How Does Spray Drying Enhance Aerosol Production Efficiency?

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century. Initially developed for milk powder production, this technology has undergone substantial transformations to become a versatile method for creating dry powders from liquid solutions or suspensions. The fundamental principle involves atomizing a liquid feed into fine droplets, exposing them to hot gas, and rapidly evaporating the solvent to form dry particles. This process has remained conceptually consistent while experiencing remarkable technical advancements over decades.

The 1950s marked a pivotal era for spray drying with the introduction of industrial-scale equipment capable of continuous production. By the 1970s, the technology had expanded beyond food applications into pharmaceuticals, where precision and reproducibility became paramount. The 1990s witnessed significant improvements in atomization technologies, including pressure nozzles, rotary atomizers, and two-fluid nozzles, each offering distinct advantages for specific applications and materials.

Recent technological evolution has focused on enhancing control over particle characteristics, including size distribution, morphology, and density. Advanced computational fluid dynamics modeling has enabled better understanding of drying chamber dynamics, leading to optimized designs that improve efficiency and product quality. Innovations in process monitoring and control systems have further refined the technology, allowing real-time adjustments based on critical process parameters.

In the context of aerosol production, spray drying technology has evolved to address specific challenges related to particle engineering for inhalation delivery. The primary objective has been to develop particles with optimal aerodynamic properties for deep lung deposition. This includes creating particles with controlled size (typically 1-5 μm), appropriate density, and suitable surface characteristics to prevent aggregation and enhance dispersion.

Current technological objectives focus on several key areas: improving energy efficiency of the drying process, enhancing scalability from laboratory to industrial production, developing continuous manufacturing capabilities, and ensuring consistent product quality. Particularly for aerosol applications, objectives include achieving narrow particle size distributions, controlling particle porosity and density, and maintaining biological activity of sensitive compounds during processing.

The evolution trajectory points toward more sophisticated hybrid technologies that combine spray drying with complementary processes such as supercritical fluid technology or electrospraying to overcome inherent limitations. Additionally, there is growing emphasis on environmentally sustainable approaches, including closed-loop solvent recovery systems and reduced energy consumption through process optimization and alternative energy sources.

The 1950s marked a pivotal era for spray drying with the introduction of industrial-scale equipment capable of continuous production. By the 1970s, the technology had expanded beyond food applications into pharmaceuticals, where precision and reproducibility became paramount. The 1990s witnessed significant improvements in atomization technologies, including pressure nozzles, rotary atomizers, and two-fluid nozzles, each offering distinct advantages for specific applications and materials.

Recent technological evolution has focused on enhancing control over particle characteristics, including size distribution, morphology, and density. Advanced computational fluid dynamics modeling has enabled better understanding of drying chamber dynamics, leading to optimized designs that improve efficiency and product quality. Innovations in process monitoring and control systems have further refined the technology, allowing real-time adjustments based on critical process parameters.

In the context of aerosol production, spray drying technology has evolved to address specific challenges related to particle engineering for inhalation delivery. The primary objective has been to develop particles with optimal aerodynamic properties for deep lung deposition. This includes creating particles with controlled size (typically 1-5 μm), appropriate density, and suitable surface characteristics to prevent aggregation and enhance dispersion.

Current technological objectives focus on several key areas: improving energy efficiency of the drying process, enhancing scalability from laboratory to industrial production, developing continuous manufacturing capabilities, and ensuring consistent product quality. Particularly for aerosol applications, objectives include achieving narrow particle size distributions, controlling particle porosity and density, and maintaining biological activity of sensitive compounds during processing.

The evolution trajectory points toward more sophisticated hybrid technologies that combine spray drying with complementary processes such as supercritical fluid technology or electrospraying to overcome inherent limitations. Additionally, there is growing emphasis on environmentally sustainable approaches, including closed-loop solvent recovery systems and reduced energy consumption through process optimization and alternative energy sources.

Market Analysis for Spray Drying in Aerosol Production

The global spray drying market in aerosol production has experienced significant growth over the past decade, driven primarily by increasing demand across pharmaceutical, food and beverage, and chemical industries. Current market valuations place the spray drying technology sector at approximately 7 billion USD, with projections indicating a compound annual growth rate of 6.5% through 2028.

The pharmaceutical sector represents the largest market segment for spray drying in aerosol production, accounting for nearly 40% of the total market share. This dominance stems from the technology's ability to produce fine, uniform particles with controlled morphology and improved bioavailability—critical factors for inhalable drug delivery systems. The COVID-19 pandemic has further accelerated this segment's growth as respiratory treatments gained heightened importance.

Food and beverage applications constitute the second-largest market segment at 30%, where spray drying enables the production of stable food powders with extended shelf life and preserved nutritional value. The growing consumer preference for convenient, ready-to-use products has bolstered demand in this sector.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, expanding healthcare infrastructure, and increasing adoption of advanced manufacturing technologies.

Market dynamics are significantly influenced by the push toward more sustainable and energy-efficient production methods. Companies are increasingly investing in spray drying technologies that reduce energy consumption and minimize environmental impact, responding to both regulatory pressures and consumer preferences for environmentally responsible manufacturing processes.

The competitive landscape features both established players and innovative startups. Major companies like GEA Group, SPX FLOW, and Buchi Labortechnik AG hold substantial market shares due to their comprehensive product portfolios and global presence. Meanwhile, emerging companies are gaining traction by offering specialized solutions for niche applications or introducing technological innovations that enhance efficiency and reduce operational costs.

Customer demand patterns indicate a growing preference for modular and flexible spray drying systems that can be easily adapted to different product formulations and batch sizes. This trend is particularly evident in contract manufacturing organizations that serve multiple industries and require versatile equipment.

Future market growth will likely be driven by technological advancements in process control, automation, and integration with other manufacturing processes. The development of hybrid technologies combining spray drying with complementary processes like microencapsulation presents significant opportunities for market expansion and differentiation.

The pharmaceutical sector represents the largest market segment for spray drying in aerosol production, accounting for nearly 40% of the total market share. This dominance stems from the technology's ability to produce fine, uniform particles with controlled morphology and improved bioavailability—critical factors for inhalable drug delivery systems. The COVID-19 pandemic has further accelerated this segment's growth as respiratory treatments gained heightened importance.

Food and beverage applications constitute the second-largest market segment at 30%, where spray drying enables the production of stable food powders with extended shelf life and preserved nutritional value. The growing consumer preference for convenient, ready-to-use products has bolstered demand in this sector.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, expanding healthcare infrastructure, and increasing adoption of advanced manufacturing technologies.

Market dynamics are significantly influenced by the push toward more sustainable and energy-efficient production methods. Companies are increasingly investing in spray drying technologies that reduce energy consumption and minimize environmental impact, responding to both regulatory pressures and consumer preferences for environmentally responsible manufacturing processes.

The competitive landscape features both established players and innovative startups. Major companies like GEA Group, SPX FLOW, and Buchi Labortechnik AG hold substantial market shares due to their comprehensive product portfolios and global presence. Meanwhile, emerging companies are gaining traction by offering specialized solutions for niche applications or introducing technological innovations that enhance efficiency and reduce operational costs.

Customer demand patterns indicate a growing preference for modular and flexible spray drying systems that can be easily adapted to different product formulations and batch sizes. This trend is particularly evident in contract manufacturing organizations that serve multiple industries and require versatile equipment.

Future market growth will likely be driven by technological advancements in process control, automation, and integration with other manufacturing processes. The development of hybrid technologies combining spray drying with complementary processes like microencapsulation presents significant opportunities for market expansion and differentiation.

Technical Challenges in Current Spray Drying Systems

Despite significant advancements in spray drying technology, several technical challenges continue to limit the efficiency and effectiveness of current systems in aerosol production. One of the primary challenges is achieving consistent particle size distribution. Conventional spray dryers often produce particles with wide size distributions, which can significantly impact aerosol performance, especially in pharmaceutical applications where precise dosing is critical. This variability stems from difficulties in maintaining uniform atomization conditions and controlling droplet formation dynamics.

Energy efficiency remains a substantial concern in spray drying operations. Current systems typically require high energy inputs for both atomization and drying processes, with thermal efficiency often below 50%. This inefficiency is particularly problematic for heat-sensitive materials, where higher temperatures can lead to degradation of active ingredients or alterations in material properties, ultimately affecting aerosol quality and performance.

Scale-up challenges present significant barriers when transitioning from laboratory to industrial production. Parameters optimized at small scales frequently do not translate directly to larger systems due to changes in fluid dynamics, heat transfer rates, and residence time distributions. This scaling issue often necessitates extensive re-optimization, increasing development costs and time-to-market for new aerosol products.

Material deposition and equipment fouling constitute persistent operational problems. Sticky materials or those with low glass transition temperatures tend to adhere to chamber walls and collection systems, reducing yield and potentially contaminating subsequent batches. These deposits can also disrupt airflow patterns within the drying chamber, further compromising process consistency and aerosol quality.

Process control limitations represent another significant challenge. Many current spray drying systems lack sophisticated real-time monitoring capabilities for critical parameters such as droplet size, moisture content, and particle morphology during operation. This deficiency makes it difficult to implement adaptive control strategies that could optimize aerosol production efficiency in response to variations in feed properties or environmental conditions.

Solvent recovery systems in conventional spray dryers often demonstrate suboptimal performance, particularly when dealing with organic solvents. Inefficient recovery not only increases operational costs but also raises environmental concerns and regulatory compliance issues, especially for pharmaceutical and food applications where residual solvent levels must be strictly controlled.

The integration of spray drying with downstream processing represents a final significant challenge. Current systems frequently require separate unit operations for particle collection, classification, and formulation, increasing process complexity and introducing potential points of failure that can compromise aerosol quality and production efficiency.

Energy efficiency remains a substantial concern in spray drying operations. Current systems typically require high energy inputs for both atomization and drying processes, with thermal efficiency often below 50%. This inefficiency is particularly problematic for heat-sensitive materials, where higher temperatures can lead to degradation of active ingredients or alterations in material properties, ultimately affecting aerosol quality and performance.

Scale-up challenges present significant barriers when transitioning from laboratory to industrial production. Parameters optimized at small scales frequently do not translate directly to larger systems due to changes in fluid dynamics, heat transfer rates, and residence time distributions. This scaling issue often necessitates extensive re-optimization, increasing development costs and time-to-market for new aerosol products.

Material deposition and equipment fouling constitute persistent operational problems. Sticky materials or those with low glass transition temperatures tend to adhere to chamber walls and collection systems, reducing yield and potentially contaminating subsequent batches. These deposits can also disrupt airflow patterns within the drying chamber, further compromising process consistency and aerosol quality.

Process control limitations represent another significant challenge. Many current spray drying systems lack sophisticated real-time monitoring capabilities for critical parameters such as droplet size, moisture content, and particle morphology during operation. This deficiency makes it difficult to implement adaptive control strategies that could optimize aerosol production efficiency in response to variations in feed properties or environmental conditions.

Solvent recovery systems in conventional spray dryers often demonstrate suboptimal performance, particularly when dealing with organic solvents. Inefficient recovery not only increases operational costs but also raises environmental concerns and regulatory compliance issues, especially for pharmaceutical and food applications where residual solvent levels must be strictly controlled.

The integration of spray drying with downstream processing represents a final significant challenge. Current systems frequently require separate unit operations for particle collection, classification, and formulation, increasing process complexity and introducing potential points of failure that can compromise aerosol quality and production efficiency.

Current Spray Drying Methods for Aerosol Production

01 Spray dryer design optimization

Optimizing the design of spray dryers can significantly improve drying efficiency. This includes modifications to the drying chamber geometry, atomizer configuration, and air flow patterns. Improved designs can enhance heat transfer, reduce energy consumption, and increase product quality. Design innovations such as multi-stage drying chambers and optimized nozzle arrangements contribute to better particle formation and more uniform drying.- Spray dryer design optimization: Optimizing the design of spray dryers can significantly improve drying efficiency. This includes modifications to the drying chamber geometry, air flow patterns, and atomization systems. Improved designs can enhance heat transfer, reduce energy consumption, and increase product quality. Key innovations include specialized nozzle configurations, optimized chamber dimensions, and improved air distribution systems that maximize contact between drying air and atomized particles.

- Process parameter control: Controlling process parameters is crucial for spray drying efficiency. Parameters such as inlet/outlet air temperature, feed rate, atomization pressure, and air flow rate significantly impact the drying process. Advanced control systems that monitor and adjust these parameters in real-time can optimize energy usage, increase throughput, and ensure consistent product quality. Automated systems that respond to changes in humidity, temperature, and particle characteristics help maintain optimal drying conditions.

- Heat recovery and energy efficiency: Implementing heat recovery systems in spray drying operations can substantially improve energy efficiency. These systems capture and reuse waste heat from exhaust air, reducing overall energy consumption. Techniques include using heat exchangers, recirculating drying air, and integrating thermal energy storage. Advanced energy-efficient designs incorporate insulation improvements, optimized combustion systems, and alternative heating methods to minimize energy losses during the drying process.

- Advanced atomization technologies: Advanced atomization technologies enhance spray drying efficiency by producing more uniform droplets and improving particle formation. Innovations include ultrasonic atomizers, high-pressure nozzles, and rotary atomizers with enhanced designs. These technologies create smaller, more consistent droplet sizes that dry more efficiently and produce particles with desired characteristics. Improved atomization leads to better control over particle size distribution, morphology, and density, resulting in higher quality dried products.

- Monitoring and automation systems: Implementing advanced monitoring and automation systems improves spray drying efficiency through real-time process optimization. These systems use sensors to continuously monitor critical parameters such as moisture content, particle size, and temperature profiles throughout the drying chamber. Machine learning algorithms and predictive models analyze this data to make automatic adjustments to operating conditions. Integrated control systems reduce operator intervention, minimize process variability, and optimize resource utilization while maintaining product quality.

02 Advanced atomization techniques

Advanced atomization methods play a crucial role in spray drying efficiency by controlling droplet size and distribution. Techniques such as ultrasonic atomization, high-pressure nozzles, and rotary atomizers can be employed to achieve specific particle characteristics. Proper atomization ensures optimal surface area for heat transfer, leading to faster drying rates and reduced energy consumption while maintaining product quality.Expand Specific Solutions03 Temperature and airflow control systems

Sophisticated control systems for managing temperature profiles and airflow patterns throughout the spray drying process can significantly enhance efficiency. These systems monitor and adjust parameters in real-time to maintain optimal drying conditions. Proper control of inlet and outlet temperatures, along with airflow velocity and distribution, prevents thermal degradation of sensitive materials while ensuring complete moisture removal and energy efficiency.Expand Specific Solutions04 Heat recovery and energy efficiency mechanisms

Implementing heat recovery systems and energy-efficient mechanisms can substantially reduce the operating costs of spray drying operations. These include recirculation of exhaust air, heat exchangers to capture waste heat, and thermal insulation of equipment. Advanced energy management systems optimize the use of thermal energy throughout the process, resulting in lower energy consumption and improved sustainability of spray drying operations.Expand Specific Solutions05 Process monitoring and automation

Integration of advanced monitoring technologies and automation systems enables real-time optimization of spray drying processes. Sensors for measuring moisture content, particle size, temperature, and pressure provide data for automated control systems to make immediate adjustments. Machine learning algorithms can predict optimal operating parameters based on feed characteristics and desired product specifications, leading to consistent product quality and maximized throughput efficiency.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The spray drying aerosol production market is currently in a growth phase, with an expanding global market driven by pharmaceutical and biotechnology applications. The technology has reached moderate maturity but continues to evolve, with significant innovations in efficiency and scalability. Key players like Vectura Ltd. and Innovata Biomed (both part of Philip Morris International) are leading pharmaceutical applications, while Ziccum AB is pioneering ambient temperature spray drying technologies. Established companies such as Wacker Chemie AG and BASF Corp. provide industrial-scale solutions, with Velico Medical developing novel medical applications. Academic institutions including Beijing University of Chemical Technology and Qingdao University contribute fundamental research, creating a competitive landscape balanced between specialized innovators and diversified chemical corporations.

Vectura Ltd.

Technical Solution: Vectura has developed proprietary PowderHale® and PowderMax® spray drying technologies specifically optimized for inhalation products. Their approach utilizes specialized atomization nozzles that create precise droplet sizes (1-5μm) under controlled conditions, resulting in particles with optimal aerodynamic properties. The company employs supercritical fluid technology in their spray drying process, which eliminates organic solvents and produces highly porous particles with enhanced dispersibility. Vectura's systems incorporate real-time process analytical technology (PAT) that monitors critical parameters such as temperature, humidity, and particle characteristics during production, enabling automated adjustments to maintain consistent quality. Their spray drying platforms achieve up to 95% yield for high-value APIs while maintaining narrow particle size distribution (GSD<1.8).

Strengths: Specialized in respiratory drug delivery with proprietary technologies specifically designed for inhalable formulations; high yield processes for expensive APIs; solvent-free options. Weaknesses: Systems primarily focused on pharmaceutical applications rather than broader industrial uses; requires significant expertise to operate effectively.

Ziccum AB

Technical Solution: Ziccum has pioneered the LaminarPace™ technology, an ambient temperature spray drying system specifically designed for thermosensitive biological materials. Unlike conventional spray dryers that operate at high temperatures (typically 80-200°C), LaminarPace™ functions at room temperature (20-25°C), making it uniquely suitable for heat-sensitive vaccines, proteins, and peptides. The system utilizes laminar airflow patterns and controlled humidity gradients to gently remove moisture from atomized droplets. This approach achieves particle engineering with minimal thermal stress, preserving biological activity of complex molecules. The technology produces dry powder particles with precisely controlled size distribution (1-5μm) and morphology optimized for pulmonary delivery, with demonstrated stability improvements of 400-600% for certain biologics compared to liquid formulations.

Strengths: Enables spray drying of extremely heat-sensitive materials that cannot withstand conventional processes; operates at ambient temperatures; preserves biological activity of complex molecules. Weaknesses: Lower throughput compared to traditional high-temperature systems; higher capital costs per unit of production; more complex humidity control requirements.

Key Patents and Innovations in Spray Drying

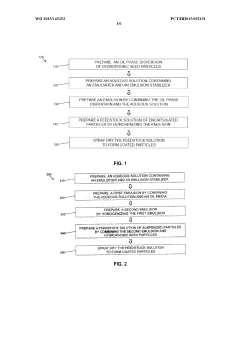

Spray-dried solid-in-oil-in-water dispersions for inhalation of active pharmaceutical ingredients

PatentWO2015145353A1

Innovation

- The development of stable solid-in-oil-in-water dispersions using hydrophobic drugs dispersed in liquid perfluorocarbons, stabilized by long-chain phospholipids, which are then spray-dried to form particles with a porous shell, maintaining the biochemical integrity and activity of the API while preventing aggregation.

Aggregate nanoparticulate medicament formulations, manufacture and use thereof

PatentWO2012051426A2

Innovation

- The development of aggregate nanoparticulate formulations through spray drying, where nanoparticulate drug and excipient particles are formed in a non-aqueous liquid without surfactants, maintaining their preselected crystalline form and resulting in particles with controlled aerodynamic diameters, enhancing physical stability and aerosolization efficiency.

Environmental Impact and Sustainability Considerations

Spray drying technology, while offering significant advantages in aerosol production efficiency, presents several important environmental and sustainability considerations that must be addressed in modern industrial applications. The energy consumption associated with spray drying processes represents a major environmental concern, as the technology typically requires substantial thermal energy for the atomization and drying phases. This energy demand contributes significantly to the carbon footprint of manufacturing operations, particularly when fossil fuels are the primary energy source.

Water usage in spray drying operations also merits careful consideration from a sustainability perspective. Although spray drying is generally considered a water-efficient technology compared to some alternative processes, the water requirements for cleaning equipment and preparing feed solutions can still be substantial in large-scale operations. Implementing closed-loop water systems and optimizing cleaning protocols can significantly reduce the overall water footprint.

Waste generation during spray drying processes primarily manifests as particulate emissions and unused product residues. Modern spray drying facilities increasingly incorporate advanced filtration systems and cyclone separators to capture these particulates, preventing their release into the atmosphere. The recovered material can often be reprocessed, contributing to a more circular production model and reducing raw material requirements.

The chemical composition of spray-dried products and their environmental fate must also be evaluated, particularly for aerosol applications. Certain propellants and carrier substances may have significant environmental impacts if released, including contributions to air pollution or potential ecological effects. Manufacturers are increasingly transitioning to environmentally benign formulations that maintain performance while reducing environmental harm.

Life cycle assessment (LCA) studies of spray drying processes reveal opportunities for sustainability improvements across the entire value chain. These improvements include the integration of renewable energy sources such as solar thermal systems or biomass for heating processes, which can substantially reduce the carbon intensity of operations. Additionally, heat recovery systems that capture and reuse thermal energy from exhaust gases represent a promising approach to improving energy efficiency.

Recent technological innovations in spray drying equipment design have focused on sustainability enhancements. These include the development of low-temperature spray drying techniques that reduce energy requirements, more efficient atomization methods that minimize waste, and advanced control systems that optimize process parameters in real-time to maximize resource efficiency while maintaining product quality.

Water usage in spray drying operations also merits careful consideration from a sustainability perspective. Although spray drying is generally considered a water-efficient technology compared to some alternative processes, the water requirements for cleaning equipment and preparing feed solutions can still be substantial in large-scale operations. Implementing closed-loop water systems and optimizing cleaning protocols can significantly reduce the overall water footprint.

Waste generation during spray drying processes primarily manifests as particulate emissions and unused product residues. Modern spray drying facilities increasingly incorporate advanced filtration systems and cyclone separators to capture these particulates, preventing their release into the atmosphere. The recovered material can often be reprocessed, contributing to a more circular production model and reducing raw material requirements.

The chemical composition of spray-dried products and their environmental fate must also be evaluated, particularly for aerosol applications. Certain propellants and carrier substances may have significant environmental impacts if released, including contributions to air pollution or potential ecological effects. Manufacturers are increasingly transitioning to environmentally benign formulations that maintain performance while reducing environmental harm.

Life cycle assessment (LCA) studies of spray drying processes reveal opportunities for sustainability improvements across the entire value chain. These improvements include the integration of renewable energy sources such as solar thermal systems or biomass for heating processes, which can substantially reduce the carbon intensity of operations. Additionally, heat recovery systems that capture and reuse thermal energy from exhaust gases represent a promising approach to improving energy efficiency.

Recent technological innovations in spray drying equipment design have focused on sustainability enhancements. These include the development of low-temperature spray drying techniques that reduce energy requirements, more efficient atomization methods that minimize waste, and advanced control systems that optimize process parameters in real-time to maximize resource efficiency while maintaining product quality.

Scale-up Challenges and Industrial Implementation

Transitioning from laboratory-scale spray drying to industrial production presents significant challenges that require careful consideration and strategic planning. The scale-up process involves complex interactions between equipment design, process parameters, and product characteristics that must be harmonized to maintain aerosol production efficiency at larger scales.

One of the primary challenges in industrial implementation is maintaining consistent particle size distribution when increasing production volume. As equipment dimensions expand, fluid dynamics within the drying chamber change substantially, potentially altering droplet formation mechanisms and drying kinetics. This can lead to variations in particle morphology and aerodynamic properties, directly impacting aerosol performance.

Heat and mass transfer efficiency represents another critical consideration during scale-up. Industrial spray dryers operate with significantly larger drying chambers and higher throughput rates, which can create temperature gradients and uneven drying conditions. These variations may result in inconsistent moisture content across particles, affecting their dispersibility and stability as aerosols.

Equipment design modifications are often necessary to accommodate industrial-scale production. Atomization devices must deliver consistent droplet formation at higher feed rates, while maintaining the precision required for aerosol applications. Multi-nozzle systems or specialized rotary atomizers are frequently employed, though each introduces unique challenges in terms of spray pattern uniformity and potential for nozzle clogging.

Process control systems become increasingly sophisticated at industrial scale to manage the complexity of operations. Advanced monitoring technologies, including real-time particle size analyzers and moisture sensors, are essential for maintaining quality parameters within acceptable ranges. Automated feedback loops that adjust process parameters in response to deviations help ensure consistent aerosol properties throughout extended production runs.

Regulatory considerations also intensify during scale-up, particularly for pharmaceutical aerosol applications. Validation protocols must demonstrate that the scaled-up process consistently produces aerosols with the same critical quality attributes as those developed at laboratory scale. This includes comprehensive documentation of equipment qualification, process validation, and cleaning verification procedures.

Economic factors ultimately determine the viability of industrial implementation. Capital investment requirements for specialized spray drying equipment must be balanced against production efficiency gains. Operating costs, including energy consumption, maintenance requirements, and yield losses, significantly impact the cost-effectiveness of spray drying for aerosol production at commercial scale.

One of the primary challenges in industrial implementation is maintaining consistent particle size distribution when increasing production volume. As equipment dimensions expand, fluid dynamics within the drying chamber change substantially, potentially altering droplet formation mechanisms and drying kinetics. This can lead to variations in particle morphology and aerodynamic properties, directly impacting aerosol performance.

Heat and mass transfer efficiency represents another critical consideration during scale-up. Industrial spray dryers operate with significantly larger drying chambers and higher throughput rates, which can create temperature gradients and uneven drying conditions. These variations may result in inconsistent moisture content across particles, affecting their dispersibility and stability as aerosols.

Equipment design modifications are often necessary to accommodate industrial-scale production. Atomization devices must deliver consistent droplet formation at higher feed rates, while maintaining the precision required for aerosol applications. Multi-nozzle systems or specialized rotary atomizers are frequently employed, though each introduces unique challenges in terms of spray pattern uniformity and potential for nozzle clogging.

Process control systems become increasingly sophisticated at industrial scale to manage the complexity of operations. Advanced monitoring technologies, including real-time particle size analyzers and moisture sensors, are essential for maintaining quality parameters within acceptable ranges. Automated feedback loops that adjust process parameters in response to deviations help ensure consistent aerosol properties throughout extended production runs.

Regulatory considerations also intensify during scale-up, particularly for pharmaceutical aerosol applications. Validation protocols must demonstrate that the scaled-up process consistently produces aerosols with the same critical quality attributes as those developed at laboratory scale. This includes comprehensive documentation of equipment qualification, process validation, and cleaning verification procedures.

Economic factors ultimately determine the viability of industrial implementation. Capital investment requirements for specialized spray drying equipment must be balanced against production efficiency gains. Operating costs, including energy consumption, maintenance requirements, and yield losses, significantly impact the cost-effectiveness of spray drying for aerosol production at commercial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!