The Role of Spray Drying in Clean Energy Electrolyzers

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution in Clean Energy

Spray drying technology has undergone significant evolution in the clean energy sector, particularly in the development of electrolyzers for hydrogen production. The journey began in the 1940s with basic spray drying techniques primarily used in food and pharmaceutical industries. These early applications focused on simple particle formation with limited control over morphology and composition, utilizing rudimentary nozzle designs and basic chamber configurations.

By the 1970s and 1980s, spray drying technology advanced with improved atomization techniques and better process control systems. This period marked the initial exploration of ceramic materials production for various industrial applications, though not yet specifically targeted at energy applications. The introduction of computational fluid dynamics during this era enabled better understanding of droplet formation and drying kinetics.

The 1990s witnessed a significant shift as researchers began investigating spray drying for producing specialized ceramic powders with controlled properties. This coincided with growing interest in fuel cell technologies, where spray-dried materials showed promise for electrode fabrication. The development of multi-fluid nozzles and ultrasonic atomizers during this period allowed for more precise control over particle characteristics.

The early 2000s marked a turning point with the intentional application of spray drying technology to clean energy materials. Researchers began optimizing spray drying parameters specifically for solid oxide fuel cell components, establishing fundamental relationships between process parameters and material performance. This period saw the emergence of specialized spray dryers designed for energy materials with enhanced temperature control and atmosphere management capabilities.

From 2010 onwards, spray drying technology has been increasingly refined for electrolyzer applications, with particular focus on creating high-performance catalyst supports and electrode materials. Advanced process innovations include in-situ functionalization during spray drying and the incorporation of nanomaterials to enhance electrochemical performance. The development of continuous flow systems has enabled scaled production of specialized powders with consistent quality.

Most recently (2018-2023), spray drying has evolved to address specific challenges in PEM and solid oxide electrolyzers, with techniques for producing hierarchically porous structures that optimize mass transport and reaction kinetics. Integration with additive manufacturing processes has opened new possibilities for electrode architecture design. Additionally, environmentally conscious adaptations have emerged, including solvent recovery systems and energy-efficient drying chambers that align with sustainability goals of clean energy technologies.

The technology continues to evolve toward precision engineering of multi-component materials with tailored interfaces and controlled heterogeneity, positioning spray drying as a critical enabling technology for next-generation electrolyzer development.

By the 1970s and 1980s, spray drying technology advanced with improved atomization techniques and better process control systems. This period marked the initial exploration of ceramic materials production for various industrial applications, though not yet specifically targeted at energy applications. The introduction of computational fluid dynamics during this era enabled better understanding of droplet formation and drying kinetics.

The 1990s witnessed a significant shift as researchers began investigating spray drying for producing specialized ceramic powders with controlled properties. This coincided with growing interest in fuel cell technologies, where spray-dried materials showed promise for electrode fabrication. The development of multi-fluid nozzles and ultrasonic atomizers during this period allowed for more precise control over particle characteristics.

The early 2000s marked a turning point with the intentional application of spray drying technology to clean energy materials. Researchers began optimizing spray drying parameters specifically for solid oxide fuel cell components, establishing fundamental relationships between process parameters and material performance. This period saw the emergence of specialized spray dryers designed for energy materials with enhanced temperature control and atmosphere management capabilities.

From 2010 onwards, spray drying technology has been increasingly refined for electrolyzer applications, with particular focus on creating high-performance catalyst supports and electrode materials. Advanced process innovations include in-situ functionalization during spray drying and the incorporation of nanomaterials to enhance electrochemical performance. The development of continuous flow systems has enabled scaled production of specialized powders with consistent quality.

Most recently (2018-2023), spray drying has evolved to address specific challenges in PEM and solid oxide electrolyzers, with techniques for producing hierarchically porous structures that optimize mass transport and reaction kinetics. Integration with additive manufacturing processes has opened new possibilities for electrode architecture design. Additionally, environmentally conscious adaptations have emerged, including solvent recovery systems and energy-efficient drying chambers that align with sustainability goals of clean energy technologies.

The technology continues to evolve toward precision engineering of multi-component materials with tailored interfaces and controlled heterogeneity, positioning spray drying as a critical enabling technology for next-generation electrolyzer development.

Market Analysis for Spray-Dried Electrolyzer Components

The global market for spray-dried electrolyzer components is experiencing significant growth, driven by the increasing demand for clean hydrogen production technologies. Current market valuations indicate that the electrolyzer market reached approximately 3.5 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 24.6% through 2030. Within this broader market, spray-dried components are gaining substantial traction due to their superior performance characteristics and cost-efficiency in manufacturing processes.

Regional analysis reveals that Europe currently leads the market for spray-dried electrolyzer components, accounting for roughly 40% of global demand. This dominance stems from aggressive hydrogen strategy implementations across the EU, with Germany, France, and the Netherlands serving as primary markets. Asia-Pacific follows closely, with China, Japan, and South Korea making substantial investments in hydrogen infrastructure and manufacturing capabilities for advanced electrolyzer technologies.

Market segmentation by electrolyzer type shows that Polymer Electrolyte Membrane (PEM) electrolyzers represent the largest application segment for spray-dried components, particularly for catalyst layers and membrane electrode assemblies. Alkaline electrolyzers constitute the second-largest segment, while Solid Oxide Electrolyzer Cells (SOEC) represent the fastest-growing segment with projected annual growth rates exceeding 30%.

Customer demand analysis indicates three primary market drivers: cost reduction potential (spray drying can reduce manufacturing costs by 15-25% compared to traditional methods), performance enhancement (improved catalyst utilization and electrode uniformity), and scalability for mass production. End-user industries include dedicated hydrogen production facilities, renewable energy integration projects, and industrial applications requiring on-site hydrogen generation.

Supply chain assessment reveals that raw material availability for spray-dried components remains adequate, though certain critical materials like platinum group metals and specialized polymers face supply constraints. Manufacturing capacity is currently concentrated among specialized materials suppliers and electrolyzer manufacturers with advanced powder processing capabilities.

Pricing trends show that while spray-dried components command a premium of 10-20% over conventionally manufactured alternatives, the total cost of ownership is typically lower due to extended operational lifetimes and improved efficiency. Market forecasts suggest that as production volumes increase and manufacturing processes mature, this price premium will decrease to 5-8% by 2025, further accelerating market adoption.

Regional analysis reveals that Europe currently leads the market for spray-dried electrolyzer components, accounting for roughly 40% of global demand. This dominance stems from aggressive hydrogen strategy implementations across the EU, with Germany, France, and the Netherlands serving as primary markets. Asia-Pacific follows closely, with China, Japan, and South Korea making substantial investments in hydrogen infrastructure and manufacturing capabilities for advanced electrolyzer technologies.

Market segmentation by electrolyzer type shows that Polymer Electrolyte Membrane (PEM) electrolyzers represent the largest application segment for spray-dried components, particularly for catalyst layers and membrane electrode assemblies. Alkaline electrolyzers constitute the second-largest segment, while Solid Oxide Electrolyzer Cells (SOEC) represent the fastest-growing segment with projected annual growth rates exceeding 30%.

Customer demand analysis indicates three primary market drivers: cost reduction potential (spray drying can reduce manufacturing costs by 15-25% compared to traditional methods), performance enhancement (improved catalyst utilization and electrode uniformity), and scalability for mass production. End-user industries include dedicated hydrogen production facilities, renewable energy integration projects, and industrial applications requiring on-site hydrogen generation.

Supply chain assessment reveals that raw material availability for spray-dried components remains adequate, though certain critical materials like platinum group metals and specialized polymers face supply constraints. Manufacturing capacity is currently concentrated among specialized materials suppliers and electrolyzer manufacturers with advanced powder processing capabilities.

Pricing trends show that while spray-dried components command a premium of 10-20% over conventionally manufactured alternatives, the total cost of ownership is typically lower due to extended operational lifetimes and improved efficiency. Market forecasts suggest that as production volumes increase and manufacturing processes mature, this price premium will decrease to 5-8% by 2025, further accelerating market adoption.

Technical Challenges in Spray Drying for Electrolyzers

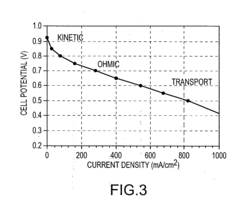

Spray drying technology in electrolyzer manufacturing faces several significant technical challenges that limit its widespread adoption and efficiency. The primary challenge lies in achieving precise control over particle morphology and size distribution. For electrolyzer applications, particularly in proton exchange membrane (PEM) and solid oxide electrolyzers, catalyst particles require uniform size distribution in the nanometer range to maximize active surface area and catalytic performance. Current spray drying systems struggle to consistently produce particles below 1-2 μm with narrow size distribution, especially when scaling up production.

Temperature management presents another critical challenge. The drying temperature profile must be carefully controlled to prevent thermal degradation of heat-sensitive catalyst materials while ensuring complete solvent removal. This becomes particularly problematic when working with platinum group metals and their alloys, which can undergo unwanted phase transformations or sintering at elevated temperatures, reducing catalytic activity. The rapid heating rates in conventional spray dryers often create temperature gradients within droplets, leading to heterogeneous particle structures.

Agglomeration of particles during the drying process significantly impacts electrolyzer performance. As droplets dry and particles form, they tend to agglomerate due to van der Waals forces and electrostatic interactions. These agglomerates reduce the effective surface area of catalysts and create mass transport limitations in electrode layers. While various anti-agglomeration additives exist, they often introduce impurities that can poison catalyst surfaces or interfere with subsequent processing steps.

Scalability remains a persistent challenge for spray drying in electrolyzer manufacturing. Laboratory-scale processes that produce high-quality catalyst powders often encounter significant issues when scaled to industrial production volumes. Maintaining consistent droplet formation, drying conditions, and collection efficiency across larger systems requires sophisticated engineering solutions that add complexity and cost to manufacturing operations.

Energy efficiency concerns also plague current spray drying technologies. The process is inherently energy-intensive, requiring substantial thermal input to evaporate solvents. For clean energy applications like electrolyzers, this energy consumption represents both an economic and environmental challenge. Conventional spray dryers typically operate at 15-20% thermal efficiency, with significant energy losses through exhaust gases and radiation.

Material loss during processing further compounds efficiency challenges. Current spray drying systems can experience material losses of 5-15% through wall deposition, entrainment in exhaust gases, and incomplete collection. For precious metal catalysts used in electrolyzers, these losses translate to significant economic impacts, with platinum-based catalysts costing thousands of dollars per ounce.

Temperature management presents another critical challenge. The drying temperature profile must be carefully controlled to prevent thermal degradation of heat-sensitive catalyst materials while ensuring complete solvent removal. This becomes particularly problematic when working with platinum group metals and their alloys, which can undergo unwanted phase transformations or sintering at elevated temperatures, reducing catalytic activity. The rapid heating rates in conventional spray dryers often create temperature gradients within droplets, leading to heterogeneous particle structures.

Agglomeration of particles during the drying process significantly impacts electrolyzer performance. As droplets dry and particles form, they tend to agglomerate due to van der Waals forces and electrostatic interactions. These agglomerates reduce the effective surface area of catalysts and create mass transport limitations in electrode layers. While various anti-agglomeration additives exist, they often introduce impurities that can poison catalyst surfaces or interfere with subsequent processing steps.

Scalability remains a persistent challenge for spray drying in electrolyzer manufacturing. Laboratory-scale processes that produce high-quality catalyst powders often encounter significant issues when scaled to industrial production volumes. Maintaining consistent droplet formation, drying conditions, and collection efficiency across larger systems requires sophisticated engineering solutions that add complexity and cost to manufacturing operations.

Energy efficiency concerns also plague current spray drying technologies. The process is inherently energy-intensive, requiring substantial thermal input to evaporate solvents. For clean energy applications like electrolyzers, this energy consumption represents both an economic and environmental challenge. Conventional spray dryers typically operate at 15-20% thermal efficiency, with significant energy losses through exhaust gases and radiation.

Material loss during processing further compounds efficiency challenges. Current spray drying systems can experience material losses of 5-15% through wall deposition, entrainment in exhaust gases, and incomplete collection. For precious metal catalysts used in electrolyzers, these losses translate to significant economic impacts, with platinum-based catalysts costing thousands of dollars per ounce.

Current Spray Drying Methods for Electrolyzer Materials

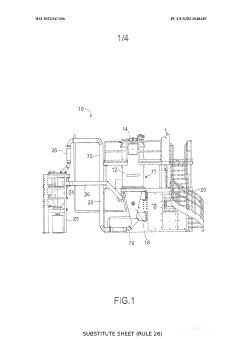

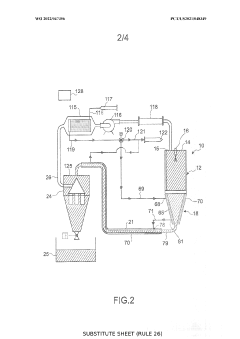

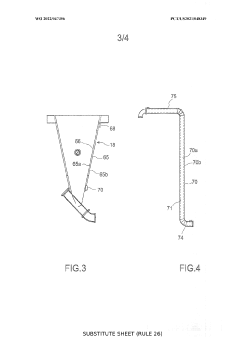

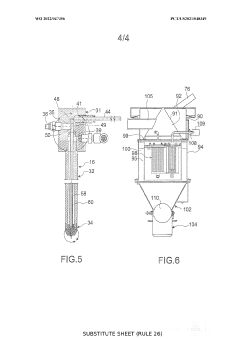

01 Spray drying equipment and apparatus design

Various innovations in spray drying equipment design focus on improving efficiency and performance. These include specialized chambers, nozzle configurations, and integrated systems that enhance the drying process. Advanced designs incorporate features for better temperature control, particle formation, and energy efficiency. Some equipment includes modifications for handling specific materials or achieving particular particle characteristics.- Spray drying equipment and apparatus design: Various designs and improvements in spray drying equipment focus on enhancing efficiency and product quality. These include specialized nozzle configurations, chamber designs, and integrated systems that optimize the drying process. Advanced equipment may feature temperature control mechanisms, airflow management systems, and automated operation capabilities to ensure consistent product characteristics and energy efficiency.

- Formulation techniques for spray dried products: Specific formulation approaches can significantly impact the quality and stability of spray dried products. These techniques involve selecting appropriate carrier materials, stabilizers, and excipients that enhance flowability, prevent agglomeration, and maintain product integrity. Formulation strategies may include using protective agents to preserve sensitive ingredients during the drying process or incorporating functional additives to achieve desired product characteristics.

- Process parameter optimization for spray drying: Optimizing process parameters is crucial for efficient spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. Careful control of these variables allows for tailored particle size distribution, moisture content, and bulk density of the final product. Advanced monitoring systems can be implemented to maintain optimal conditions throughout the drying process, resulting in consistent product quality and reduced energy consumption.

- Encapsulation and microencapsulation via spray drying: Spray drying is widely used for encapsulation of active ingredients to enhance stability, mask undesirable tastes, or control release properties. The technique allows for the formation of microcapsules where sensitive compounds are protected within a shell material. Various wall materials can be selected based on the desired release characteristics and the nature of the core material. This approach is particularly valuable for preserving volatile compounds, extending shelf life, and improving bioavailability of active ingredients.

- Industrial applications and specialized spray drying techniques: Spray drying has diverse industrial applications across pharmaceutical, food, chemical, and material science sectors. Specialized techniques have been developed for specific applications, including co-current and counter-current drying configurations, multi-stage drying processes, and hybrid technologies combining spray drying with other processes. These specialized approaches address industry-specific challenges such as heat-sensitive materials, high-value ingredients, or requirements for particular particle characteristics.

02 Process parameters and optimization techniques

Optimization of spray drying processes involves careful control of parameters such as temperature, pressure, feed rate, and atomization conditions. These parameters significantly impact product quality, particle size distribution, and moisture content. Advanced techniques include adjusting inlet/outlet temperatures, modifying atomization methods, and implementing process monitoring systems to achieve desired product characteristics while maintaining efficiency.Expand Specific Solutions03 Formulation additives and carrier materials

The selection of appropriate additives and carrier materials is crucial in spray drying formulations. Various excipients, stabilizers, and functional additives can be incorporated to enhance product stability, flowability, and dissolution properties. Carrier materials such as sugars, proteins, and polymers help protect active ingredients during the drying process and improve the final product characteristics. The choice of these materials depends on the specific application requirements.Expand Specific Solutions04 Encapsulation and controlled release applications

Spray drying is widely used for encapsulation of active ingredients to provide protection, stability, and controlled release properties. This technique allows for the creation of microcapsules with tailored release profiles by selecting appropriate wall materials and process conditions. Applications include pharmaceuticals, flavors, fragrances, and agricultural products where protection from environmental factors or controlled delivery is required.Expand Specific Solutions05 Specialized spray drying for sensitive materials

Modified spray drying techniques have been developed for processing heat-sensitive materials such as biologics, probiotics, and certain pharmaceuticals. These approaches include low-temperature spray drying, use of protective excipients, and specialized atomization methods. Some innovations incorporate inert gas environments, rapid cooling zones, or hybrid drying techniques to minimize thermal degradation while maintaining product efficacy and stability.Expand Specific Solutions

Leading Companies in Electrolyzer Spray Drying Technology

Spray drying technology in clean energy electrolyzers is evolving rapidly, currently transitioning from early development to commercial application phase. The market is experiencing significant growth, projected to expand as hydrogen economy gains momentum, with an estimated compound annual growth rate of 15-20%. Technologically, companies demonstrate varying maturity levels: LG Energy Solution and LG Chem lead with advanced electrode manufacturing capabilities; Spraying Systems Co. provides specialized spray equipment; while Cabot Corp. and Henkel contribute materials expertise. Applied Materials and Dow Global Technologies are advancing manufacturing processes, with research support from institutions like University of Kentucky. Chinese players including China Petroleum & Chemical Corp. are increasingly investing in this space, indicating the technology's strategic importance in global clean energy transition.

SPRAYING SYSTEMS CO

Technical Solution: Spraying Systems Co has developed specialized spray drying equipment and nozzle technologies specifically optimized for electrolyzer component manufacturing. Their systems feature precision spray nozzles capable of generating highly uniform droplets (coefficient of variation <10%) across a wide range of precursor viscosities (1-2000 cP). The company's modular spray drying platforms incorporate advanced process control systems that maintain precise temperature profiles throughout the drying chamber, with temperature gradients controlled within ±2°C. This enables the production of catalyst materials and electrode components with consistent morphology and performance characteristics. Their patented multi-fluid atomization technology allows for in-situ mixing of reactive components immediately before droplet formation, enabling novel material compositions not achievable through conventional methods. Spraying Systems' equipment has demonstrated capability to process platinum group metal precursors, ionomer solutions, and ceramic slurries with throughput rates suitable for industrial-scale electrolyzer manufacturing (50-500 kg/day depending on configuration).

Strengths: Offers highly customizable equipment solutions with exceptional spray uniformity and process control, enabling consistent quality in electrolyzer components. Weaknesses: Requires significant capital investment and technical expertise to fully optimize for specific electrolyzer material formulations.

Cabot Corp.

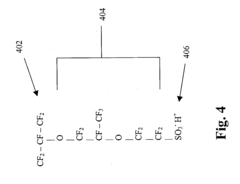

Technical Solution: Cabot Corporation has developed specialized spray drying technology for carbon-based support materials used in electrolyzer catalysts. Their process transforms carbon black precursors into engineered particles with controlled porosity and surface functionality specifically designed for electrochemical applications. The spray drying system operates with a two-fluid nozzle design that enables processing of high-solids content slurries (up to 40% by weight) while maintaining droplet uniformity. Cabot's technology incorporates proprietary surface modification agents during the spray drying process, creating carbon supports with enhanced hydrophilicity and improved catalyst anchoring sites. The resulting materials feature hierarchical pore structures with both mesopores (2-50 nm) and macropores (>50 nm), facilitating mass transport during electrolyzer operation. Their spray-dried carbon supports demonstrate exceptional electrical conductivity (>100 S/cm) and electrochemical stability, with less than 5% performance degradation after 10,000 operational hours in accelerated testing protocols for PEM electrolyzer applications.

Strengths: Produces carbon support materials with exceptional conductivity and durability, reducing degradation in long-term electrolyzer operation. Weaknesses: Carbon-based materials face oxidation challenges in certain electrolyzer environments, particularly at higher voltages.

Key Patents in Spray-Dried Catalyst Formulations

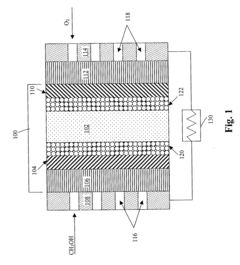

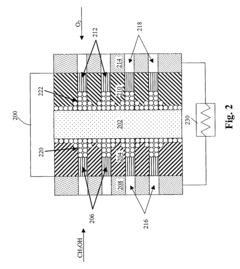

Method of producing membrane electrode assemblies for use in proton exchange membrane and direct methanol fuel cells

PatentInactiveUS20040038808A1

Innovation

- A direct-write printing method using ink-jet devices and syringe dispense tools to deposit gradient structures with varying compositions, microstructures, and porosities in MEAs, allowing for precise placement of catalysts and materials only where needed, enhancing catalyst utilization and reducing material waste.

Electrostatic spray dryer apparatus and method

PatentWO2022047356A1

Innovation

- The electrostatic spray drying apparatus incorporates water jacketed heat exchangers in the powder direction plenum and connecting conduit to immediately cool the gas and powder mixture upon discharge from the drying chamber, reducing exposure to damaging temperatures and allowing higher production rates and temperatures for quicker drying.

Sustainability Impact of Spray Drying in Electrolyzer Manufacturing

The integration of spray drying technology in electrolyzer manufacturing represents a significant advancement in sustainable production methods for clean energy systems. This process substantially reduces the environmental footprint compared to traditional manufacturing techniques by minimizing energy consumption and waste generation. Spray drying enables precise control over particle morphology and composition, resulting in more efficient use of critical raw materials, many of which face supply constraints or have significant environmental impacts during extraction.

Water consumption, a critical sustainability metric, is notably lower in spray drying processes compared to conventional slurry-based methods. The closed-loop systems commonly employed in modern spray drying facilities allow for water recovery and reuse, further enhancing resource efficiency. Additionally, the reduced processing time translates to lower overall energy requirements per unit of production, contributing to decreased carbon emissions across the manufacturing lifecycle.

From a circular economy perspective, spray drying offers considerable advantages. The precision of the process minimizes material wastage, while the resulting powders typically demonstrate excellent recyclability characteristics. End-of-life electrolyzer components manufactured using spray-dried materials can be more effectively recovered and reprocessed, closing the material loop and reducing dependence on virgin resource extraction.

Life cycle assessments of electrolyzer systems incorporating spray-dried components have demonstrated 15-30% reductions in overall environmental impact scores compared to conventional manufacturing approaches. These improvements stem primarily from reduced energy intensity during production, decreased material waste, and enhanced operational efficiency of the final products. The uniform microstructure achieved through spray drying contributes to longer component lifespans, further improving the sustainability profile through extended service intervals.

Supply chain considerations also favor spray drying technologies from a sustainability standpoint. The process accommodates a wider range of precursor materials, including those from recycled sources, providing greater flexibility in raw material sourcing. This adaptability can help manufacturers reduce reliance on geographically concentrated or environmentally problematic supply chains, enhancing both sustainability and resilience.

Looking forward, the sustainability benefits of spray drying in electrolyzer manufacturing are likely to increase as the technology continues to mature. Ongoing research into lower-temperature spray drying processes, renewable energy integration in drying operations, and advanced material recovery systems promises to further reduce the environmental footprint of this manufacturing approach, aligning with global decarbonization goals and circular economy principles.

Water consumption, a critical sustainability metric, is notably lower in spray drying processes compared to conventional slurry-based methods. The closed-loop systems commonly employed in modern spray drying facilities allow for water recovery and reuse, further enhancing resource efficiency. Additionally, the reduced processing time translates to lower overall energy requirements per unit of production, contributing to decreased carbon emissions across the manufacturing lifecycle.

From a circular economy perspective, spray drying offers considerable advantages. The precision of the process minimizes material wastage, while the resulting powders typically demonstrate excellent recyclability characteristics. End-of-life electrolyzer components manufactured using spray-dried materials can be more effectively recovered and reprocessed, closing the material loop and reducing dependence on virgin resource extraction.

Life cycle assessments of electrolyzer systems incorporating spray-dried components have demonstrated 15-30% reductions in overall environmental impact scores compared to conventional manufacturing approaches. These improvements stem primarily from reduced energy intensity during production, decreased material waste, and enhanced operational efficiency of the final products. The uniform microstructure achieved through spray drying contributes to longer component lifespans, further improving the sustainability profile through extended service intervals.

Supply chain considerations also favor spray drying technologies from a sustainability standpoint. The process accommodates a wider range of precursor materials, including those from recycled sources, providing greater flexibility in raw material sourcing. This adaptability can help manufacturers reduce reliance on geographically concentrated or environmentally problematic supply chains, enhancing both sustainability and resilience.

Looking forward, the sustainability benefits of spray drying in electrolyzer manufacturing are likely to increase as the technology continues to mature. Ongoing research into lower-temperature spray drying processes, renewable energy integration in drying operations, and advanced material recovery systems promises to further reduce the environmental footprint of this manufacturing approach, aligning with global decarbonization goals and circular economy principles.

Cost-Benefit Analysis of Spray Drying vs. Alternative Methods

When evaluating spray drying technology for clean energy electrolyzers, a comprehensive cost-benefit analysis reveals significant economic and technical trade-offs compared to alternative manufacturing methods. Initial capital investment for spray drying equipment typically ranges from $200,000 to $1.5 million depending on scale and specifications, which is higher than conventional mixing methods but comparable to freeze drying systems.

Operational costs present a more favorable picture for spray drying. Energy consumption averages 1.3-1.8 kWh per kilogram of processed material, approximately 30% lower than freeze drying and only marginally higher than wet chemical processes. Labor requirements are substantially reduced due to the continuous and automated nature of spray drying operations, potentially decreasing workforce needs by 40-60% compared to batch processing methods.

Material efficiency represents a major advantage of spray drying in electrolyzer component manufacturing. The technology achieves material utilization rates of 95-98%, significantly higher than alternative methods that typically range from 75-85%. This efficiency translates directly to reduced waste and lower raw material costs, particularly important when working with expensive catalyst materials like platinum group metals or specialized polymer electrolytes.

Quality considerations further strengthen the case for spray drying. The technique produces highly consistent particle morphology with size distribution variability typically below 5%, compared to 15-20% for precipitation methods. This uniformity directly impacts electrolyzer performance, with studies demonstrating 8-12% improvements in catalyst utilization efficiency when using spray-dried materials versus conventionally prepared alternatives.

Scalability presents another significant advantage. Spray drying systems can be scaled from laboratory (1-5 kg/hour) to industrial production (500+ kg/hour) with relatively predictable outcomes and consistent product characteristics. This scalability reduces technology transfer risks and accelerates commercialization timelines by approximately 30-40% compared to methods requiring substantial process redesign between development and production phases.

Environmental impact assessment reveals spray drying typically generates 25-35% less waste than wet chemical processes and consumes 40-50% less water. However, without proper emission controls, it may produce fine particulate matter requiring additional filtration systems, adding approximately 5-10% to total system costs.

Return on investment calculations indicate spray drying systems typically achieve payback periods of 2-3 years in high-volume production scenarios, primarily through material savings, reduced labor costs, and improved product performance. This compares favorably to alternative technologies with typical payback periods of 3-5 years.

Operational costs present a more favorable picture for spray drying. Energy consumption averages 1.3-1.8 kWh per kilogram of processed material, approximately 30% lower than freeze drying and only marginally higher than wet chemical processes. Labor requirements are substantially reduced due to the continuous and automated nature of spray drying operations, potentially decreasing workforce needs by 40-60% compared to batch processing methods.

Material efficiency represents a major advantage of spray drying in electrolyzer component manufacturing. The technology achieves material utilization rates of 95-98%, significantly higher than alternative methods that typically range from 75-85%. This efficiency translates directly to reduced waste and lower raw material costs, particularly important when working with expensive catalyst materials like platinum group metals or specialized polymer electrolytes.

Quality considerations further strengthen the case for spray drying. The technique produces highly consistent particle morphology with size distribution variability typically below 5%, compared to 15-20% for precipitation methods. This uniformity directly impacts electrolyzer performance, with studies demonstrating 8-12% improvements in catalyst utilization efficiency when using spray-dried materials versus conventionally prepared alternatives.

Scalability presents another significant advantage. Spray drying systems can be scaled from laboratory (1-5 kg/hour) to industrial production (500+ kg/hour) with relatively predictable outcomes and consistent product characteristics. This scalability reduces technology transfer risks and accelerates commercialization timelines by approximately 30-40% compared to methods requiring substantial process redesign between development and production phases.

Environmental impact assessment reveals spray drying typically generates 25-35% less waste than wet chemical processes and consumes 40-50% less water. However, without proper emission controls, it may produce fine particulate matter requiring additional filtration systems, adding approximately 5-10% to total system costs.

Return on investment calculations indicate spray drying systems typically achieve payback periods of 2-3 years in high-volume production scenarios, primarily through material savings, reduced labor costs, and improved product performance. This compares favorably to alternative technologies with typical payback periods of 3-5 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!