What Challenges are Faced in Spray Drying of Biopolymers?

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biopolymer Spray Drying Background and Objectives

Spray drying technology has evolved significantly since its inception in the late 19th century, with the first patent for spray drying equipment issued in 1872. Initially developed for the food industry to produce milk powder, this technology has progressively expanded into pharmaceutical, chemical, and biotechnology sectors. The evolution of spray drying for biopolymers specifically began gaining momentum in the 1980s, with significant advancements in equipment design and process parameters to accommodate the sensitive nature of these materials.

The technological trajectory has been characterized by increasing sophistication in atomization techniques, from simple pressure nozzles to ultrasonic and rotary atomizers, enabling better control over particle size distribution. Drying chamber designs have similarly progressed from basic cylindrical configurations to more complex geometries that optimize airflow patterns and residence time distributions, crucial factors for biopolymer integrity preservation.

Recent years have witnessed a paradigm shift toward precision engineering in spray drying, with the integration of computational fluid dynamics (CFD) modeling, real-time process analytical technology (PAT), and advanced control systems. These innovations have transformed spray drying from an empirical art to a science-driven process, particularly important for high-value biopolymer applications.

The primary technical objectives in biopolymer spray drying center around preserving the structural integrity and functionality of these complex macromolecules throughout the drying process. This includes maintaining their native conformation, biological activity, and physicochemical properties despite exposure to thermal and mechanical stresses. Additionally, achieving consistent particle morphology, size distribution, and powder flowability represents critical quality attributes that determine downstream processability and end-use performance.

Another fundamental objective involves enhancing process efficiency while minimizing energy consumption, as biopolymer spray drying typically requires specialized conditions that can be resource-intensive. The development of scalable processes that maintain product quality from laboratory to industrial production scales remains a persistent challenge in this field.

The technological goals extend to addressing specific limitations of biopolymers during spray drying, such as their tendency toward thermal degradation, susceptibility to oxidation, and challenges related to their often hygroscopic nature. Innovations in protective excipients, modified process configurations, and novel atomization technologies are being actively pursued to overcome these inherent limitations.

As sustainability becomes increasingly important across industries, emerging objectives include developing environmentally friendly spray drying processes for biopolymers, with reduced solvent usage, improved energy efficiency, and minimized waste generation. These goals align with broader industry trends toward green manufacturing practices and circular economy principles.

The technological trajectory has been characterized by increasing sophistication in atomization techniques, from simple pressure nozzles to ultrasonic and rotary atomizers, enabling better control over particle size distribution. Drying chamber designs have similarly progressed from basic cylindrical configurations to more complex geometries that optimize airflow patterns and residence time distributions, crucial factors for biopolymer integrity preservation.

Recent years have witnessed a paradigm shift toward precision engineering in spray drying, with the integration of computational fluid dynamics (CFD) modeling, real-time process analytical technology (PAT), and advanced control systems. These innovations have transformed spray drying from an empirical art to a science-driven process, particularly important for high-value biopolymer applications.

The primary technical objectives in biopolymer spray drying center around preserving the structural integrity and functionality of these complex macromolecules throughout the drying process. This includes maintaining their native conformation, biological activity, and physicochemical properties despite exposure to thermal and mechanical stresses. Additionally, achieving consistent particle morphology, size distribution, and powder flowability represents critical quality attributes that determine downstream processability and end-use performance.

Another fundamental objective involves enhancing process efficiency while minimizing energy consumption, as biopolymer spray drying typically requires specialized conditions that can be resource-intensive. The development of scalable processes that maintain product quality from laboratory to industrial production scales remains a persistent challenge in this field.

The technological goals extend to addressing specific limitations of biopolymers during spray drying, such as their tendency toward thermal degradation, susceptibility to oxidation, and challenges related to their often hygroscopic nature. Innovations in protective excipients, modified process configurations, and novel atomization technologies are being actively pursued to overcome these inherent limitations.

As sustainability becomes increasingly important across industries, emerging objectives include developing environmentally friendly spray drying processes for biopolymers, with reduced solvent usage, improved energy efficiency, and minimized waste generation. These goals align with broader industry trends toward green manufacturing practices and circular economy principles.

Market Analysis for Spray-Dried Biopolymer Products

The global market for spray-dried biopolymer products has experienced significant growth in recent years, driven by increasing demand across multiple industries including food and beverage, pharmaceuticals, cosmetics, and agriculture. The market value reached approximately $4.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028, potentially reaching $6.6 billion by the end of the forecast period.

Food and beverage applications currently dominate the market share, accounting for nearly 42% of total consumption. This is primarily due to the rising consumer preference for natural ingredients, clean-label products, and functional foods. Spray-dried biopolymers such as modified starches, proteins, and gums serve as effective stabilizers, thickeners, and encapsulation agents in various food formulations.

The pharmaceutical sector represents the fastest-growing segment with an estimated CAGR of 9.3%. The increasing focus on controlled drug delivery systems, improved bioavailability, and enhanced stability of active pharmaceutical ingredients (APIs) has accelerated the adoption of spray-dried biopolymer solutions. Particularly notable is the growing application in oral solid dosage forms and pulmonary drug delivery systems.

Geographically, North America and Europe collectively hold approximately 58% of the market share, attributed to advanced technological infrastructure, stringent regulations favoring natural ingredients, and higher consumer awareness. However, the Asia-Pacific region is emerging as a lucrative market with the highest growth rate, driven by expanding food processing industries in China and India, coupled with increasing healthcare expenditure.

Consumer trends significantly influencing market dynamics include the shift toward plant-based alternatives, sustainable sourcing, and biodegradable materials. This has particularly benefited plant-derived biopolymers such as pea protein, cellulose derivatives, and alginate, which have seen demand increase by over 12% annually since 2020.

Key challenges affecting market penetration include relatively higher production costs compared to synthetic alternatives, with spray-dried biopolymers typically commanding a 15-30% price premium. Additionally, supply chain volatility for raw materials and technical limitations in achieving consistent functional properties across batches remain significant barriers to wider adoption.

Future market opportunities lie in developing specialized formulations for 3D bioprinting materials, advanced wound care products, and agricultural applications such as controlled-release fertilizers and seed coatings. These emerging applications are expected to create new revenue streams, potentially adding $1.2 billion to the market by 2030.

Food and beverage applications currently dominate the market share, accounting for nearly 42% of total consumption. This is primarily due to the rising consumer preference for natural ingredients, clean-label products, and functional foods. Spray-dried biopolymers such as modified starches, proteins, and gums serve as effective stabilizers, thickeners, and encapsulation agents in various food formulations.

The pharmaceutical sector represents the fastest-growing segment with an estimated CAGR of 9.3%. The increasing focus on controlled drug delivery systems, improved bioavailability, and enhanced stability of active pharmaceutical ingredients (APIs) has accelerated the adoption of spray-dried biopolymer solutions. Particularly notable is the growing application in oral solid dosage forms and pulmonary drug delivery systems.

Geographically, North America and Europe collectively hold approximately 58% of the market share, attributed to advanced technological infrastructure, stringent regulations favoring natural ingredients, and higher consumer awareness. However, the Asia-Pacific region is emerging as a lucrative market with the highest growth rate, driven by expanding food processing industries in China and India, coupled with increasing healthcare expenditure.

Consumer trends significantly influencing market dynamics include the shift toward plant-based alternatives, sustainable sourcing, and biodegradable materials. This has particularly benefited plant-derived biopolymers such as pea protein, cellulose derivatives, and alginate, which have seen demand increase by over 12% annually since 2020.

Key challenges affecting market penetration include relatively higher production costs compared to synthetic alternatives, with spray-dried biopolymers typically commanding a 15-30% price premium. Additionally, supply chain volatility for raw materials and technical limitations in achieving consistent functional properties across batches remain significant barriers to wider adoption.

Future market opportunities lie in developing specialized formulations for 3D bioprinting materials, advanced wound care products, and agricultural applications such as controlled-release fertilizers and seed coatings. These emerging applications are expected to create new revenue streams, potentially adding $1.2 billion to the market by 2030.

Technical Challenges and Limitations in Biopolymer Spray Drying

Spray drying of biopolymers presents numerous technical challenges that significantly impact process efficiency and product quality. The inherent complexity of biopolymer structures, combined with their sensitivity to thermal and mechanical stresses, creates fundamental difficulties during atomization, drying, and collection phases. Most notably, the high viscosity of biopolymer solutions restricts the formation of fine droplets during atomization, leading to larger particle sizes and reduced drying efficiency.

Temperature sensitivity represents another critical limitation, as many biopolymers undergo irreversible structural changes or degradation when exposed to the high temperatures typically employed in spray drying operations. This thermal instability can compromise the functional properties of the final product, including solubility, bioactivity, and mechanical characteristics. The challenge is further compounded by the need to balance drying efficiency with product quality preservation.

Sticky behavior of biopolymers during the drying process presents significant operational difficulties. As moisture content decreases, many biopolymers transition through a glass transition phase where they exhibit adhesive properties, resulting in material deposition on chamber walls and cyclone separators. This not only reduces product yield but also necessitates frequent cleaning and maintenance, disrupting continuous production capabilities.

The hygroscopic nature of many biopolymers creates additional complications in maintaining product stability. Even after successful drying, these materials readily absorb atmospheric moisture, potentially leading to caking, reduced flowability, and microbial contamination during storage. This necessitates careful consideration of post-processing handling and packaging strategies.

Scale-up challenges represent a significant barrier to industrial implementation. Phenomena that are manageable at laboratory scale often become problematic at production scale, including heat transfer limitations, residence time distribution variations, and flow pattern inconsistencies. These factors can lead to product heterogeneity and unpredictable quality attributes in large-scale operations.

Energy efficiency concerns also plague biopolymer spray drying processes. The high latent heat of water evaporation, combined with the need for relatively low drying temperatures to preserve biopolymer functionality, results in substantial energy consumption. This not only increases operational costs but also raises environmental sustainability concerns in commercial applications.

Equipment design limitations further constrain process optimization. Conventional spray dryers, originally developed for simpler materials, often lack the specialized features necessary for handling the unique characteristics of biopolymers. Innovations in nozzle design, chamber geometry, and separation systems are needed to overcome these equipment-related challenges and improve overall process performance.

Temperature sensitivity represents another critical limitation, as many biopolymers undergo irreversible structural changes or degradation when exposed to the high temperatures typically employed in spray drying operations. This thermal instability can compromise the functional properties of the final product, including solubility, bioactivity, and mechanical characteristics. The challenge is further compounded by the need to balance drying efficiency with product quality preservation.

Sticky behavior of biopolymers during the drying process presents significant operational difficulties. As moisture content decreases, many biopolymers transition through a glass transition phase where they exhibit adhesive properties, resulting in material deposition on chamber walls and cyclone separators. This not only reduces product yield but also necessitates frequent cleaning and maintenance, disrupting continuous production capabilities.

The hygroscopic nature of many biopolymers creates additional complications in maintaining product stability. Even after successful drying, these materials readily absorb atmospheric moisture, potentially leading to caking, reduced flowability, and microbial contamination during storage. This necessitates careful consideration of post-processing handling and packaging strategies.

Scale-up challenges represent a significant barrier to industrial implementation. Phenomena that are manageable at laboratory scale often become problematic at production scale, including heat transfer limitations, residence time distribution variations, and flow pattern inconsistencies. These factors can lead to product heterogeneity and unpredictable quality attributes in large-scale operations.

Energy efficiency concerns also plague biopolymer spray drying processes. The high latent heat of water evaporation, combined with the need for relatively low drying temperatures to preserve biopolymer functionality, results in substantial energy consumption. This not only increases operational costs but also raises environmental sustainability concerns in commercial applications.

Equipment design limitations further constrain process optimization. Conventional spray dryers, originally developed for simpler materials, often lack the specialized features necessary for handling the unique characteristics of biopolymers. Innovations in nozzle design, chamber geometry, and separation systems are needed to overcome these equipment-related challenges and improve overall process performance.

Current Methodologies for Biopolymer Spray Drying

01 Thermal stability challenges in spray drying biopolymers

Biopolymers are often sensitive to high temperatures used in spray drying processes, which can lead to degradation and loss of functional properties. The thermal stress during spray drying can cause denaturation of proteins, breakdown of polysaccharide chains, and loss of bioactivity. Strategies to overcome these challenges include using lower inlet temperatures, adding protective excipients, and optimizing drying parameters to minimize exposure time to high temperatures.- Thermal degradation and stability issues: Biopolymers are often sensitive to high temperatures used in spray drying processes, which can lead to thermal degradation and loss of functional properties. This challenge requires careful control of inlet and outlet temperatures, as well as consideration of the glass transition temperature of the biopolymer. Stabilizing additives and protective agents may be incorporated to minimize thermal damage during the drying process, preserving the structural integrity and bioactivity of heat-sensitive biopolymers.

- Viscosity and atomization challenges: Biopolymer solutions often exhibit high viscosity, which can impede efficient atomization during spray drying. Poor atomization leads to larger droplet sizes, uneven drying, and suboptimal powder properties. Techniques to address this challenge include dilution of the feed solution, modification of the biopolymer structure, use of specialized atomizers designed for viscous solutions, and incorporation of viscosity-reducing agents that do not compromise the functionality of the final product.

- Stickiness and agglomeration problems: Biopolymers often contain hygroscopic components that can cause stickiness during spray drying, leading to particle agglomeration and deposition on dryer walls. This results in reduced yield, processing difficulties, and inconsistent product quality. Solutions include the addition of anti-caking agents, careful control of drying parameters, use of carrier materials with high glass transition temperatures, and implementation of two-fluid nozzle systems that can handle sticky materials more effectively.

- Encapsulation efficiency and bioactivity preservation: Maintaining the bioactivity and functional properties of biopolymers during spray drying is challenging due to exposure to heat, shear forces, and oxidation. Encapsulation techniques are often employed to protect sensitive biopolymers, but achieving high encapsulation efficiency while maintaining powder flowability presents significant challenges. Strategies include the use of protective shell materials, antioxidants, pH adjusters, and modified spray drying conditions to minimize stress on the biopolymer structure.

- Scale-up and process optimization challenges: Transitioning from laboratory-scale to industrial-scale spray drying of biopolymers presents significant challenges in maintaining product quality and process efficiency. Parameters that work well at small scale often need substantial adjustment when scaled up. Challenges include maintaining consistent particle size distribution, preventing thermal gradients, ensuring uniform residence time, and optimizing energy efficiency. Advanced process analytical technologies and computational fluid dynamics modeling are increasingly used to address these scale-up challenges.

02 Viscosity and atomization issues with biopolymer solutions

Biopolymer solutions often exhibit high viscosity, which creates challenges during atomization in spray drying. High viscosity can lead to poor droplet formation, larger particle sizes, and nozzle clogging. This affects the efficiency of the drying process and the quality of the final powder. Techniques to address these challenges include diluting the solution, using specialized atomizers designed for viscous materials, and incorporating viscosity modifiers to improve flow properties.Expand Specific Solutions03 Stickiness and agglomeration during drying

Biopolymers often contain hygroscopic components that can become sticky during the drying process, leading to particle agglomeration and adhesion to equipment surfaces. This stickiness is particularly problematic when the material reaches its glass transition temperature during drying. Solutions include adding anti-caking agents, controlling humidity in the drying chamber, optimizing drying temperatures to stay below critical stickiness points, and using specialized equipment designs to minimize wall deposition.Expand Specific Solutions04 Preservation of biopolymer functionality and structure

Maintaining the native structure and functionality of biopolymers during spray drying is challenging due to shear forces, dehydration stress, and thermal exposure. These stresses can alter protein conformation, reduce enzymatic activity, and change the rheological properties of polysaccharides. Protective strategies include incorporating stabilizers like sugars and polyols, using encapsulation techniques, controlling pH, and optimizing process parameters to minimize structural changes while ensuring adequate drying.Expand Specific Solutions05 Scale-up and process optimization challenges

Transitioning from laboratory to industrial scale spray drying of biopolymers presents significant challenges. Process parameters that work at small scale often need substantial adjustment at larger scales. Issues include maintaining consistent particle size distribution, ensuring uniform drying, preventing thermal gradients, and achieving cost-effective production. Advanced process control systems, computational fluid dynamics modeling, and systematic scale-up methodologies are employed to address these challenges and optimize large-scale biopolymer spray drying operations.Expand Specific Solutions

Leading Companies and Research Institutions in Biopolymer Processing

The spray drying of biopolymers market is currently in a growth phase, with increasing applications in pharmaceutical, food, and materials industries. The global market size is expanding steadily, projected to reach significant value due to rising demand for controlled-release drug delivery systems and sustainable biomaterials. Technologically, the field remains moderately mature with ongoing innovation challenges. Leading companies like MedImmune (AstraZeneca), Novartis, and BASF are advancing commercial applications, while specialized firms such as Peptron and Hovione Scientia focus on overcoming technical barriers in biopolymer stability and functionality. Academic institutions including CNRS and research-oriented pharmaceutical companies like Vertex and Genzyme are driving fundamental research to address process optimization challenges, particularly in maintaining bioactivity during thermal processing and controlling particle morphology.

BASF Corp.

Technical Solution: BASF has developed advanced spray drying technologies specifically for biopolymers that address stability challenges through their proprietary encapsulation system. Their approach involves a multi-stage process where biopolymers are first pre-treated with stabilizing excipients before entering a modified spray dryer with controlled atomization parameters. The company utilizes a combination of specialized nozzle designs and optimized drying chamber configurations that maintain lower temperature gradients to prevent thermal degradation of sensitive biomolecules. BASF's technology incorporates real-time process analytical tools (PAT) that continuously monitor critical quality attributes during the drying process, allowing for adaptive control of process parameters to maintain product integrity. Their systems also feature customized cyclone separators designed specifically for biopolymer collection with minimal shear stress exposure.

Strengths: Superior encapsulation efficiency resulting in enhanced stability of dried biopolymers; advanced process control systems allowing for consistent quality across batches; scalable technology from laboratory to industrial production. Weaknesses: Higher capital investment required compared to conventional systems; complex process parameters requiring specialized operator training; limited flexibility for certain highly sensitive biopolymers.

Novartis AG

Technical Solution: Novartis has pioneered a comprehensive approach to biopolymer spray drying through their ProDry™ platform, specifically addressing challenges in pharmaceutical applications. Their technology employs a modified spray drying process with controlled humidity chambers and specialized atomization techniques that minimize shear forces during droplet formation. The company has developed proprietary stabilizing formulations that incorporate protective excipients such as disaccharides and amino acids, which form amorphous matrices around biopolymers during the drying process. Novartis utilizes computational fluid dynamics modeling to optimize drying chamber designs, creating ideal temperature and airflow profiles that prevent hot spots and reduce thermal degradation. Their systems incorporate pulse atomization technology that produces more uniform droplet sizes, resulting in consistent particle morphology and improved reconstitution properties of the final powder.

Strengths: Exceptional preservation of biopolymer activity through controlled drying parameters; superior particle engineering capabilities allowing for tailored release profiles; extensive formulation expertise with various excipient combinations. Weaknesses: Technology primarily optimized for pharmaceutical applications with less focus on food or industrial biopolymers; higher processing costs compared to conventional methods; requires specialized equipment not readily available to contract manufacturers.

Critical Patents and Research in Biopolymer Drying Technology

Process for the preparation of spray-dried emulsion polymers

PatentInactiveEP0332067A1

Innovation

- Atomizing water along with the dispersion or solution, allowing it to flow separately onto a rapidly rotating atomizer disk, prevents polymer deposits by cooling and reducing temperature-related coagulation, with controlled air flow and temperature management in the spray drying process.

NANO-IN-MICRO ENCAPSULATED siRNA DRY POWDER, METHOD FOR PRODUCING THE SAME AND USE OF A POWDER FORMULATION

PatentPendingUS20250262158A1

Innovation

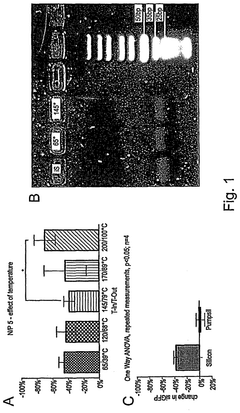

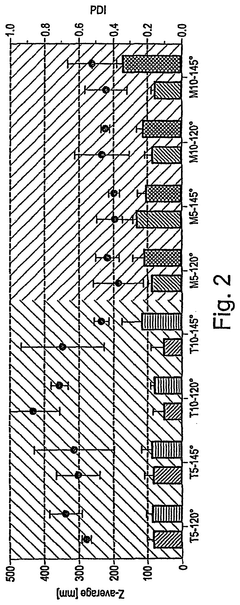

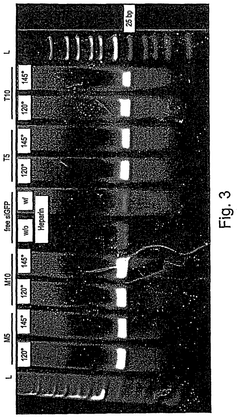

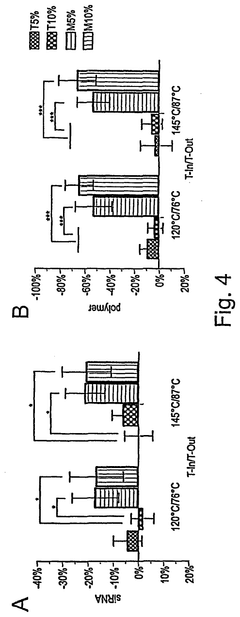

- A method involving spray drying of an aqueous suspension containing polyplexes or lipid nanoparticles, with controlled outlet temperature below the melting point of naked siRNA, and optionally an additional drying step, to preserve bioactivity and achieve desired particle size and distribution without additional stabilization.

Sustainability Aspects of Biopolymer Processing

The sustainability of biopolymer processing through spray drying represents a critical consideration in modern industrial applications. Biopolymers, derived from renewable resources, offer significant environmental advantages over petroleum-based polymers, including biodegradability and reduced carbon footprint. However, the spray drying process of these materials presents unique sustainability challenges that must be addressed for truly environmentally responsible production.

Energy consumption remains one of the most significant sustainability concerns in biopolymer spray drying. The process typically requires high temperatures (150-200°C) to achieve rapid moisture evaporation, resulting in substantial energy demands. Recent industry analyses indicate that spray drying operations can account for up to 30-40% of total energy consumption in biopolymer processing facilities, highlighting the urgent need for more energy-efficient technologies.

Water usage and management constitute another critical sustainability aspect. While spray drying inherently involves water removal, the pre-processing stages often require substantial water inputs for biopolymer dissolution or suspension preparation. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by 60-75%, though implementation challenges remain regarding maintaining water quality standards throughout multiple cycles.

Raw material sustainability extends beyond the biopolymer itself to include additives, stabilizers, and processing aids. The environmental credentials of the primary biopolymer can be compromised when combined with non-sustainable additives. Life cycle assessment (LCA) studies reveal that certain spray drying formulations may incorporate petroleum-derived surfactants or synthetic stabilizers that significantly diminish the overall sustainability profile of the final product.

Waste stream management presents ongoing challenges, particularly regarding the collection and potential reuse of fine powder particles that escape the primary collection systems. These losses typically range from 3-8% of total production volume, representing both material inefficiency and potential environmental contamination if not properly contained and processed.

Recent innovations in sustainable spray drying include the development of lower-temperature processing techniques that maintain product functionality while reducing energy requirements. Pulsed-heat delivery systems and advanced atomization technologies have demonstrated energy reductions of 15-25% in pilot-scale operations. Additionally, bio-based alternatives to traditional processing aids are emerging, with plant-derived surfactants and stabilizers showing comparable performance to synthetic options in specific applications.

The regulatory landscape increasingly influences sustainability practices in biopolymer processing, with extended producer responsibility frameworks and carbon pricing mechanisms driving industry innovation. Companies implementing comprehensive sustainability programs for their spray drying operations report not only environmental benefits but also cost savings through resource efficiency and waste reduction.

Energy consumption remains one of the most significant sustainability concerns in biopolymer spray drying. The process typically requires high temperatures (150-200°C) to achieve rapid moisture evaporation, resulting in substantial energy demands. Recent industry analyses indicate that spray drying operations can account for up to 30-40% of total energy consumption in biopolymer processing facilities, highlighting the urgent need for more energy-efficient technologies.

Water usage and management constitute another critical sustainability aspect. While spray drying inherently involves water removal, the pre-processing stages often require substantial water inputs for biopolymer dissolution or suspension preparation. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by 60-75%, though implementation challenges remain regarding maintaining water quality standards throughout multiple cycles.

Raw material sustainability extends beyond the biopolymer itself to include additives, stabilizers, and processing aids. The environmental credentials of the primary biopolymer can be compromised when combined with non-sustainable additives. Life cycle assessment (LCA) studies reveal that certain spray drying formulations may incorporate petroleum-derived surfactants or synthetic stabilizers that significantly diminish the overall sustainability profile of the final product.

Waste stream management presents ongoing challenges, particularly regarding the collection and potential reuse of fine powder particles that escape the primary collection systems. These losses typically range from 3-8% of total production volume, representing both material inefficiency and potential environmental contamination if not properly contained and processed.

Recent innovations in sustainable spray drying include the development of lower-temperature processing techniques that maintain product functionality while reducing energy requirements. Pulsed-heat delivery systems and advanced atomization technologies have demonstrated energy reductions of 15-25% in pilot-scale operations. Additionally, bio-based alternatives to traditional processing aids are emerging, with plant-derived surfactants and stabilizers showing comparable performance to synthetic options in specific applications.

The regulatory landscape increasingly influences sustainability practices in biopolymer processing, with extended producer responsibility frameworks and carbon pricing mechanisms driving industry innovation. Companies implementing comprehensive sustainability programs for their spray drying operations report not only environmental benefits but also cost savings through resource efficiency and waste reduction.

Regulatory Framework for Spray-Dried Biopolymer Applications

The regulatory landscape governing spray-dried biopolymer applications has evolved significantly in response to the growing use of these materials across pharmaceutical, food, and biomedical industries. Regulatory bodies worldwide have established frameworks that address the unique challenges associated with spray-dried biopolymers, focusing on safety, efficacy, and quality control aspects.

In the pharmaceutical sector, the FDA in the United States and the EMA in Europe have implemented specific guidelines for spray-dried biopolymers used in drug delivery systems. These regulations emphasize the importance of process validation, stability testing, and characterization of the spray-dried products. Manufacturers must demonstrate that their spray drying processes consistently produce biopolymers that meet predetermined quality attributes, particularly when these materials are intended for parenteral or inhalation applications.

Food applications of spray-dried biopolymers fall under the purview of food safety authorities such as the FDA's Center for Food Safety and Applied Nutrition (CFSAN) and the European Food Safety Authority (EFSA). These bodies require thorough safety assessments, including toxicological studies and allergenicity evaluations, before approving novel biopolymers for food use. Additionally, regulations often mandate clear labeling of spray-dried ingredients and their functional properties.

The biomedical application of spray-dried biopolymers faces perhaps the most stringent regulatory scrutiny. Medical devices incorporating these materials must undergo extensive biocompatibility testing according to ISO 10993 standards. Regulatory pathways typically involve premarket approval processes that require comprehensive documentation of manufacturing methods, quality control procedures, and clinical performance data.

A significant regulatory challenge lies in the classification of spray-dried biopolymers, as they often exist at the interface between different regulatory categories. For instance, a spray-dried protein might be regulated as a biological product, a drug excipient, or a food ingredient depending on its intended use. This ambiguity necessitates early engagement with regulatory authorities to determine appropriate pathways.

Globally, harmonization efforts are underway to standardize regulatory approaches to spray-dried biopolymers. The International Council for Harmonisation (ICH) has developed guidelines that address quality considerations for biopharmaceuticals, which include spray-dried formulations. Similarly, the International Organization for Standardization (ISO) continues to develop standards relevant to biopolymer characterization and testing.

Emerging regulations are increasingly focusing on sustainability aspects of spray-dried biopolymer production, including environmental impact assessments and life cycle analyses. This trend reflects growing concerns about resource utilization and waste generation in manufacturing processes, pushing developers to adopt greener technologies and more sustainable sourcing practices.

In the pharmaceutical sector, the FDA in the United States and the EMA in Europe have implemented specific guidelines for spray-dried biopolymers used in drug delivery systems. These regulations emphasize the importance of process validation, stability testing, and characterization of the spray-dried products. Manufacturers must demonstrate that their spray drying processes consistently produce biopolymers that meet predetermined quality attributes, particularly when these materials are intended for parenteral or inhalation applications.

Food applications of spray-dried biopolymers fall under the purview of food safety authorities such as the FDA's Center for Food Safety and Applied Nutrition (CFSAN) and the European Food Safety Authority (EFSA). These bodies require thorough safety assessments, including toxicological studies and allergenicity evaluations, before approving novel biopolymers for food use. Additionally, regulations often mandate clear labeling of spray-dried ingredients and their functional properties.

The biomedical application of spray-dried biopolymers faces perhaps the most stringent regulatory scrutiny. Medical devices incorporating these materials must undergo extensive biocompatibility testing according to ISO 10993 standards. Regulatory pathways typically involve premarket approval processes that require comprehensive documentation of manufacturing methods, quality control procedures, and clinical performance data.

A significant regulatory challenge lies in the classification of spray-dried biopolymers, as they often exist at the interface between different regulatory categories. For instance, a spray-dried protein might be regulated as a biological product, a drug excipient, or a food ingredient depending on its intended use. This ambiguity necessitates early engagement with regulatory authorities to determine appropriate pathways.

Globally, harmonization efforts are underway to standardize regulatory approaches to spray-dried biopolymers. The International Council for Harmonisation (ICH) has developed guidelines that address quality considerations for biopharmaceuticals, which include spray-dried formulations. Similarly, the International Organization for Standardization (ISO) continues to develop standards relevant to biopolymer characterization and testing.

Emerging regulations are increasingly focusing on sustainability aspects of spray-dried biopolymer production, including environmental impact assessments and life cycle analyses. This trend reflects growing concerns about resource utilization and waste generation in manufacturing processes, pushing developers to adopt greener technologies and more sustainable sourcing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!