Spray Drying and Electrostatic Charge: Implications for Packing

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century. Initially developed for milk powder production, this process has transformed into a sophisticated industrial technique applicable across pharmaceutical, food, chemical, and material science sectors. The fundamental principle remains consistent: atomizing a liquid feed into fine droplets within a hot gas medium to rapidly evaporate moisture, resulting in dry powder particles. However, the technological sophistication has advanced tremendously over the decades.

The 1950s marked a pivotal era with the introduction of automated control systems, enhancing process reliability and product consistency. By the 1970s, computational fluid dynamics began informing spray dryer design, leading to more efficient chamber geometries and flow patterns. The 1990s witnessed integration of real-time monitoring capabilities, allowing for adaptive process control and quality assurance during operation rather than post-production testing.

Recent technological advancements have focused on addressing the persistent challenge of electrostatic charge generation during spray drying. This phenomenon occurs as particles lose moisture and move through the drying chamber, creating friction-induced electrical charges. The resulting electrostatic forces significantly impact powder behavior during collection, handling, and packaging operations, often leading to agglomeration, wall deposition, and flow irregularities.

Current research objectives center on developing comprehensive models that accurately predict charge generation and distribution patterns within spray-dried powders. These models aim to account for variables including feed composition, atomization parameters, drying conditions, and material properties. Understanding these relationships is crucial for designing processes that either minimize unwanted electrostatic effects or strategically utilize controlled charging for improved product characteristics.

The industry is increasingly focused on developing innovative electrode systems and chamber designs that can actively manage charge distribution during the drying process. Simultaneously, research efforts are exploring surface modification techniques and additive formulations that can modulate the electrical properties of resulting powders without compromising product integrity or performance characteristics.

The ultimate technological goal is to achieve precise control over particle electrostatic properties, transforming what has historically been considered a processing nuisance into a beneficial parameter for enhanced powder functionality. This includes improving flowability, reducing caking tendencies, and optimizing packaging efficiency through controlled charge management. Success in this domain would represent a significant advancement in spray drying technology, potentially revolutionizing downstream handling and packaging operations across multiple industries.

The 1950s marked a pivotal era with the introduction of automated control systems, enhancing process reliability and product consistency. By the 1970s, computational fluid dynamics began informing spray dryer design, leading to more efficient chamber geometries and flow patterns. The 1990s witnessed integration of real-time monitoring capabilities, allowing for adaptive process control and quality assurance during operation rather than post-production testing.

Recent technological advancements have focused on addressing the persistent challenge of electrostatic charge generation during spray drying. This phenomenon occurs as particles lose moisture and move through the drying chamber, creating friction-induced electrical charges. The resulting electrostatic forces significantly impact powder behavior during collection, handling, and packaging operations, often leading to agglomeration, wall deposition, and flow irregularities.

Current research objectives center on developing comprehensive models that accurately predict charge generation and distribution patterns within spray-dried powders. These models aim to account for variables including feed composition, atomization parameters, drying conditions, and material properties. Understanding these relationships is crucial for designing processes that either minimize unwanted electrostatic effects or strategically utilize controlled charging for improved product characteristics.

The industry is increasingly focused on developing innovative electrode systems and chamber designs that can actively manage charge distribution during the drying process. Simultaneously, research efforts are exploring surface modification techniques and additive formulations that can modulate the electrical properties of resulting powders without compromising product integrity or performance characteristics.

The ultimate technological goal is to achieve precise control over particle electrostatic properties, transforming what has historically been considered a processing nuisance into a beneficial parameter for enhanced powder functionality. This includes improving flowability, reducing caking tendencies, and optimizing packaging efficiency through controlled charge management. Success in this domain would represent a significant advancement in spray drying technology, potentially revolutionizing downstream handling and packaging operations across multiple industries.

Market Analysis for Electrostatically Optimized Powder Products

The global market for electrostatically optimized powder products has experienced significant growth over the past decade, driven primarily by increasing demand in pharmaceutical, food processing, and advanced materials industries. Current market valuation stands at approximately 4.7 billion USD with a compound annual growth rate of 6.8% projected through 2028, according to recent industry analyses.

Pharmaceutical applications represent the largest market segment, accounting for roughly 38% of total market share. This dominance stems from the critical importance of powder flow properties and content uniformity in drug formulation and delivery systems. Manufacturers are increasingly seeking solutions that mitigate electrostatic challenges during spray drying processes to improve production efficiency and product quality.

The food and beverage industry constitutes the second-largest market segment at 27%, with particular emphasis on instant coffee, dairy powders, and nutritional supplements. Consumer demand for premium quality, easily dissolvable powders with extended shelf life has intensified research into electrostatic optimization technologies. Market research indicates that products with improved flowability command price premiums of 15-20% over conventional alternatives.

Regionally, North America and Europe currently dominate the market with combined share exceeding 60%. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by rapid industrialization in China and India, alongside expanding pharmaceutical manufacturing capabilities.

Market penetration analysis reveals significant untapped potential in emerging economies where spray drying technologies are increasingly being adopted across multiple industries. The Middle East and Africa region, while currently representing only 5% of the global market, is projected to double its market share within the next five years.

Consumer trends indicate growing preference for natural, clean-label products with minimal additives, creating demand for physical optimization methods like electrostatic charge management rather than chemical additives to improve powder properties. This shift represents a substantial opportunity for technology providers focused on electrostatic solutions.

Industry surveys highlight that manufacturers are willing to invest in premium technologies that reduce production losses, which currently average 4-7% due to powder adhesion and agglomeration issues. The return on investment for implementing advanced electrostatic management systems typically ranges from 12-18 months, making these solutions increasingly attractive despite higher initial capital requirements.

Competition in this market segment is intensifying, with approximately 25 specialized technology providers competing alongside major equipment manufacturers who are integrating electrostatic optimization features into their spray drying systems. Market consolidation through strategic acquisitions has accelerated in recent years, indicating the growing strategic importance of this technology.

Pharmaceutical applications represent the largest market segment, accounting for roughly 38% of total market share. This dominance stems from the critical importance of powder flow properties and content uniformity in drug formulation and delivery systems. Manufacturers are increasingly seeking solutions that mitigate electrostatic challenges during spray drying processes to improve production efficiency and product quality.

The food and beverage industry constitutes the second-largest market segment at 27%, with particular emphasis on instant coffee, dairy powders, and nutritional supplements. Consumer demand for premium quality, easily dissolvable powders with extended shelf life has intensified research into electrostatic optimization technologies. Market research indicates that products with improved flowability command price premiums of 15-20% over conventional alternatives.

Regionally, North America and Europe currently dominate the market with combined share exceeding 60%. However, the Asia-Pacific region is experiencing the fastest growth rate at 8.9% annually, driven by rapid industrialization in China and India, alongside expanding pharmaceutical manufacturing capabilities.

Market penetration analysis reveals significant untapped potential in emerging economies where spray drying technologies are increasingly being adopted across multiple industries. The Middle East and Africa region, while currently representing only 5% of the global market, is projected to double its market share within the next five years.

Consumer trends indicate growing preference for natural, clean-label products with minimal additives, creating demand for physical optimization methods like electrostatic charge management rather than chemical additives to improve powder properties. This shift represents a substantial opportunity for technology providers focused on electrostatic solutions.

Industry surveys highlight that manufacturers are willing to invest in premium technologies that reduce production losses, which currently average 4-7% due to powder adhesion and agglomeration issues. The return on investment for implementing advanced electrostatic management systems typically ranges from 12-18 months, making these solutions increasingly attractive despite higher initial capital requirements.

Competition in this market segment is intensifying, with approximately 25 specialized technology providers competing alongside major equipment manufacturers who are integrating electrostatic optimization features into their spray drying systems. Market consolidation through strategic acquisitions has accelerated in recent years, indicating the growing strategic importance of this technology.

Electrostatic Charge Challenges in Spray Drying Operations

Electrostatic charge generation during spray drying operations presents significant challenges for pharmaceutical, food, and chemical industries. The process inherently creates conditions conducive to charge accumulation as atomized droplets rapidly lose moisture and transform into solid particles. This phenomenon occurs due to the combination of high-velocity air movement, particle-particle collisions, and particle-equipment surface interactions within the drying chamber.

The primary mechanism of charge generation in spray drying involves triboelectric charging, where particles acquire charge through contact and separation with other materials. As the atomized droplets travel through the drying chamber, they experience numerous collisions with each other and with the equipment surfaces, leading to charge transfer. The magnitude of this charge depends on several factors including material properties, relative humidity, temperature, and equipment design.

Humidity plays a crucial role in charge dissipation. Lower humidity levels, which are common in spray drying operations, significantly increase charge retention on particles. This creates a challenging paradox as effective drying requires low humidity, yet this same condition exacerbates electrostatic issues. Studies have shown that relative humidity below 40% dramatically increases charge accumulation, with exponential effects observed below 20% RH.

Temperature gradients within the drying chamber further complicate the electrostatic landscape. Hot air used for drying reduces relative humidity and increases particle mobility, both factors contributing to enhanced charge generation. Additionally, the rapid cooling that occurs during the final stages of drying can trap charges on particle surfaces, creating stable electrets that retain charge for extended periods.

Particle size distribution significantly influences charge behavior. Smaller particles typically acquire higher charge-to-mass ratios due to their larger specific surface area. This disproportionate charging creates segregation issues during collection and packaging, as differently charged particles exhibit varying flow behaviors and adhesion tendencies.

Equipment material selection presents another critical challenge. Stainless steel, commonly used in spray dryers for sanitary requirements, tends to promote charge generation when in contact with organic materials. Alternative materials with better electrostatic properties often fail to meet regulatory or operational requirements, creating a difficult engineering compromise.

The dynamic nature of spray drying operations further complicates charge management. Variations in feed composition, process parameters, and environmental conditions create constantly shifting electrostatic profiles that resist standardized solutions. This variability makes it particularly challenging to implement consistent charge mitigation strategies across different production batches or product formulations.

The primary mechanism of charge generation in spray drying involves triboelectric charging, where particles acquire charge through contact and separation with other materials. As the atomized droplets travel through the drying chamber, they experience numerous collisions with each other and with the equipment surfaces, leading to charge transfer. The magnitude of this charge depends on several factors including material properties, relative humidity, temperature, and equipment design.

Humidity plays a crucial role in charge dissipation. Lower humidity levels, which are common in spray drying operations, significantly increase charge retention on particles. This creates a challenging paradox as effective drying requires low humidity, yet this same condition exacerbates electrostatic issues. Studies have shown that relative humidity below 40% dramatically increases charge accumulation, with exponential effects observed below 20% RH.

Temperature gradients within the drying chamber further complicate the electrostatic landscape. Hot air used for drying reduces relative humidity and increases particle mobility, both factors contributing to enhanced charge generation. Additionally, the rapid cooling that occurs during the final stages of drying can trap charges on particle surfaces, creating stable electrets that retain charge for extended periods.

Particle size distribution significantly influences charge behavior. Smaller particles typically acquire higher charge-to-mass ratios due to their larger specific surface area. This disproportionate charging creates segregation issues during collection and packaging, as differently charged particles exhibit varying flow behaviors and adhesion tendencies.

Equipment material selection presents another critical challenge. Stainless steel, commonly used in spray dryers for sanitary requirements, tends to promote charge generation when in contact with organic materials. Alternative materials with better electrostatic properties often fail to meet regulatory or operational requirements, creating a difficult engineering compromise.

The dynamic nature of spray drying operations further complicates charge management. Variations in feed composition, process parameters, and environmental conditions create constantly shifting electrostatic profiles that resist standardized solutions. This variability makes it particularly challenging to implement consistent charge mitigation strategies across different production batches or product formulations.

Current Methodologies for Mitigating Electrostatic Issues

01 Electrostatic charge control in spray drying processes

Various methods and devices are employed to control electrostatic charges generated during spray drying operations. These include specialized nozzle designs, grounding mechanisms, and charge neutralization systems that help prevent particle agglomeration and wall deposition. By managing electrostatic forces, these technologies improve product quality, reduce material losses, and enhance operational safety in spray drying applications.- Electrostatic charge control in spray drying processes: Various methods and devices are employed to control electrostatic charges generated during spray drying operations. These include specialized nozzle designs, grounding mechanisms, and charge neutralization systems that help prevent particle agglomeration and wall deposition. By managing electrostatic forces, these technologies improve product quality, reduce material losses, and enhance operational safety in spray drying applications.

- Electrostatic spray drying for pharmaceutical applications: Electrostatic spray drying techniques are specifically adapted for pharmaceutical manufacturing, where precise particle size distribution and morphology are critical. These systems utilize controlled electrostatic charging to produce uniform, fine powders with enhanced bioavailability and stability. The technology enables the production of inhalable dry powder formulations and controlled-release drug delivery systems with improved therapeutic efficacy.

- Electrostatic atomization techniques for spray drying: Electrostatic atomization enhances the spray drying process by applying electrical charges to liquid feeds, resulting in finer droplet formation and more uniform particle size distribution. These techniques utilize various electrode configurations and voltage control systems to manipulate droplet formation and trajectory. The technology improves drying efficiency, reduces energy consumption, and enables the production of specialized powder characteristics not achievable with conventional atomization methods.

- Charge mitigation systems for spray drying equipment: Specialized systems are designed to mitigate unwanted electrostatic charges in spray drying equipment, preventing operational issues such as powder adhesion to chamber walls, particle agglomeration, and potential ignition hazards. These systems incorporate ionizers, corona discharge devices, humidity control mechanisms, and specialized conductive materials. By neutralizing or dissipating charges, these technologies improve process safety, product recovery rates, and equipment longevity.

- Electrostatic powder collection and handling systems: Advanced systems for collecting and handling electrostatically charged powders after spray drying utilize electrostatic precipitation, controlled discharge mechanisms, and specialized conveying equipment. These technologies enable efficient capture of fine particles, reduce product losses, and maintain powder quality during post-drying handling. The systems incorporate precise charge measurement instruments, adaptive control algorithms, and specialized packaging solutions to manage residual charges in the final product.

02 Electrostatic spray drying nozzle configurations

Advanced nozzle designs specifically engineered for electrostatic spray drying applications incorporate features that optimize charge distribution and particle formation. These specialized nozzles may include electrode arrangements, insulating components, and precise geometry to control droplet size and charge characteristics. Such configurations enhance atomization efficiency while minimizing unwanted electrostatic effects during the drying process.Expand Specific Solutions03 Electrostatic charge measurement and monitoring systems

Systems for measuring and monitoring electrostatic charges during spray drying operations enable real-time process control and quality assurance. These technologies include sensors, detectors, and analytical instruments that quantify charge levels on particles and surfaces. By providing continuous feedback on electrostatic conditions, these systems allow for process adjustments that maintain optimal drying conditions and prevent charge-related issues.Expand Specific Solutions04 Charge reduction additives and formulations

Chemical additives and specialized formulations can be incorporated into spray drying feedstocks to modify electrostatic properties. These may include antistatic agents, conductivity enhancers, or surface-active compounds that alter the electrical characteristics of the resulting particles. By manipulating the composition of the feed material, these approaches help control charge generation and dissipation during the drying process, leading to improved product flow properties and reduced adhesion issues.Expand Specific Solutions05 Equipment design for electrostatic charge management

Specialized equipment designs address electrostatic challenges in spray drying operations through integrated charge management features. These designs may incorporate conductive materials, ionization systems, humidity control mechanisms, and optimized airflow patterns. By considering electrostatic phenomena in the fundamental design of spray drying equipment, these innovations create more stable processing environments with reduced charge-related complications.Expand Specific Solutions

Industry Leaders in Spray Drying Equipment and Solutions

The spray drying and electrostatic charge market is currently in a growth phase, with increasing applications across pharmaceutical, food, and chemical industries. The global market size is estimated to exceed $7 billion, driven by demand for efficient powder processing technologies. Technologically, the field is moderately mature but evolving rapidly with innovations in electrostatic control. Leading players include established equipment manufacturers like Spraying Systems Co. and Nordson Corp., who focus on precision spray technologies, while 3M Innovative Properties and Eastman Kodak contribute significant intellectual property. Research institutions such as Jiangsu University and Huazhong University collaborate with companies like BYK Chemie and Chr. Hansen to address challenges in powder cohesion and flowability, particularly for sensitive materials requiring controlled packing characteristics.

SPRAYING SYSTEMS CO

Technical Solution: Spraying Systems Co. has developed advanced electrostatic spray drying systems that precisely control particle charging during the atomization process. Their technology incorporates specialized nozzle designs with integrated electrode configurations that generate consistent electrostatic fields across the spray pattern. This approach allows for controlled particle charging before the drying phase begins, resulting in more uniform particle size distribution and reduced agglomeration during subsequent packing operations. The company's PulsaJet® electrostatic spray technology combines precise droplet formation with electrostatic charging to achieve optimal particle characteristics for powder handling and packing efficiency. Their systems include real-time monitoring of charge levels and automatic adjustment capabilities to maintain consistent electrostatic properties throughout production runs, addressing one of the key challenges in spray drying operations where charge variability can significantly impact packing behavior.

Strengths: Superior control over particle charge distribution leading to improved flow properties and reduced caking during storage. Their integrated approach addresses both spray formation and electrostatic management simultaneously. Weaknesses: Systems require significant technical expertise to optimize for specific formulations, and the technology demands higher initial capital investment compared to conventional spray drying equipment.

Firmenich SA

Technical Solution: Firmenich has developed proprietary spray drying technology specifically designed to address electrostatic challenges in flavor and fragrance encapsulation applications. Their ElectroSpray™ system incorporates specialized atomization nozzles with integrated charge control elements that precisely manage the electrostatic properties of particles during formation and drying. This approach allows for manipulation of particle surface characteristics to optimize downstream packing behavior. Firmenich's technology includes multi-stage drying chambers with controlled electrostatic zones that progressively modify particle charge as moisture content decreases, addressing the critical relationship between moisture content and charge development. Their systems feature specialized formulation approaches that incorporate charge-modifying additives at precise concentrations to achieve optimal electrostatic properties for specific product applications. Additionally, Firmenich has developed packaging material selection protocols that account for triboelectric interactions between dried particles and packaging materials, minimizing charge-related issues during filling and storage. This holistic approach addresses the entire process from formulation through final packaging.

Strengths: Highly specialized solutions for sensitive flavor and fragrance applications with excellent retention of volatile compounds while managing electrostatic properties. Weaknesses: Technology is optimized primarily for high-value specialty ingredients rather than bulk commodity processing, limiting broader industrial application.

Key Patents and Research on Electrostatic Charge Management

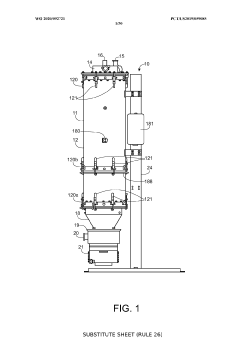

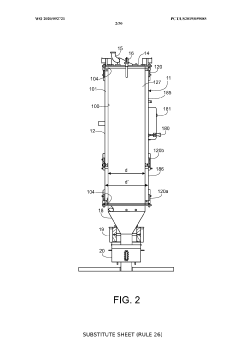

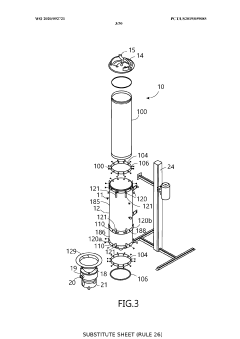

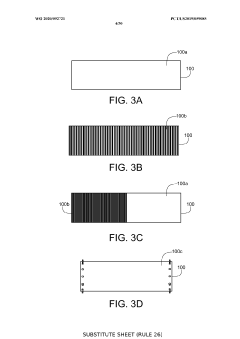

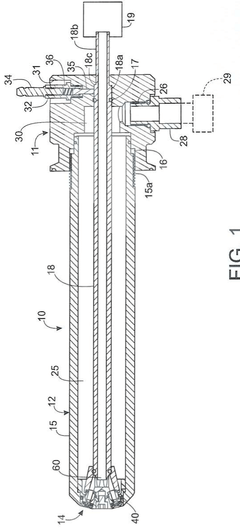

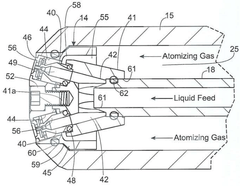

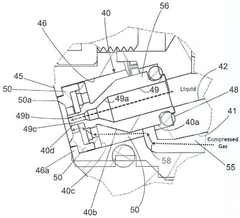

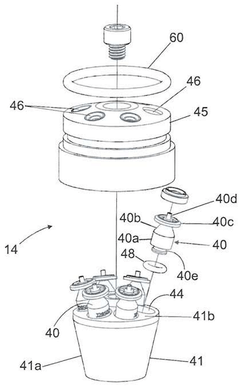

Electrostatic spray dryer system

PatentWO2020092721A2

Innovation

- A compact electrostatic spray dryer system with a non-metallic insulating liner, modular design, and advanced filtration system, including reverse pulse air filter cleaning, to prevent cross-contamination and electrical issues, while protecting products from environmental damage and optimizing particle agglomeration and removal.

Electrostatic spray drying nozzle assembly

PatentPendingAU2025204166A1

Innovation

- The development of an electrostatic sprayer with an external mix spray nozzle assembly that includes a high voltage input head, an elongated nozzle body, and a liquid feed tube made of conductive material, which allows for high flow rates, fine droplet control, and operation at low pressures, while isolating internal non-metallic components from the sprayed liquid.

Material Science Considerations for Powder Formulations

The fundamental properties of powder materials significantly influence spray drying processes and subsequent electrostatic charge development. Particle size distribution represents a critical parameter, with finer particles typically exhibiting greater susceptibility to electrostatic charging due to their increased surface area-to-volume ratio. This relationship follows inverse proportionality principles, where charging potential increases as particle diameter decreases.

Molecular structure and chemical composition of the powder formulation directly impact triboelectric charging behaviors. Materials with higher electron affinity tend to acquire negative charges, while those readily donating electrons develop positive charges. This phenomenon explains why different pharmaceutical excipients exhibit varying charging tendencies when processed through identical spray drying equipment.

Crystallinity versus amorphous state represents another crucial consideration. Crystalline materials generally demonstrate more predictable electrostatic behaviors compared to their amorphous counterparts. The ordered molecular arrangement in crystalline structures facilitates more uniform charge distribution, whereas amorphous regions create localized charge pockets that complicate packing operations.

Hygroscopicity and moisture content significantly influence powder charging characteristics. Materials with higher moisture affinity can develop conductive pathways that dissipate accumulated charges. However, this same property may lead to agglomeration issues during storage. The relationship between relative humidity and charge retention follows a non-linear pattern, with optimal processing windows typically existing between 30-50% RH.

Surface morphology, particularly roughness and porosity, affects contact area during particle collisions in spray drying chambers and subsequent packaging operations. Smoother particles tend to develop more uniform charge distributions, while highly textured surfaces create irregular charge patterns that complicate flow behaviors.

Glass transition temperature (Tg) represents a critical material science parameter for spray-dried formulations. Processing above Tg can reduce electrostatic charging through increased molecular mobility, but risks particle fusion. Conversely, operating below Tg preserves particle integrity while potentially increasing triboelectric charging.

Additive incorporation, particularly surfactants and flow enhancers, offers strategic approaches to modifying electrostatic properties. These materials can create protective surface layers that alter triboelectric charging sequences or provide conductive pathways for charge dissipation. Careful selection based on material compatibility and processing conditions remains essential for optimizing these interventions.

Molecular structure and chemical composition of the powder formulation directly impact triboelectric charging behaviors. Materials with higher electron affinity tend to acquire negative charges, while those readily donating electrons develop positive charges. This phenomenon explains why different pharmaceutical excipients exhibit varying charging tendencies when processed through identical spray drying equipment.

Crystallinity versus amorphous state represents another crucial consideration. Crystalline materials generally demonstrate more predictable electrostatic behaviors compared to their amorphous counterparts. The ordered molecular arrangement in crystalline structures facilitates more uniform charge distribution, whereas amorphous regions create localized charge pockets that complicate packing operations.

Hygroscopicity and moisture content significantly influence powder charging characteristics. Materials with higher moisture affinity can develop conductive pathways that dissipate accumulated charges. However, this same property may lead to agglomeration issues during storage. The relationship between relative humidity and charge retention follows a non-linear pattern, with optimal processing windows typically existing between 30-50% RH.

Surface morphology, particularly roughness and porosity, affects contact area during particle collisions in spray drying chambers and subsequent packaging operations. Smoother particles tend to develop more uniform charge distributions, while highly textured surfaces create irregular charge patterns that complicate flow behaviors.

Glass transition temperature (Tg) represents a critical material science parameter for spray-dried formulations. Processing above Tg can reduce electrostatic charging through increased molecular mobility, but risks particle fusion. Conversely, operating below Tg preserves particle integrity while potentially increasing triboelectric charging.

Additive incorporation, particularly surfactants and flow enhancers, offers strategic approaches to modifying electrostatic properties. These materials can create protective surface layers that alter triboelectric charging sequences or provide conductive pathways for charge dissipation. Careful selection based on material compatibility and processing conditions remains essential for optimizing these interventions.

Quality Assurance Standards for Electrostatically Stable Products

Quality assurance standards for electrostatically stable products in spray drying operations require comprehensive frameworks that address the unique challenges posed by electrostatic charge generation. These standards must establish clear parameters for measuring, monitoring, and controlling electrostatic properties throughout the production process to ensure consistent product quality and safe handling.

The foundation of these standards begins with precise measurement protocols for quantifying electrostatic charge on particles. Industry-accepted methods include Faraday cup measurements, field mill devices, and charge decay time assessments. These measurements should be conducted at multiple stages of the production process, with documented acceptable ranges specific to each product formulation.

Environmental control specifications form another critical component of these standards. Maintaining relative humidity between 40-60% has been demonstrated to significantly reduce electrostatic charge accumulation in most powder processing operations. Temperature stability within ±2°C of the designated processing temperature further ensures consistent electrostatic behavior of materials during spray drying.

Material handling guidelines must be explicitly defined within these standards. This includes specifications for grounding requirements of all processing equipment, with maximum resistance thresholds typically set at 10^6 ohms. The standards should also mandate regular verification of grounding integrity through documented testing procedures performed at established intervals.

Process validation protocols represent a cornerstone of quality assurance for electrostatically stable products. These protocols must include challenge testing under worst-case conditions (low humidity, high processing speeds) to verify that electrostatic charge remains within acceptable limits even under adverse circumstances. Statistical process control methodologies should be implemented to identify trends before they result in out-of-specification products.

Documentation requirements constitute the final essential element of these standards. Complete records must be maintained for all electrostatic measurements, environmental conditions, equipment maintenance, and operator training. Traceability systems should enable correlation between specific production batches and their corresponding electrostatic profiles.

Leading pharmaceutical and food processing companies have implemented tiered alert systems within their quality standards. These systems establish warning limits that trigger investigative actions before critical control limits are breached, providing a proactive approach to maintaining electrostatic stability throughout the spray drying and packing operations.

The foundation of these standards begins with precise measurement protocols for quantifying electrostatic charge on particles. Industry-accepted methods include Faraday cup measurements, field mill devices, and charge decay time assessments. These measurements should be conducted at multiple stages of the production process, with documented acceptable ranges specific to each product formulation.

Environmental control specifications form another critical component of these standards. Maintaining relative humidity between 40-60% has been demonstrated to significantly reduce electrostatic charge accumulation in most powder processing operations. Temperature stability within ±2°C of the designated processing temperature further ensures consistent electrostatic behavior of materials during spray drying.

Material handling guidelines must be explicitly defined within these standards. This includes specifications for grounding requirements of all processing equipment, with maximum resistance thresholds typically set at 10^6 ohms. The standards should also mandate regular verification of grounding integrity through documented testing procedures performed at established intervals.

Process validation protocols represent a cornerstone of quality assurance for electrostatically stable products. These protocols must include challenge testing under worst-case conditions (low humidity, high processing speeds) to verify that electrostatic charge remains within acceptable limits even under adverse circumstances. Statistical process control methodologies should be implemented to identify trends before they result in out-of-specification products.

Documentation requirements constitute the final essential element of these standards. Complete records must be maintained for all electrostatic measurements, environmental conditions, equipment maintenance, and operator training. Traceability systems should enable correlation between specific production batches and their corresponding electrostatic profiles.

Leading pharmaceutical and food processing companies have implemented tiered alert systems within their quality standards. These systems establish warning limits that trigger investigative actions before critical control limits are breached, providing a proactive approach to maintaining electrostatic stability throughout the spray drying and packing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!