balance between speed, durability, and environmental sustainability in their designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!