Spray Drying in Battery Manufacturing: Ingredient Stability

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Spray Drying Technology Evolution and Objectives

Spray drying technology in battery manufacturing has evolved significantly over the past several decades, transforming from a niche process to a critical method for producing high-performance battery materials. Initially developed in the food and pharmaceutical industries in the early 20th century, spray drying was first adapted for battery applications in the 1980s, primarily for simple oxide cathode materials. The technology gained substantial momentum in the 1990s when researchers discovered its potential for creating spherical particles with controlled morphology and improved electrochemical properties.

The evolution accelerated in the early 2000s with the rise of lithium-ion batteries for portable electronics. During this period, spray drying techniques were refined to produce more complex multi-component cathode materials with enhanced stability and performance characteristics. The introduction of automated process control systems around 2010 marked another significant advancement, allowing for more precise manipulation of particle size distribution and morphology.

Recent developments have focused on addressing the critical challenge of ingredient stability during the spray drying process. High-temperature exposure during conventional spray drying can degrade thermally sensitive battery components, particularly organic binders and certain electrode additives. This has prompted the development of modified spray drying techniques operating at lower temperatures or with protective atmospheres to preserve material integrity.

The current technological frontier involves the integration of advanced in-situ monitoring systems that can detect and adjust for material degradation in real-time during the spray drying process. These systems utilize spectroscopic methods to track chemical changes and ensure consistent product quality despite variations in raw material properties or processing conditions.

The primary objectives of current spray drying technology development in battery manufacturing center around four key areas: enhancing ingredient stability during processing, improving energy efficiency of the drying process, increasing production throughput without sacrificing quality, and enabling the processing of next-generation battery materials with complex compositions.

Looking forward, the industry aims to develop spray drying systems capable of maintaining material stability even for highly sensitive components, while simultaneously reducing energy consumption by 30-40% compared to conventional systems. Another critical objective is to enable the production of gradient composition particles, where material composition varies from core to surface, allowing for optimized performance characteristics throughout the particle structure.

The ultimate goal is to establish spray drying as a versatile, scalable platform technology that can rapidly adapt to new battery chemistries while maintaining strict control over material properties and stability. This would significantly accelerate the commercialization timeline for novel battery materials, potentially reducing development cycles from years to months.

The evolution accelerated in the early 2000s with the rise of lithium-ion batteries for portable electronics. During this period, spray drying techniques were refined to produce more complex multi-component cathode materials with enhanced stability and performance characteristics. The introduction of automated process control systems around 2010 marked another significant advancement, allowing for more precise manipulation of particle size distribution and morphology.

Recent developments have focused on addressing the critical challenge of ingredient stability during the spray drying process. High-temperature exposure during conventional spray drying can degrade thermally sensitive battery components, particularly organic binders and certain electrode additives. This has prompted the development of modified spray drying techniques operating at lower temperatures or with protective atmospheres to preserve material integrity.

The current technological frontier involves the integration of advanced in-situ monitoring systems that can detect and adjust for material degradation in real-time during the spray drying process. These systems utilize spectroscopic methods to track chemical changes and ensure consistent product quality despite variations in raw material properties or processing conditions.

The primary objectives of current spray drying technology development in battery manufacturing center around four key areas: enhancing ingredient stability during processing, improving energy efficiency of the drying process, increasing production throughput without sacrificing quality, and enabling the processing of next-generation battery materials with complex compositions.

Looking forward, the industry aims to develop spray drying systems capable of maintaining material stability even for highly sensitive components, while simultaneously reducing energy consumption by 30-40% compared to conventional systems. Another critical objective is to enable the production of gradient composition particles, where material composition varies from core to surface, allowing for optimized performance characteristics throughout the particle structure.

The ultimate goal is to establish spray drying as a versatile, scalable platform technology that can rapidly adapt to new battery chemistries while maintaining strict control over material properties and stability. This would significantly accelerate the commercialization timeline for novel battery materials, potentially reducing development cycles from years to months.

Market Analysis for Spray-Dried Battery Materials

The global market for spray-dried battery materials has experienced significant growth in recent years, driven by the expanding electric vehicle (EV) sector and increasing demand for high-performance energy storage solutions. Current market valuations indicate that spray-dried cathode materials alone represent a market segment worth approximately 3.2 billion USD in 2023, with projections suggesting a compound annual growth rate of 18.7% through 2030.

Asia-Pacific dominates the market landscape, accounting for over 65% of global production capacity. This regional concentration is primarily due to the established battery manufacturing ecosystems in China, South Korea, and Japan. North America and Europe are rapidly expanding their market shares, with substantial investments in domestic battery supply chains to reduce dependency on Asian imports.

Consumer electronics historically represented the largest application segment for spray-dried battery materials, but automotive applications have overtaken this position since 2021. The automotive sector now consumes nearly 52% of spray-dried battery materials, followed by consumer electronics (27%), grid storage systems (14%), and industrial applications (7%).

Market demand is increasingly focused on materials that enable higher energy density, faster charging capabilities, and longer cycle life. Spray-dried NMC (Nickel Manganese Cobalt) cathode materials currently lead the market with approximately 43% share, followed by LFP (Lithium Iron Phosphate) at 31%. The remaining market is divided among various chemistries including NCA, LMNO, and emerging silicon-based anode materials.

Price sensitivity varies significantly across application segments. While automotive manufacturers prioritize cost reduction to achieve price parity with internal combustion engines, premium consumer electronics and specialized industrial applications demonstrate greater willingness to pay for performance advantages. The average selling price for spray-dried NMC cathode materials has decreased by 8.3% annually over the past five years, reflecting both manufacturing efficiencies and competitive pressures.

Supply chain resilience has emerged as a critical market factor following recent global disruptions. Battery manufacturers are increasingly valuing suppliers who can demonstrate ingredient stability throughout the spray drying process, as this directly impacts production consistency and final product performance. Market research indicates that manufacturers are willing to pay a 5-12% premium for materials with proven stability characteristics and consistent particle morphology.

Asia-Pacific dominates the market landscape, accounting for over 65% of global production capacity. This regional concentration is primarily due to the established battery manufacturing ecosystems in China, South Korea, and Japan. North America and Europe are rapidly expanding their market shares, with substantial investments in domestic battery supply chains to reduce dependency on Asian imports.

Consumer electronics historically represented the largest application segment for spray-dried battery materials, but automotive applications have overtaken this position since 2021. The automotive sector now consumes nearly 52% of spray-dried battery materials, followed by consumer electronics (27%), grid storage systems (14%), and industrial applications (7%).

Market demand is increasingly focused on materials that enable higher energy density, faster charging capabilities, and longer cycle life. Spray-dried NMC (Nickel Manganese Cobalt) cathode materials currently lead the market with approximately 43% share, followed by LFP (Lithium Iron Phosphate) at 31%. The remaining market is divided among various chemistries including NCA, LMNO, and emerging silicon-based anode materials.

Price sensitivity varies significantly across application segments. While automotive manufacturers prioritize cost reduction to achieve price parity with internal combustion engines, premium consumer electronics and specialized industrial applications demonstrate greater willingness to pay for performance advantages. The average selling price for spray-dried NMC cathode materials has decreased by 8.3% annually over the past five years, reflecting both manufacturing efficiencies and competitive pressures.

Supply chain resilience has emerged as a critical market factor following recent global disruptions. Battery manufacturers are increasingly valuing suppliers who can demonstrate ingredient stability throughout the spray drying process, as this directly impacts production consistency and final product performance. Market research indicates that manufacturers are willing to pay a 5-12% premium for materials with proven stability characteristics and consistent particle morphology.

Current Challenges in Spray Drying Stability

Spray drying technology in battery manufacturing faces significant stability challenges that impact both process efficiency and final product quality. The primary concern revolves around maintaining the chemical and physical integrity of active materials and additives during the high-temperature drying process. Temperature sensitivity of lithium-ion battery materials, particularly cathode active materials like NMC (Nickel Manganese Cobalt oxide) and NCA (Nickel Cobalt Aluminum oxide), presents a major hurdle as these compounds can undergo phase transformations or surface reactions when exposed to elevated temperatures.

Moisture control represents another critical challenge, as residual moisture content significantly affects electrode performance. Insufficient drying leads to poor adhesion between active materials and current collectors, while excessive drying may cause material degradation or undesirable side reactions. The industry currently lacks standardized protocols for moisture content optimization across different battery chemistries.

Particle agglomeration during spray drying disrupts the homogeneous distribution of active materials and conductive additives, resulting in inconsistent electrode performance. This phenomenon is particularly problematic for high-nickel cathode materials, which demonstrate increased tendency to form agglomerates under typical spray drying conditions, compromising the electrochemical performance of the final battery cells.

Oxidation sensitivity of certain battery components, especially silicon-based anode materials and lithium metal compounds, presents additional complications. These materials readily react with oxygen at elevated temperatures, necessitating inert processing environments that add complexity and cost to manufacturing operations.

Binder degradation constitutes another significant challenge, as polymeric binders like PVDF (polyvinylidene fluoride) and CMC (carboxymethyl cellulose) can undergo thermal decomposition during spray drying. This degradation weakens the mechanical integrity of electrodes and increases internal resistance, ultimately reducing battery capacity and cycle life.

The stability of functional additives, including conductive carbon, flame retardants, and electrolyte modifiers, remains problematic during spray drying. These additives often possess different thermal properties compared to active materials, resulting in non-uniform drying behavior and potential segregation within the electrode structure.

Scale-up challenges further complicate stability issues, as parameters optimized at laboratory scale frequently fail to translate effectively to industrial production. Variations in drying kinetics across larger batch sizes lead to inconsistent material properties, creating significant hurdles for quality control and process validation in commercial manufacturing environments.

Moisture control represents another critical challenge, as residual moisture content significantly affects electrode performance. Insufficient drying leads to poor adhesion between active materials and current collectors, while excessive drying may cause material degradation or undesirable side reactions. The industry currently lacks standardized protocols for moisture content optimization across different battery chemistries.

Particle agglomeration during spray drying disrupts the homogeneous distribution of active materials and conductive additives, resulting in inconsistent electrode performance. This phenomenon is particularly problematic for high-nickel cathode materials, which demonstrate increased tendency to form agglomerates under typical spray drying conditions, compromising the electrochemical performance of the final battery cells.

Oxidation sensitivity of certain battery components, especially silicon-based anode materials and lithium metal compounds, presents additional complications. These materials readily react with oxygen at elevated temperatures, necessitating inert processing environments that add complexity and cost to manufacturing operations.

Binder degradation constitutes another significant challenge, as polymeric binders like PVDF (polyvinylidene fluoride) and CMC (carboxymethyl cellulose) can undergo thermal decomposition during spray drying. This degradation weakens the mechanical integrity of electrodes and increases internal resistance, ultimately reducing battery capacity and cycle life.

The stability of functional additives, including conductive carbon, flame retardants, and electrolyte modifiers, remains problematic during spray drying. These additives often possess different thermal properties compared to active materials, resulting in non-uniform drying behavior and potential segregation within the electrode structure.

Scale-up challenges further complicate stability issues, as parameters optimized at laboratory scale frequently fail to translate effectively to industrial production. Variations in drying kinetics across larger batch sizes lead to inconsistent material properties, creating significant hurdles for quality control and process validation in commercial manufacturing environments.

Current Ingredient Stabilization Techniques

01 Temperature control methods for ingredient stability

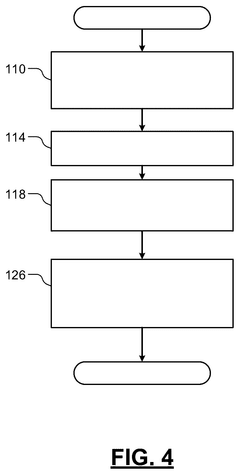

Controlling temperature during spray drying is crucial for maintaining the stability of sensitive ingredients. Lower inlet temperatures and optimized drying profiles can prevent degradation of heat-sensitive compounds. Advanced temperature monitoring systems and multi-stage drying processes help maintain ingredient integrity by minimizing thermal stress while ensuring proper moisture removal.- Temperature control strategies for ingredient stability: Controlling temperature during spray drying is crucial for maintaining ingredient stability. Lower inlet temperatures can be used for heat-sensitive compounds, while optimized temperature profiles throughout the drying process can minimize degradation. Implementing multi-stage drying with carefully controlled temperature zones helps preserve the functional properties of sensitive ingredients. These temperature management strategies are particularly important for bioactive compounds, enzymes, and vitamins that are prone to thermal degradation.

- Encapsulation techniques for protecting sensitive ingredients: Encapsulation methods can significantly enhance ingredient stability during spray drying. By creating protective matrices around sensitive compounds using materials like maltodextrins, gums, proteins, or modified starches, degradation from heat, oxygen, and moisture can be reduced. Core-shell structures provide physical barriers that shield active ingredients from processing conditions. These techniques are particularly valuable for flavors, essential oils, probiotics, and pharmaceutical actives, resulting in improved shelf life and controlled release properties in the final product.

- Formulation additives to enhance stability: Specific additives can be incorporated into spray drying formulations to enhance ingredient stability. Antioxidants prevent oxidative degradation of sensitive compounds, while pH buffers maintain optimal conditions for ingredient functionality. Carrier materials with high glass transition temperatures improve powder stability by reducing stickiness and agglomeration. Certain polymers and sugars act as protective agents by forming amorphous matrices around active ingredients. These formulation strategies help maintain the integrity of bioactive compounds throughout the spray drying process and during subsequent storage.

- Process parameter optimization for improved stability: Optimizing spray drying process parameters beyond temperature control is essential for ingredient stability. Adjusting atomization techniques (pressure, ultrasonic, or rotary) affects droplet size and drying kinetics. Feed concentration, flow rate, and nozzle design influence residence time and heat exposure. Controlling the drying chamber atmosphere, such as using inert gases or reduced oxygen environments, can prevent oxidation of sensitive ingredients. These parameter optimizations must be tailored to specific ingredient characteristics to minimize degradation while maintaining process efficiency.

- Post-drying handling and storage considerations: Proper handling and storage after spray drying significantly impact long-term ingredient stability. Immediate cooling of dried powders prevents continued thermal degradation, while appropriate packaging materials and conditions (modified atmosphere, moisture barriers) protect against environmental factors. Controlled humidity environments during powder collection and packaging prevent moisture absorption and subsequent degradation. For highly sensitive ingredients, additional stabilization treatments may be applied post-drying. These considerations ensure that the stability achieved during spray drying is maintained throughout the product's shelf life.

02 Encapsulation techniques for protecting active ingredients

Encapsulation methods provide protective barriers around sensitive ingredients during spray drying. Coating materials such as polysaccharides, proteins, or lipids shield active compounds from oxidation, heat degradation, and moisture. These techniques can significantly improve the stability and shelf life of volatile or reactive ingredients while maintaining their functional properties after reconstitution.Expand Specific Solutions03 Carrier material selection for enhanced stability

The choice of carrier materials significantly impacts ingredient stability during spray drying. Materials like maltodextrin, gum arabic, modified starches, and cyclodextrins can form protective matrices around sensitive compounds. These carriers influence glass transition temperature, particle morphology, and hygroscopicity, thereby enhancing the physical and chemical stability of the final powder.Expand Specific Solutions04 Atomization and particle engineering strategies

Advanced atomization techniques and particle engineering strategies improve ingredient stability by controlling droplet size, distribution, and drying kinetics. Ultrasonic atomization, pressure nozzles, and rotary atomizers create optimal particle morphologies that protect sensitive components. These approaches minimize surface area exposure to heat and oxygen while creating uniform particles with enhanced flowability and reconstitution properties.Expand Specific Solutions05 Antioxidant and stabilizer addition

Incorporating antioxidants and stabilizers into spray drying formulations significantly enhances ingredient stability. Compounds such as ascorbic acid, tocopherols, citric acid, and specialized enzyme stabilizers protect against oxidation and degradation during processing and storage. These additives can be integrated directly into the feed solution or applied as post-drying treatments to preserve the functional and nutritional properties of sensitive ingredients.Expand Specific Solutions

Leading Companies in Battery Spray Drying Equipment

Spray drying technology in battery manufacturing is currently in a growth phase, with increasing adoption due to its ability to enhance ingredient stability. The global market is expanding rapidly, driven by the electric vehicle boom and energy storage demands, estimated to reach significant scale by 2030. From a technical maturity perspective, industry leaders like LG Energy Solution, Samsung SDI, and Xiamen Hithium are advancing the technology through R&D investments, while companies such as Foshan Defang Nano Technology and Qujing Defang Nanotechnology are developing specialized nano-materials optimized for spray drying processes. Applied Materials and Tokyo Electron are contributing equipment innovations, creating a competitive landscape where technological differentiation is becoming increasingly important for market positioning.

LG Energy Solution Ltd.

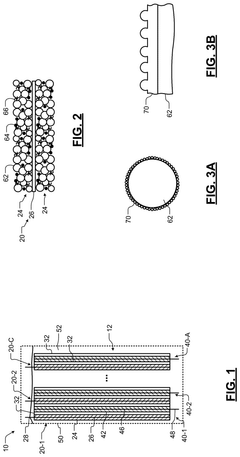

Technical Solution: LG Energy Solution has developed an advanced spray drying technology specifically for lithium-ion battery cathode materials manufacturing. Their process utilizes a multi-stage atomization system that creates uniform droplet sizes between 10-50μm, ensuring consistent particle morphology. The company employs precise temperature control mechanisms (150-400°C) during the drying process to maintain the chemical stability of active materials while removing solvents. Their proprietary binder systems are designed to withstand high-temperature processing without degradation, preserving the electrochemical properties of cathode materials. LG's spray drying technology incorporates real-time monitoring systems that adjust processing parameters based on material feed characteristics, humidity levels, and temperature fluctuations to maintain ingredient stability throughout the manufacturing process.

Strengths: Superior particle size distribution control leading to higher electrode density and improved battery capacity; integrated quality control systems that reduce batch-to-batch variations. Weaknesses: Higher capital investment requirements compared to conventional drying methods; energy-intensive process that increases production costs.

Shenzhen Hairun New Energy Technology Co. Ltd.

Technical Solution: Shenzhen Hairun has pioneered a specialized spray drying technology for battery electrode materials that focuses on preserving the chemical integrity of active ingredients. Their system employs a low-oxygen environment (<50ppm) during the atomization and drying phases to prevent oxidation of sensitive electrode components. The company's process utilizes ultrasonic atomization technology that produces fine droplets (5-30μm) without subjecting materials to high mechanical stress. Their multi-zone drying chamber design creates a controlled temperature gradient (120-350°C) that gradually removes moisture while minimizing thermal shock to particles. Hairun's technology incorporates specialized additives during the slurry preparation phase that act as protective agents during the drying process, forming temporary shells around active material particles that dissipate during subsequent processing steps.

Strengths: Exceptional preservation of electrochemical properties through controlled atmosphere processing; reduced agglomeration of particles leading to more uniform electrode coatings. Weaknesses: Lower throughput compared to conventional spray drying systems; requires specialized handling of inert gases increasing operational complexity.

Key Patents in Spray Drying Stability Enhancement

Method for coating cathode active material with alkali-doped alumina using spray drying

PatentPendingUS20250183286A1

Innovation

- A spray drying, water-based coating method using an alkali-doped alumina coating is applied to cathode active material particles, selected from various materials like lithium- and manganese-rich (LMR) or lithium nickel manganese cobalt oxide (NMC), to enhance their performance.

Method for producing extended-release preparation composition

PatentWO2010004730A1

Innovation

- The method involves spray-drying a composition containing an active ingredient, a resin component, and a solvent using a spray dryer while controlling the outlet temperature to maintain low solvent content and prevent active ingredient decomposition, specifically using a styrene-maleic anhydride copolymer and hydrophobic silica with an outlet temperature between 56°C and 64°C.

Environmental Impact Assessment

The environmental footprint of spray drying processes in battery manufacturing requires comprehensive assessment due to its significant energy consumption and potential emissions. The process typically operates at temperatures between 100-200°C, consuming substantial electrical energy that contributes to greenhouse gas emissions when powered by non-renewable sources. Studies indicate that spray drying operations can account for 15-25% of the total energy consumption in battery material production facilities.

Water usage presents another critical environmental concern, as spray drying systems require substantial quantities for both the slurry preparation and cooling operations. Although much of this water can be recycled within closed-loop systems, there remains inevitable loss through evaporation and discharge of contaminated wastewater containing trace amounts of battery materials including heavy metals and solvents.

Airborne emissions from spray drying operations primarily consist of particulate matter containing battery material components. These emissions necessitate sophisticated filtration systems to prevent the release of potentially harmful substances into the atmosphere. Modern spray drying facilities typically employ cyclone separators, bag filters, and electrostatic precipitators, achieving particulate removal efficiencies of 98-99.5%.

Waste generation represents another significant environmental impact factor. Material losses during spray drying can range from 2-8% of total throughput, creating solid waste streams that require proper handling and disposal. These wastes often contain valuable materials like lithium, cobalt, and nickel compounds that present both environmental hazards and resource recovery opportunities.

Life cycle assessment (LCA) studies comparing spray drying to alternative processing methods reveal mixed results. While spray drying consumes more energy than some alternative techniques, it often yields superior material properties that enhance battery performance and longevity, potentially offsetting initial environmental impacts through extended product life cycles.

Regulatory frameworks governing spray drying operations vary significantly across regions, with the European Union's Industrial Emissions Directive and the United States EPA's air quality standards imposing increasingly stringent requirements on particulate emissions and energy efficiency. Manufacturers must navigate these evolving regulations while balancing production requirements and environmental responsibility.

Technological innovations are gradually improving the environmental profile of spray drying operations. Recent developments include heat recovery systems that can recapture up to 30% of thermal energy, water recycling technologies that reduce freshwater consumption by 40-60%, and advanced process control systems that optimize drying parameters to minimize energy use while maintaining ingredient stability.

Water usage presents another critical environmental concern, as spray drying systems require substantial quantities for both the slurry preparation and cooling operations. Although much of this water can be recycled within closed-loop systems, there remains inevitable loss through evaporation and discharge of contaminated wastewater containing trace amounts of battery materials including heavy metals and solvents.

Airborne emissions from spray drying operations primarily consist of particulate matter containing battery material components. These emissions necessitate sophisticated filtration systems to prevent the release of potentially harmful substances into the atmosphere. Modern spray drying facilities typically employ cyclone separators, bag filters, and electrostatic precipitators, achieving particulate removal efficiencies of 98-99.5%.

Waste generation represents another significant environmental impact factor. Material losses during spray drying can range from 2-8% of total throughput, creating solid waste streams that require proper handling and disposal. These wastes often contain valuable materials like lithium, cobalt, and nickel compounds that present both environmental hazards and resource recovery opportunities.

Life cycle assessment (LCA) studies comparing spray drying to alternative processing methods reveal mixed results. While spray drying consumes more energy than some alternative techniques, it often yields superior material properties that enhance battery performance and longevity, potentially offsetting initial environmental impacts through extended product life cycles.

Regulatory frameworks governing spray drying operations vary significantly across regions, with the European Union's Industrial Emissions Directive and the United States EPA's air quality standards imposing increasingly stringent requirements on particulate emissions and energy efficiency. Manufacturers must navigate these evolving regulations while balancing production requirements and environmental responsibility.

Technological innovations are gradually improving the environmental profile of spray drying operations. Recent developments include heat recovery systems that can recapture up to 30% of thermal energy, water recycling technologies that reduce freshwater consumption by 40-60%, and advanced process control systems that optimize drying parameters to minimize energy use while maintaining ingredient stability.

Quality Control Protocols

Quality control protocols in spray drying processes for battery manufacturing require systematic approaches to ensure ingredient stability throughout the production cycle. These protocols typically begin with raw material verification, where incoming materials undergo rigorous testing for purity, particle size distribution, and chemical composition. Advanced analytical techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and inductively coupled plasma mass spectrometry (ICP-MS) are employed to detect impurities that could compromise the stability of active materials during spray drying.

In-process monitoring represents a critical component of quality control, involving real-time measurement of spray drying parameters including inlet/outlet temperatures, atomization pressure, feed rate, and chamber humidity. Modern facilities implement Process Analytical Technology (PAT) systems that utilize near-infrared spectroscopy (NIR) or Raman spectroscopy for continuous monitoring of material properties during processing. These systems can detect deviations in crystallinity, hydration state, or chemical composition that might indicate degradation of temperature-sensitive battery ingredients.

Statistical process control (SPC) methodologies are increasingly integrated into spray drying operations, establishing control limits for critical parameters and enabling early intervention when processes drift toward out-of-specification conditions. Implementation of Design of Experiments (DoE) approaches helps manufacturers identify optimal processing windows that maintain ingredient stability while maximizing throughput and energy efficiency.

Post-production testing protocols focus on evaluating the stability of spray-dried battery materials through accelerated aging studies, thermal analysis, and electrochemical performance testing. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) provide insights into thermal stability and decomposition behavior, while cyclic voltammetry and impedance spectroscopy assess electrochemical performance and degradation mechanisms.

Documentation and traceability systems form the backbone of effective quality control, with batch records capturing all processing parameters, test results, and deviations. Advanced manufacturing execution systems (MES) enable complete digital traceability from raw materials to finished products, facilitating root cause analysis when stability issues arise. These systems also support compliance with industry standards such as ISO 9001, IATF 16949 for automotive applications, and emerging battery-specific standards.

Continuous improvement methodologies like Six Sigma and lean manufacturing principles are increasingly applied to spray drying operations, driving ongoing refinement of quality control protocols. Regular review of stability data, coupled with failure mode and effects analysis (FMEA), helps manufacturers anticipate potential stability challenges and implement preventive measures before production issues occur.

In-process monitoring represents a critical component of quality control, involving real-time measurement of spray drying parameters including inlet/outlet temperatures, atomization pressure, feed rate, and chamber humidity. Modern facilities implement Process Analytical Technology (PAT) systems that utilize near-infrared spectroscopy (NIR) or Raman spectroscopy for continuous monitoring of material properties during processing. These systems can detect deviations in crystallinity, hydration state, or chemical composition that might indicate degradation of temperature-sensitive battery ingredients.

Statistical process control (SPC) methodologies are increasingly integrated into spray drying operations, establishing control limits for critical parameters and enabling early intervention when processes drift toward out-of-specification conditions. Implementation of Design of Experiments (DoE) approaches helps manufacturers identify optimal processing windows that maintain ingredient stability while maximizing throughput and energy efficiency.

Post-production testing protocols focus on evaluating the stability of spray-dried battery materials through accelerated aging studies, thermal analysis, and electrochemical performance testing. Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) provide insights into thermal stability and decomposition behavior, while cyclic voltammetry and impedance spectroscopy assess electrochemical performance and degradation mechanisms.

Documentation and traceability systems form the backbone of effective quality control, with batch records capturing all processing parameters, test results, and deviations. Advanced manufacturing execution systems (MES) enable complete digital traceability from raw materials to finished products, facilitating root cause analysis when stability issues arise. These systems also support compliance with industry standards such as ISO 9001, IATF 16949 for automotive applications, and emerging battery-specific standards.

Continuous improvement methodologies like Six Sigma and lean manufacturing principles are increasingly applied to spray drying operations, driving ongoing refinement of quality control protocols. Regular review of stability data, coupled with failure mode and effects analysis (FMEA), helps manufacturers anticipate potential stability challenges and implement preventive measures before production issues occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!