Analysis of Spray Drying Methods in Diagnostic Agents Production

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spray Drying Technology Evolution and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century, transforming from a simple dehydration method to a sophisticated process for producing complex particles with specific properties. Initially developed for milk powder production in 1872, spray drying has undergone substantial refinements in atomization techniques, drying chamber designs, and process control systems. The 1950s marked a pivotal era with the introduction of centrifugal atomizers, enabling more uniform particle size distribution. By the 1980s, computational fluid dynamics modeling revolutionized spray dryer design, optimizing airflow patterns and thermal efficiency.

In diagnostic agent production, spray drying technology has become increasingly critical due to its ability to create particles with precise morphological characteristics and physicochemical properties. The evolution of this technology in diagnostic applications can be traced to the 1990s when pharmaceutical companies began exploring its potential for creating inhalable diagnostic formulations. Subsequent advancements in nozzle technology, particularly the development of multi-fluid nozzles and ultrasonic atomizers, have enabled the production of particles with narrower size distributions and enhanced aerodynamic properties.

Recent technological developments have focused on process intensification and quality-by-design approaches. The integration of PAT (Process Analytical Technology) tools has enabled real-time monitoring and control of critical process parameters, ensuring consistent product quality. Advanced spray drying systems now incorporate sophisticated feedback control mechanisms that adjust operating conditions based on continuous measurements of particle characteristics, moisture content, and other quality attributes.

The primary objective of modern spray drying technology in diagnostic agent production is to achieve precise control over particle engineering. This includes tailoring particle size distribution, morphology, density, and surface properties to enhance diagnostic performance. For contrast agents and molecular imaging probes, spray drying aims to produce particles with optimal stability, bioavailability, and target specificity. Additionally, the technology seeks to improve encapsulation efficiency of sensitive diagnostic molecules while maintaining their biological activity throughout the drying process.

Another critical objective is scalability and process robustness. As diagnostic agents move from research to commercial production, spray drying processes must demonstrate consistent performance across different scales while maintaining product quality. This necessitates the development of predictive models and scale-up methodologies specific to diagnostic formulations. Furthermore, regulatory considerations drive objectives related to process validation, reproducibility, and compliance with GMP standards applicable to diagnostic products.

Environmental sustainability represents an emerging objective in spray drying technology development. Innovations aim to reduce energy consumption, minimize waste generation, and incorporate green solvents in the production of diagnostic agents. These advancements align with broader industry trends toward sustainable manufacturing practices while maintaining the high-quality standards essential for diagnostic applications.

In diagnostic agent production, spray drying technology has become increasingly critical due to its ability to create particles with precise morphological characteristics and physicochemical properties. The evolution of this technology in diagnostic applications can be traced to the 1990s when pharmaceutical companies began exploring its potential for creating inhalable diagnostic formulations. Subsequent advancements in nozzle technology, particularly the development of multi-fluid nozzles and ultrasonic atomizers, have enabled the production of particles with narrower size distributions and enhanced aerodynamic properties.

Recent technological developments have focused on process intensification and quality-by-design approaches. The integration of PAT (Process Analytical Technology) tools has enabled real-time monitoring and control of critical process parameters, ensuring consistent product quality. Advanced spray drying systems now incorporate sophisticated feedback control mechanisms that adjust operating conditions based on continuous measurements of particle characteristics, moisture content, and other quality attributes.

The primary objective of modern spray drying technology in diagnostic agent production is to achieve precise control over particle engineering. This includes tailoring particle size distribution, morphology, density, and surface properties to enhance diagnostic performance. For contrast agents and molecular imaging probes, spray drying aims to produce particles with optimal stability, bioavailability, and target specificity. Additionally, the technology seeks to improve encapsulation efficiency of sensitive diagnostic molecules while maintaining their biological activity throughout the drying process.

Another critical objective is scalability and process robustness. As diagnostic agents move from research to commercial production, spray drying processes must demonstrate consistent performance across different scales while maintaining product quality. This necessitates the development of predictive models and scale-up methodologies specific to diagnostic formulations. Furthermore, regulatory considerations drive objectives related to process validation, reproducibility, and compliance with GMP standards applicable to diagnostic products.

Environmental sustainability represents an emerging objective in spray drying technology development. Innovations aim to reduce energy consumption, minimize waste generation, and incorporate green solvents in the production of diagnostic agents. These advancements align with broader industry trends toward sustainable manufacturing practices while maintaining the high-quality standards essential for diagnostic applications.

Market Analysis of Spray-Dried Diagnostic Reagents

The global market for spray-dried diagnostic reagents has experienced significant growth over the past decade, driven by increasing demand for rapid, accurate, and stable diagnostic solutions. Currently valued at approximately 3.2 billion USD, this market segment is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028, outpacing the broader diagnostic reagent market's growth of 5.6%.

North America dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to expanding healthcare infrastructure and increasing adoption of advanced diagnostic technologies. Latin America and Africa remain emerging markets with substantial growth potential as healthcare systems continue to develop.

The clinical diagnostics sector accounts for 65% of spray-dried reagent applications, with immunoassays being the largest sub-segment. Point-of-care testing applications have shown remarkable growth, expanding at 12.3% annually as healthcare delivery increasingly shifts toward decentralized models. Research applications constitute approximately 20% of the market, while industrial and environmental testing applications make up the remaining 15%.

Key market drivers include the increasing prevalence of chronic and infectious diseases, growing demand for rapid diagnostic solutions, and technological advancements in spray drying techniques that enhance reagent stability and performance. The COVID-19 pandemic significantly accelerated market growth, with spray-dried reagents playing a crucial role in rapid test development.

Consumer preferences are shifting toward diagnostic products offering longer shelf life, ambient temperature stability, and reduced logistical requirements – all benefits provided by spray-dried formulations. This trend is particularly pronounced in resource-limited settings where cold chain infrastructure is inadequate.

Market challenges include high initial investment costs for spray drying equipment, regulatory hurdles for novel diagnostic products, and competition from alternative stabilization technologies such as lyophilization. Additionally, environmental concerns regarding energy consumption in spray drying processes are gaining attention.

The competitive landscape features both specialized reagent manufacturers and integrated diagnostic companies. Major players include Roche Diagnostics, Abbott Laboratories, and Thermo Fisher Scientific, which collectively hold approximately 45% market share. However, innovative startups focusing exclusively on advanced spray drying technologies for diagnostics are gaining traction, particularly in specialized application niches.

North America dominates the market with a 42% share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to expanding healthcare infrastructure and increasing adoption of advanced diagnostic technologies. Latin America and Africa remain emerging markets with substantial growth potential as healthcare systems continue to develop.

The clinical diagnostics sector accounts for 65% of spray-dried reagent applications, with immunoassays being the largest sub-segment. Point-of-care testing applications have shown remarkable growth, expanding at 12.3% annually as healthcare delivery increasingly shifts toward decentralized models. Research applications constitute approximately 20% of the market, while industrial and environmental testing applications make up the remaining 15%.

Key market drivers include the increasing prevalence of chronic and infectious diseases, growing demand for rapid diagnostic solutions, and technological advancements in spray drying techniques that enhance reagent stability and performance. The COVID-19 pandemic significantly accelerated market growth, with spray-dried reagents playing a crucial role in rapid test development.

Consumer preferences are shifting toward diagnostic products offering longer shelf life, ambient temperature stability, and reduced logistical requirements – all benefits provided by spray-dried formulations. This trend is particularly pronounced in resource-limited settings where cold chain infrastructure is inadequate.

Market challenges include high initial investment costs for spray drying equipment, regulatory hurdles for novel diagnostic products, and competition from alternative stabilization technologies such as lyophilization. Additionally, environmental concerns regarding energy consumption in spray drying processes are gaining attention.

The competitive landscape features both specialized reagent manufacturers and integrated diagnostic companies. Major players include Roche Diagnostics, Abbott Laboratories, and Thermo Fisher Scientific, which collectively hold approximately 45% market share. However, innovative startups focusing exclusively on advanced spray drying technologies for diagnostics are gaining traction, particularly in specialized application niches.

Current Challenges in Diagnostic Agent Spray Drying

Spray drying technology in diagnostic agent production faces several significant challenges that impede optimal performance and product quality. The foremost challenge is maintaining the biological activity of sensitive diagnostic components during the drying process. The high temperatures typically employed in conventional spray drying (often 100-200°C inlet temperatures) can denature proteins, degrade antibodies, and compromise the functionality of enzymes critical to diagnostic accuracy.

Particle size control represents another major hurdle in diagnostic agent spray drying. Diagnostic applications frequently require precise particle size distributions to ensure consistent flow properties, dissolution rates, and ultimately diagnostic performance. Current spray drying technologies often produce heterogeneous particle populations that necessitate additional processing steps like sieving or milling, increasing production costs and risking product damage.

Scalability issues present significant obstacles when transitioning from laboratory development to commercial production. Parameters optimized at small scales often fail to translate directly to industrial equipment, requiring extensive reformulation and process redesign. This challenge is particularly acute for diagnostic reagents where batch-to-batch consistency is paramount for reliable test results.

Moisture content control remains problematic in spray-dried diagnostic formulations. Residual moisture can accelerate degradation reactions and compromise shelf stability, while excessive drying may damage sensitive components. The narrow acceptable moisture range for many diagnostic agents (typically 1-3%) demands precise process control that current systems struggle to maintain consistently.

Excipient compatibility issues further complicate spray drying of diagnostic agents. Stabilizers, buffers, and other formulation components necessary for diagnostic functionality may interact unpredictably under spray drying conditions, leading to reduced activity or altered performance characteristics. The limited selection of excipients approved for diagnostic applications constrains formulation flexibility.

Cross-contamination risks are heightened in spray drying operations due to product residues in equipment and airborne particle generation. For diagnostic agents, where even trace contamination can lead to false results, this necessitates extensive cleaning validation and dedicated equipment that increases manufacturing costs significantly.

Energy efficiency concerns also plague current spray drying methods for diagnostic agents. The process typically requires substantial energy input for both heating and subsequent cooling, contributing to high production costs and environmental impact. More sustainable approaches are needed, particularly as diagnostic testing volumes continue to increase globally.

Particle size control represents another major hurdle in diagnostic agent spray drying. Diagnostic applications frequently require precise particle size distributions to ensure consistent flow properties, dissolution rates, and ultimately diagnostic performance. Current spray drying technologies often produce heterogeneous particle populations that necessitate additional processing steps like sieving or milling, increasing production costs and risking product damage.

Scalability issues present significant obstacles when transitioning from laboratory development to commercial production. Parameters optimized at small scales often fail to translate directly to industrial equipment, requiring extensive reformulation and process redesign. This challenge is particularly acute for diagnostic reagents where batch-to-batch consistency is paramount for reliable test results.

Moisture content control remains problematic in spray-dried diagnostic formulations. Residual moisture can accelerate degradation reactions and compromise shelf stability, while excessive drying may damage sensitive components. The narrow acceptable moisture range for many diagnostic agents (typically 1-3%) demands precise process control that current systems struggle to maintain consistently.

Excipient compatibility issues further complicate spray drying of diagnostic agents. Stabilizers, buffers, and other formulation components necessary for diagnostic functionality may interact unpredictably under spray drying conditions, leading to reduced activity or altered performance characteristics. The limited selection of excipients approved for diagnostic applications constrains formulation flexibility.

Cross-contamination risks are heightened in spray drying operations due to product residues in equipment and airborne particle generation. For diagnostic agents, where even trace contamination can lead to false results, this necessitates extensive cleaning validation and dedicated equipment that increases manufacturing costs significantly.

Energy efficiency concerns also plague current spray drying methods for diagnostic agents. The process typically requires substantial energy input for both heating and subsequent cooling, contributing to high production costs and environmental impact. More sustainable approaches are needed, particularly as diagnostic testing volumes continue to increase globally.

Contemporary Spray Drying Methodologies

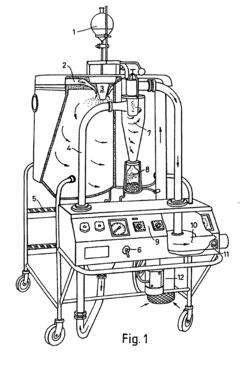

01 Spray drying equipment and apparatus design

Various designs of spray drying equipment and apparatus have been developed to improve efficiency and product quality. These designs include specialized nozzles, chambers, and control systems that optimize the atomization, drying, and collection processes. Innovations in equipment design focus on enhancing heat transfer, reducing energy consumption, and improving the uniformity of dried particles.- Spray drying equipment and apparatus design: Various designs of spray drying equipment and apparatus have been developed to improve efficiency and product quality. These designs include specialized nozzles, chambers, and control systems that optimize the atomization and drying process. Innovations in equipment design focus on enhancing heat transfer, reducing energy consumption, and improving particle formation characteristics during the spray drying process.

- Process parameters optimization for spray drying: Optimization of process parameters is crucial for effective spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. By carefully controlling these variables, manufacturers can achieve desired particle characteristics, moisture content, and product stability. Advanced control systems enable real-time adjustments to maintain optimal drying conditions throughout the process.

- Formulation techniques for spray-dried products: Specific formulation techniques have been developed to enhance the properties of spray-dried products. These include the addition of carriers, stabilizers, and other excipients that improve flowability, stability, and dissolution characteristics. Formulation strategies may involve pre-treatment of feed materials, adjustment of solid content, or incorporation of functional additives to achieve desired product attributes after spray drying.

- Novel applications of spray drying technology: Spray drying technology has expanded beyond traditional applications to include novel uses across various industries. These applications include encapsulation of active ingredients, production of advanced materials, pharmaceutical formulations, and specialty food products. The versatility of spray drying enables the creation of particles with controlled release properties, enhanced bioavailability, or specific functional characteristics tailored to end-use requirements.

- Sustainable and energy-efficient spray drying methods: Advancements in sustainable and energy-efficient spray drying methods focus on reducing environmental impact and operational costs. These innovations include heat recovery systems, alternative energy sources, improved insulation, and process intensification techniques. Modified spray drying approaches may incorporate pulsed flows, multi-stage drying, or hybrid technologies that combine spray drying with other drying methods to optimize resource utilization.

02 Process parameters optimization for spray drying

Optimization of process parameters is crucial for effective spray drying operations. Key parameters include inlet/outlet temperatures, feed rate, atomization pressure, and residence time. By carefully controlling these variables, manufacturers can achieve desired particle characteristics, moisture content, and product stability while minimizing thermal degradation of heat-sensitive materials.Expand Specific Solutions03 Formulation techniques for spray-dried products

Specific formulation techniques have been developed to enhance the properties of spray-dried products. These include the addition of carriers, stabilizers, and other excipients that improve flowability, stability, and dissolution characteristics. Formulation strategies may involve pre-treatment of feed materials, adjustment of solid content, or incorporation of functional additives to achieve desired product attributes.Expand Specific Solutions04 Encapsulation and controlled release applications

Spray drying is widely used for encapsulation of active ingredients to provide protection and controlled release properties. This technique allows for the entrapment of volatile, sensitive compounds within a protective matrix, enhancing stability and shelf-life. Various wall materials and processing conditions can be employed to tailor the release kinetics of the encapsulated substances for specific applications in pharmaceuticals, food, and agriculture.Expand Specific Solutions05 Sustainable and energy-efficient spray drying methods

Innovations in sustainable and energy-efficient spray drying methods focus on reducing environmental impact and operational costs. These approaches include heat recovery systems, alternative energy sources, and process intensification techniques. Advanced control strategies and equipment modifications help minimize energy consumption while maintaining product quality. Some methods incorporate recycling of process streams and reduction of waste materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spray drying technology in diagnostic agents production is currently in a growth phase, with an expanding market driven by increasing demand for advanced diagnostic tools. The global market size is estimated to be significant, with projections showing continued expansion due to healthcare advancements and personalized medicine trends. Technologically, the field demonstrates varying maturity levels across players. Leading companies like Novartis AG, Novo Nordisk A/S, and Lonza Ltd. have established advanced spray drying capabilities with sophisticated formulation expertise. Mid-tier innovators including Hovione Scientia, CyDex Pharmaceuticals, and Aridis Pharmaceuticals are developing specialized applications, while research institutions such as CSIR South Africa and Zhejiang University contribute fundamental research. The competitive landscape is characterized by increasing specialization in niche diagnostic applications and growing integration with pharmaceutical manufacturing processes.

Novartis AG

Technical Solution: Novartis has developed an advanced spray drying platform called PrecisionDry™ for diagnostic agent production. Their technology employs a multi-nozzle array system with pressure-swirl atomizers that creates uniform particles with controlled morphology (typically 2-8μm), essential for diagnostic test consistency. Novartis's approach incorporates a modified drying chamber with optimized temperature zones (inlet temperatures of 100-160°C and outlet temperatures of 45-75°C) that minimize thermal degradation of sensitive diagnostic biomolecules. Their systems feature proprietary formulation technology that integrates protective excipients during the spray drying process, including specialized sugar-based matrices that stabilize proteins and maintain approximately 90-95% of initial activity. Novartis has pioneered the application of Quality by Design (QbD) principles to spray drying, with comprehensive process parameter mapping that identifies critical control points for consistent diagnostic reagent production. Their technology has demonstrated superior storage stability for dried diagnostic components, with typical shelf-life extension of 24-36 months compared to conventional formulations.

Strengths: Extensive pharmaceutical development expertise applied to diagnostic reagent production; sophisticated quality systems and regulatory compliance capabilities; advanced formulation technology for biomolecule stabilization; comprehensive process understanding through QbD implementation. Weaknesses: Primary focus on pharmaceutical applications rather than diagnostics specifically; higher cost structure compared to dedicated diagnostic manufacturers; complex technology requiring specialized expertise.

Hovione Scientia Ltd.

Technical Solution: Hovione has developed a specialized spray drying platform called DiagDry™ specifically engineered for diagnostic reagent production. Their technology employs a proprietary two-fluid nozzle design that creates uniform droplets with controlled morphology, critical for diagnostic test consistency. Hovione's approach incorporates adaptive drying parameters that respond to material properties in real-time, with typical residence times of 2-5 seconds and temperature gradients precisely controlled within ±1.5°C. Their systems feature innovative electrostatic particle collection technology that achieves recovery rates of 92-98% for high-value diagnostic compounds. Hovione has pioneered the integration of specialized excipients during the spray drying process that act as molecular stabilizers, preserving the activity of enzymes and antibodies commonly used in diagnostic applications. Their technology has demonstrated the ability to produce amorphous solid dispersions with enhanced dissolution properties, improving the performance of diagnostic reagents in rapid test formats.

Strengths: Specialized expertise in diagnostic reagent formulation; superior particle engineering capabilities; high recovery rates for valuable materials; demonstrated success in preserving biological activity of sensitive components. Weaknesses: Limited production capacity compared to larger manufacturers; higher cost structure for small-batch production; technology primarily optimized for pharmaceutical rather than purely diagnostic applications.

Key Patents and Technical Innovations

Preparation of diagnostic agents

PatentInactiveEP0681843B2

Innovation

- A process involving the atomization of a protein solution in an aqueous liquid carrier to form hollow microcapsules with 96-98% monomeric protein, where the microcapsules are predominantly 1-8 μm in diameter and produced without reducing the water solubility of the outer layer, using hydrophilic and biodegradable proteins like human serum albumin, and controlled evaporation to ensure hollowness and size consistency.

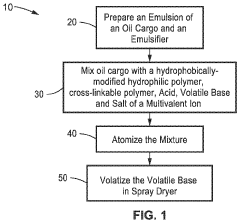

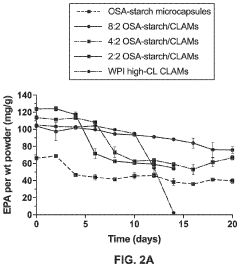

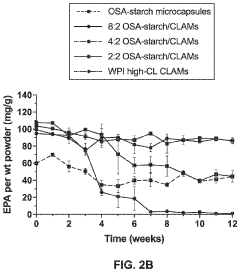

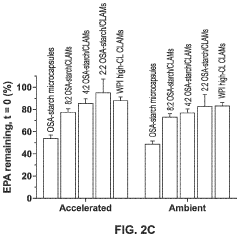

Spray drying methods for encapsulation of oxygen labile cargo in cross-linked polymer microcapsules

PatentInactiveUS20220105487A1

Innovation

- A single-step spray drying method using cross-linked alginate microcapsules with hydrophobically functionalized starch, where in situ internal gelation occurs during spray drying, providing enhanced storage stability and controlled release of cargo through pH control and the use of a volatile base to liberate calcium ions for cross-linking alginate polymers.

Quality Control Standards

Quality control standards in spray drying processes for diagnostic agents production represent a critical framework ensuring consistent product quality, safety, and efficacy. These standards must address multiple dimensions of the manufacturing process, from raw material specifications to final product validation.

The pharmaceutical industry has established rigorous quality control parameters specifically for spray-dried diagnostic agents, including particle size distribution, moisture content, and morphological characteristics. Particle size uniformity typically requires a coefficient of variation below 10%, with size ranges precisely defined based on the diagnostic application. For respiratory diagnostic agents, particles between 1-5 μm are generally targeted, while for injectable diagnostics, narrower distributions around 1-3 μm are essential.

Residual moisture content represents another critical quality parameter, with most specifications requiring levels below 2% to ensure product stability and prevent microbial contamination. Advanced analytical techniques including Karl Fischer titration and thermogravimetric analysis are employed for precise moisture determination, with validation protocols requiring measurement accuracy within ±0.2%.

Morphological characteristics of spray-dried particles are evaluated using scanning electron microscopy and laser diffraction techniques. Quality standards typically specify sphericity indices exceeding 0.85 for optimal flow properties and consistent dissolution profiles. Surface roughness parameters are quantified using atomic force microscopy, with acceptable roughness values defined based on the specific diagnostic application.

Process validation protocols for spray drying of diagnostic agents follow ICH Q8, Q9, and Q10 guidelines, requiring demonstration of consistent quality across three consecutive production batches. Critical process parameters including inlet temperature, atomization pressure, and feed concentration must be validated within defined operational ranges to ensure reproducible product characteristics.

Stability testing represents an essential component of quality control standards, with accelerated and long-term stability studies conducted according to ICH Q1A guidelines. Diagnostic agents typically require demonstration of chemical stability, physical characteristics, and diagnostic performance throughout the claimed shelf life, with acceptance criteria including less than 5% degradation of active ingredients and maintenance of particle characteristics within 10% of initial specifications.

Regulatory compliance frameworks including FDA 21 CFR Part 210/211 and EU GMP guidelines establish additional quality control requirements specific to diagnostic agents, including validation of analytical methods, equipment qualification, and comprehensive documentation of manufacturing processes. These standards ensure that spray-dried diagnostic agents consistently meet predefined quality attributes essential for accurate diagnostic performance.

The pharmaceutical industry has established rigorous quality control parameters specifically for spray-dried diagnostic agents, including particle size distribution, moisture content, and morphological characteristics. Particle size uniformity typically requires a coefficient of variation below 10%, with size ranges precisely defined based on the diagnostic application. For respiratory diagnostic agents, particles between 1-5 μm are generally targeted, while for injectable diagnostics, narrower distributions around 1-3 μm are essential.

Residual moisture content represents another critical quality parameter, with most specifications requiring levels below 2% to ensure product stability and prevent microbial contamination. Advanced analytical techniques including Karl Fischer titration and thermogravimetric analysis are employed for precise moisture determination, with validation protocols requiring measurement accuracy within ±0.2%.

Morphological characteristics of spray-dried particles are evaluated using scanning electron microscopy and laser diffraction techniques. Quality standards typically specify sphericity indices exceeding 0.85 for optimal flow properties and consistent dissolution profiles. Surface roughness parameters are quantified using atomic force microscopy, with acceptable roughness values defined based on the specific diagnostic application.

Process validation protocols for spray drying of diagnostic agents follow ICH Q8, Q9, and Q10 guidelines, requiring demonstration of consistent quality across three consecutive production batches. Critical process parameters including inlet temperature, atomization pressure, and feed concentration must be validated within defined operational ranges to ensure reproducible product characteristics.

Stability testing represents an essential component of quality control standards, with accelerated and long-term stability studies conducted according to ICH Q1A guidelines. Diagnostic agents typically require demonstration of chemical stability, physical characteristics, and diagnostic performance throughout the claimed shelf life, with acceptance criteria including less than 5% degradation of active ingredients and maintenance of particle characteristics within 10% of initial specifications.

Regulatory compliance frameworks including FDA 21 CFR Part 210/211 and EU GMP guidelines establish additional quality control requirements specific to diagnostic agents, including validation of analytical methods, equipment qualification, and comprehensive documentation of manufacturing processes. These standards ensure that spray-dried diagnostic agents consistently meet predefined quality attributes essential for accurate diagnostic performance.

Scalability and Cost Efficiency

Scalability of spray drying processes in diagnostic agent production represents a critical factor for commercial viability. Laboratory-scale processes typically operate at 1-5 kg/h throughput, while industrial applications can achieve 50-1000 kg/h, demonstrating significant scaling potential. The transition between scales, however, presents technical challenges including maintaining particle size distribution, morphology, and diagnostic performance characteristics. Successful scale-up requires sophisticated process parameter adjustments, particularly atomization pressure, feed concentration, and drying temperature profiles.

Cost efficiency analysis reveals that spray drying offers compelling economic advantages compared to alternative production methods such as freeze-drying. Operating costs typically range from $5-15 per kilogram of finished diagnostic agent, with energy consumption representing 30-40% of production expenses. Modern spray dryers achieve thermal efficiency ratings of 65-75%, significantly higher than the 35-45% observed in older systems, translating to substantial energy savings in large-scale operations.

Capital investment requirements vary considerably based on production scale and automation level. Small-scale GMP-compliant systems suitable for clinical-grade diagnostic agents start at approximately $500,000, while fully automated industrial systems can exceed $5 million. Return on investment calculations indicate payback periods of 2-4 years for most diagnostic applications, contingent upon production volume and market demand.

Batch-to-batch consistency represents another dimension of scalability challenges. Data from industry implementations shows that coefficient of variation for critical quality attributes typically decreases from 8-12% in pilot scale to 3-5% in full production scale, reflecting improved process stability at larger volumes. This consistency is particularly crucial for diagnostic agents where performance reliability directly impacts clinical outcomes.

Resource utilization metrics indicate that spray drying consumes 30-50% less water than alternative production methods, with modern closed-loop systems further reducing consumption by 15-25%. Similarly, footprint efficiency shows that production capacity per square meter of facility space is approximately 2.5 times higher for spray drying compared to lyophilization processes, offering significant advantages for manufacturing facility design and capacity planning.

Regulatory considerations also impact scalability economics, with validation costs for spray-dried diagnostic agents averaging $150,000-300,000 per product. However, these costs are typically 20-30% lower than alternative production methods due to the well-established regulatory framework for spray drying technology in pharmaceutical and diagnostic applications.

Cost efficiency analysis reveals that spray drying offers compelling economic advantages compared to alternative production methods such as freeze-drying. Operating costs typically range from $5-15 per kilogram of finished diagnostic agent, with energy consumption representing 30-40% of production expenses. Modern spray dryers achieve thermal efficiency ratings of 65-75%, significantly higher than the 35-45% observed in older systems, translating to substantial energy savings in large-scale operations.

Capital investment requirements vary considerably based on production scale and automation level. Small-scale GMP-compliant systems suitable for clinical-grade diagnostic agents start at approximately $500,000, while fully automated industrial systems can exceed $5 million. Return on investment calculations indicate payback periods of 2-4 years for most diagnostic applications, contingent upon production volume and market demand.

Batch-to-batch consistency represents another dimension of scalability challenges. Data from industry implementations shows that coefficient of variation for critical quality attributes typically decreases from 8-12% in pilot scale to 3-5% in full production scale, reflecting improved process stability at larger volumes. This consistency is particularly crucial for diagnostic agents where performance reliability directly impacts clinical outcomes.

Resource utilization metrics indicate that spray drying consumes 30-50% less water than alternative production methods, with modern closed-loop systems further reducing consumption by 15-25%. Similarly, footprint efficiency shows that production capacity per square meter of facility space is approximately 2.5 times higher for spray drying compared to lyophilization processes, offering significant advantages for manufacturing facility design and capacity planning.

Regulatory considerations also impact scalability economics, with validation costs for spray-dried diagnostic agents averaging $150,000-300,000 per product. However, these costs are typically 20-30% lower than alternative production methods due to the well-established regulatory framework for spray drying technology in pharmaceutical and diagnostic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!