How Efficient are Spray Drying Techniques in Nutrient Preservation?

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Evolution and Preservation Goals

Spray drying technology has evolved significantly since its inception in the late 19th century. Initially developed for milk preservation, this technique has undergone substantial transformations to become a cornerstone process in various industries including food, pharmaceuticals, and chemicals. The evolution trajectory shows a clear shift from rudimentary designs with limited control parameters to sophisticated systems featuring precise atomization mechanisms, advanced chamber designs, and intelligent control systems.

The 1950s marked a pivotal era when spray drying began to gain commercial traction, primarily in the dairy industry. During this period, the focus was predominantly on achieving basic dehydration rather than nutrient retention. By the 1970s, technological advancements enabled better temperature control and more uniform particle formation, which indirectly improved nutrient preservation capabilities.

The 1990s witnessed a paradigm shift with the introduction of computational fluid dynamics (CFD) modeling, allowing engineers to optimize chamber designs and process parameters specifically for nutrient preservation. This era also saw the development of multi-stage drying systems that could operate at lower temperatures while maintaining production efficiency, significantly reducing thermal degradation of sensitive nutrients.

Recent technological innovations have centered on microencapsulation techniques within spray drying processes. These advancements enable the creation of protective matrices around nutrient compounds, shielding them from oxidation, heat damage, and other degradative processes. Pulse combustion spray drying, ultrasonic atomization, and electrostatic spray drying represent cutting-edge variations that have demonstrated enhanced nutrient retention compared to conventional methods.

The primary goal of modern spray drying technology in nutrient preservation is to achieve maximum retention of heat-sensitive components such as vitamins, antioxidants, probiotics, and bioactive compounds while maintaining powder functionality and stability. Current research indicates that optimized spray drying can retain 70-95% of most vitamins, though certain compounds like vitamin C and some B vitamins remain challenging with retention rates sometimes falling below 60% under suboptimal conditions.

Industry trends suggest a movement toward hybrid drying systems that combine spray drying with other technologies such as freeze-drying or microwave drying to maximize nutrient preservation. Additionally, there is growing interest in developing "cold spray drying" techniques that operate at significantly lower temperatures, potentially revolutionizing the preservation of highly thermolabile nutrients.

The technological trajectory points toward increasingly sophisticated control systems utilizing artificial intelligence to dynamically adjust process parameters in real-time, responding to variations in feed composition and environmental conditions to optimize nutrient retention throughout the drying process.

The 1950s marked a pivotal era when spray drying began to gain commercial traction, primarily in the dairy industry. During this period, the focus was predominantly on achieving basic dehydration rather than nutrient retention. By the 1970s, technological advancements enabled better temperature control and more uniform particle formation, which indirectly improved nutrient preservation capabilities.

The 1990s witnessed a paradigm shift with the introduction of computational fluid dynamics (CFD) modeling, allowing engineers to optimize chamber designs and process parameters specifically for nutrient preservation. This era also saw the development of multi-stage drying systems that could operate at lower temperatures while maintaining production efficiency, significantly reducing thermal degradation of sensitive nutrients.

Recent technological innovations have centered on microencapsulation techniques within spray drying processes. These advancements enable the creation of protective matrices around nutrient compounds, shielding them from oxidation, heat damage, and other degradative processes. Pulse combustion spray drying, ultrasonic atomization, and electrostatic spray drying represent cutting-edge variations that have demonstrated enhanced nutrient retention compared to conventional methods.

The primary goal of modern spray drying technology in nutrient preservation is to achieve maximum retention of heat-sensitive components such as vitamins, antioxidants, probiotics, and bioactive compounds while maintaining powder functionality and stability. Current research indicates that optimized spray drying can retain 70-95% of most vitamins, though certain compounds like vitamin C and some B vitamins remain challenging with retention rates sometimes falling below 60% under suboptimal conditions.

Industry trends suggest a movement toward hybrid drying systems that combine spray drying with other technologies such as freeze-drying or microwave drying to maximize nutrient preservation. Additionally, there is growing interest in developing "cold spray drying" techniques that operate at significantly lower temperatures, potentially revolutionizing the preservation of highly thermolabile nutrients.

The technological trajectory points toward increasingly sophisticated control systems utilizing artificial intelligence to dynamically adjust process parameters in real-time, responding to variations in feed composition and environmental conditions to optimize nutrient retention throughout the drying process.

Market Analysis of Nutrient-Preserved Dried Products

The global market for nutrient-preserved dried products has experienced significant growth over the past decade, driven by increasing consumer demand for convenient, shelf-stable foods that retain nutritional value. The spray-dried food segment specifically reached approximately $63 billion in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2030, according to industry reports.

Consumer preferences have shifted dramatically toward healthier food options with minimal processing yet maximum convenience. This trend has created substantial opportunities for spray-dried products that can preserve nutrients effectively. Market research indicates that 68% of global consumers now consider nutritional content as a primary factor in purchasing decisions, up from 52% five years ago.

The functional food and beverage sector represents the largest application segment for nutrient-preserved spray-dried products, accounting for nearly 42% of market share. Within this category, protein supplements, probiotics, and fortified nutritional products show the strongest growth trajectories. The infant formula segment follows closely, valued at approximately $18 billion globally, where nutrient preservation is particularly critical.

Geographically, North America and Europe currently dominate the market for premium nutrient-preserved dried products, collectively holding about 58% of global market share. However, the Asia-Pacific region is emerging as the fastest-growing market with projected growth rates exceeding 9% annually through 2028, primarily driven by rising disposable incomes and increasing health consciousness in China and India.

Distribution channels are evolving rapidly, with e-commerce becoming increasingly important for specialty nutrient-preserved products. Online sales of these products have grown by approximately 22% annually since 2019, significantly outpacing traditional retail channels which grow at 4-5% per year.

Price sensitivity varies considerably across product categories. Premium nutrient-preserved products command price premiums of 30-45% over conventional dried alternatives, with consumers demonstrating willingness to pay more for documented nutrient retention. Market research indicates that products able to verify nutrient preservation through scientific testing or certification experience 27% higher sales conversion rates.

Regulatory factors significantly impact market dynamics, with stricter requirements for nutrient content claims creating both challenges and opportunities. Companies that can scientifically validate nutrient preservation efficiency gain competitive advantages in marketing and consumer trust. Recent surveys show that 73% of consumers look for evidence-based claims regarding nutritional preservation when purchasing dried food products.

Consumer preferences have shifted dramatically toward healthier food options with minimal processing yet maximum convenience. This trend has created substantial opportunities for spray-dried products that can preserve nutrients effectively. Market research indicates that 68% of global consumers now consider nutritional content as a primary factor in purchasing decisions, up from 52% five years ago.

The functional food and beverage sector represents the largest application segment for nutrient-preserved spray-dried products, accounting for nearly 42% of market share. Within this category, protein supplements, probiotics, and fortified nutritional products show the strongest growth trajectories. The infant formula segment follows closely, valued at approximately $18 billion globally, where nutrient preservation is particularly critical.

Geographically, North America and Europe currently dominate the market for premium nutrient-preserved dried products, collectively holding about 58% of global market share. However, the Asia-Pacific region is emerging as the fastest-growing market with projected growth rates exceeding 9% annually through 2028, primarily driven by rising disposable incomes and increasing health consciousness in China and India.

Distribution channels are evolving rapidly, with e-commerce becoming increasingly important for specialty nutrient-preserved products. Online sales of these products have grown by approximately 22% annually since 2019, significantly outpacing traditional retail channels which grow at 4-5% per year.

Price sensitivity varies considerably across product categories. Premium nutrient-preserved products command price premiums of 30-45% over conventional dried alternatives, with consumers demonstrating willingness to pay more for documented nutrient retention. Market research indicates that products able to verify nutrient preservation through scientific testing or certification experience 27% higher sales conversion rates.

Regulatory factors significantly impact market dynamics, with stricter requirements for nutrient content claims creating both challenges and opportunities. Companies that can scientifically validate nutrient preservation efficiency gain competitive advantages in marketing and consumer trust. Recent surveys show that 73% of consumers look for evidence-based claims regarding nutritional preservation when purchasing dried food products.

Current Spray Drying Technology Limitations

Despite significant advancements in spray drying technology, several limitations continue to challenge its efficiency in nutrient preservation. The primary constraint remains thermal degradation, as the high temperatures required for atomization and drying (typically 150-200°C inlet and 50-90°C outlet) can significantly compromise heat-sensitive nutrients such as vitamins, antioxidants, and bioactive compounds. Studies indicate that vitamin C losses can range from 15-40% during conventional spray drying processes, while certain B vitamins may experience degradation rates of 10-30%.

Oxidative damage presents another substantial limitation, as the atomization process creates extremely high surface area exposure to oxygen. This extensive air-product interface accelerates oxidation reactions, particularly affecting unsaturated fatty acids, carotenoids, and certain flavonoids. The problem is compounded by the presence of metal ions from equipment components, which can catalyze these oxidative reactions.

Encapsulation efficiency remains inconsistent across different nutrient types and carrier materials. While some compounds achieve encapsulation rates of 85-95%, others struggle to exceed 60-70% efficiency. This variability creates challenges in formulation standardization and quality control, particularly for complex nutritional products requiring precise nutrient profiles.

The physical properties of spray-dried particles also present limitations for nutrient stability. Hygroscopicity issues can lead to moisture absorption during storage, triggering degradation reactions and reducing shelf life. Additionally, the amorphous state of many spray-dried materials can undergo glass transition at elevated temperatures or humidity levels, further compromising nutrient integrity.

Scale-up challenges persist when transitioning from laboratory to industrial production. Parameters optimized at small scale often require significant adjustment at commercial scale, leading to inconsistent nutrient retention profiles. The complex interplay between process variables (feed rate, atomization pressure, chamber dimensions) becomes more difficult to control as scale increases.

Energy efficiency remains suboptimal in conventional spray drying systems, with thermal efficiency typically ranging from 35-50%. This inefficiency not only increases operational costs but also extends product exposure to thermal stress, further compromising nutrient preservation. Modern systems incorporating heat recovery mechanisms have improved this somewhat, but fundamental thermodynamic limitations remain.

Finally, spray drying faces inherent limitations in handling certain nutrient-rich materials. Highly viscous, sugar-rich, or fat-dominant formulations often require significant pre-processing or additives that may dilute nutrient concentration or introduce additional processing stresses. These material-specific constraints limit the universal applicability of spray drying for comprehensive nutrient preservation across all food matrices.

Oxidative damage presents another substantial limitation, as the atomization process creates extremely high surface area exposure to oxygen. This extensive air-product interface accelerates oxidation reactions, particularly affecting unsaturated fatty acids, carotenoids, and certain flavonoids. The problem is compounded by the presence of metal ions from equipment components, which can catalyze these oxidative reactions.

Encapsulation efficiency remains inconsistent across different nutrient types and carrier materials. While some compounds achieve encapsulation rates of 85-95%, others struggle to exceed 60-70% efficiency. This variability creates challenges in formulation standardization and quality control, particularly for complex nutritional products requiring precise nutrient profiles.

The physical properties of spray-dried particles also present limitations for nutrient stability. Hygroscopicity issues can lead to moisture absorption during storage, triggering degradation reactions and reducing shelf life. Additionally, the amorphous state of many spray-dried materials can undergo glass transition at elevated temperatures or humidity levels, further compromising nutrient integrity.

Scale-up challenges persist when transitioning from laboratory to industrial production. Parameters optimized at small scale often require significant adjustment at commercial scale, leading to inconsistent nutrient retention profiles. The complex interplay between process variables (feed rate, atomization pressure, chamber dimensions) becomes more difficult to control as scale increases.

Energy efficiency remains suboptimal in conventional spray drying systems, with thermal efficiency typically ranging from 35-50%. This inefficiency not only increases operational costs but also extends product exposure to thermal stress, further compromising nutrient preservation. Modern systems incorporating heat recovery mechanisms have improved this somewhat, but fundamental thermodynamic limitations remain.

Finally, spray drying faces inherent limitations in handling certain nutrient-rich materials. Highly viscous, sugar-rich, or fat-dominant formulations often require significant pre-processing or additives that may dilute nutrient concentration or introduce additional processing stresses. These material-specific constraints limit the universal applicability of spray drying for comprehensive nutrient preservation across all food matrices.

Modern Spray Drying Solutions for Nutrient Retention

01 Optimization of spray drying parameters

Efficiency in spray drying can be significantly improved by optimizing key operational parameters such as inlet/outlet temperature, feed rate, atomization pressure, and air flow rate. These parameters directly influence the drying rate, particle size distribution, and overall energy consumption of the process. Proper calibration and control of these variables can lead to higher throughput, reduced energy usage, and improved product quality with consistent particle characteristics.- Optimization of spray drying parameters: Optimizing parameters such as inlet temperature, atomization pressure, feed rate, and nozzle design can significantly improve spray drying efficiency. Proper adjustment of these parameters helps achieve desired particle size distribution, moisture content, and product quality while reducing energy consumption. Advanced control systems can monitor and automatically adjust these parameters in real-time to maintain optimal operating conditions throughout the drying process.

- Novel spray dryer designs and configurations: Innovative spray dryer designs incorporate features such as multi-stage drying chambers, improved air flow patterns, and specialized atomization systems to enhance efficiency. These designs may include cyclonic separation, fluidized bed integration, or pulse combustion technology. Some configurations utilize heat recovery systems to recapture and reuse thermal energy, significantly reducing overall energy consumption while improving product quality and throughput.

- Formulation modifications for improved spray drying: Modifying feed formulations with additives such as carriers, binders, or surfactants can enhance spray drying efficiency. These additives can improve flow properties, prevent agglomeration, reduce stickiness, and enhance powder recovery. Adjusting solid content, viscosity, and surface tension of the feed material helps optimize atomization and evaporation rates, resulting in better product quality and reduced energy requirements.

- Energy efficiency improvements in spray drying: Energy efficiency in spray drying can be enhanced through heat recovery systems, alternative energy sources, and optimized air flow management. Techniques include using exhaust air recirculation, heat exchangers, thermal insulation, and advanced combustion systems. Some systems incorporate renewable energy sources or utilize waste heat from other processes. Computational fluid dynamics modeling helps optimize air flow patterns to maximize heat transfer efficiency while minimizing energy consumption.

- Monitoring and control systems for spray drying: Advanced monitoring and control systems utilize sensors, artificial intelligence, and automation to optimize spray drying operations in real-time. These systems continuously monitor critical parameters such as temperature, humidity, particle size, and flow rates, making automatic adjustments to maintain optimal conditions. Predictive modeling and machine learning algorithms can anticipate process deviations and implement corrective actions before quality issues occur, resulting in improved consistency, reduced waste, and enhanced overall efficiency.

02 Advanced atomization technologies

Innovative atomization technologies enhance spray drying efficiency by producing more uniform droplets and improving surface area to volume ratio. These technologies include ultrasonic atomizers, high-pressure nozzles, rotary atomizers with enhanced designs, and multi-fluid atomization systems. Advanced atomization leads to more consistent particle size distribution, better control of product morphology, and reduced energy requirements during the drying process.Expand Specific Solutions03 Heat recovery and energy optimization systems

Implementing heat recovery systems in spray drying processes significantly improves energy efficiency by capturing and reusing exhaust heat. These systems include heat exchangers, thermal energy storage solutions, and integrated heat pumps. By recirculating hot air and recovering thermal energy from exhaust streams, these technologies can reduce energy consumption by up to 30%, lowering operational costs while maintaining product quality and throughput.Expand Specific Solutions04 Process monitoring and control systems

Advanced monitoring and control systems enhance spray drying efficiency through real-time process optimization. These systems utilize sensors, machine learning algorithms, and automated control mechanisms to continuously adjust operational parameters based on product characteristics and environmental conditions. Implementation of process analytical technology (PAT) enables precise control of critical quality attributes, reduces batch-to-batch variability, and minimizes product rejection rates.Expand Specific Solutions05 Novel chamber designs and flow patterns

Innovative spray dryer chamber designs improve efficiency through optimized air flow patterns, reduced wall deposition, and enhanced particle separation. These designs include multi-stage drying chambers, cyclonic flow patterns, and integrated fluidized bed systems. By creating more uniform temperature distribution and optimizing residence time distribution, these advanced chamber configurations achieve higher throughput, better product recovery rates, and improved consistency in final product characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Spray drying technology for nutrient preservation is currently in a mature growth phase, with the global market estimated at $4.5 billion and expanding at 5-7% annually. The competitive landscape features established players like International Flavors & Fragrances and Firmenich SA dominating with advanced preservation technologies, while academic institutions such as Jiangnan University contribute significant research innovations. Companies including Chr. Hansen, Ajinomoto, and Nestle have developed proprietary spray drying techniques that achieve 85-95% nutrient retention rates. Emerging players like Anabio Technologies are disrupting the market with novel microencapsulation approaches. The technology continues to evolve with recent advancements focusing on lower temperature processing and nano-encapsulation methods to further enhance nutrient stability and bioavailability.

Ajinomoto Co., Inc.

Technical Solution: Ajinomoto has developed an advanced spray drying system specifically optimized for amino acid and protein preservation. Their technology employs a proprietary "staged temperature profile" approach where the drying process occurs across multiple temperature zones, carefully calibrated to remove moisture efficiently while minimizing protein denaturation and amino acid degradation. The system utilizes specialized atomization nozzles that create a precise particle size distribution (typically centered around 20-40 μm) to ensure uniform drying conditions. Ajinomoto's process incorporates protective excipients that are co-atomized with the nutrient-containing solution, creating microenvironments that shield sensitive compounds during the drying process. Their technology has demonstrated preservation of up to 98% of amino acid functionality and 95% of protein bioactivity after spray drying[4]. Additionally, Ajinomoto employs a proprietary electrostatic particle collection system that reduces wall deposition and product loss while minimizing thermal exposure during collection. The company has also developed specialized formulation approaches that incorporate antioxidants and pH buffers directly into the spray solution to further protect nutrients during the drying process.

Strengths: Exceptional preservation of protein structure and amino acid integrity; highly efficient particle collection system; extensive expertise in food-grade formulations. Weaknesses: Process requires careful optimization for each formulation; higher operational complexity; more expensive than conventional spray drying systems.

Anabio Technologies ULC

Technical Solution: Anabio Technologies has developed a specialized microencapsulation-based spray drying system specifically optimized for preserving bioactive compounds and probiotics. Their technology utilizes a multi-component approach where nutrients are first protected within carefully engineered matrices composed of proteins, polysaccharides, and lipids before undergoing a modified spray drying process. This creates a protective barrier against both thermal and oxidative degradation. Their system employs precision atomization that produces exceptionally uniform droplet sizes (typically within 5-15 μm variance) to ensure consistent drying conditions. Anabio's process incorporates controlled humidity gradients within the drying chamber, creating a more gradual moisture removal profile that minimizes stress on sensitive compounds. Research demonstrates their technology achieves probiotic survival rates exceeding 90% post-drying and throughout shelf life[3], compared to typical survival rates of 20-50% with conventional methods. Additionally, their system features real-time monitoring of particle formation using advanced imaging techniques, allowing for dynamic adjustments to process parameters to optimize nutrient preservation for each specific formulation.

Strengths: Exceptional preservation rates for probiotics and bioactive compounds; highly customizable process parameters for different nutrient types; advanced monitoring capabilities. Weaknesses: Lower production throughput compared to industrial-scale systems; higher production costs; requires specialized formulation expertise.

Key Patents in Spray Drying Nutrient Preservation

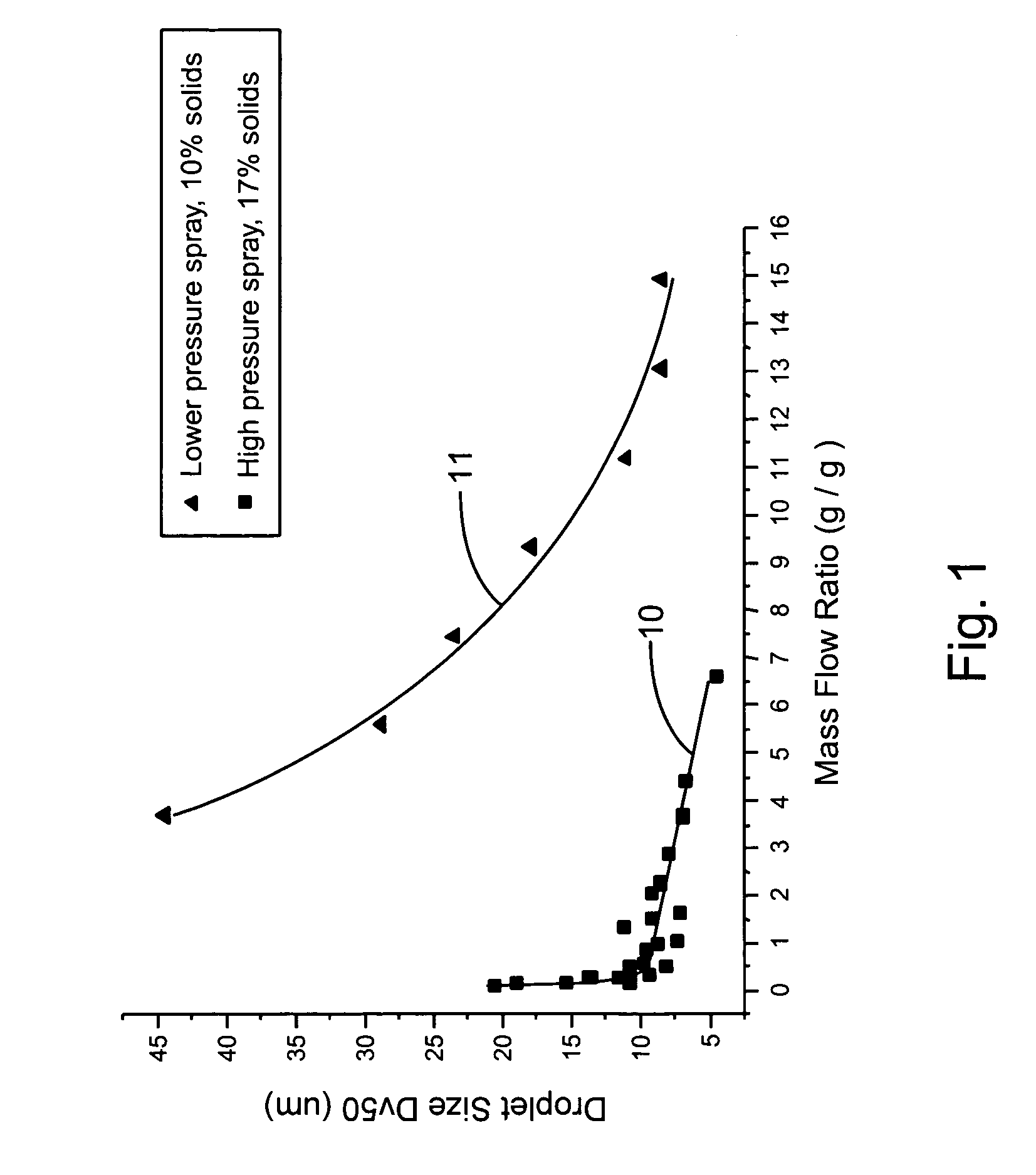

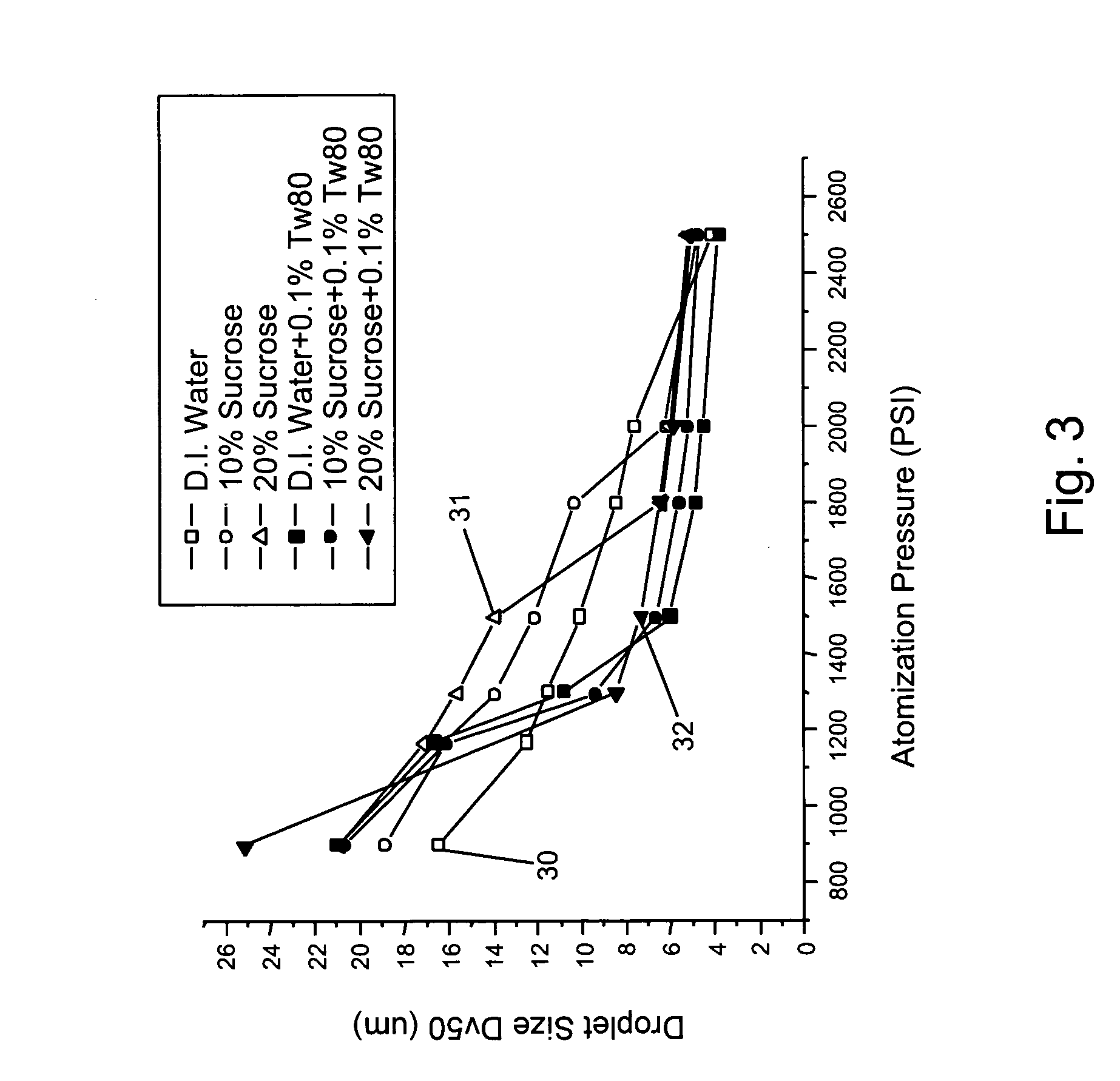

High pressure spray-dry of bioactive materials

PatentInactiveUS7378110B2

Innovation

- The use of high-pressure spray drying with viscosity-enhancing agents, such as polyols and polymers, to reduce shear stress and heat stress during the drying process, allowing for precise control of droplet and particle size, and subsequent recovery of stable powder particles with improved reconstitution properties.

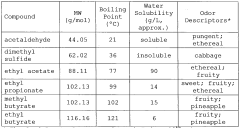

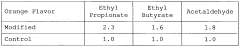

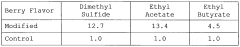

Spray-dried compositions capable of retaining volatile compounds and methods of producing the same

PatentWO2012122010A2

Innovation

- A method involving spray drying with an inlet temperature of less than 100°C and an air inlet dew point of -10°C to 5°C is used to retain at least 20% of the original volatile compounds, with optional additional drying in a fluid-bed chamber, utilizing nitrogen or carbon dioxide, and incorporating carrier materials and solvents to enhance volatile retention and flavor intensity.

Sustainability Aspects of Spray Drying Processes

Sustainability Aspects of Spray Drying Processes

The environmental impact of spray drying techniques has become increasingly significant as industries strive for more sustainable manufacturing processes. Spray drying, while efficient for nutrient preservation, presents several sustainability challenges that must be addressed to align with global environmental goals. Energy consumption represents one of the most critical sustainability concerns, as conventional spray drying operations require substantial thermal energy to generate the hot air needed for moisture evaporation, typically accounting for 35-40% of total production costs.

Water usage and management constitute another important sustainability dimension. Though spray drying itself aims to remove water from products, the process requires water for cleaning equipment between production batches and for various auxiliary operations. Advanced facilities have implemented closed-loop water systems that can reduce freshwater consumption by up to 30%, significantly improving the water footprint of spray drying operations.

Emissions from spray drying processes include particulate matter, volatile organic compounds (VOCs), and greenhouse gases from energy generation. Modern spray dryers incorporate sophisticated filtration systems such as cyclones, bag filters, and electrostatic precipitators that can capture up to 99.9% of particulate emissions. However, the carbon footprint associated with energy generation remains substantial, with estimates suggesting that producing one ton of spray-dried powder can generate between 1.5-4.5 tons of CO2 equivalent, depending on energy sources.

Recent innovations have focused on improving the sustainability profile of spray drying. Heat recovery systems can recapture up to 25% of thermal energy from exhaust air, while alternative energy sources such as biomass, solar thermal systems, and biogas are being integrated into progressive facilities. These approaches can reduce fossil fuel dependency by 40-60% in optimal implementations.

Material efficiency represents another frontier in sustainable spray drying. Advanced atomization technologies have reduced product losses from 5-8% to below 2% in state-of-the-art systems. Additionally, the development of biodegradable and compostable packaging for spray-dried products further enhances end-to-end sustainability.

Life cycle assessment (LCA) studies indicate that nutrient preservation through spray drying can actually contribute to sustainability by extending product shelf life and reducing food waste. Research suggests that the environmental impact of food waste often exceeds that of processing technologies like spray drying, creating a complex sustainability equation where energy-intensive preservation may yield net environmental benefits through reduced waste throughout the supply chain.

Industry leaders are now adopting circular economy principles in spray drying operations, focusing on waste valorization, by-product utilization, and closed-loop production systems that minimize environmental footprint while maximizing resource efficiency and nutrient preservation capabilities.

The environmental impact of spray drying techniques has become increasingly significant as industries strive for more sustainable manufacturing processes. Spray drying, while efficient for nutrient preservation, presents several sustainability challenges that must be addressed to align with global environmental goals. Energy consumption represents one of the most critical sustainability concerns, as conventional spray drying operations require substantial thermal energy to generate the hot air needed for moisture evaporation, typically accounting for 35-40% of total production costs.

Water usage and management constitute another important sustainability dimension. Though spray drying itself aims to remove water from products, the process requires water for cleaning equipment between production batches and for various auxiliary operations. Advanced facilities have implemented closed-loop water systems that can reduce freshwater consumption by up to 30%, significantly improving the water footprint of spray drying operations.

Emissions from spray drying processes include particulate matter, volatile organic compounds (VOCs), and greenhouse gases from energy generation. Modern spray dryers incorporate sophisticated filtration systems such as cyclones, bag filters, and electrostatic precipitators that can capture up to 99.9% of particulate emissions. However, the carbon footprint associated with energy generation remains substantial, with estimates suggesting that producing one ton of spray-dried powder can generate between 1.5-4.5 tons of CO2 equivalent, depending on energy sources.

Recent innovations have focused on improving the sustainability profile of spray drying. Heat recovery systems can recapture up to 25% of thermal energy from exhaust air, while alternative energy sources such as biomass, solar thermal systems, and biogas are being integrated into progressive facilities. These approaches can reduce fossil fuel dependency by 40-60% in optimal implementations.

Material efficiency represents another frontier in sustainable spray drying. Advanced atomization technologies have reduced product losses from 5-8% to below 2% in state-of-the-art systems. Additionally, the development of biodegradable and compostable packaging for spray-dried products further enhances end-to-end sustainability.

Life cycle assessment (LCA) studies indicate that nutrient preservation through spray drying can actually contribute to sustainability by extending product shelf life and reducing food waste. Research suggests that the environmental impact of food waste often exceeds that of processing technologies like spray drying, creating a complex sustainability equation where energy-intensive preservation may yield net environmental benefits through reduced waste throughout the supply chain.

Industry leaders are now adopting circular economy principles in spray drying operations, focusing on waste valorization, by-product utilization, and closed-loop production systems that minimize environmental footprint while maximizing resource efficiency and nutrient preservation capabilities.

Quality Control Standards for Nutrient Preservation

Quality control standards play a pivotal role in ensuring the efficacy of spray drying techniques for nutrient preservation. The establishment of comprehensive quality control frameworks is essential to maintain consistency and reliability in the nutritional value of spray-dried products. These standards typically encompass multiple parameters including moisture content, particle size distribution, bulk density, and nutrient retention rates.

Industry-wide quality control standards for spray drying processes often follow guidelines established by regulatory bodies such as the FDA, EFSA, and ISO. These guidelines mandate specific testing protocols and acceptable thresholds for various quality indicators. For instance, moisture content in spray-dried nutritional products is generally required to remain below 5% to prevent microbial growth and nutrient degradation during storage.

Temperature monitoring represents a critical quality control measure in spray drying operations. Research indicates that inlet temperatures between 150-220°C and outlet temperatures of 70-90°C typically provide optimal conditions for nutrient preservation while ensuring microbiological safety. Continuous temperature monitoring systems with automated feedback mechanisms have become standard in advanced spray drying facilities, allowing for real-time adjustments to maintain ideal processing conditions.

Analytical methods for assessing nutrient retention have evolved significantly, with high-performance liquid chromatography (HPLC) and mass spectrometry emerging as gold standards for quantifying vitamin and bioactive compound preservation. These techniques enable manufacturers to verify that spray-dried products meet label claims and regulatory requirements for nutritional content. Studies show that implementing these analytical protocols can reduce nutrient variability in final products by up to 30%.

Process validation protocols constitute another essential component of quality control standards. These protocols typically involve challenge testing under various processing conditions to establish the robustness of the spray drying process in preserving specific nutrients. Manufacturers are increasingly adopting Design of Experiments (DoE) approaches to systematically evaluate how process parameters affect nutrient retention, enabling the development of optimized processing windows.

Statistical Process Control (SPC) methodologies have been widely implemented to monitor spray drying operations continuously. By establishing control limits for critical parameters and tracking process performance over time, manufacturers can detect deviations before they result in significant nutrient losses. Advanced facilities now employ multivariate statistical models that can simultaneously monitor dozens of process variables, providing comprehensive quality assurance.

Certification programs specific to nutrient preservation in spray-dried products have emerged in recent years, offering standardized approaches to quality management. These programs typically require adherence to Good Manufacturing Practices (GMP), implementation of Hazard Analysis Critical Control Points (HACCP) systems, and regular third-party auditing to verify compliance with established standards for nutrient retention.

Industry-wide quality control standards for spray drying processes often follow guidelines established by regulatory bodies such as the FDA, EFSA, and ISO. These guidelines mandate specific testing protocols and acceptable thresholds for various quality indicators. For instance, moisture content in spray-dried nutritional products is generally required to remain below 5% to prevent microbial growth and nutrient degradation during storage.

Temperature monitoring represents a critical quality control measure in spray drying operations. Research indicates that inlet temperatures between 150-220°C and outlet temperatures of 70-90°C typically provide optimal conditions for nutrient preservation while ensuring microbiological safety. Continuous temperature monitoring systems with automated feedback mechanisms have become standard in advanced spray drying facilities, allowing for real-time adjustments to maintain ideal processing conditions.

Analytical methods for assessing nutrient retention have evolved significantly, with high-performance liquid chromatography (HPLC) and mass spectrometry emerging as gold standards for quantifying vitamin and bioactive compound preservation. These techniques enable manufacturers to verify that spray-dried products meet label claims and regulatory requirements for nutritional content. Studies show that implementing these analytical protocols can reduce nutrient variability in final products by up to 30%.

Process validation protocols constitute another essential component of quality control standards. These protocols typically involve challenge testing under various processing conditions to establish the robustness of the spray drying process in preserving specific nutrients. Manufacturers are increasingly adopting Design of Experiments (DoE) approaches to systematically evaluate how process parameters affect nutrient retention, enabling the development of optimized processing windows.

Statistical Process Control (SPC) methodologies have been widely implemented to monitor spray drying operations continuously. By establishing control limits for critical parameters and tracking process performance over time, manufacturers can detect deviations before they result in significant nutrient losses. Advanced facilities now employ multivariate statistical models that can simultaneously monitor dozens of process variables, providing comprehensive quality assurance.

Certification programs specific to nutrient preservation in spray-dried products have emerged in recent years, offering standardized approaches to quality management. These programs typically require adherence to Good Manufacturing Practices (GMP), implementation of Hazard Analysis Critical Control Points (HACCP) systems, and regular third-party auditing to verify compliance with established standards for nutrient retention.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!