What Role Does Spray Drying Play in Catalytic Efficiency?

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying in Catalysis: Background and Objectives

Spray drying technology has evolved significantly over the past century, transforming from a simple dehydration method to a sophisticated technique for catalyst preparation. Initially developed in the dairy industry during the 1870s, spray drying found its way into chemical processing by the mid-20th century. The technology's application in catalysis began gaining momentum in the 1980s, when researchers recognized its potential for creating catalytic materials with controlled morphology and composition.

The fundamental principle of spray drying involves atomizing a liquid feed into fine droplets that are rapidly dried in a hot gas stream, resulting in powder formation. This seemingly straightforward process has proven remarkably versatile for catalyst synthesis, offering precise control over particle size, porosity, and compositional homogeneity—all critical factors affecting catalytic performance.

Recent technological advancements have significantly expanded spray drying capabilities in catalyst preparation. Modern spray dryers incorporate sophisticated atomization systems, precise temperature control mechanisms, and advanced collection devices that enable the production of catalysts with increasingly complex structures and functionalities. The integration of computational fluid dynamics and process modeling has further enhanced our understanding of droplet formation and drying kinetics, leading to more predictable and reproducible catalyst properties.

The global push toward sustainable chemical processes and renewable energy solutions has intensified interest in spray drying technology for catalyst development. Industries ranging from petroleum refining to pharmaceutical manufacturing are seeking more efficient catalytic systems that can operate under milder conditions while delivering higher yields and selectivity. Spray drying offers a scalable approach to meeting these demands through the creation of tailored catalyst architectures.

The primary technical objective in this field is to establish clear correlations between spray drying parameters and resulting catalytic efficiency. This includes understanding how factors such as feed composition, atomization conditions, drying temperature profiles, and post-processing treatments influence catalyst activity, selectivity, and stability. Researchers aim to develop predictive models that can guide the rational design of spray-dried catalysts for specific applications.

Another critical goal is to overcome current limitations in producing hierarchically structured catalysts with optimized mass transfer properties. This involves developing strategies to control pore architecture across multiple length scales while maintaining high dispersion of active sites. Additionally, there is growing interest in utilizing spray drying for the preparation of supported metal catalysts, mixed oxide systems, and novel composite materials that combine multiple functionalities within a single particle.

The fundamental principle of spray drying involves atomizing a liquid feed into fine droplets that are rapidly dried in a hot gas stream, resulting in powder formation. This seemingly straightforward process has proven remarkably versatile for catalyst synthesis, offering precise control over particle size, porosity, and compositional homogeneity—all critical factors affecting catalytic performance.

Recent technological advancements have significantly expanded spray drying capabilities in catalyst preparation. Modern spray dryers incorporate sophisticated atomization systems, precise temperature control mechanisms, and advanced collection devices that enable the production of catalysts with increasingly complex structures and functionalities. The integration of computational fluid dynamics and process modeling has further enhanced our understanding of droplet formation and drying kinetics, leading to more predictable and reproducible catalyst properties.

The global push toward sustainable chemical processes and renewable energy solutions has intensified interest in spray drying technology for catalyst development. Industries ranging from petroleum refining to pharmaceutical manufacturing are seeking more efficient catalytic systems that can operate under milder conditions while delivering higher yields and selectivity. Spray drying offers a scalable approach to meeting these demands through the creation of tailored catalyst architectures.

The primary technical objective in this field is to establish clear correlations between spray drying parameters and resulting catalytic efficiency. This includes understanding how factors such as feed composition, atomization conditions, drying temperature profiles, and post-processing treatments influence catalyst activity, selectivity, and stability. Researchers aim to develop predictive models that can guide the rational design of spray-dried catalysts for specific applications.

Another critical goal is to overcome current limitations in producing hierarchically structured catalysts with optimized mass transfer properties. This involves developing strategies to control pore architecture across multiple length scales while maintaining high dispersion of active sites. Additionally, there is growing interest in utilizing spray drying for the preparation of supported metal catalysts, mixed oxide systems, and novel composite materials that combine multiple functionalities within a single particle.

Market Analysis of Spray-Dried Catalysts

The global market for spray-dried catalysts has been experiencing robust growth, driven by increasing demand across multiple industrial sectors. Currently valued at approximately $4.2 billion, this market segment is projected to grow at a compound annual growth rate (CAGR) of 5.7% through 2028, significantly outpacing the broader catalyst market's growth rate of 4.3%.

Petroleum refining remains the dominant application sector, accounting for roughly 38% of spray-dried catalyst consumption. This dominance stems from the critical role these catalysts play in fluid catalytic cracking (FCC) processes, where their uniform particle size distribution and enhanced surface area significantly improve conversion rates and product selectivity. The chemical synthesis sector follows closely at 29% market share, with pharmaceutical applications (14%), environmental remediation (11%), and other industries (8%) comprising the remainder.

Regionally, North America currently leads the market with approximately 32% share, followed by Europe (28%) and Asia-Pacific (26%). However, the most dramatic growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid industrialization and increasing environmental regulations are driving demand. These markets are expected to grow at nearly twice the global average rate over the next five years.

A notable market trend is the increasing preference for customized spray-dried catalyst formulations tailored to specific industrial processes. This shift has created a premium segment within the market, where specialized catalysts command price premiums of 30-45% over standard formulations. This trend is particularly evident in fine chemical synthesis and pharmaceutical applications, where process efficiency and product purity requirements are exceptionally stringent.

The competitive landscape features both established chemical companies and specialized catalyst manufacturers. Major players include BASF, Johnson Matthey, Clariant, and Albemarle, collectively holding approximately 58% market share. However, several mid-sized specialized manufacturers have been gaining ground through technological innovation and focus on high-growth application niches.

Customer buying behavior is increasingly influenced by performance metrics beyond initial catalyst cost, with total cost of ownership calculations becoming standard practice. Factors such as catalyst lifetime, regeneration potential, and process yield improvements are now key decision drivers. This shift has created opportunities for premium-positioned products that can demonstrate superior long-term economic value despite higher initial investment costs.

Supply chain considerations have become increasingly important following recent global disruptions, with many end-users now prioritizing supply security and geographical diversification of catalyst sources. This has accelerated the development of regional production capabilities and created opportunities for new market entrants in previously underserved regions.

Petroleum refining remains the dominant application sector, accounting for roughly 38% of spray-dried catalyst consumption. This dominance stems from the critical role these catalysts play in fluid catalytic cracking (FCC) processes, where their uniform particle size distribution and enhanced surface area significantly improve conversion rates and product selectivity. The chemical synthesis sector follows closely at 29% market share, with pharmaceutical applications (14%), environmental remediation (11%), and other industries (8%) comprising the remainder.

Regionally, North America currently leads the market with approximately 32% share, followed by Europe (28%) and Asia-Pacific (26%). However, the most dramatic growth is occurring in the Asia-Pacific region, particularly in China and India, where rapid industrialization and increasing environmental regulations are driving demand. These markets are expected to grow at nearly twice the global average rate over the next five years.

A notable market trend is the increasing preference for customized spray-dried catalyst formulations tailored to specific industrial processes. This shift has created a premium segment within the market, where specialized catalysts command price premiums of 30-45% over standard formulations. This trend is particularly evident in fine chemical synthesis and pharmaceutical applications, where process efficiency and product purity requirements are exceptionally stringent.

The competitive landscape features both established chemical companies and specialized catalyst manufacturers. Major players include BASF, Johnson Matthey, Clariant, and Albemarle, collectively holding approximately 58% market share. However, several mid-sized specialized manufacturers have been gaining ground through technological innovation and focus on high-growth application niches.

Customer buying behavior is increasingly influenced by performance metrics beyond initial catalyst cost, with total cost of ownership calculations becoming standard practice. Factors such as catalyst lifetime, regeneration potential, and process yield improvements are now key decision drivers. This shift has created opportunities for premium-positioned products that can demonstrate superior long-term economic value despite higher initial investment costs.

Supply chain considerations have become increasingly important following recent global disruptions, with many end-users now prioritizing supply security and geographical diversification of catalyst sources. This has accelerated the development of regional production capabilities and created opportunities for new market entrants in previously underserved regions.

Current Challenges in Spray Drying Technology

Despite significant advancements in spray drying technology for catalyst preparation, several critical challenges continue to impede optimal catalytic efficiency. One of the primary obstacles is achieving precise control over particle morphology and size distribution. The rapid evaporation process inherent to spray drying often leads to unpredictable particle formation dynamics, resulting in heterogeneous catalyst structures that compromise performance consistency. This variability directly impacts active site distribution and accessibility, which are crucial determinants of catalytic efficiency.

Temperature management presents another significant challenge, as the thermal gradients within spray dryers can cause uneven heating of catalyst precursors. This thermal inconsistency may lead to partial decomposition of heat-sensitive components or incomplete formation of desired crystalline phases, ultimately affecting the catalyst's activity and selectivity. The delicate balance between drying temperature, residence time, and feed properties remains difficult to optimize across different catalyst formulations.

Scalability issues further complicate industrial implementation of spray-dried catalysts. Laboratory-scale successes often encounter significant hurdles when transferred to production environments, with parameters requiring substantial recalibration. The complex interplay between equipment dimensions, atomization mechanisms, and drying chamber dynamics creates scaling challenges that can alter fundamental catalyst properties during manufacturing scale-up.

Agglomeration phenomena represent another persistent challenge, particularly for catalysts requiring high surface area and porosity. As droplets dry, surface tension forces can drive particles together, forming unwanted agglomerates that reduce accessible surface area and create diffusion limitations. These effects are especially problematic for reactions where mass transfer plays a critical role in determining overall catalytic performance.

Feed formulation complexity adds another layer of difficulty, as the rheological properties of precursor solutions significantly impact atomization quality and subsequent particle formation. Viscosity fluctuations, precipitation of components during processing, and interactions between precursors can lead to inconsistent spray patterns and heterogeneous catalyst compositions. These variations directly translate to performance inconsistencies in the final catalytic system.

Energy efficiency concerns also persist, as conventional spray drying remains an energy-intensive process. The substantial thermal energy required for solvent evaporation contributes significantly to production costs and environmental impact. This challenge is particularly relevant for catalyst manufacturing, where energy consumption affects both economic viability and sustainability metrics of the resulting catalytic processes.

Advanced monitoring and real-time control capabilities remain underdeveloped for spray drying in catalyst production. Unlike other manufacturing techniques, spray drying offers limited opportunities for in-process adjustments once operation begins, making predictive modeling and precise initial parameter selection critical for success.

Temperature management presents another significant challenge, as the thermal gradients within spray dryers can cause uneven heating of catalyst precursors. This thermal inconsistency may lead to partial decomposition of heat-sensitive components or incomplete formation of desired crystalline phases, ultimately affecting the catalyst's activity and selectivity. The delicate balance between drying temperature, residence time, and feed properties remains difficult to optimize across different catalyst formulations.

Scalability issues further complicate industrial implementation of spray-dried catalysts. Laboratory-scale successes often encounter significant hurdles when transferred to production environments, with parameters requiring substantial recalibration. The complex interplay between equipment dimensions, atomization mechanisms, and drying chamber dynamics creates scaling challenges that can alter fundamental catalyst properties during manufacturing scale-up.

Agglomeration phenomena represent another persistent challenge, particularly for catalysts requiring high surface area and porosity. As droplets dry, surface tension forces can drive particles together, forming unwanted agglomerates that reduce accessible surface area and create diffusion limitations. These effects are especially problematic for reactions where mass transfer plays a critical role in determining overall catalytic performance.

Feed formulation complexity adds another layer of difficulty, as the rheological properties of precursor solutions significantly impact atomization quality and subsequent particle formation. Viscosity fluctuations, precipitation of components during processing, and interactions between precursors can lead to inconsistent spray patterns and heterogeneous catalyst compositions. These variations directly translate to performance inconsistencies in the final catalytic system.

Energy efficiency concerns also persist, as conventional spray drying remains an energy-intensive process. The substantial thermal energy required for solvent evaporation contributes significantly to production costs and environmental impact. This challenge is particularly relevant for catalyst manufacturing, where energy consumption affects both economic viability and sustainability metrics of the resulting catalytic processes.

Advanced monitoring and real-time control capabilities remain underdeveloped for spray drying in catalyst production. Unlike other manufacturing techniques, spray drying offers limited opportunities for in-process adjustments once operation begins, making predictive modeling and precise initial parameter selection critical for success.

Contemporary Spray Drying Methods for Catalysts

01 Spray drying techniques for catalyst preparation

Spray drying is utilized as an effective method for preparing catalysts with enhanced efficiency. This process involves atomizing a catalyst precursor solution into fine droplets and rapidly drying them in a hot gas stream, resulting in uniform catalyst particles with controlled morphology and size distribution. The technique allows for the incorporation of various active components and supports, leading to improved catalytic performance and stability.- Spray drying techniques for catalyst preparation: Spray drying is utilized as an effective method for preparing catalysts with enhanced catalytic efficiency. This technique allows for the production of spherical catalyst particles with uniform size distribution and controlled morphology. The process involves atomizing a catalyst precursor solution into fine droplets and rapidly drying them in a hot gas stream, resulting in catalyst particles with high surface area and improved activity. This method enables better control over catalyst properties such as porosity, particle size, and composition.

- Catalyst formulation optimization for spray drying: The formulation of catalyst precursors for spray drying significantly impacts the final catalytic efficiency. Key considerations include the selection of appropriate metal salts, support materials, binders, and additives that enhance dispersion and prevent agglomeration during the spray drying process. Optimized formulations can lead to catalysts with improved metal dispersion, enhanced thermal stability, and higher active site accessibility, ultimately resulting in superior catalytic performance in various chemical reactions.

- Process parameters affecting catalytic efficiency in spray-dried catalysts: Various spray drying process parameters significantly influence the catalytic efficiency of the resulting materials. These parameters include inlet and outlet temperatures, feed rate, atomization pressure, and drying gas flow rate. Careful control of these variables allows for the optimization of catalyst properties such as particle size distribution, porosity, surface area, and active site dispersion. By fine-tuning these parameters, manufacturers can produce catalysts with enhanced activity, selectivity, and stability for specific applications.

- Equipment design for improved catalyst spray drying: Specialized equipment designs for spray drying can significantly enhance the catalytic efficiency of the produced materials. Innovations include modified atomizers, optimized drying chambers, improved heat transfer systems, and advanced collection devices. These design improvements enable better control over particle formation, reduce thermal degradation of active components, and minimize catalyst loss during processing. Advanced spray drying equipment can produce catalysts with more uniform properties and higher activity compared to conventional methods.

- Post-treatment of spray-dried catalysts for efficiency enhancement: Various post-treatment methods can be applied to spray-dried catalysts to further enhance their catalytic efficiency. These treatments include calcination under controlled atmospheres, reduction processes, acid or base treatments, and surface modification techniques. Post-treatments can optimize the catalyst's active site accessibility, improve metal dispersion, enhance pore structure, and increase stability under reaction conditions. These modifications result in catalysts with significantly improved performance in terms of activity, selectivity, and longevity.

02 Catalyst formulation optimization for spray drying

The formulation of catalyst slurries or solutions for spray drying significantly impacts catalytic efficiency. Key parameters include the selection of precursor compounds, binders, dispersants, and pH adjustments. Optimized formulations ensure proper dispersion of active components, prevent agglomeration during drying, and create porous structures with high surface area, ultimately enhancing catalytic activity and selectivity in various chemical processes.Expand Specific Solutions03 Process parameters affecting catalyst efficiency in spray drying

Critical spray drying process parameters such as inlet/outlet temperature, atomization pressure, feed rate, and gas flow significantly influence the final catalyst properties. Careful control of these parameters enables the production of catalysts with optimized particle size, porosity, surface area, and active site distribution. These factors directly impact catalytic efficiency by affecting mass transfer, diffusion limitations, and active site accessibility during reactions.Expand Specific Solutions04 Equipment design for enhanced catalyst spray drying

Specialized equipment designs for spray drying catalysts feature innovations such as multi-fluid nozzles, cyclone separators, and controlled atmosphere chambers. These design elements enable precise control over drying conditions, particle formation, and collection efficiency. Advanced spray dryer configurations minimize thermal degradation of sensitive catalyst components while maximizing yield and ensuring consistent product quality, resulting in catalysts with superior performance.Expand Specific Solutions05 Post-treatment of spray-dried catalysts

Post-treatment processes applied to spray-dried catalysts, including calcination, reduction, and activation steps, are crucial for achieving optimal catalytic efficiency. These treatments remove organic components, create the desired crystal structure, and generate active sites. Controlled atmosphere processing, temperature programming, and specialized activation protocols significantly enhance catalyst performance by optimizing metal dispersion, surface properties, and active site density.Expand Specific Solutions

Leading Companies and Research Institutions

Spray drying technology in catalytic efficiency is evolving rapidly, currently transitioning from early development to commercial application phase. The global market for spray-dried catalysts is expanding, driven by increasing demand for more efficient chemical processes across industries. Technologically, the field shows varying maturity levels among key players. Companies like Univation Technologies and W.R. Grace demonstrate advanced capabilities in polymer catalysis applications, while SINOPEC Beijing Research Institute and Shanghai Research Institute of Chemical Industry are making significant progress in petrochemical applications. Cabot Corp. and Wacker Chemie AG are leveraging spray drying for specialty catalyst formulations. The technology enables precise particle engineering, improved catalyst dispersion, and enhanced thermal stability, offering substantial efficiency improvements over conventional catalyst preparation methods.

W. R. Grace & Co.-Conn.

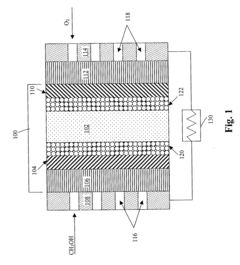

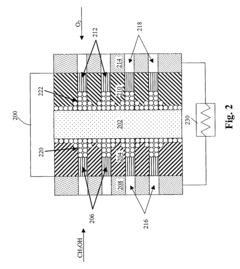

Technical Solution: W. R. Grace & Co. has developed advanced spray drying technology specifically for fluid catalytic cracking (FCC) catalysts and other zeolite-based catalytic materials. Their process begins with a carefully formulated slurry containing zeolite crystals, clay binders, and alumina or silica components that undergo controlled atomization through specialized pressure nozzles, creating spherical particles with diameters typically ranging from 60-150 microns[2]. The company's spray drying technology incorporates a counter-current drying chamber design that maximizes heat transfer efficiency while minimizing thermal stress on catalyst components. Grace's process enables precise control over catalyst particle density and pore structure through adjustments in slurry composition and spray drying parameters. Their technology also features sophisticated air flow management systems that ensure uniform drying conditions throughout the chamber, critical for maintaining consistent catalyst properties[6]. Recent innovations include modified spray drying techniques that create catalyst particles with hierarchical pore structures, significantly enhancing molecular diffusion within catalyst particles while maintaining mechanical integrity. Grace has also developed specialized additives that, when incorporated during spray drying, can enhance catalyst resistance to metals poisoning and hydrothermal degradation.

Strengths: Produces highly attrition-resistant catalyst particles with excellent fluidization properties, critical for FCC and other fluidized bed applications. Their process creates catalysts with optimized accessibility to active sites, enhancing catalytic efficiency and selectivity.

Weaknesses: The process requires precise control of multiple parameters, increasing operational complexity. The technology is optimized primarily for petroleum refining applications and may require significant modifications for other catalyst types.

Cabot Corp.

Technical Solution: Cabot Corporation has pioneered spray drying techniques specifically for carbon-supported catalysts used in fuel cells and electrochemical applications. Their proprietary process begins with a carefully formulated slurry containing carbon black, catalyst precursors, and binding agents that undergo controlled atomization through specialized rotary atomizers. This creates spherical particles with diameters ranging from 20-80 microns with highly porous structures[2]. The company's spray drying technology incorporates a two-zone drying chamber with precisely controlled temperature gradients that facilitate optimal moisture removal while preventing catalyst deactivation. Cabot's process enables the incorporation of multiple catalytic metals (Pt, Pd, Ru) with precise loading and distribution throughout the carbon support matrix. Their technology also features in-line particle classification systems that ensure narrow particle size distributions, critical for applications requiring uniform catalyst performance[4]. Recent innovations include modified spray drying techniques that create hierarchical pore structures within catalyst particles, significantly enhancing mass transport properties.

Strengths: Produces catalysts with exceptional metal dispersion and utilization efficiency, particularly valuable for precious metal catalysts. Their process creates particles with controlled porosity that enhances reactant access to active sites while maintaining mechanical stability.

Weaknesses: The process requires precise control of slurry rheology, which can be challenging with certain catalyst formulations. Energy consumption is relatively high compared to some alternative drying methods, potentially increasing production costs.

Key Patents and Technical Innovations

Catalyst precursor, catalyst using same, production method for compound and production method for catalyst

PatentPendingUS20240238768A1

Innovation

- A catalyst precursor with a specific average particle diameter range (10 μm to 40 μm) and hollow particle proportion (0.0% to 4.3%) is developed, which improves catalytic activity and yield when used in catalytic gas phase oxidation reactions, and is further optimized by controlling drying parameters like rotation speed and temperature.

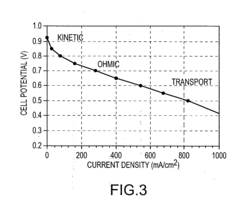

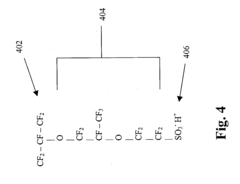

Method of producing membrane electrode assemblies for use in proton exchange membrane and direct methanol fuel cells

PatentInactiveUS20040038808A1

Innovation

- A direct-write printing method using ink-jet devices and syringe dispense tools to deposit gradient structures with varying compositions, microstructures, and porosities in MEAs, allowing for precise placement of catalysts and materials only where needed, enhancing catalyst utilization and reducing material waste.

Sustainability Aspects of Spray Drying Processes

Sustainability Aspects of Spray Drying Processes in catalytic applications have become increasingly important as industries strive to reduce environmental footprints while maintaining efficiency. The energy-intensive nature of spray drying processes presents significant sustainability challenges that must be addressed through innovative approaches and technological advancements.

Energy consumption represents one of the primary sustainability concerns in spray drying for catalyst production. Traditional spray drying systems require substantial thermal energy to atomize and dry catalyst precursors, contributing to high carbon emissions when powered by fossil fuels. Recent developments have focused on heat recovery systems and process optimization to reduce overall energy requirements, with some advanced systems achieving energy savings of 20-30% compared to conventional methods.

Water usage and management constitute another critical sustainability aspect. Spray drying typically involves aqueous solutions or slurries that require significant water resources. Closed-loop water systems and water recovery technologies have emerged as promising solutions, enabling up to 80% reduction in freshwater consumption in modern spray drying facilities used for catalyst production.

Raw material efficiency has direct implications for sustainability in catalyst preparation via spray drying. The process allows precise control over particle morphology and composition, reducing waste and improving material utilization. Advanced formulation techniques have enabled manufacturers to decrease precious metal loading while maintaining or even enhancing catalytic performance, thereby conserving scarce resources.

Emissions control represents a significant sustainability challenge in spray drying operations. Particulate matter and volatile organic compounds may be released during the process, requiring effective filtration and scrubbing systems. Modern spray drying facilities incorporate advanced emission control technologies that can capture over 99% of particulates, significantly reducing environmental impact.

Life cycle assessment (LCA) studies have demonstrated that optimized spray drying processes can reduce the overall environmental impact of catalyst production by 15-25% compared to alternative preparation methods. These improvements stem from better energy efficiency, reduced waste generation, and enhanced catalyst performance leading to longer service life.

The integration of renewable energy sources with spray drying operations presents a promising pathway toward carbon-neutral catalyst production. Solar thermal systems and biomass-derived heat sources have been successfully implemented in pilot-scale operations, demonstrating the feasibility of sustainable energy integration without compromising product quality or process reliability.

Energy consumption represents one of the primary sustainability concerns in spray drying for catalyst production. Traditional spray drying systems require substantial thermal energy to atomize and dry catalyst precursors, contributing to high carbon emissions when powered by fossil fuels. Recent developments have focused on heat recovery systems and process optimization to reduce overall energy requirements, with some advanced systems achieving energy savings of 20-30% compared to conventional methods.

Water usage and management constitute another critical sustainability aspect. Spray drying typically involves aqueous solutions or slurries that require significant water resources. Closed-loop water systems and water recovery technologies have emerged as promising solutions, enabling up to 80% reduction in freshwater consumption in modern spray drying facilities used for catalyst production.

Raw material efficiency has direct implications for sustainability in catalyst preparation via spray drying. The process allows precise control over particle morphology and composition, reducing waste and improving material utilization. Advanced formulation techniques have enabled manufacturers to decrease precious metal loading while maintaining or even enhancing catalytic performance, thereby conserving scarce resources.

Emissions control represents a significant sustainability challenge in spray drying operations. Particulate matter and volatile organic compounds may be released during the process, requiring effective filtration and scrubbing systems. Modern spray drying facilities incorporate advanced emission control technologies that can capture over 99% of particulates, significantly reducing environmental impact.

Life cycle assessment (LCA) studies have demonstrated that optimized spray drying processes can reduce the overall environmental impact of catalyst production by 15-25% compared to alternative preparation methods. These improvements stem from better energy efficiency, reduced waste generation, and enhanced catalyst performance leading to longer service life.

The integration of renewable energy sources with spray drying operations presents a promising pathway toward carbon-neutral catalyst production. Solar thermal systems and biomass-derived heat sources have been successfully implemented in pilot-scale operations, demonstrating the feasibility of sustainable energy integration without compromising product quality or process reliability.

Scale-up Considerations for Industrial Applications

Scaling up spray drying processes from laboratory to industrial scale presents significant engineering challenges that directly impact catalytic efficiency. The transition requires careful consideration of equipment design, process parameters, and quality control measures to maintain or enhance the catalytic properties achieved at smaller scales.

Industrial spray dryers operate at throughputs several orders of magnitude higher than laboratory equipment, necessitating adjustments in atomization systems, chamber dimensions, and heat transfer mechanisms. The atomization device selection becomes particularly critical, with pressure nozzles, rotary atomizers, and two-fluid nozzles offering different advantages depending on the catalyst precursor properties and desired particle characteristics.

Heat and mass transfer dynamics change dramatically with scale, affecting drying kinetics and consequently the morphology, porosity, and surface area of catalyst particles. Engineers must recalibrate residence times and temperature profiles to ensure uniform drying without thermal degradation of active components. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting these complex interactions before capital-intensive scale-up investments.

Feed preparation strategies require adaptation at industrial scale, with considerations for continuous mixing, stabilization of suspensions, and prevention of nozzle clogging. Precursor formulations often need adjustment to accommodate the different atomization stresses and evaporation rates encountered in larger systems. Additives that enhance flowability or prevent agglomeration may become necessary when producing at tonnage scale.

Energy efficiency becomes a paramount concern in industrial applications, with heat recovery systems and process integration offering significant operational cost reductions. Modern spray drying facilities incorporate cyclones, bag filters, and electrostatic precipitators to maximize product recovery while meeting increasingly stringent environmental regulations regarding particulate emissions.

Quality control strategies must evolve with scale, implementing in-line monitoring of particle size distribution, moisture content, and bulk density. Statistical process control methodologies help maintain consistency across production batches, essential for catalysts where performance is highly sensitive to physical properties. Advanced PAT (Process Analytical Technology) tools enable real-time adjustments to process parameters, minimizing off-specification production.

Economic considerations ultimately drive industrial scale-up decisions, balancing capital expenditure against operational efficiency and product quality. The higher throughput of industrial spray dryers reduces unit production costs, but this advantage must be weighed against potential compromises in catalytic performance if morphological control diminishes. Successful scale-up strategies maintain the critical quality attributes that determine catalytic efficiency while optimizing production economics.

Industrial spray dryers operate at throughputs several orders of magnitude higher than laboratory equipment, necessitating adjustments in atomization systems, chamber dimensions, and heat transfer mechanisms. The atomization device selection becomes particularly critical, with pressure nozzles, rotary atomizers, and two-fluid nozzles offering different advantages depending on the catalyst precursor properties and desired particle characteristics.

Heat and mass transfer dynamics change dramatically with scale, affecting drying kinetics and consequently the morphology, porosity, and surface area of catalyst particles. Engineers must recalibrate residence times and temperature profiles to ensure uniform drying without thermal degradation of active components. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting these complex interactions before capital-intensive scale-up investments.

Feed preparation strategies require adaptation at industrial scale, with considerations for continuous mixing, stabilization of suspensions, and prevention of nozzle clogging. Precursor formulations often need adjustment to accommodate the different atomization stresses and evaporation rates encountered in larger systems. Additives that enhance flowability or prevent agglomeration may become necessary when producing at tonnage scale.

Energy efficiency becomes a paramount concern in industrial applications, with heat recovery systems and process integration offering significant operational cost reductions. Modern spray drying facilities incorporate cyclones, bag filters, and electrostatic precipitators to maximize product recovery while meeting increasingly stringent environmental regulations regarding particulate emissions.

Quality control strategies must evolve with scale, implementing in-line monitoring of particle size distribution, moisture content, and bulk density. Statistical process control methodologies help maintain consistency across production batches, essential for catalysts where performance is highly sensitive to physical properties. Advanced PAT (Process Analytical Technology) tools enable real-time adjustments to process parameters, minimizing off-specification production.

Economic considerations ultimately drive industrial scale-up decisions, balancing capital expenditure against operational efficiency and product quality. The higher throughput of industrial spray dryers reduces unit production costs, but this advantage must be weighed against potential compromises in catalytic performance if morphological control diminishes. Successful scale-up strategies maintain the critical quality attributes that determine catalytic efficiency while optimizing production economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!