Spray Drying Techniques in Adhesives: A Technical Exploration

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Adhesives Background and Objectives

Spray drying technology in adhesive manufacturing represents a significant advancement in the evolution of bonding materials. Originating in the early 20th century primarily for food and pharmaceutical applications, this technology has gradually transitioned into adhesive production over the past four decades. The technique involves atomizing a liquid adhesive formulation into fine droplets and rapidly drying them in a hot gas stream to form powder particles, offering unique advantages in storage, handling, and application compared to traditional liquid adhesives.

The historical progression of spray drying in adhesives has been marked by continuous refinement in equipment design, process control, and formulation science. Initially limited by energy efficiency concerns and inconsistent particle characteristics, modern spray drying systems now incorporate sophisticated atomization mechanisms, precise temperature control, and advanced cyclone collection systems that have dramatically improved product quality and process efficiency.

Current technological trends in spray dried adhesives focus on developing environmentally sustainable formulations with reduced volatile organic compounds (VOCs), enhanced biodegradability, and lower energy consumption during both production and application. The industry is witnessing a shift toward water-based systems that can be spray dried effectively while maintaining performance characteristics comparable to solvent-based alternatives.

The primary technical objectives of this exploration are multifaceted. First, we aim to comprehensively evaluate existing spray drying technologies specifically optimized for adhesive applications, identifying key process parameters that influence final product characteristics. Second, we seek to analyze the relationship between spray drying conditions and critical adhesive properties such as bond strength, open time, and shelf stability.

Additionally, this research intends to investigate novel formulation approaches that enhance the spray drying efficiency of adhesive compounds while preserving or improving their functional properties. This includes examining the role of various additives, polymers, and stabilizers in facilitating the spray drying process and their impact on the final adhesive performance.

Furthermore, we aim to assess the scalability challenges associated with spray dried adhesive production, identifying potential bottlenecks in technology transfer from laboratory to industrial scale. This includes evaluation of equipment requirements, process economics, and quality control methodologies necessary for consistent commercial production.

The ultimate goal is to establish a comprehensive technical foundation that guides future innovation in spray dried adhesive technology, enabling the development of next-generation products with superior performance characteristics, reduced environmental impact, and broader application potential across diverse industrial sectors.

The historical progression of spray drying in adhesives has been marked by continuous refinement in equipment design, process control, and formulation science. Initially limited by energy efficiency concerns and inconsistent particle characteristics, modern spray drying systems now incorporate sophisticated atomization mechanisms, precise temperature control, and advanced cyclone collection systems that have dramatically improved product quality and process efficiency.

Current technological trends in spray dried adhesives focus on developing environmentally sustainable formulations with reduced volatile organic compounds (VOCs), enhanced biodegradability, and lower energy consumption during both production and application. The industry is witnessing a shift toward water-based systems that can be spray dried effectively while maintaining performance characteristics comparable to solvent-based alternatives.

The primary technical objectives of this exploration are multifaceted. First, we aim to comprehensively evaluate existing spray drying technologies specifically optimized for adhesive applications, identifying key process parameters that influence final product characteristics. Second, we seek to analyze the relationship between spray drying conditions and critical adhesive properties such as bond strength, open time, and shelf stability.

Additionally, this research intends to investigate novel formulation approaches that enhance the spray drying efficiency of adhesive compounds while preserving or improving their functional properties. This includes examining the role of various additives, polymers, and stabilizers in facilitating the spray drying process and their impact on the final adhesive performance.

Furthermore, we aim to assess the scalability challenges associated with spray dried adhesive production, identifying potential bottlenecks in technology transfer from laboratory to industrial scale. This includes evaluation of equipment requirements, process economics, and quality control methodologies necessary for consistent commercial production.

The ultimate goal is to establish a comprehensive technical foundation that guides future innovation in spray dried adhesive technology, enabling the development of next-generation products with superior performance characteristics, reduced environmental impact, and broader application potential across diverse industrial sectors.

Market Analysis for Spray-Dried Adhesive Products

The global market for spray-dried adhesives has been experiencing significant growth, driven by increasing demand across multiple industries including construction, packaging, automotive, and consumer goods. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 5.7% through 2028. This growth trajectory is supported by the superior performance characteristics of spray-dried adhesive products, including extended shelf life, improved handling properties, and reduced transportation costs compared to liquid alternatives.

The construction sector represents the largest market segment, accounting for roughly 38% of total consumption. This dominance stems from the widespread application of spray-dried adhesives in tile installation, drywall finishing, and concrete modification. The packaging industry follows closely at 27% market share, where these products are valued for their consistent performance in high-speed manufacturing environments and compatibility with automated application systems.

Regional analysis reveals that North America and Europe currently lead market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region is demonstrating the most rapid growth rate at 7.9% annually, driven by expanding construction activities in China and India, alongside growing manufacturing sectors throughout Southeast Asia. Latin America shows promising growth potential, particularly in Brazil and Mexico where industrial modernization efforts are increasing demand for advanced adhesive technologies.

Market segmentation by product type indicates that polyvinyl acetate-based formulations hold the largest share at 42%, followed by polyurethane derivatives at 23% and acrylic-based products at 19%. Specialty formulations designed for specific applications comprise the remaining market share, with bio-based alternatives representing the fastest-growing segment at 11.3% annual growth.

Customer demand patterns are evolving toward environmentally sustainable options, with 67% of industrial purchasers citing environmental considerations as important decision factors. This shift is driving innovation in water-based formulations and bio-sourced raw materials. Additionally, there is increasing demand for spray-dried adhesives with enhanced performance characteristics such as moisture resistance, thermal stability, and faster setting times.

Price sensitivity varies significantly by application sector, with construction and general assembly markets demonstrating higher price elasticity compared to specialized industrial applications where performance characteristics typically outweigh cost considerations. The average price point has increased by 3.2% annually over the past five years, reflecting both raw material cost fluctuations and the trend toward higher-performance formulations.

The construction sector represents the largest market segment, accounting for roughly 38% of total consumption. This dominance stems from the widespread application of spray-dried adhesives in tile installation, drywall finishing, and concrete modification. The packaging industry follows closely at 27% market share, where these products are valued for their consistent performance in high-speed manufacturing environments and compatibility with automated application systems.

Regional analysis reveals that North America and Europe currently lead market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region is demonstrating the most rapid growth rate at 7.9% annually, driven by expanding construction activities in China and India, alongside growing manufacturing sectors throughout Southeast Asia. Latin America shows promising growth potential, particularly in Brazil and Mexico where industrial modernization efforts are increasing demand for advanced adhesive technologies.

Market segmentation by product type indicates that polyvinyl acetate-based formulations hold the largest share at 42%, followed by polyurethane derivatives at 23% and acrylic-based products at 19%. Specialty formulations designed for specific applications comprise the remaining market share, with bio-based alternatives representing the fastest-growing segment at 11.3% annual growth.

Customer demand patterns are evolving toward environmentally sustainable options, with 67% of industrial purchasers citing environmental considerations as important decision factors. This shift is driving innovation in water-based formulations and bio-sourced raw materials. Additionally, there is increasing demand for spray-dried adhesives with enhanced performance characteristics such as moisture resistance, thermal stability, and faster setting times.

Price sensitivity varies significantly by application sector, with construction and general assembly markets demonstrating higher price elasticity compared to specialized industrial applications where performance characteristics typically outweigh cost considerations. The average price point has increased by 3.2% annually over the past five years, reflecting both raw material cost fluctuations and the trend toward higher-performance formulations.

Technical Challenges in Adhesive Spray Drying

Spray drying technology in adhesive manufacturing faces several significant technical challenges that impede optimal performance and widespread adoption. The primary challenge lies in achieving precise control over particle size distribution, which directly impacts the adhesive's final properties. When particles are inconsistently sized, the resulting adhesive may exhibit unpredictable bonding strength, curing times, and shelf stability. This variability creates substantial quality control issues in industrial applications where consistency is paramount.

Temperature management presents another formidable obstacle. The delicate balance between sufficient drying and avoiding thermal degradation of heat-sensitive adhesive components requires sophisticated control systems. Many adhesive formulations contain polymers, resins, or additives that can undergo unwanted chemical changes or degradation when exposed to excessive heat, resulting in diminished performance characteristics or complete product failure.

Feed solution rheology significantly complicates the spray drying process for adhesives. Highly viscous formulations, common in many high-performance adhesives, resist efficient atomization, leading to nozzle clogging, irregular spray patterns, and ultimately inconsistent dried particles. Engineers must carefully formulate solutions that balance viscosity requirements with spray drying processability.

Agglomeration and wall deposition represent persistent operational challenges. The inherently sticky nature of adhesive materials promotes unwanted particle cohesion during the drying process, forming oversized agglomerates that compromise product quality. Similarly, adhesive materials readily adhere to drying chamber walls, reducing yield, creating cleaning difficulties, and potentially contaminating subsequent batches.

Moisture content control remains exceptionally challenging yet critical for adhesive performance. Insufficient drying leaves excess moisture that can compromise shelf stability and bonding strength, while over-drying may render the adhesive brittle or unable to properly activate upon application. This narrow processing window demands precise monitoring and control systems.

Scale-up difficulties present significant barriers to commercial implementation. Laboratory-optimized spray drying parameters often fail to translate directly to production-scale equipment due to differences in heat transfer dynamics, residence time distributions, and atomization characteristics. This necessitates extensive and costly re-optimization during industrial implementation.

Energy efficiency concerns also plague adhesive spray drying operations. The process inherently requires substantial thermal energy input, contributing to high operational costs and environmental impact. This challenge is particularly acute for water-based adhesive formulations that demand significant energy to evaporate their high water content.

These technical challenges collectively necessitate innovative approaches in equipment design, process control strategies, and formulation science to advance spray drying technology for adhesive applications.

Temperature management presents another formidable obstacle. The delicate balance between sufficient drying and avoiding thermal degradation of heat-sensitive adhesive components requires sophisticated control systems. Many adhesive formulations contain polymers, resins, or additives that can undergo unwanted chemical changes or degradation when exposed to excessive heat, resulting in diminished performance characteristics or complete product failure.

Feed solution rheology significantly complicates the spray drying process for adhesives. Highly viscous formulations, common in many high-performance adhesives, resist efficient atomization, leading to nozzle clogging, irregular spray patterns, and ultimately inconsistent dried particles. Engineers must carefully formulate solutions that balance viscosity requirements with spray drying processability.

Agglomeration and wall deposition represent persistent operational challenges. The inherently sticky nature of adhesive materials promotes unwanted particle cohesion during the drying process, forming oversized agglomerates that compromise product quality. Similarly, adhesive materials readily adhere to drying chamber walls, reducing yield, creating cleaning difficulties, and potentially contaminating subsequent batches.

Moisture content control remains exceptionally challenging yet critical for adhesive performance. Insufficient drying leaves excess moisture that can compromise shelf stability and bonding strength, while over-drying may render the adhesive brittle or unable to properly activate upon application. This narrow processing window demands precise monitoring and control systems.

Scale-up difficulties present significant barriers to commercial implementation. Laboratory-optimized spray drying parameters often fail to translate directly to production-scale equipment due to differences in heat transfer dynamics, residence time distributions, and atomization characteristics. This necessitates extensive and costly re-optimization during industrial implementation.

Energy efficiency concerns also plague adhesive spray drying operations. The process inherently requires substantial thermal energy input, contributing to high operational costs and environmental impact. This challenge is particularly acute for water-based adhesive formulations that demand significant energy to evaporate their high water content.

These technical challenges collectively necessitate innovative approaches in equipment design, process control strategies, and formulation science to advance spray drying technology for adhesive applications.

Current Spray Drying Methods for Adhesives

01 Spray drying equipment and apparatus design

Various designs of spray drying equipment and apparatus have been developed to improve efficiency and product quality. These designs include specialized nozzles, atomizers, and chamber configurations that optimize the drying process. Innovations in equipment design focus on enhancing heat transfer, reducing energy consumption, and improving particle formation characteristics during the spray drying process.- Spray drying equipment and apparatus design: Various designs of spray drying equipment and apparatus have been developed to improve efficiency and product quality. These designs include specialized nozzles, atomizers, and chamber configurations that optimize the drying process. Innovations in equipment design focus on enhancing heat transfer, controlling particle size distribution, and reducing energy consumption during the spray drying process.

- Process parameters optimization for spray drying: Optimization of process parameters is crucial for effective spray drying. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. By carefully controlling these variables, manufacturers can achieve desired product characteristics such as particle size, moisture content, and flowability. Advanced control systems enable real-time adjustments to maintain optimal drying conditions throughout the process.

- Formulation techniques for spray-dried products: Specialized formulation techniques have been developed to enhance the properties of spray-dried products. These include the addition of carriers, binders, and stabilizers to improve product stability, solubility, and bioavailability. Formulation strategies may involve the use of excipients to protect sensitive ingredients during the drying process or to modify the release characteristics of the final product.

- Novel applications of spray drying technology: Spray drying technology has been adapted for various novel applications across different industries. These applications include the production of pharmaceutical formulations with enhanced bioavailability, encapsulation of flavors and fragrances, development of specialized food ingredients, and creation of advanced materials with unique properties. The versatility of spray drying enables its use in producing powders with tailored characteristics for specific end-use requirements.

- Sustainable and energy-efficient spray drying methods: Recent innovations focus on developing more sustainable and energy-efficient spray drying methods. These include heat recovery systems, alternative energy sources, and process intensification techniques that reduce the environmental impact of spray drying operations. Advanced designs incorporate features to minimize energy consumption, reduce emissions, and optimize resource utilization while maintaining product quality and production efficiency.

02 Process parameters optimization for spray drying

Optimization of process parameters is crucial for effective spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. Controlling these parameters allows for precise manipulation of particle size, morphology, and moisture content of the final product. Advanced control systems and methodologies have been developed to maintain optimal conditions throughout the drying process.Expand Specific Solutions03 Formulation techniques for spray-dried products

Specialized formulation techniques have been developed to enhance the properties of spray-dried products. These include the addition of carriers, stabilizers, and other excipients that improve flowability, stability, and dissolution characteristics. Formulation strategies are tailored to specific applications, such as pharmaceuticals, food products, or industrial materials, to achieve desired product attributes while maintaining functionality.Expand Specific Solutions04 Energy-efficient spray drying systems

Energy efficiency improvements in spray drying technology focus on heat recovery systems, alternative energy sources, and optimized air flow designs. These innovations reduce operational costs and environmental impact while maintaining product quality. Advanced heat exchanger designs, recirculation systems, and intelligent control algorithms contribute to significant energy savings in modern spray drying operations.Expand Specific Solutions05 Novel applications and specialized spray drying techniques

Novel applications of spray drying include microencapsulation, production of engineered particles with specific properties, and processing of heat-sensitive materials. Specialized techniques such as co-current, counter-current, and mixed-flow drying configurations have been developed for specific product requirements. These advanced applications extend the utility of spray drying beyond conventional drying operations to the creation of functional materials with tailored characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spray drying techniques in adhesives market is currently in a growth phase, characterized by increasing adoption across various industrial applications. The global market size for spray dried adhesives is expanding steadily, driven by demand for improved performance and efficiency in manufacturing processes. From a technical maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Henkel, BASF, and 3M Innovative Properties have established sophisticated spray drying capabilities, while companies such as Bostik and Covestro Deutschland are actively developing proprietary technologies. Chinese players including Sinopec and its Beijing Research Institute are making significant investments to close the technology gap. Academic institutions like Carnegie Mellon University and Zhejiang University are contributing fundamental research, creating a competitive ecosystem where both established corporations and specialized firms like Hovione Farmaciência and ALFA KLEBSTOFFE are driving innovation.

BASF Corp.

Technical Solution: BASF has developed an innovative spray drying platform for adhesive formulations that incorporates their proprietary microencapsulation technology. Their process utilizes specialized two-fluid nozzles operating at precisely controlled pressures (typically 5-15 bar) to create adhesive droplets with tailored morphology. BASF's technology features a multi-stage drying process with carefully controlled temperature profiles (inlet temperatures of 150-200°C and outlet temperatures of 70-90°C) to preserve the functional properties of temperature-sensitive components. The company has engineered spray-dried adhesive powders with core-shell structures where reactive components remain separated until activation, enabling one-component systems with extended shelf life. Their process incorporates in-line particle size analysis and automated feed adjustment systems to maintain consistent product quality throughout production campaigns. BASF has successfully applied this technology to create spray-dried structural adhesives for automotive and aerospace applications, where the powdered format allows precise application to complex geometries before heat activation.

Strengths: Excellent stability of reactive components in powdered form; precise control of particle morphology; ability to create "dormant" adhesive systems activated by specific triggers; reduced waste through targeted application. Weaknesses: Complex process control requirements; higher production costs compared to conventional liquid systems; potential challenges with complete redispersion of highly crosslinked systems.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced spray drying techniques for pressure-sensitive adhesives (PSAs) that involve atomizing adhesive solutions into fine droplets and rapidly drying them in controlled temperature chambers. Their patented technology creates spherical adhesive particles with tailored morphology and controlled particle size distribution (typically 10-100 μm). The process incorporates specialized nozzle designs that enable high-throughput production while maintaining uniform particle characteristics. 3M's spray-dried adhesives feature core-shell structures where functional additives can be encapsulated within the adhesive matrix, allowing for controlled release properties and enhanced performance characteristics. The company has integrated this technology into manufacturing lines capable of producing tons of spray-dried adhesive powders annually, which can be reactivated through heat or pressure application in downstream processes.

Strengths: Superior particle morphology control allowing precise adhesive performance tuning; excellent shelf stability of powdered adhesives; reduced VOC emissions compared to solvent-based systems; ability to create multi-functional adhesive systems through encapsulation. Weaknesses: Higher initial capital investment for spray drying equipment; energy-intensive drying process; potential thermal degradation of heat-sensitive adhesive components during processing.

Key Patents and Technical Innovations

Adhesive composition, method for bonding to a metal surface and rubber to metal adhesive

PatentInactiveAU2005262499A1

Innovation

- A solids dispersion of a nitroso compound, halogenated polyolefin, and inert spheroidal particles in a volatile liquid carrier, with a viscosity of 50-500 cps, is used to create a sprayable adhesive that maintains dry film thickness control and improves bonding performance without solvent dilution.

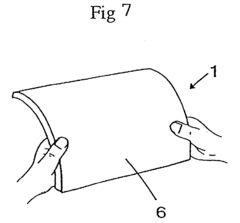

Method to apply a finishing coat onto the surface of a plastic or composite material

PatentInactiveEP1346778A3

Innovation

- A method involving surface pre-treatment, application of a thermosetting adhesive, and subsequent thermal spraying with adjustable temperature and material combinations to enhance adhesion, including degreasing, sanding, applying a thermosetting adhesive, heating it near its gel point, adding a binder, and coating with additional materials like ceramics or metals using various spraying techniques.

Environmental Impact and Sustainability Considerations

The environmental impact of spray drying techniques in adhesive manufacturing has become increasingly significant as industries face growing pressure to adopt sustainable practices. Traditional adhesive production methods often involve volatile organic compounds (VOCs) and high energy consumption, contributing to air pollution and carbon emissions. Spray drying offers several environmental advantages, including reduced solvent usage and more efficient material utilization, potentially decreasing the overall environmental footprint of adhesive production.

Water-based spray dried adhesive systems represent a major advancement in sustainability, eliminating or significantly reducing the need for organic solvents that contribute to air pollution and pose health risks. These systems typically reduce VOC emissions by 70-90% compared to conventional solvent-based adhesives, aligning with increasingly stringent environmental regulations in North America, Europe, and Asia.

Energy consumption remains a critical consideration in spray drying operations. The process requires substantial thermal energy for atomization and drying, with typical industrial spray dryers consuming between 1.2-2.5 kWh per kilogram of water evaporated. Recent technological innovations have focused on heat recovery systems and process optimization, achieving energy efficiency improvements of 15-30% in modern spray drying installations for adhesives.

Waste reduction represents another sustainability advantage of spray drying technology. The process achieves product recovery rates of 95-98%, significantly higher than alternative production methods. Additionally, the precise control over particle characteristics enables manufacturers to optimize material usage and reduce overformulation, further minimizing resource consumption and waste generation.

Life cycle assessment (LCA) studies comparing spray dried adhesives with conventional alternatives demonstrate notable sustainability benefits. Research indicates that spray dried adhesive systems can reduce global warming potential by 30-45% and decrease freshwater ecotoxicity by up to 60% compared to solvent-based alternatives, primarily due to reduced chemical emissions and lower energy requirements during application.

Future sustainability improvements in spray drying technology for adhesives are focusing on several promising directions. These include the development of bio-based raw materials compatible with spray drying processes, advanced energy recovery systems utilizing waste heat, and closed-loop water recycling systems that minimize freshwater consumption. Additionally, emerging technologies like pulsed combustion spray drying and ultrasonic atomization show potential for further reducing energy requirements by 20-35% compared to conventional spray drying methods.

Water-based spray dried adhesive systems represent a major advancement in sustainability, eliminating or significantly reducing the need for organic solvents that contribute to air pollution and pose health risks. These systems typically reduce VOC emissions by 70-90% compared to conventional solvent-based adhesives, aligning with increasingly stringent environmental regulations in North America, Europe, and Asia.

Energy consumption remains a critical consideration in spray drying operations. The process requires substantial thermal energy for atomization and drying, with typical industrial spray dryers consuming between 1.2-2.5 kWh per kilogram of water evaporated. Recent technological innovations have focused on heat recovery systems and process optimization, achieving energy efficiency improvements of 15-30% in modern spray drying installations for adhesives.

Waste reduction represents another sustainability advantage of spray drying technology. The process achieves product recovery rates of 95-98%, significantly higher than alternative production methods. Additionally, the precise control over particle characteristics enables manufacturers to optimize material usage and reduce overformulation, further minimizing resource consumption and waste generation.

Life cycle assessment (LCA) studies comparing spray dried adhesives with conventional alternatives demonstrate notable sustainability benefits. Research indicates that spray dried adhesive systems can reduce global warming potential by 30-45% and decrease freshwater ecotoxicity by up to 60% compared to solvent-based alternatives, primarily due to reduced chemical emissions and lower energy requirements during application.

Future sustainability improvements in spray drying technology for adhesives are focusing on several promising directions. These include the development of bio-based raw materials compatible with spray drying processes, advanced energy recovery systems utilizing waste heat, and closed-loop water recycling systems that minimize freshwater consumption. Additionally, emerging technologies like pulsed combustion spray drying and ultrasonic atomization show potential for further reducing energy requirements by 20-35% compared to conventional spray drying methods.

Quality Control and Performance Testing Methodologies

Quality control and performance testing are critical components in the development and production of spray-dried adhesives. Standardized testing protocols ensure consistent product quality and reliable performance across various applications. The adhesive industry employs several key methodologies to evaluate spray-dried adhesive formulations throughout the production cycle.

Rheological testing serves as a fundamental quality control measure, assessing viscosity, flow behavior, and structural stability of adhesive formulations before and after spray drying. These properties directly influence application characteristics and final bond strength. Advanced rheometers capable of measuring complex viscoelastic properties under varying temperature and shear conditions provide comprehensive data for quality assurance.

Particle size distribution analysis represents another essential testing methodology, typically conducted using laser diffraction or dynamic light scattering techniques. The uniformity and specific size range of spray-dried adhesive particles significantly impact dissolution rates, storage stability, and application performance. Modern analytical instruments can detect particle size variations with precision down to submicron levels, enabling tight quality control parameters.

Moisture content determination through thermogravimetric analysis or Karl Fischer titration ensures spray-dried adhesives maintain optimal moisture levels. Excessive moisture can compromise shelf stability and bonding performance, while insufficient moisture may affect reconstitution properties. Establishing acceptable moisture content ranges specific to each adhesive formulation is crucial for consistent product quality.

Bond strength testing methodologies include lap shear, peel, and tensile tests conducted under standardized conditions. These tests evaluate the fundamental performance characteristics of spray-dried adhesives after reconstitution and application. Environmental conditioning chambers allow for performance assessment under various temperature and humidity conditions, simulating real-world application environments.

Accelerated aging protocols provide insights into long-term stability and performance. Exposing spray-dried adhesives to elevated temperatures, humidity cycles, and UV radiation helps predict shelf life and identify potential degradation mechanisms. Correlation studies between accelerated aging results and real-time stability data establish reliable predictive models for quality assurance purposes.

Spectroscopic techniques, including FTIR and Raman spectroscopy, enable chemical composition verification and detection of potential contaminants or degradation products. These non-destructive analytical methods can be integrated into production lines for real-time quality monitoring, allowing immediate corrective actions when deviations occur.

Statistical process control methodologies applied to these testing protocols establish control limits and identify trends before they result in quality issues. Advanced data analytics incorporating machine learning algorithms can detect subtle patterns in quality parameters, enabling predictive quality management rather than reactive approaches.

Rheological testing serves as a fundamental quality control measure, assessing viscosity, flow behavior, and structural stability of adhesive formulations before and after spray drying. These properties directly influence application characteristics and final bond strength. Advanced rheometers capable of measuring complex viscoelastic properties under varying temperature and shear conditions provide comprehensive data for quality assurance.

Particle size distribution analysis represents another essential testing methodology, typically conducted using laser diffraction or dynamic light scattering techniques. The uniformity and specific size range of spray-dried adhesive particles significantly impact dissolution rates, storage stability, and application performance. Modern analytical instruments can detect particle size variations with precision down to submicron levels, enabling tight quality control parameters.

Moisture content determination through thermogravimetric analysis or Karl Fischer titration ensures spray-dried adhesives maintain optimal moisture levels. Excessive moisture can compromise shelf stability and bonding performance, while insufficient moisture may affect reconstitution properties. Establishing acceptable moisture content ranges specific to each adhesive formulation is crucial for consistent product quality.

Bond strength testing methodologies include lap shear, peel, and tensile tests conducted under standardized conditions. These tests evaluate the fundamental performance characteristics of spray-dried adhesives after reconstitution and application. Environmental conditioning chambers allow for performance assessment under various temperature and humidity conditions, simulating real-world application environments.

Accelerated aging protocols provide insights into long-term stability and performance. Exposing spray-dried adhesives to elevated temperatures, humidity cycles, and UV radiation helps predict shelf life and identify potential degradation mechanisms. Correlation studies between accelerated aging results and real-time stability data establish reliable predictive models for quality assurance purposes.

Spectroscopic techniques, including FTIR and Raman spectroscopy, enable chemical composition verification and detection of potential contaminants or degradation products. These non-destructive analytical methods can be integrated into production lines for real-time quality monitoring, allowing immediate corrective actions when deviations occur.

Statistical process control methodologies applied to these testing protocols establish control limits and identify trends before they result in quality issues. Advanced data analytics incorporating machine learning algorithms can detect subtle patterns in quality parameters, enabling predictive quality management rather than reactive approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!