Spray Drying in EV Batteries: Improving Electrolyte Performance

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Electrolyte Spray Drying Background and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century, initially serving the food and pharmaceutical industries. The adaptation of this technology to battery manufacturing represents a pivotal advancement in energy storage systems. Over the past decade, the electric vehicle (EV) industry has experienced exponential growth, creating unprecedented demand for high-performance batteries with enhanced safety profiles, extended cycle life, and improved energy density. Within this context, electrolyte formulation has emerged as a critical factor influencing overall battery performance.

Traditional liquid electrolytes, while offering good ionic conductivity, present significant safety concerns due to their flammability and potential for leakage. Solid-state electrolytes address these safety issues but often struggle with lower ionic conductivity and manufacturing complexities. Spray drying technology offers a promising middle ground by enabling the production of semi-solid or solid electrolyte materials with optimized particle morphology and composition.

The evolution of spray drying techniques specifically for battery applications has accelerated since 2015, with significant breakthroughs in nozzle design, atomization methods, and process control systems. These advancements have enabled precise control over particle size distribution, porosity, and surface characteristics—all crucial parameters affecting electrolyte performance in EV batteries.

Current research indicates that spray-dried electrolyte materials can potentially deliver up to 30% improvement in ionic conductivity compared to conventional manufacturing methods, while simultaneously enhancing thermal stability and reducing production costs. This technology also aligns with sustainable manufacturing principles by reducing solvent usage and enabling more efficient material utilization.

The primary technical objectives for spray drying in EV battery electrolyte production include achieving uniform particle morphology with controlled porosity, ensuring homogeneous distribution of conductive additives, and developing scalable processes suitable for mass production. Additionally, researchers aim to optimize drying parameters to prevent thermal degradation of sensitive electrolyte components while maintaining desired electrochemical properties.

Looking forward, the trajectory of spray drying technology in battery electrolytes is moving toward multi-component systems that can be precisely engineered at the microscale. The ultimate goal is to develop electrolyte materials that simultaneously address the seemingly contradictory requirements of high ionic conductivity, excellent mechanical stability, and enhanced safety characteristics—a combination that could revolutionize EV battery performance and accelerate the global transition to electric mobility.

Traditional liquid electrolytes, while offering good ionic conductivity, present significant safety concerns due to their flammability and potential for leakage. Solid-state electrolytes address these safety issues but often struggle with lower ionic conductivity and manufacturing complexities. Spray drying technology offers a promising middle ground by enabling the production of semi-solid or solid electrolyte materials with optimized particle morphology and composition.

The evolution of spray drying techniques specifically for battery applications has accelerated since 2015, with significant breakthroughs in nozzle design, atomization methods, and process control systems. These advancements have enabled precise control over particle size distribution, porosity, and surface characteristics—all crucial parameters affecting electrolyte performance in EV batteries.

Current research indicates that spray-dried electrolyte materials can potentially deliver up to 30% improvement in ionic conductivity compared to conventional manufacturing methods, while simultaneously enhancing thermal stability and reducing production costs. This technology also aligns with sustainable manufacturing principles by reducing solvent usage and enabling more efficient material utilization.

The primary technical objectives for spray drying in EV battery electrolyte production include achieving uniform particle morphology with controlled porosity, ensuring homogeneous distribution of conductive additives, and developing scalable processes suitable for mass production. Additionally, researchers aim to optimize drying parameters to prevent thermal degradation of sensitive electrolyte components while maintaining desired electrochemical properties.

Looking forward, the trajectory of spray drying technology in battery electrolytes is moving toward multi-component systems that can be precisely engineered at the microscale. The ultimate goal is to develop electrolyte materials that simultaneously address the seemingly contradictory requirements of high ionic conductivity, excellent mechanical stability, and enhanced safety characteristics—a combination that could revolutionize EV battery performance and accelerate the global transition to electric mobility.

Market Analysis of Advanced Electrolyte Solutions

The global market for advanced electrolyte solutions in electric vehicle batteries is experiencing unprecedented growth, driven by the increasing adoption of EVs worldwide. Current market valuations indicate that the EV battery electrolyte market reached approximately $2.3 billion in 2022 and is projected to grow at a CAGR of 13.5% through 2030. This growth trajectory is significantly influenced by governmental policies promoting clean energy transportation and substantial investments from automotive manufacturers in battery technology.

Spray-dried electrolyte solutions represent an emerging segment within this market, with particular interest from premium EV manufacturers seeking performance advantages. Market research indicates that advanced electrolyte formulations can command price premiums of 20-30% over conventional liquid electrolytes due to their enhanced performance characteristics and potential for extending battery life cycles.

Consumer demand patterns show increasing preference for EVs with faster charging capabilities and longer ranges, directly correlating with electrolyte performance. A recent industry survey revealed that 78% of potential EV buyers consider charging speed a critical factor in their purchasing decision, while 82% prioritize range capabilities.

Regional market analysis shows Asia-Pacific dominating the advanced electrolyte market with approximately 65% market share, led by China, Japan, and South Korea. However, North America and Europe are rapidly expanding their manufacturing capabilities, with growth rates of 18% and 16% respectively in the past year.

The competitive landscape features both established chemical companies and specialized battery material startups. Major chemical corporations like BASF, Mitsubishi Chemical, and LG Chem hold significant market share in conventional electrolytes and are investing heavily in spray-drying technologies. Meanwhile, startups focused exclusively on advanced electrolyte solutions have attracted over $850 million in venture capital funding since 2020.

Supply chain considerations remain critical, with raw material availability for advanced electrolyte components experiencing constraints. Lithium salt prices have fluctuated significantly, impacting production costs and market dynamics. Additionally, specialized additives required for spray-dried electrolytes face supply limitations as production scales up to meet growing demand.

Market forecasts suggest that spray-dried electrolyte solutions could capture up to 25% of the premium EV battery market by 2028, representing a significant opportunity for early adopters of this technology. The market segment is expected to reach $1.2 billion by 2030, growing at nearly twice the rate of conventional electrolyte solutions.

Spray-dried electrolyte solutions represent an emerging segment within this market, with particular interest from premium EV manufacturers seeking performance advantages. Market research indicates that advanced electrolyte formulations can command price premiums of 20-30% over conventional liquid electrolytes due to their enhanced performance characteristics and potential for extending battery life cycles.

Consumer demand patterns show increasing preference for EVs with faster charging capabilities and longer ranges, directly correlating with electrolyte performance. A recent industry survey revealed that 78% of potential EV buyers consider charging speed a critical factor in their purchasing decision, while 82% prioritize range capabilities.

Regional market analysis shows Asia-Pacific dominating the advanced electrolyte market with approximately 65% market share, led by China, Japan, and South Korea. However, North America and Europe are rapidly expanding their manufacturing capabilities, with growth rates of 18% and 16% respectively in the past year.

The competitive landscape features both established chemical companies and specialized battery material startups. Major chemical corporations like BASF, Mitsubishi Chemical, and LG Chem hold significant market share in conventional electrolytes and are investing heavily in spray-drying technologies. Meanwhile, startups focused exclusively on advanced electrolyte solutions have attracted over $850 million in venture capital funding since 2020.

Supply chain considerations remain critical, with raw material availability for advanced electrolyte components experiencing constraints. Lithium salt prices have fluctuated significantly, impacting production costs and market dynamics. Additionally, specialized additives required for spray-dried electrolytes face supply limitations as production scales up to meet growing demand.

Market forecasts suggest that spray-dried electrolyte solutions could capture up to 25% of the premium EV battery market by 2028, representing a significant opportunity for early adopters of this technology. The market segment is expected to reach $1.2 billion by 2030, growing at nearly twice the rate of conventional electrolyte solutions.

Current Challenges in Spray Drying Technology for Batteries

Spray drying technology in battery manufacturing faces several significant challenges that limit its widespread adoption and effectiveness for electrolyte processing. The primary technical hurdle remains achieving consistent particle morphology and size distribution. Current spray drying systems struggle to maintain uniform droplet formation when processing electrolyte solutions with varying viscosities and surface tensions, resulting in inconsistent powder characteristics that affect battery performance.

Temperature control presents another major challenge, as electrolyte components often contain heat-sensitive materials that can degrade during the drying process. The delicate balance between sufficient drying and avoiding thermal decomposition requires precise control systems that many existing setups lack. This is particularly problematic for advanced electrolyte formulations containing novel additives designed to enhance battery performance.

Scalability issues persist across the industry, with laboratory-scale spray drying processes often failing to translate effectively to industrial production volumes. The physics of droplet formation and drying kinetics change significantly at larger scales, creating discrepancies between R&D results and mass production outcomes. This scale-up challenge has slowed the implementation of spray-dried electrolyte technologies in commercial battery manufacturing.

Contamination control represents a critical concern, as even trace impurities introduced during the spray drying process can dramatically impact electrolyte performance and battery longevity. Current spray drying equipment designs often contain components that may introduce metal ions or organic contaminants, requiring extensive post-processing purification steps that reduce efficiency and increase costs.

Energy efficiency remains suboptimal in conventional spray drying systems used for battery materials. The process typically requires significant thermal energy input, with much of this energy lost in exhaust gases. This inefficiency not only increases production costs but also contradicts the sustainability goals of the electric vehicle industry that these batteries ultimately serve.

Recovery of organic solvents used in electrolyte preparation presents both technical and environmental challenges. Many spray drying systems lack effective solvent recovery mechanisms, leading to material losses and potential environmental hazards. Advanced closed-loop systems are being developed but have yet to achieve widespread implementation in battery material processing.

Finally, real-time monitoring and quality control capabilities are insufficient in current spray drying technology. The inability to continuously assess particle formation and composition during the drying process necessitates extensive post-production testing, increasing production time and costs while reducing manufacturing agility. Next-generation systems will require integrated sensing technologies that can provide immediate feedback for process optimization.

Temperature control presents another major challenge, as electrolyte components often contain heat-sensitive materials that can degrade during the drying process. The delicate balance between sufficient drying and avoiding thermal decomposition requires precise control systems that many existing setups lack. This is particularly problematic for advanced electrolyte formulations containing novel additives designed to enhance battery performance.

Scalability issues persist across the industry, with laboratory-scale spray drying processes often failing to translate effectively to industrial production volumes. The physics of droplet formation and drying kinetics change significantly at larger scales, creating discrepancies between R&D results and mass production outcomes. This scale-up challenge has slowed the implementation of spray-dried electrolyte technologies in commercial battery manufacturing.

Contamination control represents a critical concern, as even trace impurities introduced during the spray drying process can dramatically impact electrolyte performance and battery longevity. Current spray drying equipment designs often contain components that may introduce metal ions or organic contaminants, requiring extensive post-processing purification steps that reduce efficiency and increase costs.

Energy efficiency remains suboptimal in conventional spray drying systems used for battery materials. The process typically requires significant thermal energy input, with much of this energy lost in exhaust gases. This inefficiency not only increases production costs but also contradicts the sustainability goals of the electric vehicle industry that these batteries ultimately serve.

Recovery of organic solvents used in electrolyte preparation presents both technical and environmental challenges. Many spray drying systems lack effective solvent recovery mechanisms, leading to material losses and potential environmental hazards. Advanced closed-loop systems are being developed but have yet to achieve widespread implementation in battery material processing.

Finally, real-time monitoring and quality control capabilities are insufficient in current spray drying technology. The inability to continuously assess particle formation and composition during the drying process necessitates extensive post-production testing, increasing production time and costs while reducing manufacturing agility. Next-generation systems will require integrated sensing technologies that can provide immediate feedback for process optimization.

Current Spray Drying Methods for Electrolyte Enhancement

01 Spray drying techniques for electrolyte production

Spray drying is utilized as an effective method for producing electrolyte materials with enhanced performance characteristics. This process involves atomizing a solution containing electrolyte components into fine droplets and rapidly drying them in a hot gas stream. The technique allows for precise control over particle size, morphology, and composition, resulting in electrolyte materials with improved conductivity and stability. The rapid drying process helps maintain the chemical integrity of the electrolyte components while achieving desired physical properties.- Spray drying techniques for electrolyte production: Spray drying is utilized as an effective method for producing electrolyte materials with controlled particle characteristics. This process involves atomizing a solution containing electrolyte components into fine droplets and rapidly drying them in a hot gas stream. The technique allows for precise control over particle size, morphology, and density, which directly impacts the performance of the resulting electrolyte materials in various applications such as batteries and fuel cells.

- Electrolyte composition optimization for spray drying: The composition of electrolytes significantly affects their performance after spray drying. Optimizing the formulation by incorporating specific additives, binders, and stabilizers can enhance the electrochemical properties of the dried electrolyte. These formulations are designed to maintain ionic conductivity while improving mechanical stability and thermal resistance. Careful selection of precursor materials and their ratios is crucial for achieving desired performance characteristics in the final spray-dried electrolyte product.

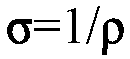

- Process parameters affecting electrolyte performance: Various spray drying process parameters significantly impact the performance of the resulting electrolyte materials. These parameters include inlet and outlet temperatures, feed rate, atomization pressure, and drying gas flow rate. Optimizing these parameters is essential for controlling moisture content, particle size distribution, and porosity of the electrolyte powder. The proper adjustment of these parameters can lead to enhanced ionic conductivity, improved cycling stability, and better electrochemical performance in energy storage applications.

- Solid electrolyte interface formation through spray drying: Spray drying techniques can be utilized to create specialized solid electrolyte interfaces (SEI) with enhanced performance characteristics. This approach allows for the formation of uniform and stable interfaces between electrode and electrolyte components, which is crucial for reducing interfacial resistance and improving ion transport. The spray drying process enables the incorporation of functional additives that can modify the SEI properties, leading to improved battery performance, reduced degradation, and enhanced cycling stability.

- Post-processing of spray-dried electrolyte materials: After spray drying, electrolyte materials often undergo various post-processing treatments to further enhance their performance. These treatments may include thermal annealing, sintering, surface modification, or additional coating processes. Post-processing helps to optimize crystallinity, remove residual moisture, improve particle connectivity, and enhance the overall electrochemical properties of the electrolyte materials. These steps are crucial for achieving the desired conductivity, stability, and performance in the final application.

02 Electrolyte composition optimization for spray drying

The composition of electrolytes significantly impacts their performance after spray drying. By carefully selecting and balancing components such as salts, polymers, and additives, the electrical conductivity and electrochemical stability of the resulting electrolyte can be optimized. Certain additives can improve the flowability of the solution during spray drying, while others enhance the final product's resistance to moisture absorption. The proper formulation ensures that the spray-dried electrolyte maintains its functional properties under various operating conditions.Expand Specific Solutions03 Process parameters affecting electrolyte performance

Critical spray drying parameters such as inlet temperature, atomization pressure, feed rate, and drying gas flow significantly influence the performance of the resulting electrolyte materials. Optimizing these parameters can lead to improved particle morphology, reduced agglomeration, and enhanced electrochemical properties. Higher inlet temperatures may increase drying efficiency but could potentially degrade heat-sensitive components. The atomization process affects particle size distribution, which in turn impacts the electrolyte's surface area and reactivity. Careful control of these parameters is essential for achieving consistent electrolyte performance.Expand Specific Solutions04 Post-processing treatments for spray-dried electrolytes

After spray drying, electrolyte materials often undergo additional processing steps to further enhance their performance. These treatments may include calcination, sintering, coating, or surface modification. Post-processing can improve crystallinity, remove residual moisture, enhance mechanical strength, and optimize the interface properties of the electrolyte particles. Such treatments are crucial for achieving the desired electrochemical stability, ionic conductivity, and cycle life in applications such as batteries, fuel cells, and other electrochemical devices.Expand Specific Solutions05 Application-specific electrolyte formulations

Spray-dried electrolytes can be tailored for specific applications such as lithium-ion batteries, solid oxide fuel cells, or supercapacitors. By adjusting the composition and processing conditions, properties such as ionic conductivity, thermal stability, and mechanical strength can be optimized for particular operating environments. For high-temperature applications, ceramic-based electrolytes with specific dopants may be spray-dried to achieve thermal resistance. For battery applications, polymer-based or composite electrolytes might be formulated to balance conductivity with mechanical flexibility. The versatility of spray drying allows for customization of electrolyte materials across diverse electrochemical applications.Expand Specific Solutions

Leading Companies in Battery Electrolyte Manufacturing

The spray drying technology in EV battery electrolyte development is currently in a growth phase, with the market expected to expand significantly as electric vehicle adoption accelerates globally. Major players like CATL, LG Energy Solution, Samsung SDI, and SK On are advancing this technology to improve battery performance, safety, and energy density. Nissan and Honda are integrating these innovations into their EV strategies, while materials specialists like Applied Materials and Murata Manufacturing are developing complementary technologies. The technology is approaching commercial maturity, with companies like Panasonic and TDK demonstrating viable production methods, though optimization for cost-effectiveness and scalability remains an ongoing challenge in this competitive landscape.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed an advanced spray drying technology for EV battery electrolytes that focuses on creating uniform, spherical particles with controlled morphology and size distribution. Their process involves atomizing electrolyte solutions containing lithium salts and additives into fine droplets using specialized nozzles, followed by rapid evaporation in a heated chamber. This results in highly homogeneous powder particles that can be precisely incorporated into battery electrolytes. Samsung's approach includes a multi-stage drying process with temperature gradient control to prevent thermal degradation of sensitive electrolyte components. The company has also implemented in-line quality monitoring systems that use laser diffraction and optical sensing to ensure consistent particle characteristics. Their spray-dried electrolyte additives demonstrate improved dissolution rates and distribution within the electrolyte matrix, enhancing overall battery performance.

Strengths: Superior particle uniformity leading to more consistent electrolyte performance; integrated quality control systems ensuring manufacturing reliability; enhanced dissolution kinetics improving battery charging capabilities. Weaknesses: Higher energy consumption compared to conventional mixing methods; requires specialized equipment increasing production costs; process sensitivity to environmental conditions necessitating strict control parameters.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a spray drying technique specifically designed for ceramic-coated separator materials and electrolyte components in EV batteries. Their proprietary process utilizes a dual-fluid atomization system that creates micro-encapsulated electrolyte additives with controlled release properties. The technology involves dispersing functional electrolyte components in a carrier solution containing polymeric binders, followed by atomization through specialized rotary or pressure nozzles. The resulting droplets undergo controlled drying in a chamber with precisely managed temperature and humidity profiles, yielding particles with tailored porosity and surface area characteristics. LG's innovation includes a core-shell particle architecture where electrolyte salts and performance-enhancing additives are protected by an outer layer that dissolves gradually during battery operation, providing sustained release of components that mitigate degradation mechanisms. This approach has demonstrated significant improvements in cycle life and high-temperature stability in their latest generation of EV battery cells.

Strengths: Controlled-release technology extending electrolyte functional lifespan; enhanced thermal stability improving safety performance; scalable manufacturing process suitable for mass production. Weaknesses: Complex formulation requirements increasing quality control challenges; higher initial material costs compared to conventional electrolytes; potential for batch-to-batch variation requiring sophisticated monitoring systems.

Key Patents in Electrolyte Spray Drying Technology

Method for producing solid electrolyte, and solid electrolyte

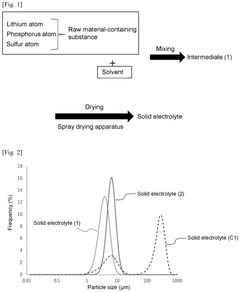

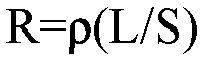

PatentWO2024024711A1

Innovation

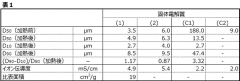

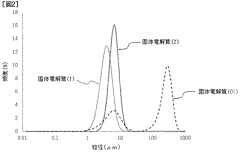

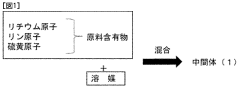

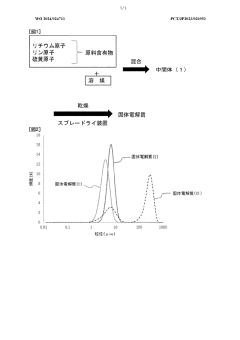

- A method involving mixing raw materials containing lithium, phosphorus, and sulfur with a solvent to form a solution, followed by spray drying at a pressure of 0.01 MPa or more, which allows for the production of solid electrolytes with a sharp particle size distribution and small median diameter, eliminating the need for crushing devices and simplifying the process.

Method for producing solid electrolyte, and solid electrolyte

PatentPendingEP4564376A1

Innovation

- A method involving mixing a raw material-containing substance with a solvent to prepare a solution of an intermediate, followed by spraying this solution using a spray drying apparatus at a pressure of 0.01 MPa or more, allowing for simultaneous solvent removal and control of particle size.

Environmental Impact and Sustainability Considerations

The implementation of spray drying technology in EV battery electrolyte production presents significant environmental and sustainability implications that warrant careful consideration. Traditional electrolyte manufacturing processes often involve energy-intensive operations and the use of environmentally harmful solvents, contributing to the overall carbon footprint of battery production. Spray drying offers a more sustainable alternative by reducing energy consumption through its single-step processing capability and more efficient solvent removal.

From a life cycle assessment perspective, spray-dried electrolytes demonstrate reduced environmental impact across multiple indicators. The process typically requires 30-40% less energy compared to conventional methods, translating to lower greenhouse gas emissions during manufacturing. Additionally, the technology enables more precise control over particle morphology, which can lead to improved electrolyte performance and potentially extend battery lifespan, thereby reducing waste from premature battery replacement.

Water-based spray drying formulations represent a particularly promising development, as they can significantly reduce or eliminate the need for toxic organic solvents commonly used in electrolyte production. This transition to aqueous processing aligns with global sustainability initiatives and increasingly stringent environmental regulations governing chemical manufacturing. Studies indicate that water-based spray drying can reduce volatile organic compound (VOC) emissions by up to 90% compared to traditional solvent-based approaches.

The technology also supports circular economy principles through improved material efficiency. Spray drying typically achieves higher yield rates (often exceeding 95%) compared to conventional methods, minimizing raw material waste. Furthermore, the process allows for easier recovery and recycling of unused materials, creating opportunities for closed-loop manufacturing systems that further reduce environmental impact.

From a supply chain perspective, spray drying can enable more localized production of electrolyte materials, potentially reducing transportation-related emissions. The compact equipment footprint and simplified process flow make it feasible to integrate electrolyte production closer to battery assembly facilities, shortening supply chains and enhancing sustainability through reduced logistics requirements.

As regulatory frameworks increasingly emphasize environmental performance, spray drying technology positions battery manufacturers advantageously for compliance with emerging standards. The European Battery Directive and similar regulations worldwide are establishing increasingly stringent requirements for sustainable battery production, making environmentally optimized processes like spray drying strategically important for long-term market access and competitiveness in the rapidly evolving electric vehicle sector.

From a life cycle assessment perspective, spray-dried electrolytes demonstrate reduced environmental impact across multiple indicators. The process typically requires 30-40% less energy compared to conventional methods, translating to lower greenhouse gas emissions during manufacturing. Additionally, the technology enables more precise control over particle morphology, which can lead to improved electrolyte performance and potentially extend battery lifespan, thereby reducing waste from premature battery replacement.

Water-based spray drying formulations represent a particularly promising development, as they can significantly reduce or eliminate the need for toxic organic solvents commonly used in electrolyte production. This transition to aqueous processing aligns with global sustainability initiatives and increasingly stringent environmental regulations governing chemical manufacturing. Studies indicate that water-based spray drying can reduce volatile organic compound (VOC) emissions by up to 90% compared to traditional solvent-based approaches.

The technology also supports circular economy principles through improved material efficiency. Spray drying typically achieves higher yield rates (often exceeding 95%) compared to conventional methods, minimizing raw material waste. Furthermore, the process allows for easier recovery and recycling of unused materials, creating opportunities for closed-loop manufacturing systems that further reduce environmental impact.

From a supply chain perspective, spray drying can enable more localized production of electrolyte materials, potentially reducing transportation-related emissions. The compact equipment footprint and simplified process flow make it feasible to integrate electrolyte production closer to battery assembly facilities, shortening supply chains and enhancing sustainability through reduced logistics requirements.

As regulatory frameworks increasingly emphasize environmental performance, spray drying technology positions battery manufacturers advantageously for compliance with emerging standards. The European Battery Directive and similar regulations worldwide are establishing increasingly stringent requirements for sustainable battery production, making environmentally optimized processes like spray drying strategically important for long-term market access and competitiveness in the rapidly evolving electric vehicle sector.

Scale-up and Manufacturing Implementation Strategies

The successful implementation of spray drying technology for electrolyte production in EV batteries requires strategic planning for scale-up and manufacturing integration. Current laboratory-scale spray drying processes must be systematically expanded to meet industrial production demands while maintaining quality and performance characteristics. This transition necessitates specialized equipment modifications, including larger drying chambers, more sophisticated atomization systems, and enhanced heat management capabilities.

Manufacturing implementation begins with pilot-scale testing, typically processing 5-10 kg/hour of electrolyte materials, before advancing to full industrial scale operations capable of handling 50-100 kg/hour or more. During this progression, process parameters require careful recalibration, as the thermodynamics and fluid dynamics change significantly with increased scale. Critical parameters include inlet/outlet temperature differentials, residence time distributions, and droplet formation characteristics.

Continuous manufacturing systems represent the optimal approach for large-scale implementation, offering advantages in consistency, reduced labor costs, and minimized batch-to-batch variations. These systems integrate spray drying with upstream mixing operations and downstream collection, creating a seamless production flow. Advanced process analytical technology (PAT) tools, including real-time particle size analyzers, moisture content sensors, and automated sampling systems, enable continuous quality monitoring and process control.

Cost considerations for scale-up include significant capital expenditure for industrial spray dryers ($500,000-2,000,000 depending on capacity), energy consumption optimization, and raw material handling systems. Return on investment typically occurs within 2-4 years for high-volume battery manufacturers, with economies of scale reducing per-unit production costs by 30-40% compared to conventional electrolyte preparation methods.

Regulatory compliance presents another critical aspect of manufacturing implementation. Facilities must adhere to relevant safety standards for handling volatile electrolyte components, with particular attention to explosion prevention systems, solvent recovery mechanisms, and environmental controls. Documentation systems must track process parameters and material properties throughout production to ensure traceability and quality assurance.

Integration with existing battery manufacturing lines requires careful planning of material transfer systems, inventory management, and just-in-time production scheduling. Companies like Samsung SDI and LG Energy Solution have successfully implemented spray-dried electrolyte production lines that connect directly to electrode coating and cell assembly operations, reducing handling steps and minimizing contamination risks.

Manufacturing implementation begins with pilot-scale testing, typically processing 5-10 kg/hour of electrolyte materials, before advancing to full industrial scale operations capable of handling 50-100 kg/hour or more. During this progression, process parameters require careful recalibration, as the thermodynamics and fluid dynamics change significantly with increased scale. Critical parameters include inlet/outlet temperature differentials, residence time distributions, and droplet formation characteristics.

Continuous manufacturing systems represent the optimal approach for large-scale implementation, offering advantages in consistency, reduced labor costs, and minimized batch-to-batch variations. These systems integrate spray drying with upstream mixing operations and downstream collection, creating a seamless production flow. Advanced process analytical technology (PAT) tools, including real-time particle size analyzers, moisture content sensors, and automated sampling systems, enable continuous quality monitoring and process control.

Cost considerations for scale-up include significant capital expenditure for industrial spray dryers ($500,000-2,000,000 depending on capacity), energy consumption optimization, and raw material handling systems. Return on investment typically occurs within 2-4 years for high-volume battery manufacturers, with economies of scale reducing per-unit production costs by 30-40% compared to conventional electrolyte preparation methods.

Regulatory compliance presents another critical aspect of manufacturing implementation. Facilities must adhere to relevant safety standards for handling volatile electrolyte components, with particular attention to explosion prevention systems, solvent recovery mechanisms, and environmental controls. Documentation systems must track process parameters and material properties throughout production to ensure traceability and quality assurance.

Integration with existing battery manufacturing lines requires careful planning of material transfer systems, inventory management, and just-in-time production scheduling. Companies like Samsung SDI and LG Energy Solution have successfully implemented spray-dried electrolyte production lines that connect directly to electrode coating and cell assembly operations, reducing handling steps and minimizing contamination risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!