Research on Spray Drying Techniques for Polymer Coatings

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Coating Spray Drying Background and Objectives

Spray drying technology for polymer coatings has evolved significantly over the past several decades, transitioning from basic industrial applications to sophisticated processes capable of producing highly engineered materials. Initially developed in the 1940s for food and pharmaceutical industries, polymer spray drying techniques have gradually expanded into the coatings sector since the 1970s, driven by increasing demands for specialized surface treatments across multiple industries including automotive, construction, electronics, and medical devices.

The evolution of this technology has been characterized by continuous improvements in atomization techniques, drying chamber designs, and process control systems. Early spray drying systems suffered from inconsistent particle size distribution and limited control over morphology, whereas modern systems can achieve precise control over particle characteristics including size, porosity, and surface properties. This progression has been accelerated by advancements in computational fluid dynamics, allowing for better understanding and optimization of the complex heat and mass transfer processes involved.

Recent technological trends indicate a growing focus on environmentally sustainable coating solutions, with particular emphasis on water-based polymer systems that reduce or eliminate volatile organic compounds (VOCs). Additionally, there is increasing interest in developing spray drying techniques compatible with high-performance polymers such as fluoropolymers, silicones, and specialty acrylics that can withstand extreme conditions while maintaining their protective and functional properties.

The primary technical objectives of current research in polymer coating spray drying include enhancing process efficiency, improving coating uniformity and adhesion, extending durability under harsh environmental conditions, and reducing environmental impact. Specific goals encompass the development of nano-structured coatings with self-healing capabilities, smart coatings that respond to environmental stimuli, and multi-functional coatings that combine protection with additional properties such as conductivity or antimicrobial activity.

Another significant objective is the scaling of laboratory processes to industrial production while maintaining quality and performance. This includes addressing challenges related to heat sensitivity of certain polymers, preventing agglomeration during drying, and ensuring consistent particle morphology across large production volumes. The integration of real-time monitoring and control systems represents a critical advancement toward achieving these goals.

Furthermore, research aims to expand the range of substrates that can be effectively coated using spray-dried polymer materials, including complex geometries and temperature-sensitive materials. This requires innovations in both the polymer formulations and the application techniques to ensure optimal adhesion, coverage, and performance across diverse substrate materials and shapes.

The evolution of this technology has been characterized by continuous improvements in atomization techniques, drying chamber designs, and process control systems. Early spray drying systems suffered from inconsistent particle size distribution and limited control over morphology, whereas modern systems can achieve precise control over particle characteristics including size, porosity, and surface properties. This progression has been accelerated by advancements in computational fluid dynamics, allowing for better understanding and optimization of the complex heat and mass transfer processes involved.

Recent technological trends indicate a growing focus on environmentally sustainable coating solutions, with particular emphasis on water-based polymer systems that reduce or eliminate volatile organic compounds (VOCs). Additionally, there is increasing interest in developing spray drying techniques compatible with high-performance polymers such as fluoropolymers, silicones, and specialty acrylics that can withstand extreme conditions while maintaining their protective and functional properties.

The primary technical objectives of current research in polymer coating spray drying include enhancing process efficiency, improving coating uniformity and adhesion, extending durability under harsh environmental conditions, and reducing environmental impact. Specific goals encompass the development of nano-structured coatings with self-healing capabilities, smart coatings that respond to environmental stimuli, and multi-functional coatings that combine protection with additional properties such as conductivity or antimicrobial activity.

Another significant objective is the scaling of laboratory processes to industrial production while maintaining quality and performance. This includes addressing challenges related to heat sensitivity of certain polymers, preventing agglomeration during drying, and ensuring consistent particle morphology across large production volumes. The integration of real-time monitoring and control systems represents a critical advancement toward achieving these goals.

Furthermore, research aims to expand the range of substrates that can be effectively coated using spray-dried polymer materials, including complex geometries and temperature-sensitive materials. This requires innovations in both the polymer formulations and the application techniques to ensure optimal adhesion, coverage, and performance across diverse substrate materials and shapes.

Market Analysis for Spray-Dried Polymer Coating Applications

The global market for spray-dried polymer coatings has experienced significant growth over the past decade, driven primarily by increasing demand in the pharmaceutical, food, and advanced materials industries. Current market valuations indicate that the spray-dried polymer coatings sector represents a substantial segment within the broader specialty coatings market, with particularly strong performance in regions with developed manufacturing capabilities.

In the pharmaceutical sector, spray-dried polymer coatings have gained traction due to their ability to provide controlled release properties, enhance drug stability, and improve bioavailability. This application segment has shown consistent annual growth rates exceeding the industry average, particularly for formulations addressing complex drug delivery challenges. The rising prevalence of chronic diseases and the growing emphasis on patient-centric drug delivery systems continue to fuel demand in this sector.

The food industry represents another major market for spray-dried polymer coatings, where they serve as effective encapsulation agents for flavors, colors, and nutritional ingredients. Consumer preference for clean-label products with extended shelf life has accelerated adoption in this segment. Additionally, the functional food market's expansion has created new opportunities for spray-dried polymer systems that can deliver bioactive compounds efficiently.

Industrial applications of spray-dried polymer coatings span multiple sectors including electronics, automotive, and construction. In these fields, the technology offers advantages in terms of uniform application, reduced material waste, and enhanced performance characteristics. The electronics industry, in particular, has embraced spray-dried polymer coatings for circuit board protection and component insulation.

Regional market analysis reveals that North America and Europe currently lead in terms of market value, owing to their established pharmaceutical and food processing industries. However, the Asia-Pacific region demonstrates the highest growth potential, with rapidly expanding manufacturing capabilities and increasing investment in advanced coating technologies. Countries like China, India, and South Korea are emerging as significant markets due to their growing industrial base and rising healthcare expenditures.

Market forecasts suggest that environmental regulations will increasingly shape the spray-dried polymer coatings landscape. The transition toward water-based and solvent-free formulations represents both a challenge and an opportunity for industry players. Companies that can develop environmentally friendly solutions without compromising performance characteristics are likely to gain competitive advantage in the evolving regulatory environment.

Customer segmentation analysis indicates varying needs across different industries, with pharmaceutical manufacturers prioritizing precision and consistency, food processors focusing on safety and sensory neutrality, and industrial users emphasizing durability and cost-effectiveness. This diversity of requirements has led to increased specialization among suppliers and the development of customized spray-dried polymer coating solutions for specific applications.

In the pharmaceutical sector, spray-dried polymer coatings have gained traction due to their ability to provide controlled release properties, enhance drug stability, and improve bioavailability. This application segment has shown consistent annual growth rates exceeding the industry average, particularly for formulations addressing complex drug delivery challenges. The rising prevalence of chronic diseases and the growing emphasis on patient-centric drug delivery systems continue to fuel demand in this sector.

The food industry represents another major market for spray-dried polymer coatings, where they serve as effective encapsulation agents for flavors, colors, and nutritional ingredients. Consumer preference for clean-label products with extended shelf life has accelerated adoption in this segment. Additionally, the functional food market's expansion has created new opportunities for spray-dried polymer systems that can deliver bioactive compounds efficiently.

Industrial applications of spray-dried polymer coatings span multiple sectors including electronics, automotive, and construction. In these fields, the technology offers advantages in terms of uniform application, reduced material waste, and enhanced performance characteristics. The electronics industry, in particular, has embraced spray-dried polymer coatings for circuit board protection and component insulation.

Regional market analysis reveals that North America and Europe currently lead in terms of market value, owing to their established pharmaceutical and food processing industries. However, the Asia-Pacific region demonstrates the highest growth potential, with rapidly expanding manufacturing capabilities and increasing investment in advanced coating technologies. Countries like China, India, and South Korea are emerging as significant markets due to their growing industrial base and rising healthcare expenditures.

Market forecasts suggest that environmental regulations will increasingly shape the spray-dried polymer coatings landscape. The transition toward water-based and solvent-free formulations represents both a challenge and an opportunity for industry players. Companies that can develop environmentally friendly solutions without compromising performance characteristics are likely to gain competitive advantage in the evolving regulatory environment.

Customer segmentation analysis indicates varying needs across different industries, with pharmaceutical manufacturers prioritizing precision and consistency, food processors focusing on safety and sensory neutrality, and industrial users emphasizing durability and cost-effectiveness. This diversity of requirements has led to increased specialization among suppliers and the development of customized spray-dried polymer coating solutions for specific applications.

Current Challenges in Polymer Spray Drying Technology

Despite significant advancements in polymer spray drying technology, several critical challenges continue to impede its widespread industrial application and optimization. One of the primary obstacles remains the precise control of particle morphology and size distribution. The complex interplay between process parameters such as inlet temperature, feed concentration, atomization pressure, and drying gas flow rate creates significant variability in the final coating properties. This challenge is particularly pronounced when working with high molecular weight polymers that exhibit non-Newtonian behavior during atomization.

Thermal degradation presents another substantial hurdle in polymer spray drying. Many specialty coating polymers contain temperature-sensitive functional groups that can undergo chemical changes or degradation when exposed to the high temperatures inherent in conventional spray drying processes. This degradation often compromises the intended performance characteristics of the coating, including adhesion strength, barrier properties, and aesthetic qualities.

Scalability issues continue to plague the transition from laboratory to industrial implementation. Processes that demonstrate excellent results at small scales frequently encounter unforeseen complications during scale-up, including heat transfer inefficiencies, increased residence time distributions, and flow pattern inconsistencies within larger drying chambers. These factors contribute to batch-to-batch variability and reduced product quality at commercial scales.

Energy efficiency remains a significant concern, as conventional spray drying systems for polymers typically operate at thermal efficiencies below 50%. The high energy consumption not only increases production costs but also contributes to the environmental footprint of coating manufacturing processes. This challenge is exacerbated when dealing with high-solids polymer formulations that require substantial thermal energy for solvent evaporation.

Solvent recovery and environmental considerations pose additional challenges. Many polymer coating formulations utilize organic solvents that must be efficiently recovered or safely disposed of following the drying process. Current recovery systems often struggle to achieve high efficiency while maintaining economic viability, particularly for complex solvent mixtures commonly used in advanced coating formulations.

Agglomeration and wall deposition during the drying process represent persistent operational challenges. Partially dried polymer particles frequently adhere to equipment surfaces or agglomerate with other particles, leading to product loss, quality issues, and increased maintenance requirements. These phenomena are particularly problematic with tacky or low-glass-transition-temperature polymers commonly used in flexible coating applications.

Instrumentation and real-time monitoring capabilities remain insufficient for comprehensive process control. The lack of reliable in-situ measurement technologies for critical parameters such as particle formation dynamics, moisture content evolution, and coating microstructure development limits the ability to implement advanced control strategies that could address many of the aforementioned challenges.

Thermal degradation presents another substantial hurdle in polymer spray drying. Many specialty coating polymers contain temperature-sensitive functional groups that can undergo chemical changes or degradation when exposed to the high temperatures inherent in conventional spray drying processes. This degradation often compromises the intended performance characteristics of the coating, including adhesion strength, barrier properties, and aesthetic qualities.

Scalability issues continue to plague the transition from laboratory to industrial implementation. Processes that demonstrate excellent results at small scales frequently encounter unforeseen complications during scale-up, including heat transfer inefficiencies, increased residence time distributions, and flow pattern inconsistencies within larger drying chambers. These factors contribute to batch-to-batch variability and reduced product quality at commercial scales.

Energy efficiency remains a significant concern, as conventional spray drying systems for polymers typically operate at thermal efficiencies below 50%. The high energy consumption not only increases production costs but also contributes to the environmental footprint of coating manufacturing processes. This challenge is exacerbated when dealing with high-solids polymer formulations that require substantial thermal energy for solvent evaporation.

Solvent recovery and environmental considerations pose additional challenges. Many polymer coating formulations utilize organic solvents that must be efficiently recovered or safely disposed of following the drying process. Current recovery systems often struggle to achieve high efficiency while maintaining economic viability, particularly for complex solvent mixtures commonly used in advanced coating formulations.

Agglomeration and wall deposition during the drying process represent persistent operational challenges. Partially dried polymer particles frequently adhere to equipment surfaces or agglomerate with other particles, leading to product loss, quality issues, and increased maintenance requirements. These phenomena are particularly problematic with tacky or low-glass-transition-temperature polymers commonly used in flexible coating applications.

Instrumentation and real-time monitoring capabilities remain insufficient for comprehensive process control. The lack of reliable in-situ measurement technologies for critical parameters such as particle formation dynamics, moisture content evolution, and coating microstructure development limits the ability to implement advanced control strategies that could address many of the aforementioned challenges.

Current Spray Drying Solutions for Polymer Coatings

01 Spray drying parameters for polymer coating formation

Specific spray drying parameters such as temperature, pressure, and flow rate can be optimized to create effective polymer coatings. These parameters affect the morphology, thickness, and adhesion properties of the resulting polymer film. Controlling these variables allows for the production of uniform coatings with desired characteristics such as controlled release properties, improved stability, and enhanced surface properties.- Spray drying parameters for polymer coating formulations: Specific spray drying parameters such as temperature, pressure, and flow rate can be optimized to achieve desired polymer coating properties. These parameters affect the morphology, particle size, and uniformity of the coating. Controlling these variables allows for the production of polymer coatings with consistent quality and performance characteristics for various applications.

- Polymer selection and modification for spray-dried coatings: The selection and modification of polymers significantly impact the performance of spray-dried coatings. Different polymers offer varying properties such as adhesion strength, flexibility, and durability. Polymer modifications, including crosslinking agents and plasticizers, can enhance coating performance. The molecular weight and chemical structure of the polymer influence the coating's physical and chemical properties.

- Solvent systems for polymer spray drying: The choice of solvent system is crucial in spray drying of polymer coatings. Solvent selection affects polymer solubility, solution viscosity, and drying behavior. Water-based systems offer environmental benefits, while organic solvents may provide better polymer compatibility. Co-solvent systems can be employed to optimize drying efficiency and coating quality. The solvent evaporation rate influences the microstructure and properties of the final coating.

- Additives and functional ingredients in spray-dried polymer coatings: Various additives can be incorporated into spray-dried polymer coatings to enhance functionality. These include surfactants for improved wetting and adhesion, pigments for color and opacity, UV stabilizers for weather resistance, and antimicrobial agents for protective properties. Functional fillers can modify mechanical properties, while release agents can provide controlled delivery of active ingredients. The proper dispersion and compatibility of these additives with the polymer matrix is essential for optimal coating performance.

- Equipment design and process optimization for polymer spray drying: The design of spray drying equipment significantly impacts the quality of polymer coatings. Nozzle design affects droplet size and distribution, while drying chamber geometry influences particle flow patterns and residence time. Atomization techniques, including pressure, rotary, and ultrasonic methods, offer different advantages for specific coating applications. Process optimization strategies, such as feed rate control and multi-stage drying, can enhance efficiency and product quality. Advanced monitoring and control systems enable consistent production of high-quality polymer coatings.

02 Polymer selection and formulation for spray dried coatings

The selection of appropriate polymers and their formulation is critical for successful spray dried coatings. Different polymers offer varying properties such as flexibility, durability, and compatibility with substrates. Formulations may include plasticizers, cross-linking agents, and other additives to enhance coating performance. The molecular weight and concentration of polymers in the spray solution significantly impact the coating quality and functional properties.Expand Specific Solutions03 Solvent systems for polymer spray drying

The choice of solvent system plays a crucial role in spray drying of polymer coatings. Solvent properties affect polymer dissolution, spray atomization, evaporation rate, and final coating characteristics. Water-based, organic, and mixed solvent systems can be employed depending on the polymer type and desired coating properties. Proper solvent selection can improve process efficiency, reduce environmental impact, and enhance coating quality.Expand Specific Solutions04 Equipment design for polymer spray drying

Specialized equipment designs for spray drying of polymer coatings include modified nozzle configurations, chamber designs, and collection systems. These design elements influence particle size distribution, coating uniformity, and process efficiency. Advanced equipment may incorporate features for electrostatic charging, ultrasonic atomization, or multi-stage drying to achieve specific coating characteristics and improve product quality.Expand Specific Solutions05 Post-processing techniques for spray dried polymer coatings

After spray drying, polymer coatings often require post-processing treatments to achieve optimal performance. These techniques include thermal curing, UV treatment, annealing, or additional coating layers. Post-processing can enhance adhesion, mechanical strength, barrier properties, and functional characteristics of the polymer coating. The selection of appropriate post-processing methods depends on the polymer type, substrate material, and intended application of the coated product.Expand Specific Solutions

Leading Companies and Research Institutions in Spray Drying

The spray drying techniques for polymer coatings market is in a growth phase, with increasing applications across industries like pharmaceuticals, electronics, and automotive. The global market size is expanding due to rising demand for advanced coating solutions. Technologically, the field is moderately mature but continues to evolve with innovations in process efficiency and material compatibility. Leading players include BASF Corp., which dominates with comprehensive polymer solutions, while LG Chem and Wacker Chemie AG focus on specialty applications. Research institutions like Zhejiang University and SINOPEC Beijing Research Institute contribute significant advancements. Companies like Rohm & Haas and PPG Industries Ohio bring expertise in industrial applications, while Shin-Etsu Chemical and DKS Co. are developing next-generation formulations with enhanced performance characteristics.

BASF Corp.

Technical Solution: BASF has developed advanced spray drying technologies for polymer coatings that utilize a combination of specialized atomization techniques and controlled drying parameters. Their process employs modified twin-fluid nozzles that create uniform droplet sizes between 10-50 μm, optimizing particle morphology and coating performance. BASF's system incorporates real-time process analytical technology (PAT) for monitoring critical quality attributes during spray drying, allowing for adaptive control of process parameters. Their technology enables the production of polymer coatings with tailored surface properties, including controlled porosity (ranging from 5-30%) and specific surface area (up to 200 m²/g), which enhances adhesion and functional performance. BASF has also pioneered the use of sustainable solvents and reduced energy consumption in their spray drying operations by implementing heat recovery systems that achieve up to 30% energy savings.

Strengths: Superior control over particle morphology and size distribution; integrated PAT systems for quality assurance; energy-efficient operations with heat recovery systems. Weaknesses: Higher capital investment requirements compared to conventional methods; process complexity requires specialized technical expertise; limited flexibility for very small batch production.

Wacker Chemie AG

Technical Solution: Wacker Chemie has developed a specialized spray drying technology called "PolyDry" for silicone and organic polymer coatings. Their system utilizes a combination of ultrasonic and pressure nozzle atomization that can be selected based on specific polymer properties and target particle characteristics. The technology incorporates a multi-zone drying chamber with precisely controlled temperature profiles (typically 60-180°C) that prevents thermal degradation while ensuring complete solvent removal. Wacker's process features advanced computational fluid dynamics modeling that optimizes airflow patterns within the drying chamber, reducing particle agglomeration and improving collection efficiency (typically >95%). Their system enables the production of spray-dried polymer particles with controlled hydrophobicity/hydrophilicity ratios through surface modification during the drying process. Wacker has demonstrated the ability to produce polymer coatings with exceptional redispersion properties, achieving stable suspensions with minimal additives. The technology has been successfully applied to silicone-organic hybrid polymers, achieving unique combinations of flexibility and durability in the resulting coatings.

Strengths: Exceptional expertise with silicone and hybrid polymer systems; superior particle collection efficiency; ability to modify surface properties during the drying process. Weaknesses: Higher capital costs compared to conventional spray dryers; more complex validation procedures for pharmaceutical applications; limited throughput for very high viscosity polymer solutions.

Key Patents and Technical Innovations in Polymer Spray Drying

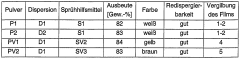

Method for producing polymer powders that can be easily redispersed in water

PatentWO2005080478A1

Innovation

- The process involves spray drying an aqueous polymer dispersion in the presence of a spray assistant prepared by reacting dihydroxydiphenyl sulfone with an aliphatic aldehyde and sodium sulfite, which improves the redispersibility and color stability of the polymer powders.

Production Of Pulverulent Coating Compositions For Stable Protective Coatings For Pharmaceutical Dosage Forms

PatentActiveUS20120219694A1

Innovation

- A process involving the radical polymerization of N,N-diethylaminoethyl methacrylate and esters of α,β-ethylenically unsaturated mono- and dicarboxylic acids, followed by spray processing with a drying gas at controlled temperatures to produce polymer powders with specific glass transition and film-forming temperatures, which are then redispersed in water with auxiliaries to create stable coating compositions.

Environmental Impact and Sustainability Considerations

Spray drying techniques for polymer coatings present significant environmental considerations that must be addressed as this technology continues to evolve. The process inherently consumes substantial energy during the atomization and drying phases, with thermal energy requirements representing a major environmental impact factor. Modern spray drying systems have made considerable progress in energy efficiency through heat recovery systems and optimized process parameters, reducing the carbon footprint by up to 30% compared to conventional methods.

Solvent selection remains a critical environmental concern in polymer coating applications. Traditional spray drying often relies on volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. The industry has been transitioning toward water-based formulations and environmentally benign solvents, though challenges in achieving equivalent coating performance persist. Recent advancements in green chemistry have yielded promising alternatives that maintain coating integrity while reducing environmental harm.

Waste generation during spray drying operations primarily manifests as overspray and particulate emissions. Advanced containment systems and electrostatic precipitation technologies have demonstrated 85-95% capture efficiency for these materials, significantly reducing environmental discharge. Closed-loop processing systems that reclaim and reuse overspray materials represent an emerging sustainable approach, though implementation costs remain prohibitive for smaller operations.

Life cycle assessment (LCA) studies of spray-dried polymer coatings reveal that environmental impacts extend beyond the manufacturing process to raw material sourcing and end-of-life considerations. Biopolymer alternatives derived from renewable resources show promise in reducing the overall environmental footprint, with recent research demonstrating comparable performance characteristics to petroleum-based polymers in certain applications.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on coating technologies. The European Union's REACH regulations and similar initiatives globally have accelerated research into environmentally responsible spray drying techniques. Companies adopting sustainable practices have reported not only regulatory compliance benefits but also market advantages as consumer preferences shift toward environmentally conscious products.

Water consumption represents another significant sustainability concern, particularly in water-scarce regions. Innovative water recycling systems integrated with spray drying operations have demonstrated reduction potential of 40-60% in freshwater requirements. These systems employ membrane filtration and advanced oxidation processes to treat and recirculate process water without compromising coating quality.

Solvent selection remains a critical environmental concern in polymer coating applications. Traditional spray drying often relies on volatile organic compounds (VOCs) that contribute to air pollution and pose health risks. The industry has been transitioning toward water-based formulations and environmentally benign solvents, though challenges in achieving equivalent coating performance persist. Recent advancements in green chemistry have yielded promising alternatives that maintain coating integrity while reducing environmental harm.

Waste generation during spray drying operations primarily manifests as overspray and particulate emissions. Advanced containment systems and electrostatic precipitation technologies have demonstrated 85-95% capture efficiency for these materials, significantly reducing environmental discharge. Closed-loop processing systems that reclaim and reuse overspray materials represent an emerging sustainable approach, though implementation costs remain prohibitive for smaller operations.

Life cycle assessment (LCA) studies of spray-dried polymer coatings reveal that environmental impacts extend beyond the manufacturing process to raw material sourcing and end-of-life considerations. Biopolymer alternatives derived from renewable resources show promise in reducing the overall environmental footprint, with recent research demonstrating comparable performance characteristics to petroleum-based polymers in certain applications.

Regulatory frameworks worldwide are increasingly imposing stricter environmental standards on coating technologies. The European Union's REACH regulations and similar initiatives globally have accelerated research into environmentally responsible spray drying techniques. Companies adopting sustainable practices have reported not only regulatory compliance benefits but also market advantages as consumer preferences shift toward environmentally conscious products.

Water consumption represents another significant sustainability concern, particularly in water-scarce regions. Innovative water recycling systems integrated with spray drying operations have demonstrated reduction potential of 40-60% in freshwater requirements. These systems employ membrane filtration and advanced oxidation processes to treat and recirculate process water without compromising coating quality.

Scale-up Challenges and Industrial Implementation

The transition from laboratory-scale spray drying to industrial production presents significant challenges that must be addressed systematically. When scaling up polymer coating processes, maintaining consistent product quality becomes increasingly difficult due to the complex interplay of process parameters. Industrial spray dryers operate at significantly higher throughput rates, requiring careful adjustment of atomization conditions, drying chamber dimensions, and residence times to achieve comparable coating characteristics.

One of the primary scale-up challenges involves heat and mass transfer phenomena, which do not scale linearly with equipment size. Industrial implementations must account for these non-linear relationships to prevent issues such as incomplete solvent evaporation or thermal degradation of polymer materials. The larger diameter of industrial atomizers also creates different droplet size distributions compared to laboratory equipment, necessitating recalibration of process parameters to maintain desired coating morphology and thickness uniformity.

Equipment design considerations become paramount during scale-up. Industrial spray dryers require sophisticated control systems to manage the increased complexity of operations. The selection of appropriate atomization devices—whether rotary, pressure, or two-fluid nozzles—must be reevaluated at industrial scale, as their performance characteristics change significantly with increased throughput requirements. Additionally, the design of drying chambers must account for proper air flow patterns to prevent wall deposition and agglomeration issues that are less pronounced in laboratory settings.

Economic factors heavily influence industrial implementation decisions. Capital investment for industrial spray drying equipment is substantial, requiring careful cost-benefit analysis. Operating costs, particularly energy consumption for heating large volumes of drying gas, can significantly impact production economics. Manufacturers must optimize energy recovery systems and consider alternative heating methods to maintain economic viability while achieving desired coating properties.

Regulatory compliance presents another layer of complexity for industrial implementation. Scaling up polymer coating processes often necessitates additional validation steps to ensure consistent product quality and safety. Documentation requirements become more stringent, particularly for applications in regulated industries such as pharmaceuticals or food packaging. Process analytical technology (PAT) implementation becomes essential for real-time monitoring and control of critical quality attributes during continuous production.

Sustainability considerations have gained increasing importance in industrial spray drying operations. Modern implementations must address solvent recovery systems, emission control technologies, and energy efficiency measures to meet environmental regulations and corporate sustainability goals. The development of water-based polymer coating formulations has partially addressed these concerns, though their implementation at industrial scale presents unique challenges related to drying efficiency and coating performance.

One of the primary scale-up challenges involves heat and mass transfer phenomena, which do not scale linearly with equipment size. Industrial implementations must account for these non-linear relationships to prevent issues such as incomplete solvent evaporation or thermal degradation of polymer materials. The larger diameter of industrial atomizers also creates different droplet size distributions compared to laboratory equipment, necessitating recalibration of process parameters to maintain desired coating morphology and thickness uniformity.

Equipment design considerations become paramount during scale-up. Industrial spray dryers require sophisticated control systems to manage the increased complexity of operations. The selection of appropriate atomization devices—whether rotary, pressure, or two-fluid nozzles—must be reevaluated at industrial scale, as their performance characteristics change significantly with increased throughput requirements. Additionally, the design of drying chambers must account for proper air flow patterns to prevent wall deposition and agglomeration issues that are less pronounced in laboratory settings.

Economic factors heavily influence industrial implementation decisions. Capital investment for industrial spray drying equipment is substantial, requiring careful cost-benefit analysis. Operating costs, particularly energy consumption for heating large volumes of drying gas, can significantly impact production economics. Manufacturers must optimize energy recovery systems and consider alternative heating methods to maintain economic viability while achieving desired coating properties.

Regulatory compliance presents another layer of complexity for industrial implementation. Scaling up polymer coating processes often necessitates additional validation steps to ensure consistent product quality and safety. Documentation requirements become more stringent, particularly for applications in regulated industries such as pharmaceuticals or food packaging. Process analytical technology (PAT) implementation becomes essential for real-time monitoring and control of critical quality attributes during continuous production.

Sustainability considerations have gained increasing importance in industrial spray drying operations. Modern implementations must address solvent recovery systems, emission control technologies, and energy efficiency measures to meet environmental regulations and corporate sustainability goals. The development of water-based polymer coating formulations has partially addressed these concerns, though their implementation at industrial scale presents unique challenges related to drying efficiency and coating performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!