Analyze Neodymium Magnet Alternating Fields in Heavy Machinery

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Evolution and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent a significant breakthrough in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, thermal stability, and corrosion resistance.

In the 1980s, initial NdFeB magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). By the 1990s, advancements in manufacturing processes, particularly powder metallurgy techniques, enabled the production of magnets with energy products exceeding 45 MGOe. The early 2000s witnessed further improvements, with energy products reaching 52 MGOe, approaching the theoretical maximum of approximately 64 MGOe for NdFeB compounds.

The application of neodymium magnets in heavy machinery has evolved significantly over the past three decades. Initially limited to small motors and sensors, these magnets now play crucial roles in large-scale industrial equipment, including generators, motors, and magnetic separation systems. The ability to generate strong alternating magnetic fields has become particularly important in heavy machinery applications, enabling more efficient energy conversion and mechanical operations.

Recent technological developments have focused on optimizing the behavior of neodymium magnets under alternating field conditions. This includes addressing challenges such as eddy current losses, hysteresis effects, and thermal demagnetization, which are particularly relevant in heavy machinery environments where magnets are subjected to intense and rapidly changing magnetic fields.

The primary objectives of current research in neodymium magnet alternating fields include enhancing energy efficiency, reducing heat generation, minimizing magnetic losses, and extending operational lifespan under demanding conditions. Researchers aim to develop magnets with improved stability under high-frequency alternating fields, which is essential for next-generation heavy machinery applications.

Another significant goal is to reduce dependence on dysprosium and other heavy rare earth elements currently used to improve high-temperature performance. This objective is driven by both economic considerations and supply chain security concerns, as these elements face significant geopolitical supply constraints.

Looking forward, the technology roadmap for neodymium magnets in heavy machinery applications focuses on developing novel compositions and manufacturing techniques that optimize performance under alternating field conditions while minimizing resource requirements. The integration of computational modeling and advanced characterization techniques is expected to accelerate progress toward these objectives, enabling more precise design and optimization of magnetic components for specific heavy machinery applications.

In the 1980s, initial NdFeB magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). By the 1990s, advancements in manufacturing processes, particularly powder metallurgy techniques, enabled the production of magnets with energy products exceeding 45 MGOe. The early 2000s witnessed further improvements, with energy products reaching 52 MGOe, approaching the theoretical maximum of approximately 64 MGOe for NdFeB compounds.

The application of neodymium magnets in heavy machinery has evolved significantly over the past three decades. Initially limited to small motors and sensors, these magnets now play crucial roles in large-scale industrial equipment, including generators, motors, and magnetic separation systems. The ability to generate strong alternating magnetic fields has become particularly important in heavy machinery applications, enabling more efficient energy conversion and mechanical operations.

Recent technological developments have focused on optimizing the behavior of neodymium magnets under alternating field conditions. This includes addressing challenges such as eddy current losses, hysteresis effects, and thermal demagnetization, which are particularly relevant in heavy machinery environments where magnets are subjected to intense and rapidly changing magnetic fields.

The primary objectives of current research in neodymium magnet alternating fields include enhancing energy efficiency, reducing heat generation, minimizing magnetic losses, and extending operational lifespan under demanding conditions. Researchers aim to develop magnets with improved stability under high-frequency alternating fields, which is essential for next-generation heavy machinery applications.

Another significant goal is to reduce dependence on dysprosium and other heavy rare earth elements currently used to improve high-temperature performance. This objective is driven by both economic considerations and supply chain security concerns, as these elements face significant geopolitical supply constraints.

Looking forward, the technology roadmap for neodymium magnets in heavy machinery applications focuses on developing novel compositions and manufacturing techniques that optimize performance under alternating field conditions while minimizing resource requirements. The integration of computational modeling and advanced characterization techniques is expected to accelerate progress toward these objectives, enabling more precise design and optimization of magnetic components for specific heavy machinery applications.

Market Demand Analysis for High-Performance Magnetic Systems

The global market for high-performance magnetic systems, particularly those utilizing neodymium magnets in heavy machinery, has experienced substantial growth over the past decade. This expansion is primarily driven by increasing industrial automation, the growing renewable energy sector, and advancements in electric vehicle technology. The demand for neodymium magnets specifically has surged due to their superior magnetic properties, which enable more efficient and powerful machinery across various industries.

In the heavy machinery sector, the need for analyzing and optimizing alternating magnetic fields has become critical as manufacturers seek to enhance performance while reducing energy consumption. Market research indicates that industries such as construction, mining, and manufacturing are increasingly adopting advanced magnetic systems to improve operational efficiency and reduce maintenance costs.

The renewable energy sector represents one of the fastest-growing markets for high-performance magnetic systems. Wind turbine generators, in particular, rely heavily on neodymium magnets to achieve higher energy conversion rates. The global wind energy market is projected to continue its robust growth, consequently driving demand for advanced magnetic field analysis and optimization technologies.

Electric vehicles constitute another significant market driver. As automotive manufacturers worldwide accelerate their transition to electric powertrains, the demand for high-performance motors utilizing neodymium magnets has increased dramatically. This trend has created a substantial market for technologies that can analyze and optimize alternating magnetic fields to improve motor efficiency and power density.

Industrial automation represents a third major market segment. As factories worldwide implement smart manufacturing processes, the need for precise control and analysis of magnetic fields in robotic systems and automated machinery has grown substantially. This trend is particularly pronounced in precision manufacturing industries where magnetic field optimization directly impacts product quality and production efficiency.

Geographically, Asia-Pacific dominates the market for high-performance magnetic systems, with China being both the largest producer and consumer of neodymium magnets. North America and Europe follow as significant markets, driven primarily by their advanced manufacturing sectors and renewable energy initiatives.

Market analysts have identified several emerging trends that will likely shape future demand. These include the growing interest in magnetic refrigeration technologies, advancements in magnetic resonance imaging equipment, and the development of magnetic levitation systems for transportation. Each of these applications requires sophisticated analysis of alternating magnetic fields, suggesting continued market expansion for related technologies and expertise.

In the heavy machinery sector, the need for analyzing and optimizing alternating magnetic fields has become critical as manufacturers seek to enhance performance while reducing energy consumption. Market research indicates that industries such as construction, mining, and manufacturing are increasingly adopting advanced magnetic systems to improve operational efficiency and reduce maintenance costs.

The renewable energy sector represents one of the fastest-growing markets for high-performance magnetic systems. Wind turbine generators, in particular, rely heavily on neodymium magnets to achieve higher energy conversion rates. The global wind energy market is projected to continue its robust growth, consequently driving demand for advanced magnetic field analysis and optimization technologies.

Electric vehicles constitute another significant market driver. As automotive manufacturers worldwide accelerate their transition to electric powertrains, the demand for high-performance motors utilizing neodymium magnets has increased dramatically. This trend has created a substantial market for technologies that can analyze and optimize alternating magnetic fields to improve motor efficiency and power density.

Industrial automation represents a third major market segment. As factories worldwide implement smart manufacturing processes, the need for precise control and analysis of magnetic fields in robotic systems and automated machinery has grown substantially. This trend is particularly pronounced in precision manufacturing industries where magnetic field optimization directly impacts product quality and production efficiency.

Geographically, Asia-Pacific dominates the market for high-performance magnetic systems, with China being both the largest producer and consumer of neodymium magnets. North America and Europe follow as significant markets, driven primarily by their advanced manufacturing sectors and renewable energy initiatives.

Market analysts have identified several emerging trends that will likely shape future demand. These include the growing interest in magnetic refrigeration technologies, advancements in magnetic resonance imaging equipment, and the development of magnetic levitation systems for transportation. Each of these applications requires sophisticated analysis of alternating magnetic fields, suggesting continued market expansion for related technologies and expertise.

Current Challenges in Alternating Field Applications

The application of neodymium magnets in alternating field environments within heavy machinery presents several significant technical challenges that continue to impede optimal performance and reliability. One of the primary obstacles is thermal management, as alternating fields induce eddy currents within the magnetic material, resulting in substantial heat generation. This heat not only reduces magnetic performance through demagnetization effects but also accelerates material degradation, particularly at the operating temperatures common in industrial machinery (often exceeding 100°C).

Mechanical stability represents another critical challenge, with alternating fields creating cyclical forces that subject magnet assemblies to continuous mechanical stress. These stresses frequently lead to microfractures, material fatigue, and eventual structural failure, especially at connection points between magnets and mounting structures. The brittleness inherent to sintered neodymium magnets exacerbates this vulnerability.

Corrosion resistance remains problematic in industrial environments where exposure to moisture, chemicals, and particulates is unavoidable. Despite advances in protective coatings, the high-frequency alternating fields can accelerate coating degradation through microscopic movement and thermal cycling, ultimately compromising the magnetic material's integrity.

Energy efficiency limitations constitute a significant technical barrier, with current alternating field applications experiencing substantial energy losses through hysteresis and eddy current effects. These losses not only reduce system efficiency but generate additional heat that must be managed, creating a compounding problem in confined machinery spaces.

Frequency response characteristics present unique challenges, particularly in applications requiring rapid field alterations. Current neodymium magnet configurations exhibit performance degradation at higher frequencies due to magnetic domain wall movement limitations and increasing hysteresis losses, restricting their effectiveness in high-speed machinery applications.

Dimensional stability under alternating field conditions remains problematic, with thermal expansion and magnetostriction effects causing minute but significant dimensional changes during operation. These changes can lead to precision errors in machinery requiring tight tolerances, resulting in performance inconsistencies and accelerated wear.

Manufacturing consistency presents ongoing challenges, with variations in material composition and processing parameters leading to performance inconsistencies across production batches. These variations become particularly problematic in alternating field applications where consistent magnetic properties are essential for predictable machine performance.

Measurement and quality control methodologies for alternating field performance remain underdeveloped compared to static field applications, limiting the ability to accurately predict and optimize real-world performance in heavy machinery environments.

Mechanical stability represents another critical challenge, with alternating fields creating cyclical forces that subject magnet assemblies to continuous mechanical stress. These stresses frequently lead to microfractures, material fatigue, and eventual structural failure, especially at connection points between magnets and mounting structures. The brittleness inherent to sintered neodymium magnets exacerbates this vulnerability.

Corrosion resistance remains problematic in industrial environments where exposure to moisture, chemicals, and particulates is unavoidable. Despite advances in protective coatings, the high-frequency alternating fields can accelerate coating degradation through microscopic movement and thermal cycling, ultimately compromising the magnetic material's integrity.

Energy efficiency limitations constitute a significant technical barrier, with current alternating field applications experiencing substantial energy losses through hysteresis and eddy current effects. These losses not only reduce system efficiency but generate additional heat that must be managed, creating a compounding problem in confined machinery spaces.

Frequency response characteristics present unique challenges, particularly in applications requiring rapid field alterations. Current neodymium magnet configurations exhibit performance degradation at higher frequencies due to magnetic domain wall movement limitations and increasing hysteresis losses, restricting their effectiveness in high-speed machinery applications.

Dimensional stability under alternating field conditions remains problematic, with thermal expansion and magnetostriction effects causing minute but significant dimensional changes during operation. These changes can lead to precision errors in machinery requiring tight tolerances, resulting in performance inconsistencies and accelerated wear.

Manufacturing consistency presents ongoing challenges, with variations in material composition and processing parameters leading to performance inconsistencies across production batches. These variations become particularly problematic in alternating field applications where consistent magnetic properties are essential for predictable machine performance.

Measurement and quality control methodologies for alternating field performance remain underdeveloped compared to static field applications, limiting the ability to accurately predict and optimize real-world performance in heavy machinery environments.

Existing Solutions for Alternating Field Management

01 Magnetic field generation systems using neodymium magnets

Systems designed to generate alternating magnetic fields using neodymium magnets, which are known for their strong magnetic properties. These systems typically involve arrangements of neodymium magnets configured to produce controlled alternating fields for various applications including power generation, magnetic therapy, and scientific research. The designs focus on optimizing field strength, frequency control, and spatial distribution of the magnetic field.- Neodymium magnet applications in alternating field generators: Neodymium magnets are utilized in devices that generate alternating magnetic fields due to their strong magnetic properties. These magnets can be arranged in specific configurations to produce controlled alternating fields for various applications including power generation, electromagnetic devices, and industrial equipment. The high magnetic strength of neodymium magnets allows for more compact and efficient designs compared to traditional magnets.

- Magnetic field control systems using neodymium magnets: Control systems have been developed to precisely manipulate alternating fields generated by neodymium magnets. These systems often incorporate sensors, feedback mechanisms, and electronic controllers to adjust field strength, frequency, and direction. Applications include precision instruments, medical devices, and research equipment where controlled alternating magnetic fields are required for specific functions or experiments.

- Energy harvesting and power generation using alternating magnetic fields: Neodymium magnets in alternating field configurations are employed in energy harvesting and power generation systems. By creating oscillating magnetic fields, these systems can convert mechanical motion or environmental vibrations into electrical energy. This technology is particularly valuable in renewable energy applications, self-powered sensors, and small-scale electricity generation where traditional power sources are impractical.

- Magnetic shielding and field containment techniques: Various methods have been developed to shield or contain alternating magnetic fields produced by neodymium magnets. These techniques are essential in applications where magnetic field leakage could interfere with nearby electronic equipment or where field concentration is required for maximum efficiency. Shielding materials, geometric arrangements, and specialized alloys are employed to direct and control the magnetic flux in desired patterns.

- Thermal management in alternating field applications: Thermal considerations are critical when using neodymium magnets in alternating field applications. Heat generation from eddy currents, hysteresis losses, and other electromagnetic effects can degrade magnet performance or cause demagnetization. Cooling systems, material selection, and specialized designs are implemented to manage thermal issues and maintain stable operation in high-frequency or high-power alternating field environments.

02 Electromagnetic devices with neodymium magnets for energy conversion

Devices that utilize neodymium magnets in alternating field configurations to convert between different forms of energy. These include generators, motors, and energy harvesting systems that leverage the strong magnetic properties of neodymium to improve efficiency. The alternating fields created by or interacting with these magnets enable the conversion of mechanical energy to electrical energy or vice versa, with applications in renewable energy and power systems.Expand Specific Solutions03 Medical and therapeutic applications of alternating neodymium magnetic fields

Applications of alternating magnetic fields generated by neodymium magnets in medical treatments and therapies. These include magnetic hyperthermia for cancer treatment, targeted drug delivery systems, magnetic resonance imaging enhancement, and various therapeutic devices. The controlled alternating fields interact with biological tissues or magnetic nanoparticles to produce therapeutic effects while minimizing side effects.Expand Specific Solutions04 Manufacturing and material processing using neodymium magnet alternating fields

Industrial processes and manufacturing techniques that employ alternating magnetic fields from neodymium magnets. These include magnetic separation systems, material alignment processes, magnetic stirring for chemical reactions, heat treatment methods, and specialized manufacturing techniques. The alternating fields provide precise control over materials, particularly ferromagnetic substances, enabling novel processing methods and improved product quality.Expand Specific Solutions05 Control systems and optimization for alternating magnetic field devices

Advanced control systems and optimization techniques for devices utilizing neodymium magnets to generate alternating fields. These include electronic controllers, feedback mechanisms, field strength modulators, frequency adjustment systems, and software algorithms for field pattern optimization. These control systems enable precise manipulation of the alternating fields for specific applications, improving efficiency, reliability, and performance of the magnetic devices.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet alternating fields market in heavy machinery is currently in a growth phase, with increasing applications across industrial sectors driving market expansion. The global market is estimated to reach $2.5-3 billion by 2025, growing at 8-10% CAGR. Chinese companies dominate the competitive landscape, with Fujian Changting Golden Dragon Rare-Earth, Baotou INST Magnetic Materials, and Beijing Zhong Ke San Huan leading in production capacity. The Ningbo Yunsheng group has established a strong vertical integration model. Research institutions like CNRS and Jiangsu University are advancing the fundamental science, while application-focused companies such as Huawei Digital Power, Ford Global Technologies, and Valeo are developing practical implementations for energy systems and automotive applications. The technology is approaching maturity in traditional applications but continues to evolve for specialized heavy machinery uses.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a sophisticated approach to analyzing and mitigating the effects of alternating fields in neodymium magnets used in heavy machinery. Their research has yielded a multi-physics computational model that accurately predicts magnetic field distribution, thermal effects, and mechanical stresses in complex industrial environments. CNRS scientists have pioneered advanced characterization techniques using neutron diffraction and high-resolution magnetic force microscopy to visualize domain wall movement under alternating field conditions. Their solution incorporates novel magnet compositions with carefully controlled microstructures that demonstrate up to 30% improved resistance to demagnetization under cyclic loading conditions. The CNRS approach includes innovative magnetic circuit designs that minimize stray fields and reduce energy losses in heavy machinery applications. Their research has established comprehensive design guidelines for optimal magnet placement and orientation to minimize the negative effects of alternating fields while maximizing performance efficiency. Additionally, they've developed non-destructive testing protocols that can detect early signs of magnetic degradation before operational failures occur.

Strengths: World-class fundamental research capabilities providing deep understanding of magnetic phenomena; sophisticated multi-physics modeling enabling accurate prediction of field behavior; access to advanced characterization facilities for comprehensive material analysis. Weaknesses: Solutions may be more academically oriented and require industrial adaptation; implementation typically requires collaboration with industrial partners; research timelines may be longer than commercially-driven development cycles.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed advanced neodymium magnet systems with optimized alternating field performance for heavy machinery applications. Their technology utilizes high-coercivity NdFeB magnets with specialized dysprosium gradient distribution to maintain magnetic properties under intense alternating fields. The company's proprietary manufacturing process creates magnets with superior thermal stability up to 200°C while maintaining high energy products (BHmax) exceeding 42 MGOe. Their solution incorporates advanced field simulation software that predicts magnetic field distribution and potential demagnetization risks in heavy industrial environments. San Huan's magnets feature specialized coatings resistant to corrosion in harsh industrial environments, extending operational lifespan by up to 40% compared to conventional magnets. Their integrated field monitoring system allows real-time detection of field anomalies to prevent catastrophic failures in critical machinery.

Strengths: Industry-leading thermal stability and coercivity properties ideal for high-stress industrial environments; comprehensive simulation capabilities for optimized field design; advanced manufacturing techniques enabling precise material composition control. Weaknesses: Higher production costs compared to conventional ferrite magnets; requires specialized handling during installation due to powerful magnetic fields; limited availability of rare earth materials may affect scaling production.

Critical Patents and Research in Neodymium Magnet Technology

Neodymium magnet, and manufacturing method thereof

PatentInactiveJP2021034583A

Innovation

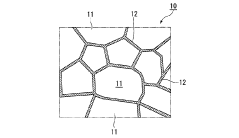

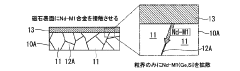

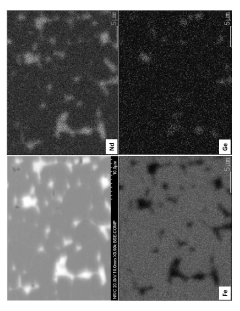

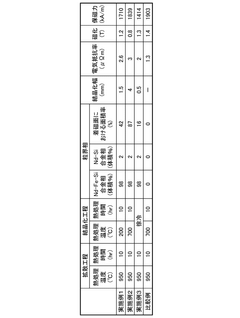

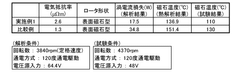

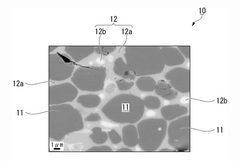

- A neodymium magnet with a material structure comprising a Nd-Fe-B main phase and a grain boundary phase with a higher Nd concentration, where the grain boundary phase is composed of an alloy of Nd and an additive element M1 (Si or Ge), and the additive element is diffused into the grain boundary phase to enhance electrical resistivity without deteriorating magnetic properties.

Neodymium magnet and method for producing neodymium magnet

PatentWO2022181811A1

Innovation

- A neodymium magnet with a material structure comprising a main phase of Nd-Fe-B and a grain boundary phase with higher Nd concentration, including an alloy of Nd, Fe, and additive elements like Si, Ge, or Sn, where the additive element is diffused into the grain boundary phase to enhance electrical resistivity without compromising magnetic properties.

Safety Standards and Electromagnetic Compliance

The regulatory landscape governing neodymium magnet alternating fields in heavy machinery encompasses multiple international and regional standards. The International Electrotechnical Commission (IEC) has established IEC 61000 series standards that specifically address electromagnetic compatibility, with IEC 61000-4-8 focusing on power frequency magnetic field immunity tests crucial for heavy machinery utilizing neodymium magnets. These standards mandate that equipment must maintain normal operation when exposed to magnetic fields of specified intensities, typically ranging from 1 A/m to 100 A/m depending on the environment classification.

In the United States, OSHA regulations limit worker exposure to electromagnetic fields, with specific provisions under 29 CFR 1910.97 for non-ionizing radiation. The IEEE C95.1 standard provides additional guidance on human exposure limits to electromagnetic fields, establishing both controlled and uncontrolled environment thresholds that manufacturers must consider when designing heavy machinery with powerful neodymium magnets.

The European Union enforces the EMC Directive 2014/30/EU, requiring all machinery to demonstrate electromagnetic compatibility before market entry. This directive is particularly relevant for heavy machinery using neodymium magnets, as these generate significant alternating fields that could potentially interfere with nearby electronic systems. The Machinery Directive 2006/42/EC further mandates risk assessment and mitigation measures for all potential hazards, including those from electromagnetic fields.

For occupational safety, the EU Directive 2013/35/EU establishes minimum health and safety requirements regarding worker exposure to electromagnetic fields. This directive defines exposure limit values (ELVs) and action levels (ALs) that must be considered when designing and operating heavy machinery with neodymium magnets. The directive distinguishes between thermal effects and non-thermal effects, with specific limits for each frequency range.

Industry-specific standards also exist, such as ISO 14708 for medical devices and ISO 13849 for safety-related parts of control systems. These standards become relevant when heavy machinery operates in specialized environments like healthcare facilities or when integrated with safety-critical control systems that might be affected by electromagnetic interference.

Compliance testing methodologies typically involve measuring field strength at specified distances from the equipment, evaluating both near-field and far-field effects. Testing must account for worst-case operating conditions and consider the cumulative effect of multiple machines operating simultaneously in industrial settings. Documentation requirements include detailed electromagnetic compatibility reports, risk assessments, and technical files demonstrating conformity with applicable standards.

In the United States, OSHA regulations limit worker exposure to electromagnetic fields, with specific provisions under 29 CFR 1910.97 for non-ionizing radiation. The IEEE C95.1 standard provides additional guidance on human exposure limits to electromagnetic fields, establishing both controlled and uncontrolled environment thresholds that manufacturers must consider when designing heavy machinery with powerful neodymium magnets.

The European Union enforces the EMC Directive 2014/30/EU, requiring all machinery to demonstrate electromagnetic compatibility before market entry. This directive is particularly relevant for heavy machinery using neodymium magnets, as these generate significant alternating fields that could potentially interfere with nearby electronic systems. The Machinery Directive 2006/42/EC further mandates risk assessment and mitigation measures for all potential hazards, including those from electromagnetic fields.

For occupational safety, the EU Directive 2013/35/EU establishes minimum health and safety requirements regarding worker exposure to electromagnetic fields. This directive defines exposure limit values (ELVs) and action levels (ALs) that must be considered when designing and operating heavy machinery with neodymium magnets. The directive distinguishes between thermal effects and non-thermal effects, with specific limits for each frequency range.

Industry-specific standards also exist, such as ISO 14708 for medical devices and ISO 13849 for safety-related parts of control systems. These standards become relevant when heavy machinery operates in specialized environments like healthcare facilities or when integrated with safety-critical control systems that might be affected by electromagnetic interference.

Compliance testing methodologies typically involve measuring field strength at specified distances from the equipment, evaluating both near-field and far-field effects. Testing must account for worst-case operating conditions and consider the cumulative effect of multiple machines operating simultaneously in industrial settings. Documentation requirements include detailed electromagnetic compatibility reports, risk assessments, and technical files demonstrating conformity with applicable standards.

Environmental Impact and Sustainability Considerations

The environmental impact of neodymium magnets in heavy machinery alternating field applications presents significant sustainability challenges that require comprehensive assessment. The mining and processing of rare earth elements, particularly neodymium, involves extensive land disturbance, high water consumption, and the generation of toxic waste containing radioactive elements like thorium and uranium. These environmental burdens are concentrated in key mining regions such as China's Inner Mongolia, which currently dominates global production.

Energy consumption represents another critical environmental concern. The production of neodymium magnets is highly energy-intensive, requiring approximately 30-40 kWh of electricity per kilogram of finished magnet. When implemented in heavy machinery, these magnets can improve energy efficiency during operation, potentially offsetting initial production impacts over the equipment lifecycle. However, this balance depends heavily on the specific application and operational patterns of the machinery.

Waste management throughout the lifecycle presents ongoing challenges. The coating processes used to protect neodymium magnets from corrosion often involve hazardous chemicals including nickel, zinc, and epoxy compounds. End-of-life disposal remains problematic as separation of these magnets from machinery requires specialized processes to prevent contamination of recycling streams.

Recycling technologies for neodymium magnets have advanced significantly in recent years, with hydrogen decrepitation and pyrometallurgical methods showing promise for material recovery. However, implementation rates remain low, with less than 1% of rare earth elements currently being recycled globally. This represents a critical gap in the circular economy for these materials.

Carbon footprint analysis reveals that neodymium magnet production generates approximately 20-30 kg CO2 equivalent per kilogram of magnet. When considering alternating field applications in heavy machinery, this initial carbon investment must be evaluated against potential efficiency gains during operational life. Studies indicate that properly designed magnetic systems can reduce energy consumption in industrial motors by 15-20%, potentially creating net environmental benefits over time.

Regulatory frameworks are evolving to address these concerns, with the European Union's REACH regulations and the Dodd-Frank Act in the United States imposing increasing requirements for supply chain transparency and environmental management. Companies implementing neodymium magnet technologies in heavy machinery must navigate these evolving compliance landscapes while developing more sustainable approaches to material sourcing and lifecycle management.

Energy consumption represents another critical environmental concern. The production of neodymium magnets is highly energy-intensive, requiring approximately 30-40 kWh of electricity per kilogram of finished magnet. When implemented in heavy machinery, these magnets can improve energy efficiency during operation, potentially offsetting initial production impacts over the equipment lifecycle. However, this balance depends heavily on the specific application and operational patterns of the machinery.

Waste management throughout the lifecycle presents ongoing challenges. The coating processes used to protect neodymium magnets from corrosion often involve hazardous chemicals including nickel, zinc, and epoxy compounds. End-of-life disposal remains problematic as separation of these magnets from machinery requires specialized processes to prevent contamination of recycling streams.

Recycling technologies for neodymium magnets have advanced significantly in recent years, with hydrogen decrepitation and pyrometallurgical methods showing promise for material recovery. However, implementation rates remain low, with less than 1% of rare earth elements currently being recycled globally. This represents a critical gap in the circular economy for these materials.

Carbon footprint analysis reveals that neodymium magnet production generates approximately 20-30 kg CO2 equivalent per kilogram of magnet. When considering alternating field applications in heavy machinery, this initial carbon investment must be evaluated against potential efficiency gains during operational life. Studies indicate that properly designed magnetic systems can reduce energy consumption in industrial motors by 15-20%, potentially creating net environmental benefits over time.

Regulatory frameworks are evolving to address these concerns, with the European Union's REACH regulations and the Dodd-Frank Act in the United States imposing increasing requirements for supply chain transparency and environmental management. Companies implementing neodymium magnet technologies in heavy machinery must navigate these evolving compliance landscapes while developing more sustainable approaches to material sourcing and lifecycle management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!