Analysis of Spray Drying in High-Performance Fibers Manufacturing

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution in Fiber Manufacturing

Spray drying technology in fiber manufacturing has undergone significant evolution since its initial application in the 1940s. Originally developed for food and pharmaceutical industries, the adaptation of spray drying for fiber production represented a paradigm shift in manufacturing capabilities. The first-generation systems were characterized by simple single-fluid nozzles with limited control over particle morphology and size distribution, resulting in fibers with inconsistent properties.

The 1970s marked a critical turning point with the introduction of two-fluid nozzle systems, enabling better atomization and improved fiber precursor distribution. This advancement coincided with the growing demand for specialized fibers in aerospace and defense applications, driving further technological refinement. The incorporation of centrifugal atomizers in the 1980s allowed for higher throughput and more uniform droplet formation, essential for consistent fiber quality.

A significant breakthrough occurred in the early 1990s with the development of ultrasonic spray drying systems, which dramatically improved control over particle size distribution and morphology. This innovation enabled manufacturers to produce fibers with more precise mechanical properties and surface characteristics, expanding their application potential in technical textiles and composites.

The digital revolution of the 2000s brought sophisticated process control systems and real-time monitoring capabilities to spray drying operations. Manufacturers implemented closed-loop control algorithms that could adjust processing parameters dynamically, resulting in unprecedented consistency in fiber properties and substantial reductions in material waste.

Recent advancements have focused on sustainability and energy efficiency. Modern spray drying systems incorporate heat recovery mechanisms, reducing energy consumption by up to 30% compared to earlier generations. Additionally, the integration of computational fluid dynamics (CFD) modeling has enabled predictive design of spray dryers specifically optimized for high-performance fiber precursors.

The miniaturization trend has also influenced spray drying technology, with the development of lab-scale and pilot systems that facilitate rapid prototyping and material development. These systems have accelerated innovation cycles in fiber manufacturing, allowing for faster iteration and commercialization of novel fiber types.

The most cutting-edge development is the emergence of hybrid spray drying systems that combine multiple atomization mechanisms and incorporate in-line functionalization capabilities. These systems can produce complex multi-component fibers with gradient properties and embedded functional elements, opening new frontiers in smart textiles and responsive materials.

The 1970s marked a critical turning point with the introduction of two-fluid nozzle systems, enabling better atomization and improved fiber precursor distribution. This advancement coincided with the growing demand for specialized fibers in aerospace and defense applications, driving further technological refinement. The incorporation of centrifugal atomizers in the 1980s allowed for higher throughput and more uniform droplet formation, essential for consistent fiber quality.

A significant breakthrough occurred in the early 1990s with the development of ultrasonic spray drying systems, which dramatically improved control over particle size distribution and morphology. This innovation enabled manufacturers to produce fibers with more precise mechanical properties and surface characteristics, expanding their application potential in technical textiles and composites.

The digital revolution of the 2000s brought sophisticated process control systems and real-time monitoring capabilities to spray drying operations. Manufacturers implemented closed-loop control algorithms that could adjust processing parameters dynamically, resulting in unprecedented consistency in fiber properties and substantial reductions in material waste.

Recent advancements have focused on sustainability and energy efficiency. Modern spray drying systems incorporate heat recovery mechanisms, reducing energy consumption by up to 30% compared to earlier generations. Additionally, the integration of computational fluid dynamics (CFD) modeling has enabled predictive design of spray dryers specifically optimized for high-performance fiber precursors.

The miniaturization trend has also influenced spray drying technology, with the development of lab-scale and pilot systems that facilitate rapid prototyping and material development. These systems have accelerated innovation cycles in fiber manufacturing, allowing for faster iteration and commercialization of novel fiber types.

The most cutting-edge development is the emergence of hybrid spray drying systems that combine multiple atomization mechanisms and incorporate in-line functionalization capabilities. These systems can produce complex multi-component fibers with gradient properties and embedded functional elements, opening new frontiers in smart textiles and responsive materials.

Market Demand for High-Performance Fibers

The high-performance fiber market has experienced substantial growth over the past decade, driven primarily by increasing demand from aerospace, defense, automotive, and sporting goods industries. Global market valuation reached approximately 53 billion USD in 2022, with projections indicating a compound annual growth rate (CAGR) of 9.7% through 2030, potentially reaching 110 billion USD by the end of the forecast period.

Aerospace and defense sectors remain the largest consumers of high-performance fibers, accounting for roughly 38% of total market demand. These industries require materials with exceptional strength-to-weight ratios, heat resistance, and durability for applications in aircraft components, ballistic protection, and structural reinforcements. The automotive industry follows closely, representing about 24% of market consumption, as manufacturers increasingly adopt lightweight materials to improve fuel efficiency and meet stringent emission standards.

Regional analysis reveals Asia-Pacific as the dominant market, holding approximately 42% of global market share, with China and Japan leading production capabilities. North America and Europe follow with 28% and 23% market shares respectively, primarily driven by defense applications and high-end sporting goods manufacturing.

The market demonstrates clear segmentation by fiber type. Aramid fibers currently lead with 35% market share, valued for their heat resistance and mechanical strength. Carbon fibers follow at 30%, with particularly strong growth projections due to expanding applications in automotive lightweighting and renewable energy infrastructure. Other significant segments include ultra-high-molecular-weight polyethylene (UHMWPE) at 15% and polybenzimidazole (PBI) fibers at 8%.

Consumer trends indicate growing demand for specialized performance characteristics, including flame resistance, chemical stability, and enhanced tensile strength. Industries are increasingly willing to pay premium prices for fibers that deliver superior performance in extreme conditions, with particular emphasis on temperature resistance and dimensional stability.

Supply chain challenges present significant market constraints, with raw material volatility affecting production costs. The energy-intensive nature of traditional manufacturing processes has created market opportunities for more sustainable production methods, with spray drying technology emerging as a potential solution for reducing energy consumption by up to 30% compared to conventional techniques while maintaining or enhancing fiber performance characteristics.

Market forecasts suggest specialized applications in medical textiles, filtration systems, and renewable energy infrastructure will drive the next wave of growth, with these emerging segments expected to expand at rates exceeding 12% annually through 2030.

Aerospace and defense sectors remain the largest consumers of high-performance fibers, accounting for roughly 38% of total market demand. These industries require materials with exceptional strength-to-weight ratios, heat resistance, and durability for applications in aircraft components, ballistic protection, and structural reinforcements. The automotive industry follows closely, representing about 24% of market consumption, as manufacturers increasingly adopt lightweight materials to improve fuel efficiency and meet stringent emission standards.

Regional analysis reveals Asia-Pacific as the dominant market, holding approximately 42% of global market share, with China and Japan leading production capabilities. North America and Europe follow with 28% and 23% market shares respectively, primarily driven by defense applications and high-end sporting goods manufacturing.

The market demonstrates clear segmentation by fiber type. Aramid fibers currently lead with 35% market share, valued for their heat resistance and mechanical strength. Carbon fibers follow at 30%, with particularly strong growth projections due to expanding applications in automotive lightweighting and renewable energy infrastructure. Other significant segments include ultra-high-molecular-weight polyethylene (UHMWPE) at 15% and polybenzimidazole (PBI) fibers at 8%.

Consumer trends indicate growing demand for specialized performance characteristics, including flame resistance, chemical stability, and enhanced tensile strength. Industries are increasingly willing to pay premium prices for fibers that deliver superior performance in extreme conditions, with particular emphasis on temperature resistance and dimensional stability.

Supply chain challenges present significant market constraints, with raw material volatility affecting production costs. The energy-intensive nature of traditional manufacturing processes has created market opportunities for more sustainable production methods, with spray drying technology emerging as a potential solution for reducing energy consumption by up to 30% compared to conventional techniques while maintaining or enhancing fiber performance characteristics.

Market forecasts suggest specialized applications in medical textiles, filtration systems, and renewable energy infrastructure will drive the next wave of growth, with these emerging segments expected to expand at rates exceeding 12% annually through 2030.

Technical Challenges in Spray Drying Processes

Spray drying technology in high-performance fiber manufacturing faces several significant technical challenges that limit its efficiency and widespread adoption. The primary challenge lies in maintaining precise control over the drying parameters, as even minor fluctuations in temperature, pressure, or atomization can lead to inconsistent fiber properties. This sensitivity becomes particularly problematic when scaling up production from laboratory to industrial levels, where maintaining uniform conditions throughout larger spray chambers becomes increasingly difficult.

The atomization process itself presents another major hurdle. Creating uniform droplets with consistent size distribution is essential for producing homogeneous fibers, yet achieving this uniformity remains technically demanding. Current atomization technologies often struggle to deliver the required precision, especially when processing high-viscosity polymer solutions that are common in high-performance fiber production. The rheological properties of these solutions can change dramatically during the spraying process, further complicating control efforts.

Thermal management represents a critical challenge in spray drying for fiber manufacturing. The rapid evaporation of solvents creates significant temperature gradients within the drying chamber, which can lead to uneven solidification rates across different regions of the forming fibers. These thermal inconsistencies often result in structural defects, varying crystallinity, and non-uniform mechanical properties in the final product, compromising the overall fiber performance.

Solvent recovery and environmental concerns constitute another set of technical challenges. Many high-performance fibers require specialized solvents that are expensive and potentially hazardous. Efficient recovery systems are technically complex to design and operate, particularly when dealing with solvent mixtures or when trying to prevent contamination that could affect subsequent production batches. Regulatory requirements for emissions control add another layer of technical complexity to the process.

The formation of fiber morphology during spray drying presents unique challenges not encountered in other fiber production methods. Controlling the internal pore structure, surface characteristics, and cross-sectional geometry requires sophisticated understanding of the complex interplay between solution properties, drying kinetics, and solidification mechanisms. Current technology often struggles to provide the level of morphological control needed for the most demanding applications in aerospace, defense, and medical fields.

Energy efficiency remains a persistent challenge, as spray drying is inherently energy-intensive. The process requires significant thermal input to achieve rapid solvent evaporation, yet heat recovery and utilization systems for spray dryers are often inadequate. Developing more efficient heat exchange systems while maintaining precise temperature control throughout the process represents a significant technical hurdle that impacts both operational costs and environmental footprint.

The atomization process itself presents another major hurdle. Creating uniform droplets with consistent size distribution is essential for producing homogeneous fibers, yet achieving this uniformity remains technically demanding. Current atomization technologies often struggle to deliver the required precision, especially when processing high-viscosity polymer solutions that are common in high-performance fiber production. The rheological properties of these solutions can change dramatically during the spraying process, further complicating control efforts.

Thermal management represents a critical challenge in spray drying for fiber manufacturing. The rapid evaporation of solvents creates significant temperature gradients within the drying chamber, which can lead to uneven solidification rates across different regions of the forming fibers. These thermal inconsistencies often result in structural defects, varying crystallinity, and non-uniform mechanical properties in the final product, compromising the overall fiber performance.

Solvent recovery and environmental concerns constitute another set of technical challenges. Many high-performance fibers require specialized solvents that are expensive and potentially hazardous. Efficient recovery systems are technically complex to design and operate, particularly when dealing with solvent mixtures or when trying to prevent contamination that could affect subsequent production batches. Regulatory requirements for emissions control add another layer of technical complexity to the process.

The formation of fiber morphology during spray drying presents unique challenges not encountered in other fiber production methods. Controlling the internal pore structure, surface characteristics, and cross-sectional geometry requires sophisticated understanding of the complex interplay between solution properties, drying kinetics, and solidification mechanisms. Current technology often struggles to provide the level of morphological control needed for the most demanding applications in aerospace, defense, and medical fields.

Energy efficiency remains a persistent challenge, as spray drying is inherently energy-intensive. The process requires significant thermal input to achieve rapid solvent evaporation, yet heat recovery and utilization systems for spray dryers are often inadequate. Developing more efficient heat exchange systems while maintaining precise temperature control throughout the process represents a significant technical hurdle that impacts both operational costs and environmental footprint.

Current Spray Drying Solutions for Fiber Production

01 Spray drying equipment and apparatus design

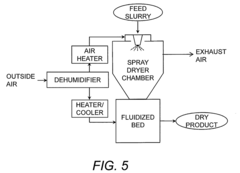

Various innovations in spray drying equipment design focus on improving efficiency and performance. These include specialized chambers, nozzle configurations, and integrated systems that enhance the drying process. Advanced designs incorporate features for better temperature control, particle formation, and energy efficiency, allowing for more precise control over the final product characteristics.- Spray drying equipment and apparatus design: Various innovations in spray drying equipment design focus on improving efficiency and product quality. These include specialized chambers, atomizers, and integrated systems that optimize the drying process. Advanced designs incorporate features for better temperature control, particle formation, and energy efficiency. Some equipment includes modifications for handling heat-sensitive materials or achieving specific particle characteristics.

- Formulation techniques for spray dried products: Specific formulation approaches enhance the properties of spray dried materials. These techniques involve selecting appropriate carriers, excipients, and processing aids to improve stability, flowability, and dissolution characteristics. Formulation strategies may include using protective agents for sensitive compounds, adjusting solid content, or incorporating functional additives to achieve desired product attributes such as controlled release or enhanced bioavailability.

- Process parameters optimization for spray drying: Optimization of spray drying process parameters is crucial for product quality and process efficiency. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and drying gas flow rate. Advanced control strategies monitor and adjust these parameters in real-time to maintain consistent product characteristics. Optimization approaches may involve statistical methods, modeling, or machine learning to determine ideal operating conditions for specific materials.

- Specialized spray drying for sensitive materials: Modified spray drying techniques protect heat-sensitive compounds such as proteins, probiotics, and pharmaceuticals. These approaches include low-temperature drying, protective formulations, and specialized atomization methods. Some techniques incorporate inert gas environments or additional stabilizing steps to preserve biological activity or chemical integrity. These methods enable the successful drying of materials that would otherwise degrade under conventional spray drying conditions.

- Industrial applications of spray drying technology: Spray drying finds diverse applications across multiple industries including food, pharmaceuticals, chemicals, and materials science. In food processing, it's used for producing powdered milk, instant coffee, and flavor encapsulation. Pharmaceutical applications include creating stable drug formulations with enhanced bioavailability. In materials science, spray drying enables production of specialized powders with controlled particle characteristics for ceramics, catalysts, and advanced materials.

02 Formulation techniques for spray dried products

Specific formulation approaches can significantly impact the quality and stability of spray dried products. These techniques involve selecting appropriate carrier materials, stabilizers, and excipients to protect active ingredients during the drying process. Formulation strategies may include using protective agents, pH modifiers, or specialized polymers to enhance product stability, solubility, and bioavailability of the final dried material.Expand Specific Solutions03 Process parameter optimization for spray drying

Optimizing process parameters is crucial for achieving desired product characteristics in spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and drying gas flow rate. Careful control of these variables allows manufacturers to manipulate particle size, morphology, moisture content, and other critical quality attributes of the final product while maximizing process efficiency and yield.Expand Specific Solutions04 Specialized applications of spray drying technology

Spray drying has been adapted for specialized applications across various industries. These include pharmaceutical formulations for improved drug delivery, food ingredient encapsulation for enhanced stability and controlled release, ceramic powder production, and advanced material synthesis. The versatility of spray drying enables its use in creating products with unique properties tailored to specific industrial needs.Expand Specific Solutions05 Innovations in spray drying for sensitive materials

Advanced spray drying techniques have been developed specifically for processing heat-sensitive materials such as proteins, probiotics, and bioactive compounds. These innovations include low-temperature spray drying, protective formulation strategies, and modified process conditions that minimize thermal degradation. Such approaches enable the successful drying of delicate substances while maintaining their functional properties and biological activity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spray drying technology in high-performance fibers manufacturing is currently in a growth phase, with an estimated market size of $3-4 billion and expanding at 5-7% annually. The competitive landscape features established industrial equipment manufacturers like Shandong Tianli Energy and GEA Systems North America providing core drying systems, alongside specialty materials companies such as DuPont, Asahi Kasei, and Henkel developing proprietary fiber formulations. Technical maturity varies significantly across applications, with conventional fiber drying being well-established while advanced applications for high-performance and specialty fibers remain in development. Companies like Oerlikon Textile and Cabot Corporation are advancing the technology through innovations in nozzle design, temperature control systems, and specialized additives that enhance fiber properties during the spray drying process.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed a sophisticated spray drying platform for high-performance fiber production that centers on their patented "controlled atmosphere spray drying" (CASD) technology. This approach utilizes modified atmospheric conditions within the drying chamber to precisely control the evaporation rate and polymer chain alignment during fiber formation. Their system incorporates multi-stage temperature zones that gradually remove solvents while maintaining optimal polymer orientation, resulting in fibers with exceptional mechanical properties. Asahi's technology employs specialized atomization nozzles that create micro-droplets with controlled morphology, enabling the production of hollow, porous, or solid fibers depending on application requirements. The company has integrated advanced computational fluid dynamics modeling to optimize spray patterns and drying conditions for each specific polymer formulation. Their process has demonstrated the ability to produce ultra-fine fibers (sub-micron diameter) with tensile strengths exceeding 3.5 GPa while maintaining production efficiency.

Strengths: Exceptional control over fiber microstructure; versatility in producing various fiber morphologies; advanced process modeling capabilities; proven commercial implementation across multiple fiber types. Weaknesses: Higher energy consumption compared to some competing technologies; complex system maintenance requirements; limited flexibility for rapid formulation changes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced spray drying technologies specifically for high-performance fiber manufacturing, focusing on their Kevlar® and Nomex® product lines. Their proprietary process involves atomizing polymer solutions into fine droplets using specialized nozzle designs that create uniform particle size distribution. The company employs a controlled temperature gradient system within their spray dryers, allowing precise manipulation of fiber morphology and crystallinity. DuPont's technology incorporates real-time monitoring systems that adjust processing parameters based on humidity, temperature, and particle formation dynamics. Their approach enables the production of fibers with enhanced tensile strength (up to 30% improvement compared to conventional methods) while maintaining flexibility. The company has also pioneered solvent recovery systems that recapture up to 95% of solvents used in the process, significantly reducing environmental impact and production costs.

Strengths: Superior control over fiber morphology and properties; excellent solvent recovery capabilities; proven scalability for industrial production; extensive intellectual property protection. Weaknesses: Higher initial capital investment requirements; process complexity requires specialized operator training; energy consumption remains relatively high despite efficiency improvements.

Key Patents and Innovations in Spray Drying Technology

Spray-dried compositions capable of retaining volatile compounds and methods of producing the same

PatentActiveUS20180027855A1

Innovation

- A method involving spray drying with an inlet temperature of less than 100°C and an air inlet dew point of −10° C. to 5° C. is used to retain at least 20% of the original volatile compounds, employing commercially available spray dryer nozzles and geometries, and potentially a secondary fluid-bed drying step to maintain flavor intensity and quality.

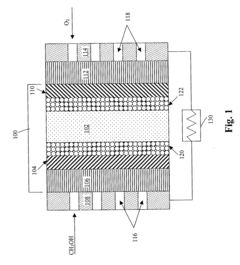

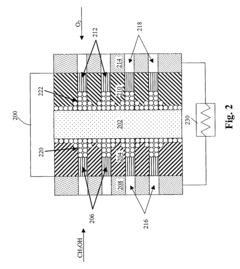

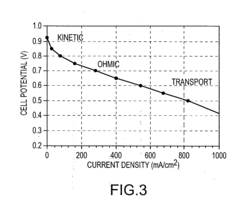

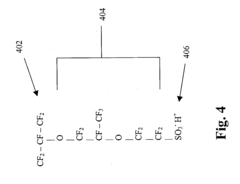

Method of producing membrane electrode assemblies for use in proton exchange membrane and direct methanol fuel cells

PatentInactiveUS20040038808A1

Innovation

- A direct-write printing method using ink-jet devices and syringe dispense tools to deposit gradient structures with varying compositions, microstructures, and porosities in MEAs, allowing for precise placement of catalysts and materials only where needed, enhancing catalyst utilization and reducing material waste.

Environmental Impact and Sustainability Considerations

The spray drying process in high-performance fiber manufacturing presents significant environmental challenges that must be addressed for sustainable industrial practices. Energy consumption represents one of the most critical environmental concerns, as the process requires substantial thermal energy to atomize and dry fiber precursor solutions. This intensive energy demand contributes to greenhouse gas emissions, particularly when fossil fuels serve as the primary energy source. Modern facilities are increasingly implementing heat recovery systems and exploring renewable energy alternatives to mitigate these impacts.

Water usage constitutes another major environmental consideration. Spray drying operations typically consume large volumes of water, both as a solvent in fiber precursor solutions and for equipment cleaning. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 60% in optimized manufacturing settings, representing a significant sustainability improvement for regions facing water scarcity challenges.

Chemical emissions during spray drying operations pose additional environmental risks. Volatile organic compounds (VOCs) and particulate matter released during the process can contribute to air pollution and potential health hazards for workers and surrounding communities. Current regulatory frameworks in most industrialized nations mandate emission control technologies such as thermal oxidizers and high-efficiency filtration systems to minimize these impacts.

Waste management presents ongoing challenges, particularly regarding the disposal of off-specification products and process residues. The chemical composition of high-performance fiber precursors often contains substances that require specialized handling and disposal protocols. Leading manufacturers have developed closed-loop systems that reprocess production waste, significantly reducing landfill contributions and hazardous waste generation.

Life cycle assessment (LCA) studies comparing spray drying to alternative fiber production methods have yielded mixed results regarding overall environmental footprint. While spray drying typically demonstrates higher energy intensity than some competing processes, it often achieves superior material efficiency and reduced chemical waste generation. These trade-offs necessitate comprehensive sustainability evaluations specific to each application context.

Industry initiatives toward greener spray drying technologies have accelerated in recent years, with significant investments in bio-based solvents, energy-efficient atomization technologies, and advanced process control systems that optimize resource utilization. These innovations have demonstrated potential to reduce the environmental footprint of spray-dried high-performance fibers by 25-40% compared to conventional manufacturing approaches, while maintaining or enhancing product performance characteristics.

Water usage constitutes another major environmental consideration. Spray drying operations typically consume large volumes of water, both as a solvent in fiber precursor solutions and for equipment cleaning. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 60% in optimized manufacturing settings, representing a significant sustainability improvement for regions facing water scarcity challenges.

Chemical emissions during spray drying operations pose additional environmental risks. Volatile organic compounds (VOCs) and particulate matter released during the process can contribute to air pollution and potential health hazards for workers and surrounding communities. Current regulatory frameworks in most industrialized nations mandate emission control technologies such as thermal oxidizers and high-efficiency filtration systems to minimize these impacts.

Waste management presents ongoing challenges, particularly regarding the disposal of off-specification products and process residues. The chemical composition of high-performance fiber precursors often contains substances that require specialized handling and disposal protocols. Leading manufacturers have developed closed-loop systems that reprocess production waste, significantly reducing landfill contributions and hazardous waste generation.

Life cycle assessment (LCA) studies comparing spray drying to alternative fiber production methods have yielded mixed results regarding overall environmental footprint. While spray drying typically demonstrates higher energy intensity than some competing processes, it often achieves superior material efficiency and reduced chemical waste generation. These trade-offs necessitate comprehensive sustainability evaluations specific to each application context.

Industry initiatives toward greener spray drying technologies have accelerated in recent years, with significant investments in bio-based solvents, energy-efficient atomization technologies, and advanced process control systems that optimize resource utilization. These innovations have demonstrated potential to reduce the environmental footprint of spray-dried high-performance fibers by 25-40% compared to conventional manufacturing approaches, while maintaining or enhancing product performance characteristics.

Quality Control and Characterization Methods

Quality control in spray drying processes for high-performance fiber manufacturing requires sophisticated characterization methods to ensure consistent product quality. The primary techniques employed include scanning electron microscopy (SEM) and transmission electron microscopy (TEM), which provide detailed morphological information about fiber structure, surface characteristics, and internal defects at micro and nano scales. These imaging techniques are essential for evaluating the uniformity of fiber diameter and identifying structural anomalies that may affect performance.

Spectroscopic methods such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy are widely utilized to analyze the chemical composition and molecular structure of spray-dried fibers. These non-destructive techniques can detect chemical changes during processing and verify the presence of specific functional groups, ensuring that the desired chemical properties are maintained throughout the manufacturing process.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), provide critical information about the thermal stability and phase transitions of high-performance fibers. These methods help in determining optimal processing parameters and predicting the thermal behavior of the final product under various environmental conditions.

Mechanical testing represents another crucial aspect of quality control, encompassing tensile strength, elongation at break, and modulus measurements. Advanced instruments such as dynamic mechanical analyzers and universal testing machines are employed to characterize the mechanical properties of fibers, ensuring they meet the stringent requirements for high-performance applications.

Particle size analysis using laser diffraction or dynamic light scattering techniques is particularly important for monitoring the consistency of spray-dried particles before fiber formation. These methods provide real-time data on particle size distribution, which directly influences the final fiber properties and processing behavior.

In-line monitoring systems have gained significant traction in modern manufacturing environments, allowing continuous assessment of critical parameters during production. These systems often incorporate spectroscopic sensors, rheological measurements, and computer vision technologies to detect deviations from quality standards without interrupting the production process.

Statistical process control (SPC) methodologies are increasingly integrated with characterization data to establish control limits and identify trends that may indicate potential quality issues. Advanced data analytics and machine learning algorithms are being developed to correlate multiple quality parameters, enabling more comprehensive quality assessment and predictive maintenance strategies in spray drying operations for high-performance fiber manufacturing.

Spectroscopic methods such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman spectroscopy are widely utilized to analyze the chemical composition and molecular structure of spray-dried fibers. These non-destructive techniques can detect chemical changes during processing and verify the presence of specific functional groups, ensuring that the desired chemical properties are maintained throughout the manufacturing process.

Thermal analysis techniques, including Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), provide critical information about the thermal stability and phase transitions of high-performance fibers. These methods help in determining optimal processing parameters and predicting the thermal behavior of the final product under various environmental conditions.

Mechanical testing represents another crucial aspect of quality control, encompassing tensile strength, elongation at break, and modulus measurements. Advanced instruments such as dynamic mechanical analyzers and universal testing machines are employed to characterize the mechanical properties of fibers, ensuring they meet the stringent requirements for high-performance applications.

Particle size analysis using laser diffraction or dynamic light scattering techniques is particularly important for monitoring the consistency of spray-dried particles before fiber formation. These methods provide real-time data on particle size distribution, which directly influences the final fiber properties and processing behavior.

In-line monitoring systems have gained significant traction in modern manufacturing environments, allowing continuous assessment of critical parameters during production. These systems often incorporate spectroscopic sensors, rheological measurements, and computer vision technologies to detect deviations from quality standards without interrupting the production process.

Statistical process control (SPC) methodologies are increasingly integrated with characterization data to establish control limits and identify trends that may indicate potential quality issues. Advanced data analytics and machine learning algorithms are being developed to correlate multiple quality parameters, enabling more comprehensive quality assessment and predictive maintenance strategies in spray drying operations for high-performance fiber manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!