The Role of Spray Drying in Innovative Textile Coatings

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century, transforming from a simple dehydration method to a sophisticated process for creating functional materials. Initially developed for the food and pharmaceutical industries, spray drying has undergone remarkable technological advancements that have expanded its applications into the textile sector. The fundamental principle remains consistent: atomization of a liquid feed into fine droplets, followed by rapid evaporation in a hot gas stream to form dry particles. However, modern spray drying systems incorporate precision controls, advanced atomization techniques, and innovative chamber designs that enable the production of particles with tailored characteristics.

In the textile industry, spray drying technology has emerged as a revolutionary approach for developing innovative coatings with enhanced functional properties. The evolution of this technology in textiles can be traced through several key developmental phases. The early applications in the 1970s focused primarily on simple color additives and basic finishes. By the 1990s, advancements in nozzle technology and drying chamber designs facilitated more uniform particle size distribution, enabling the creation of more consistent textile coatings.

The 21st century has witnessed transformative developments in spray drying for textiles, particularly with the integration of nanotechnology. Modern spray dryers can produce nano-encapsulated functional agents that can be incorporated into textile coatings, providing properties such as antimicrobial protection, UV resistance, and controlled release of fragrances or therapeutic compounds. The evolution of atomization technologies, including ultrasonic and electrohydrodynamic atomization, has further expanded the capability to produce particles with precise morphologies and sizes.

The primary technological objectives for spray drying in textile coatings center around several critical areas. First, achieving greater control over particle characteristics, including size distribution, morphology, and internal structure, remains a fundamental goal. This control directly influences coating uniformity, adhesion properties, and functional performance. Second, enhancing energy efficiency of the drying process addresses both economic and environmental concerns, with innovations in heat recovery systems and alternative energy sources being actively pursued.

Another significant objective is the development of scalable processes that maintain product quality from laboratory to industrial production. This includes addressing challenges related to heat and mass transfer during scale-up, as well as ensuring consistent particle properties across different production volumes. Additionally, there is growing emphasis on environmentally sustainable approaches, including the use of water-based formulations instead of organic solvents, biodegradable encapsulation materials, and reduced energy consumption.

The technological trajectory aims to integrate spray drying with other advanced manufacturing techniques, such as 3D printing and digital textile printing, to create next-generation smart textiles with programmable functionalities. This convergence represents the frontier of textile innovation, where spray-dried functional particles become integral components of interactive, responsive fabric systems.

In the textile industry, spray drying technology has emerged as a revolutionary approach for developing innovative coatings with enhanced functional properties. The evolution of this technology in textiles can be traced through several key developmental phases. The early applications in the 1970s focused primarily on simple color additives and basic finishes. By the 1990s, advancements in nozzle technology and drying chamber designs facilitated more uniform particle size distribution, enabling the creation of more consistent textile coatings.

The 21st century has witnessed transformative developments in spray drying for textiles, particularly with the integration of nanotechnology. Modern spray dryers can produce nano-encapsulated functional agents that can be incorporated into textile coatings, providing properties such as antimicrobial protection, UV resistance, and controlled release of fragrances or therapeutic compounds. The evolution of atomization technologies, including ultrasonic and electrohydrodynamic atomization, has further expanded the capability to produce particles with precise morphologies and sizes.

The primary technological objectives for spray drying in textile coatings center around several critical areas. First, achieving greater control over particle characteristics, including size distribution, morphology, and internal structure, remains a fundamental goal. This control directly influences coating uniformity, adhesion properties, and functional performance. Second, enhancing energy efficiency of the drying process addresses both economic and environmental concerns, with innovations in heat recovery systems and alternative energy sources being actively pursued.

Another significant objective is the development of scalable processes that maintain product quality from laboratory to industrial production. This includes addressing challenges related to heat and mass transfer during scale-up, as well as ensuring consistent particle properties across different production volumes. Additionally, there is growing emphasis on environmentally sustainable approaches, including the use of water-based formulations instead of organic solvents, biodegradable encapsulation materials, and reduced energy consumption.

The technological trajectory aims to integrate spray drying with other advanced manufacturing techniques, such as 3D printing and digital textile printing, to create next-generation smart textiles with programmable functionalities. This convergence represents the frontier of textile innovation, where spray-dried functional particles become integral components of interactive, responsive fabric systems.

Market Analysis for Advanced Textile Coating Solutions

The global market for advanced textile coatings is experiencing robust growth, driven by increasing demand for functional textiles across various industries. Current market valuation stands at approximately 7.2 billion USD with projections indicating growth to reach 9.5 billion USD by 2027, representing a compound annual growth rate of 5.8%. This expansion is particularly evident in technical textiles, which constitute nearly 40% of the overall textile coating market.

Consumer preferences are shifting dramatically toward textiles with enhanced properties such as water resistance, antimicrobial protection, and UV shielding. This shift has created significant opportunities for spray-dried coating technologies, which offer superior performance characteristics compared to traditional coating methods. Market research indicates that consumers are willing to pay premium prices for textiles with these advanced functionalities, with price elasticity studies showing up to 30% higher price acceptance for properly marketed performance textiles.

Geographically, Asia-Pacific dominates the market with approximately 45% share, followed by Europe (25%) and North America (20%). China and India are experiencing the fastest growth rates due to expanding manufacturing capabilities and increasing domestic consumption. However, European markets lead in innovation and high-value applications, particularly in medical and protective clothing segments.

By application segment, sportswear and outdoor apparel represent the largest market share at 32%, followed by industrial protective clothing (24%), medical textiles (18%), and home textiles (15%). The automotive textile segment, though smaller at 11%, is showing the fastest growth rate as vehicle manufacturers increasingly adopt advanced textile solutions for interior applications.

Key market drivers include growing awareness of health and hygiene, increasing participation in outdoor activities, stringent workplace safety regulations, and sustainability concerns. The COVID-19 pandemic has accelerated demand for antimicrobial and antiviral textile coatings, creating a new high-growth subsegment estimated at 850 million USD.

Challenges in market adoption include cost considerations, technical limitations in maintaining fabric breathability while adding functional properties, and regulatory hurdles particularly for medical and childcare applications. Environmental regulations are increasingly influencing market dynamics, with water-based and solvent-free coating technologies gaining market share over traditional solvent-based systems.

Spray drying technology is positioned to capture significant market share due to its ability to create uniform, durable coatings with precise control over particle size and distribution. Market analysis indicates that spray-dried coatings command a price premium of 15-20% over conventional coating technologies, reflecting their superior performance characteristics and application versatility.

Consumer preferences are shifting dramatically toward textiles with enhanced properties such as water resistance, antimicrobial protection, and UV shielding. This shift has created significant opportunities for spray-dried coating technologies, which offer superior performance characteristics compared to traditional coating methods. Market research indicates that consumers are willing to pay premium prices for textiles with these advanced functionalities, with price elasticity studies showing up to 30% higher price acceptance for properly marketed performance textiles.

Geographically, Asia-Pacific dominates the market with approximately 45% share, followed by Europe (25%) and North America (20%). China and India are experiencing the fastest growth rates due to expanding manufacturing capabilities and increasing domestic consumption. However, European markets lead in innovation and high-value applications, particularly in medical and protective clothing segments.

By application segment, sportswear and outdoor apparel represent the largest market share at 32%, followed by industrial protective clothing (24%), medical textiles (18%), and home textiles (15%). The automotive textile segment, though smaller at 11%, is showing the fastest growth rate as vehicle manufacturers increasingly adopt advanced textile solutions for interior applications.

Key market drivers include growing awareness of health and hygiene, increasing participation in outdoor activities, stringent workplace safety regulations, and sustainability concerns. The COVID-19 pandemic has accelerated demand for antimicrobial and antiviral textile coatings, creating a new high-growth subsegment estimated at 850 million USD.

Challenges in market adoption include cost considerations, technical limitations in maintaining fabric breathability while adding functional properties, and regulatory hurdles particularly for medical and childcare applications. Environmental regulations are increasingly influencing market dynamics, with water-based and solvent-free coating technologies gaining market share over traditional solvent-based systems.

Spray drying technology is positioned to capture significant market share due to its ability to create uniform, durable coatings with precise control over particle size and distribution. Market analysis indicates that spray-dried coatings command a price premium of 15-20% over conventional coating technologies, reflecting their superior performance characteristics and application versatility.

Technical Challenges in Spray Drying for Textiles

Despite significant advancements in spray drying technology for textile coatings, several technical challenges continue to impede optimal implementation and performance. One of the primary obstacles is achieving uniform particle size distribution during the atomization process. When droplet sizes vary significantly, the resulting coating exhibits inconsistent thickness and adhesion properties, leading to quality control issues in the final textile product. This challenge is particularly pronounced when working with high-viscosity formulations containing functional additives such as antimicrobial agents or phase-change materials.

Temperature control represents another critical challenge in spray drying for textile applications. The delicate balance between sufficient drying and avoiding thermal degradation of heat-sensitive compounds requires precise engineering controls. Many functional textile coatings incorporate temperature-sensitive components like natural extracts, enzymes, or specialized polymers that can lose their efficacy when exposed to excessive heat during the drying process. This necessitates sophisticated temperature monitoring and feedback systems that many existing spray drying setups lack.

Nozzle clogging presents a persistent operational challenge, especially when working with formulations containing high solid content or particulate additives. Clogging not only disrupts production continuity but also affects the consistency of the spray pattern, resulting in uneven coating distribution across the textile substrate. The development of self-cleaning nozzle systems and optimized formulation rheology remains an active area of research to address this limitation.

Scale-up difficulties constitute a significant barrier when transitioning from laboratory-scale development to industrial production. Parameters optimized at small scales often perform unpredictably when implemented in large-scale spray drying operations. Factors such as residence time, air flow dynamics, and heat transfer efficiency change dramatically with scale, requiring extensive re-optimization and validation procedures that increase development costs and time-to-market.

Energy efficiency concerns also plague current spray drying technologies in textile applications. The process inherently consumes substantial energy for atomization and hot air generation. With increasing emphasis on sustainable manufacturing practices, reducing the energy footprint of spray drying operations has become a priority. Current systems typically operate at 30-40% thermal efficiency, leaving significant room for improvement through heat recovery systems and alternative energy sources.

Formulation stability during the spray drying process presents another technical hurdle. Many coating formulations undergo physical and chemical changes during atomization and drying, potentially altering their intended functionality. Issues such as phase separation, agglomeration, and chemical degradation can compromise the performance of the final textile coating, necessitating extensive formulation engineering and stabilization strategies.

Temperature control represents another critical challenge in spray drying for textile applications. The delicate balance between sufficient drying and avoiding thermal degradation of heat-sensitive compounds requires precise engineering controls. Many functional textile coatings incorporate temperature-sensitive components like natural extracts, enzymes, or specialized polymers that can lose their efficacy when exposed to excessive heat during the drying process. This necessitates sophisticated temperature monitoring and feedback systems that many existing spray drying setups lack.

Nozzle clogging presents a persistent operational challenge, especially when working with formulations containing high solid content or particulate additives. Clogging not only disrupts production continuity but also affects the consistency of the spray pattern, resulting in uneven coating distribution across the textile substrate. The development of self-cleaning nozzle systems and optimized formulation rheology remains an active area of research to address this limitation.

Scale-up difficulties constitute a significant barrier when transitioning from laboratory-scale development to industrial production. Parameters optimized at small scales often perform unpredictably when implemented in large-scale spray drying operations. Factors such as residence time, air flow dynamics, and heat transfer efficiency change dramatically with scale, requiring extensive re-optimization and validation procedures that increase development costs and time-to-market.

Energy efficiency concerns also plague current spray drying technologies in textile applications. The process inherently consumes substantial energy for atomization and hot air generation. With increasing emphasis on sustainable manufacturing practices, reducing the energy footprint of spray drying operations has become a priority. Current systems typically operate at 30-40% thermal efficiency, leaving significant room for improvement through heat recovery systems and alternative energy sources.

Formulation stability during the spray drying process presents another technical hurdle. Many coating formulations undergo physical and chemical changes during atomization and drying, potentially altering their intended functionality. Issues such as phase separation, agglomeration, and chemical degradation can compromise the performance of the final textile coating, necessitating extensive formulation engineering and stabilization strategies.

Current Spray Drying Methods for Textile Coatings

01 Spray drying equipment and apparatus design

Various designs and improvements in spray drying equipment focus on enhancing efficiency and performance. These include specialized chambers, nozzle configurations, and integrated systems that optimize the drying process. Advanced designs incorporate features for better temperature control, particle formation, and energy efficiency while minimizing product degradation during the drying process.- Spray drying equipment and apparatus design: Various innovations in spray drying equipment design focus on improving efficiency and product quality. These include specialized chambers, atomizers, and integrated systems that enhance particle formation and collection. Advanced designs incorporate features for temperature control, airflow management, and reduced energy consumption, allowing for better control of particle size and morphology during the drying process.

- Spray drying process parameters optimization: Optimization of spray drying process parameters is crucial for achieving desired product characteristics. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. By carefully controlling these variables, manufacturers can enhance product stability, improve yield, and ensure consistent particle size distribution. Process optimization also contributes to energy efficiency and reduced production costs.

- Formulation techniques for spray-dried products: Specialized formulation techniques for spray drying focus on enhancing product stability, solubility, and bioavailability. These include the use of carrier materials, stabilizers, and functional excipients that protect active ingredients during the drying process. Advanced formulation approaches enable the production of amorphous solid dispersions, microencapsulated materials, and engineered particles with specific release profiles or improved handling properties.

- Spray drying applications in pharmaceutical and food industries: Spray drying is widely applied in pharmaceutical and food industries for producing stable, free-flowing powders with controlled properties. In pharmaceuticals, it enables the production of inhalable formulations, taste-masked drugs, and solid dispersions with enhanced bioavailability. Food applications include the production of instant powders, flavor encapsulation, and shelf-stable ingredients. The technology allows for continuous production while preserving heat-sensitive components.

- Novel spray drying technologies and innovations: Emerging spray drying technologies incorporate innovative approaches such as aseptic processing, supercritical fluid integration, and electrostatic assistance. These advancements enable the production of specialized particles with unique characteristics, improved efficiency, and reduced environmental impact. Novel technologies also focus on miniaturization for small-batch production, continuous manufacturing integration, and real-time process analytical tools for quality monitoring and control.

02 Formulation techniques for spray drying

Specific formulation approaches are used to enhance spray drying outcomes for various substances. These techniques involve selecting appropriate carriers, excipients, and stabilizers that improve flowability, prevent agglomeration, and protect active ingredients during the drying process. Formulation strategies can be tailored to specific product requirements, such as improved dissolution, stability, or bioavailability of the final dried product.Expand Specific Solutions03 Process parameters optimization for spray drying

Optimization of process parameters is crucial for successful spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and drying gas flow rate. These parameters significantly impact product characteristics such as particle size, moisture content, and powder properties. Advanced control systems and methodologies help maintain optimal conditions throughout the drying process to achieve desired product specifications.Expand Specific Solutions04 Specialized applications of spray drying technology

Spray drying is applied across various specialized fields including pharmaceuticals, food processing, ceramics, and chemical manufacturing. Each application requires specific adaptations of the spray drying process to meet unique requirements. For pharmaceuticals, spray drying enables production of inhalable powders and controlled-release formulations. In food processing, it preserves flavors and nutrients while extending shelf life. Industrial applications include catalyst preparation and ceramic powder production.Expand Specific Solutions05 Innovations in spray drying for sustainable manufacturing

Recent innovations focus on making spray drying more sustainable and environmentally friendly. These include energy recovery systems, alternative heat sources, reduced water consumption, and improved thermal efficiency. Advanced designs incorporate closed-loop systems that minimize waste and emissions. Other innovations include hybrid technologies that combine spray drying with other processes to reduce overall energy consumption and environmental impact.Expand Specific Solutions

Industry Leaders in Spray Drying Textile Applications

The spray drying technology in textile coatings is evolving rapidly, currently transitioning from early adoption to growth phase. The market is expanding at a significant rate, driven by increasing demand for functional textiles with specialized coatings. Key players like Henkel, DuPont, and BASF Coatings are leading innovation through substantial R&D investments, while companies such as ZoomEssence and Hovione are advancing microencapsulation techniques specifically for textile applications. Established chemical manufacturers including Akzo Nobel and PPG Europe are integrating spray drying into their existing coating technologies, creating more durable and functional textile finishes. The technology is approaching maturity in industrial applications but continues to evolve in specialized textile segments, with universities like Beijing University of Chemical Technology and University of Massachusetts contributing significant research advancements.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced spray drying technology for textile coatings that enables the production of microcapsules containing functional ingredients such as fragrances, antimicrobial agents, and phase-change materials. Their process utilizes a proprietary atomization technique that creates uniform particle sizes between 10-50 microns, optimized for textile application. The technology incorporates temperature-controlled drying chambers that preserve heat-sensitive active ingredients while ensuring complete encapsulation. Henkel's spray-dried coatings feature controlled-release mechanisms triggered by mechanical action, temperature changes, or moisture, allowing for long-lasting functionality in textiles. Their system also includes specialized binding agents that enhance adhesion to various fabric types while maintaining breathability and comfort. Recent innovations have focused on water-based formulations that reduce VOC emissions during the coating process.

Strengths: Superior encapsulation efficiency (>90%) preserving active ingredients; excellent adhesion to multiple fabric types; environmentally friendly water-based formulations. Weaknesses: Higher production costs compared to conventional coating methods; requires specialized equipment for optimal application; some formulations may reduce fabric breathability.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered spray drying technology for textile coatings through their Innovative Textile Solutions division. Their approach utilizes a multi-stage atomization process that creates nano-structured particles with controlled morphology and size distribution (typically 5-30 microns). The technology incorporates specialized drying chambers with precise temperature gradients that allow for the creation of layered particles with different functional properties in each layer. DuPont's spray-dried coatings include advanced repellent technologies that combine oleophobic and hydrophobic properties while maintaining fabric breathability. Their process also enables the incorporation of antimicrobial agents, UV protectants, and flame retardants in stable, durable formulations. The company has developed proprietary binder systems that create strong mechanical bonds with textile fibers while remaining flexible and resistant to washing. Recent innovations include bio-based coating materials derived from renewable resources that maintain performance while reducing environmental impact.

Strengths: Exceptional durability with coatings lasting 50+ wash cycles; precise control over particle morphology enabling multi-functional properties; industry-leading R&D capabilities for custom solutions. Weaknesses: Higher cost compared to conventional coatings; some formulations require specialized application equipment; potential for reduced fabric hand-feel with heavier applications.

Key Patents and Innovations in Spray Dried Coatings

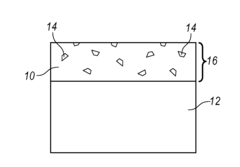

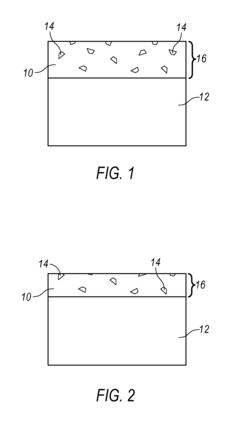

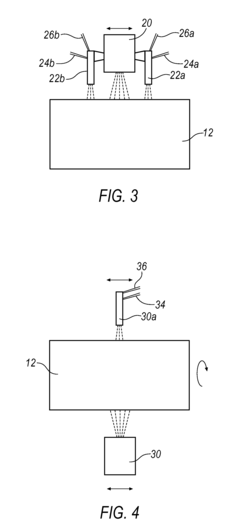

Thermal spray coating with a dispersion of solid lubricant particles

PatentInactiveUS20120180747A1

Innovation

- Incorporating solid lubricant particles dispersed throughout the thickness of a thermal spray coating, which are physically entrapped within a base material, allowing new particles to be exposed as the coating wears, maintaining low friction and extending the component's life.

A method of pi ece dyeing and dry ng of text le products in an individual mach i ne with spraying method without usi ng any watering system

PatentWO2021066759A3

Innovation

- Non-aqueous medium dyeing process using spray technology that eliminates traditional water systems, reducing water consumption and environmental impact.

- Integration of dyeing and drying processes in a single machine, streamlining textile production workflow and reducing processing time.

- Direct application of dyes through spraying method, potentially improving dye utilization efficiency and reducing chemical waste.

Environmental Impact and Sustainability Considerations

The environmental impact of spray drying in textile coating applications represents a critical consideration as industries increasingly prioritize sustainability. Traditional textile coating methods often involve solvent-based systems that release volatile organic compounds (VOCs) into the atmosphere, contributing to air pollution and potential health hazards. Spray drying technology offers significant environmental advantages by enabling water-based formulations that substantially reduce or eliminate VOC emissions, aligning with stringent environmental regulations worldwide.

Energy consumption remains a key environmental factor in spray drying operations. The process requires considerable thermal energy for the evaporation phase, which traditionally relies on fossil fuel sources. Recent advancements have focused on improving energy efficiency through heat recovery systems, optimized atomization techniques, and alternative energy sources. Some innovative facilities have implemented renewable energy solutions, including solar thermal systems and biomass-derived heat sources, reducing the carbon footprint associated with the drying process by up to 40%.

Water management presents another important sustainability dimension. While spray drying utilizes water as a carrier medium instead of organic solvents, the technology must address water consumption concerns. Closed-loop water systems that recapture and purify process water have been developed, reducing freshwater requirements by 60-80% compared to conventional operations. Additionally, advanced filtration systems can recover valuable coating materials from wastewater streams, minimizing both water pollution and material waste.

The life cycle assessment (LCA) of spray-dried textile coatings reveals favorable sustainability metrics compared to traditional methods. Studies indicate that the reduced environmental impact stems not only from the production process but extends throughout the product lifecycle. Textiles treated with spray-dried coatings often demonstrate enhanced durability, reducing replacement frequency and associated resource consumption. Furthermore, the precise application enabled by spray drying minimizes excess material usage, with material efficiency improvements of 15-25% commonly reported.

Biodegradability and end-of-life considerations have gained prominence in textile coating development. Spray drying facilitates the incorporation of bio-based and biodegradable polymers that would be challenging to apply through conventional methods. These environmentally friendly formulations can be engineered to maintain performance standards while reducing environmental persistence. Research indicates that certain spray-dried biopolymer coatings can achieve over 90% biodegradation within standardized testing conditions, compared to less than 10% for traditional synthetic coatings.

Energy consumption remains a key environmental factor in spray drying operations. The process requires considerable thermal energy for the evaporation phase, which traditionally relies on fossil fuel sources. Recent advancements have focused on improving energy efficiency through heat recovery systems, optimized atomization techniques, and alternative energy sources. Some innovative facilities have implemented renewable energy solutions, including solar thermal systems and biomass-derived heat sources, reducing the carbon footprint associated with the drying process by up to 40%.

Water management presents another important sustainability dimension. While spray drying utilizes water as a carrier medium instead of organic solvents, the technology must address water consumption concerns. Closed-loop water systems that recapture and purify process water have been developed, reducing freshwater requirements by 60-80% compared to conventional operations. Additionally, advanced filtration systems can recover valuable coating materials from wastewater streams, minimizing both water pollution and material waste.

The life cycle assessment (LCA) of spray-dried textile coatings reveals favorable sustainability metrics compared to traditional methods. Studies indicate that the reduced environmental impact stems not only from the production process but extends throughout the product lifecycle. Textiles treated with spray-dried coatings often demonstrate enhanced durability, reducing replacement frequency and associated resource consumption. Furthermore, the precise application enabled by spray drying minimizes excess material usage, with material efficiency improvements of 15-25% commonly reported.

Biodegradability and end-of-life considerations have gained prominence in textile coating development. Spray drying facilitates the incorporation of bio-based and biodegradable polymers that would be challenging to apply through conventional methods. These environmentally friendly formulations can be engineered to maintain performance standards while reducing environmental persistence. Research indicates that certain spray-dried biopolymer coatings can achieve over 90% biodegradation within standardized testing conditions, compared to less than 10% for traditional synthetic coatings.

Quality Control and Performance Testing Methodologies

Quality control and performance testing methodologies for spray-dried textile coatings require systematic approaches to ensure consistent product quality and functional performance. The evaluation framework typically encompasses both in-process controls and final product testing, creating a comprehensive quality assurance system.

In-process quality control begins with raw material characterization, where particle size distribution, viscosity, and chemical composition of coating formulations are assessed prior to spray drying. During the spray drying process itself, critical parameters including inlet/outlet temperatures, atomization pressure, feed rate, and chamber humidity must be continuously monitored and controlled within predetermined specifications to ensure coating consistency.

Post-production testing involves physical characterization of the spray-dried coating powders. Particle morphology analysis using scanning electron microscopy (SEM) provides insights into surface characteristics and structural integrity. Particle size distribution analysis using laser diffraction techniques ensures coating application uniformity, while flowability tests predict handling behavior during subsequent textile application processes.

When applied to textiles, coatings undergo rigorous performance testing protocols aligned with international standards. Adhesion testing, typically performed via tape tests or cross-hatch methods according to ISO 2409 or ASTM D3359, evaluates the coating's bonding strength to textile substrates. Abrasion resistance testing using Martindale or Taber abraders (ASTM D4966, ISO 12947) assesses durability under mechanical stress conditions.

Functional performance testing is tailored to the specific properties the coating aims to impart. Water repellency is evaluated through spray tests (AATCC 22) or hydrostatic pressure tests (ISO 811). For antimicrobial coatings, efficacy testing against specific microorganisms follows AATCC 100 or ISO 20743 protocols. UV protection properties are assessed via transmittance measurements and calculation of UPF (Ultraviolet Protection Factor) values according to AATCC 183 or EN 13758.

Environmental durability testing subjects coated textiles to accelerated aging conditions, including exposure to UV radiation (ISO 105-B02), washing cycles (ISO 6330), and temperature/humidity cycling. These tests predict long-term performance and coating stability under real-world conditions.

Statistical quality control methods, including Statistical Process Control (SPC) and Design of Experiments (DOE), are increasingly employed to optimize spray drying parameters and coating formulations. These approaches help identify critical quality attributes and establish robust process control strategies, minimizing batch-to-batch variability while maximizing coating performance consistency.

Advanced analytical techniques such as FTIR spectroscopy and thermal analysis (DSC/TGA) provide deeper insights into coating chemistry and stability, supporting both quality control and ongoing product development efforts in the rapidly evolving field of spray-dried textile coatings.

In-process quality control begins with raw material characterization, where particle size distribution, viscosity, and chemical composition of coating formulations are assessed prior to spray drying. During the spray drying process itself, critical parameters including inlet/outlet temperatures, atomization pressure, feed rate, and chamber humidity must be continuously monitored and controlled within predetermined specifications to ensure coating consistency.

Post-production testing involves physical characterization of the spray-dried coating powders. Particle morphology analysis using scanning electron microscopy (SEM) provides insights into surface characteristics and structural integrity. Particle size distribution analysis using laser diffraction techniques ensures coating application uniformity, while flowability tests predict handling behavior during subsequent textile application processes.

When applied to textiles, coatings undergo rigorous performance testing protocols aligned with international standards. Adhesion testing, typically performed via tape tests or cross-hatch methods according to ISO 2409 or ASTM D3359, evaluates the coating's bonding strength to textile substrates. Abrasion resistance testing using Martindale or Taber abraders (ASTM D4966, ISO 12947) assesses durability under mechanical stress conditions.

Functional performance testing is tailored to the specific properties the coating aims to impart. Water repellency is evaluated through spray tests (AATCC 22) or hydrostatic pressure tests (ISO 811). For antimicrobial coatings, efficacy testing against specific microorganisms follows AATCC 100 or ISO 20743 protocols. UV protection properties are assessed via transmittance measurements and calculation of UPF (Ultraviolet Protection Factor) values according to AATCC 183 or EN 13758.

Environmental durability testing subjects coated textiles to accelerated aging conditions, including exposure to UV radiation (ISO 105-B02), washing cycles (ISO 6330), and temperature/humidity cycling. These tests predict long-term performance and coating stability under real-world conditions.

Statistical quality control methods, including Statistical Process Control (SPC) and Design of Experiments (DOE), are increasingly employed to optimize spray drying parameters and coating formulations. These approaches help identify critical quality attributes and establish robust process control strategies, minimizing batch-to-batch variability while maximizing coating performance consistency.

Advanced analytical techniques such as FTIR spectroscopy and thermal analysis (DSC/TGA) provide deeper insights into coating chemistry and stability, supporting both quality control and ongoing product development efforts in the rapidly evolving field of spray-dried textile coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!