Testing Pintle Hitch Design in Extreme Environmental Conditions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pintle Hitch Evolution

The evolution of the pintle hitch design has been a journey of continuous improvement, driven by the need for more robust and versatile towing solutions. Initially developed in the mid-20th century, the pintle hitch was primarily used in military applications due to its ability to handle heavy loads and operate in challenging terrains. The early designs featured a simple hook and lunette ring system, which provided a secure connection but lacked the refinement needed for civilian use.

As the demand for heavy-duty towing in commercial and industrial sectors grew, the pintle hitch design underwent significant modifications. The 1970s and 1980s saw the introduction of enhanced safety features, such as locking mechanisms and improved weight distribution systems. These advancements made pintle hitches more suitable for a wider range of applications, including construction, agriculture, and long-haul transportation.

The 1990s marked a turning point in pintle hitch evolution with the integration of advanced materials and manufacturing techniques. High-strength alloys and precision engineering allowed for the creation of lighter yet more durable hitches capable of handling increased loads. This period also saw the development of combination pintle hitches, which incorporated both a ball mount and a pintle hook, offering greater versatility for different towing needs.

In the early 2000s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Manufacturers introduced designs with adjustable height settings, quick-release mechanisms, and improved corrosion resistance. These features not only enhanced the user experience but also contributed to increased safety and efficiency in towing operations.

The past decade has witnessed a surge in technological integration within pintle hitch designs. Smart sensors and electronic monitoring systems have been incorporated to provide real-time data on load distribution, hitch integrity, and potential safety issues. This technological leap has significantly improved the reliability and safety of pintle hitches, particularly in extreme environmental conditions.

Recent developments in pintle hitch design have focused on addressing the challenges posed by extreme environments. Engineers have been working on innovative solutions to combat issues such as extreme temperature fluctuations, high humidity, and corrosive atmospheres. Advanced coating technologies and self-lubricating materials have been employed to enhance durability and performance in harsh conditions.

The latest evolution in pintle hitch design involves the use of computer-aided engineering and simulation tools to optimize performance under various environmental stresses. These advanced modeling techniques allow designers to predict and mitigate potential failure points before physical prototypes are built, leading to more robust and reliable designs suitable for extreme conditions.

As the demand for heavy-duty towing in commercial and industrial sectors grew, the pintle hitch design underwent significant modifications. The 1970s and 1980s saw the introduction of enhanced safety features, such as locking mechanisms and improved weight distribution systems. These advancements made pintle hitches more suitable for a wider range of applications, including construction, agriculture, and long-haul transportation.

The 1990s marked a turning point in pintle hitch evolution with the integration of advanced materials and manufacturing techniques. High-strength alloys and precision engineering allowed for the creation of lighter yet more durable hitches capable of handling increased loads. This period also saw the development of combination pintle hitches, which incorporated both a ball mount and a pintle hook, offering greater versatility for different towing needs.

In the early 2000s, the focus shifted towards improving the ergonomics and ease of use of pintle hitches. Manufacturers introduced designs with adjustable height settings, quick-release mechanisms, and improved corrosion resistance. These features not only enhanced the user experience but also contributed to increased safety and efficiency in towing operations.

The past decade has witnessed a surge in technological integration within pintle hitch designs. Smart sensors and electronic monitoring systems have been incorporated to provide real-time data on load distribution, hitch integrity, and potential safety issues. This technological leap has significantly improved the reliability and safety of pintle hitches, particularly in extreme environmental conditions.

Recent developments in pintle hitch design have focused on addressing the challenges posed by extreme environments. Engineers have been working on innovative solutions to combat issues such as extreme temperature fluctuations, high humidity, and corrosive atmospheres. Advanced coating technologies and self-lubricating materials have been employed to enhance durability and performance in harsh conditions.

The latest evolution in pintle hitch design involves the use of computer-aided engineering and simulation tools to optimize performance under various environmental stresses. These advanced modeling techniques allow designers to predict and mitigate potential failure points before physical prototypes are built, leading to more robust and reliable designs suitable for extreme conditions.

Market Demand Analysis

The market demand for pintle hitch designs capable of withstanding extreme environmental conditions has been steadily increasing in recent years. This growth is primarily driven by the expanding sectors of heavy-duty transportation, military logistics, and off-road recreational vehicles. These industries require robust and reliable towing solutions that can perform consistently in challenging environments, ranging from arctic tundras to scorching deserts.

In the heavy-duty transportation sector, there is a growing need for pintle hitches that can maintain structural integrity and functionality under extreme temperature fluctuations, high humidity, and corrosive conditions. This demand is particularly pronounced in industries such as oil and gas, mining, and construction, where equipment often operates in remote and harsh environments. The ability to securely tow heavy loads across rugged terrains and in adverse weather conditions is crucial for operational efficiency and safety.

The military logistics sector represents another significant market for advanced pintle hitch designs. Armed forces worldwide are seeking towing solutions that can withstand the rigors of combat zones, including exposure to sand, dust, extreme heat, and sub-zero temperatures. The demand for pintle hitches that can perform reliably in these conditions is driven by the need for rapid deployment and mobility of military vehicles and equipment.

The off-road recreational vehicle market has also contributed to the increased demand for robust pintle hitch designs. As more enthusiasts venture into extreme terrains and climates for activities such as overlanding and expedition-style camping, there is a growing need for towing systems that can handle the stress of off-road travel in diverse environmental conditions. This market segment values pintle hitches that offer both durability and versatility.

Environmental factors such as corrosion resistance, thermal stability, and resistance to UV radiation are becoming increasingly important considerations in pintle hitch design. Manufacturers are responding to this demand by developing innovative materials and coatings that enhance the longevity and performance of pintle hitches in extreme conditions. This trend is expected to continue as end-users seek products that offer extended service life and reduced maintenance requirements.

The global market for specialized towing equipment, including pintle hitches designed for extreme conditions, is projected to grow significantly over the next decade. This growth is fueled by increasing investments in infrastructure development, expansion of mining and construction activities in remote areas, and the ongoing modernization of military fleets worldwide. As a result, there is a clear opportunity for manufacturers who can develop and validate pintle hitch designs that excel in extreme environmental testing.

In the heavy-duty transportation sector, there is a growing need for pintle hitches that can maintain structural integrity and functionality under extreme temperature fluctuations, high humidity, and corrosive conditions. This demand is particularly pronounced in industries such as oil and gas, mining, and construction, where equipment often operates in remote and harsh environments. The ability to securely tow heavy loads across rugged terrains and in adverse weather conditions is crucial for operational efficiency and safety.

The military logistics sector represents another significant market for advanced pintle hitch designs. Armed forces worldwide are seeking towing solutions that can withstand the rigors of combat zones, including exposure to sand, dust, extreme heat, and sub-zero temperatures. The demand for pintle hitches that can perform reliably in these conditions is driven by the need for rapid deployment and mobility of military vehicles and equipment.

The off-road recreational vehicle market has also contributed to the increased demand for robust pintle hitch designs. As more enthusiasts venture into extreme terrains and climates for activities such as overlanding and expedition-style camping, there is a growing need for towing systems that can handle the stress of off-road travel in diverse environmental conditions. This market segment values pintle hitches that offer both durability and versatility.

Environmental factors such as corrosion resistance, thermal stability, and resistance to UV radiation are becoming increasingly important considerations in pintle hitch design. Manufacturers are responding to this demand by developing innovative materials and coatings that enhance the longevity and performance of pintle hitches in extreme conditions. This trend is expected to continue as end-users seek products that offer extended service life and reduced maintenance requirements.

The global market for specialized towing equipment, including pintle hitches designed for extreme conditions, is projected to grow significantly over the next decade. This growth is fueled by increasing investments in infrastructure development, expansion of mining and construction activities in remote areas, and the ongoing modernization of military fleets worldwide. As a result, there is a clear opportunity for manufacturers who can develop and validate pintle hitch designs that excel in extreme environmental testing.

Environmental Challenges

Testing pintle hitch designs in extreme environmental conditions presents a multitude of challenges that must be carefully considered and addressed. These environmental factors can significantly impact the performance, durability, and safety of the hitch system, potentially leading to catastrophic failures if not properly accounted for.

One of the primary environmental challenges is extreme temperature variations. Pintle hitches may be subjected to temperatures ranging from sub-zero conditions in arctic regions to scorching heat in desert environments. These temperature fluctuations can affect the material properties of the hitch components, potentially causing thermal expansion or contraction, which may lead to misalignment or increased wear. Additionally, extreme cold can make materials brittle, increasing the risk of fractures, while high temperatures can accelerate corrosion and degradation of protective coatings.

Moisture and humidity pose another significant challenge, particularly in coastal or tropical regions. Prolonged exposure to moisture can lead to corrosion of metal components, compromising the structural integrity of the hitch. Salt spray in marine environments further exacerbates this issue, accelerating the corrosion process and potentially leading to premature failure. Proper selection of corrosion-resistant materials and protective coatings becomes crucial in these conditions.

Dust and particulate matter present in arid or industrial environments can infiltrate moving parts of the pintle hitch, causing increased friction and wear. This abrasive action can lead to accelerated degradation of components and reduced operational efficiency. Adequate sealing and filtration systems must be incorporated into the design to mitigate these effects.

Vibration and shock loads are environmental factors that are often overlooked but can have a significant impact on pintle hitch performance. Off-road conditions, rough terrain, and high-speed travel can subject the hitch to intense vibrations and sudden impacts. These forces can lead to fatigue failure, loosening of fasteners, and misalignment of components over time. Robust design considerations, including proper material selection and advanced damping systems, are essential to ensure long-term reliability under these conditions.

Ultraviolet (UV) radiation presents a unique challenge, particularly for non-metallic components of the pintle hitch system. Prolonged exposure to UV rays can cause degradation of polymers and elastomers, leading to cracking, discoloration, and loss of mechanical properties. This is especially critical for seals, gaskets, and any plastic components that may be incorporated into the design.

Biological factors, such as microbial growth and insect infestation, can also pose challenges in certain environments. Fungal growth in humid conditions can lead to material degradation, while insects may build nests in cavities, potentially obstructing moving parts or sensors. Consideration of these factors in the design phase can help prevent unexpected failures and maintenance issues.

Addressing these environmental challenges requires a comprehensive approach to testing and validation. Engineers must develop rigorous test protocols that simulate the most extreme conditions the pintle hitch may encounter during its operational life. This may involve the use of environmental chambers, salt spray tests, vibration tables, and accelerated weathering techniques to evaluate the long-term performance and durability of the hitch design under various environmental stressors.

One of the primary environmental challenges is extreme temperature variations. Pintle hitches may be subjected to temperatures ranging from sub-zero conditions in arctic regions to scorching heat in desert environments. These temperature fluctuations can affect the material properties of the hitch components, potentially causing thermal expansion or contraction, which may lead to misalignment or increased wear. Additionally, extreme cold can make materials brittle, increasing the risk of fractures, while high temperatures can accelerate corrosion and degradation of protective coatings.

Moisture and humidity pose another significant challenge, particularly in coastal or tropical regions. Prolonged exposure to moisture can lead to corrosion of metal components, compromising the structural integrity of the hitch. Salt spray in marine environments further exacerbates this issue, accelerating the corrosion process and potentially leading to premature failure. Proper selection of corrosion-resistant materials and protective coatings becomes crucial in these conditions.

Dust and particulate matter present in arid or industrial environments can infiltrate moving parts of the pintle hitch, causing increased friction and wear. This abrasive action can lead to accelerated degradation of components and reduced operational efficiency. Adequate sealing and filtration systems must be incorporated into the design to mitigate these effects.

Vibration and shock loads are environmental factors that are often overlooked but can have a significant impact on pintle hitch performance. Off-road conditions, rough terrain, and high-speed travel can subject the hitch to intense vibrations and sudden impacts. These forces can lead to fatigue failure, loosening of fasteners, and misalignment of components over time. Robust design considerations, including proper material selection and advanced damping systems, are essential to ensure long-term reliability under these conditions.

Ultraviolet (UV) radiation presents a unique challenge, particularly for non-metallic components of the pintle hitch system. Prolonged exposure to UV rays can cause degradation of polymers and elastomers, leading to cracking, discoloration, and loss of mechanical properties. This is especially critical for seals, gaskets, and any plastic components that may be incorporated into the design.

Biological factors, such as microbial growth and insect infestation, can also pose challenges in certain environments. Fungal growth in humid conditions can lead to material degradation, while insects may build nests in cavities, potentially obstructing moving parts or sensors. Consideration of these factors in the design phase can help prevent unexpected failures and maintenance issues.

Addressing these environmental challenges requires a comprehensive approach to testing and validation. Engineers must develop rigorous test protocols that simulate the most extreme conditions the pintle hitch may encounter during its operational life. This may involve the use of environmental chambers, salt spray tests, vibration tables, and accelerated weathering techniques to evaluate the long-term performance and durability of the hitch design under various environmental stressors.

Current Testing Methods

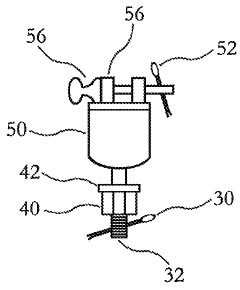

01 Pintle hitch locking mechanisms

Various locking mechanisms are employed in pintle hitch designs to secure the connection between the towing vehicle and the trailer. These mechanisms may include spring-loaded latches, safety pins, or automated locking systems that ensure a secure coupling and prevent accidental disconnection during towing.- Pintle hitch locking mechanisms: Various locking mechanisms are employed in pintle hitch designs to secure the connection between the towing vehicle and the trailer. These mechanisms may include spring-loaded latches, safety pins, or automated locking systems that ensure a secure coupling and prevent accidental disconnection during towing.

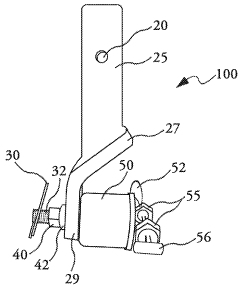

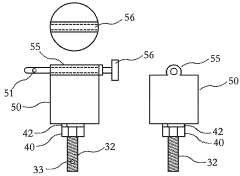

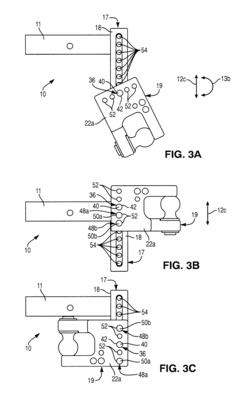

- Adjustable pintle hitch designs: Adjustable pintle hitch designs allow for versatility in towing different types of trailers or accommodating various vehicle heights. These designs may incorporate features such as multiple mounting positions, height-adjustable components, or interchangeable pintle hooks to adapt to different towing requirements.

- Integration of safety features: Pintle hitch designs often incorporate safety features to enhance towing security and prevent accidents. These may include built-in safety chains, breakaway systems, or visual indicators to confirm proper coupling. Such features aim to improve overall towing safety and comply with regulatory requirements.

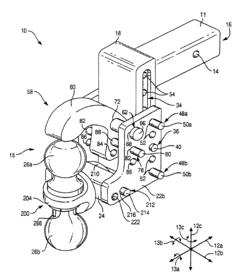

- Enhanced load distribution and stability: Advanced pintle hitch designs focus on improving load distribution and stability during towing. This may involve incorporating weight distribution systems, anti-sway mechanisms, or specialized geometries that help maintain proper alignment between the towing vehicle and the trailer, reducing stress on the hitch and improving overall towing performance.

- Multi-functional pintle hitch designs: Some pintle hitch designs incorporate multiple functionalities to increase versatility and convenience. These may include integrated ball mounts, combination pintle hook and ball hitch designs, or quick-release mechanisms for easy switching between different towing configurations. Such designs aim to provide flexibility for various towing needs with a single hitch system.

02 Adjustable pintle hitch designs

Adjustable pintle hitch designs allow for versatility in towing different types of trailers or accommodating various vehicle heights. These designs may incorporate features such as multiple mounting positions, height-adjustable components, or pivoting mechanisms to ensure proper alignment and weight distribution.Expand Specific Solutions03 Integration of safety features

Pintle hitch designs often incorporate safety features to enhance towing security and prevent accidents. These may include built-in safety chains, breakaway systems, or visual indicators to confirm proper coupling. Some designs also integrate sensors or electronic monitoring systems to alert the driver of potential issues during towing.Expand Specific Solutions04 Enhanced durability and load capacity

Pintle hitch designs focus on improving durability and increasing load capacity to handle heavy-duty towing applications. This may involve using high-strength materials, reinforced structures, or innovative weight distribution systems to enhance the overall performance and longevity of the hitch.Expand Specific Solutions05 Multi-functional pintle hitch designs

Some pintle hitch designs incorporate multiple functionalities to increase versatility and convenience. These may include combination designs that can accommodate different types of couplings, integrated storage solutions, or quick-release mechanisms for easy attachment and detachment of trailers.Expand Specific Solutions

Industry Leaders

The testing of pintle hitch design in extreme environmental conditions represents a niche but critical area within the automotive and heavy equipment industries. The market is in a growth phase, driven by increasing demand for robust towing solutions in challenging environments. While the market size is relatively small, it is expanding due to the rising need for reliable hitches in sectors like mining, construction, and off-road applications. Technologically, the field is advancing, with companies like Schlumberger Technologies, XCMG Construction Machinery, and Zoomlion Heavy Industry leading innovation. These firms are developing more durable and adaptable pintle hitch designs, incorporating advanced materials and smart technologies to enhance performance in extreme conditions.

XCMG Construction Machinery Co., Ltd.

Technical Solution: XCMG has developed robust pintle hitch designs for their heavy construction equipment, focusing on extreme environmental conditions. Their approach includes using advanced alloys and surface treatments to enhance corrosion resistance and wear properties. XCMG employs a modular design philosophy, allowing for easy maintenance and replacement of components in harsh environments[3]. The company's testing regimen involves subjecting the pintle hitch to extreme temperature variations, high-load cyclic testing, and exposure to abrasive materials to simulate real-world conditions encountered in construction sites worldwide[4].

Strengths: Modular design for easy maintenance, extensive field testing experience. Weaknesses: May have limitations in certain specialized extreme environments outside of construction applications.

Schlumberger Holdings Ltd.

Technical Solution: Schlumberger has developed advanced pintle hitch designs for extreme environmental conditions, particularly in the oil and gas industry. Their technology incorporates high-strength materials and innovative sealing mechanisms to withstand harsh temperatures, pressures, and corrosive environments. The company utilizes computational fluid dynamics (CFD) and finite element analysis (FEA) to optimize the hitch design for maximum durability and performance[1]. Schlumberger's testing protocols include thermal cycling, high-pressure testing, and accelerated wear simulations to ensure reliability in diverse operational scenarios[2].

Strengths: Extensive experience in extreme environments, advanced simulation capabilities, and comprehensive testing protocols. Weaknesses: Potentially higher costs due to specialized materials and design complexity.

Key Innovations

Pintle hitch connector

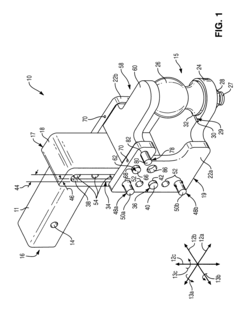

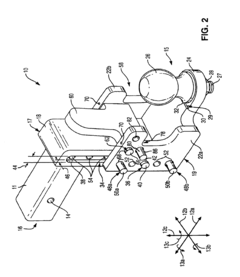

PatentInactiveUS20180104998A1

Innovation

- A pintle hitch connector with a cylindrical trailer contact portion and a threaded portion featuring a locking mechanism and load securing pin, along with a universal connector design that includes a curved hitch bracket and connecting pin, simplifying attachment and reducing manufacturing costs.

Stowable-lock, convertible-pintle hitch

PatentInactiveUS6789815B2

Innovation

- A stowable pintle hitch system with a trunnion, base, and mount configuration that allows for adjustable positioning and locking, enabling the hitch to be easily secured and released, accommodating twisting motions through a retainer mechanism that pivots and translates, and includes a silencing spacer for reduced noise and wear.

Material Advancements

Material advancements play a crucial role in enhancing the performance and durability of pintle hitch designs under extreme environmental conditions. Recent developments in materials science have led to significant improvements in the strength, corrosion resistance, and thermal stability of components used in pintle hitch systems.

High-strength alloys, such as advanced steel grades and titanium alloys, have been developed to withstand the intense mechanical stresses experienced by pintle hitches during towing operations. These materials offer superior tensile strength and fatigue resistance, allowing for increased load-bearing capacity and extended service life. Additionally, the use of lightweight alloys helps reduce the overall weight of the hitch system, contributing to improved fuel efficiency and vehicle performance.

Corrosion-resistant materials have become increasingly important for pintle hitch designs exposed to harsh environments. Advanced coatings and surface treatments, such as ceramic-based composites and nanostructured materials, provide enhanced protection against chemical degradation and wear. These innovations significantly extend the lifespan of pintle hitches in marine and industrial applications where exposure to salt water, chemicals, and abrasive particles is common.

Thermal management has been addressed through the development of materials with improved heat dissipation properties. Composite materials incorporating carbon fibers or ceramic particles offer excellent thermal conductivity, helping to maintain optimal operating temperatures in extreme heat or cold conditions. This is particularly important for pintle hitches used in heavy-duty applications where friction and mechanical stress can generate significant heat.

Smart materials and self-healing composites represent the cutting edge of material advancements for pintle hitch designs. Shape memory alloys and piezoelectric materials can adapt to changing environmental conditions, providing dynamic load distribution and vibration damping. Self-healing polymers and composites have the potential to automatically repair minor damage, reducing maintenance requirements and extending the operational life of pintle hitch systems.

Nanotechnology has also contributed to material advancements in pintle hitch design. Nanostructured materials and coatings offer improved wear resistance, reduced friction, and enhanced lubrication properties. These innovations can significantly improve the performance and reliability of pintle hitches under extreme conditions, such as high-temperature environments or applications with frequent load cycles.

High-strength alloys, such as advanced steel grades and titanium alloys, have been developed to withstand the intense mechanical stresses experienced by pintle hitches during towing operations. These materials offer superior tensile strength and fatigue resistance, allowing for increased load-bearing capacity and extended service life. Additionally, the use of lightweight alloys helps reduce the overall weight of the hitch system, contributing to improved fuel efficiency and vehicle performance.

Corrosion-resistant materials have become increasingly important for pintle hitch designs exposed to harsh environments. Advanced coatings and surface treatments, such as ceramic-based composites and nanostructured materials, provide enhanced protection against chemical degradation and wear. These innovations significantly extend the lifespan of pintle hitches in marine and industrial applications where exposure to salt water, chemicals, and abrasive particles is common.

Thermal management has been addressed through the development of materials with improved heat dissipation properties. Composite materials incorporating carbon fibers or ceramic particles offer excellent thermal conductivity, helping to maintain optimal operating temperatures in extreme heat or cold conditions. This is particularly important for pintle hitches used in heavy-duty applications where friction and mechanical stress can generate significant heat.

Smart materials and self-healing composites represent the cutting edge of material advancements for pintle hitch designs. Shape memory alloys and piezoelectric materials can adapt to changing environmental conditions, providing dynamic load distribution and vibration damping. Self-healing polymers and composites have the potential to automatically repair minor damage, reducing maintenance requirements and extending the operational life of pintle hitch systems.

Nanotechnology has also contributed to material advancements in pintle hitch design. Nanostructured materials and coatings offer improved wear resistance, reduced friction, and enhanced lubrication properties. These innovations can significantly improve the performance and reliability of pintle hitches under extreme conditions, such as high-temperature environments or applications with frequent load cycles.

Safety Regulations

Safety regulations play a crucial role in the testing and implementation of pintle hitch designs, especially when considering extreme environmental conditions. These regulations are designed to ensure the safety of both the vehicle and its occupants, as well as other road users and the surrounding environment.

In the context of pintle hitch design testing, safety regulations typically cover a wide range of aspects. These include structural integrity, load-bearing capacity, corrosion resistance, and performance under various weather conditions. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's Vehicle Certification Agency (VCA) set stringent standards for pintle hitch designs.

One of the key areas of focus in safety regulations is the ability of the pintle hitch to withstand extreme environmental conditions. This includes testing for performance in extreme temperatures, ranging from sub-zero arctic conditions to scorching desert heat. Regulations often require manufacturers to demonstrate that their pintle hitch designs can maintain structural integrity and functionality across these temperature ranges.

Additionally, safety regulations address the hitch's resistance to corrosion, particularly in environments with high humidity or exposure to salt water. This is crucial for ensuring long-term reliability and safety, especially in coastal or marine applications. Manufacturers must provide evidence of corrosion resistance through accelerated weathering tests and long-term exposure studies.

Another important aspect of safety regulations for pintle hitch designs is their performance under dynamic loading conditions. This includes testing for shock loads, vibration resistance, and fatigue strength. Regulatory standards often specify minimum requirements for these parameters, ensuring that the hitch can withstand the stresses associated with towing in various road conditions and terrains.

Safety regulations also extend to the compatibility of pintle hitch designs with different vehicle types and towing configurations. This includes specifications for proper installation, weight distribution, and load capacity limits. Manufacturers must provide clear guidelines and documentation to ensure that end-users can safely install and operate the pintle hitch within its intended parameters.

Furthermore, safety regulations often require extensive field testing of pintle hitch designs in real-world extreme environmental conditions. This may involve conducting trials in arctic regions, desert environments, and high-altitude locations to validate the hitch's performance and durability. Such testing helps identify potential failure modes and allows manufacturers to refine their designs to meet or exceed regulatory requirements.

In the context of pintle hitch design testing, safety regulations typically cover a wide range of aspects. These include structural integrity, load-bearing capacity, corrosion resistance, and performance under various weather conditions. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European Union's Vehicle Certification Agency (VCA) set stringent standards for pintle hitch designs.

One of the key areas of focus in safety regulations is the ability of the pintle hitch to withstand extreme environmental conditions. This includes testing for performance in extreme temperatures, ranging from sub-zero arctic conditions to scorching desert heat. Regulations often require manufacturers to demonstrate that their pintle hitch designs can maintain structural integrity and functionality across these temperature ranges.

Additionally, safety regulations address the hitch's resistance to corrosion, particularly in environments with high humidity or exposure to salt water. This is crucial for ensuring long-term reliability and safety, especially in coastal or marine applications. Manufacturers must provide evidence of corrosion resistance through accelerated weathering tests and long-term exposure studies.

Another important aspect of safety regulations for pintle hitch designs is their performance under dynamic loading conditions. This includes testing for shock loads, vibration resistance, and fatigue strength. Regulatory standards often specify minimum requirements for these parameters, ensuring that the hitch can withstand the stresses associated with towing in various road conditions and terrains.

Safety regulations also extend to the compatibility of pintle hitch designs with different vehicle types and towing configurations. This includes specifications for proper installation, weight distribution, and load capacity limits. Manufacturers must provide clear guidelines and documentation to ensure that end-users can safely install and operate the pintle hitch within its intended parameters.

Furthermore, safety regulations often require extensive field testing of pintle hitch designs in real-world extreme environmental conditions. This may involve conducting trials in arctic regions, desert environments, and high-altitude locations to validate the hitch's performance and durability. Such testing helps identify potential failure modes and allows manufacturers to refine their designs to meet or exceed regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!