How to Implement Neodymium Magnets in Low-Noise Audio Devices

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnets in Audio: Background and Objectives

Neodymium magnets have revolutionized the audio industry since their commercial introduction in the 1980s. Developed initially by General Motors and Sumitomo Special Metals, these rare-earth magnets offer exceptional magnetic strength-to-size ratio, providing up to ten times the magnetic energy of traditional ferrite magnets. This breakthrough has enabled significant miniaturization and performance improvements in audio transducers, including speakers, headphones, and microphones.

The evolution of neodymium magnet technology in audio applications has followed a clear trajectory from initial adoption in high-end professional equipment to widespread implementation across consumer audio devices. Early challenges included cost barriers and manufacturing complexities, but economies of scale and production refinements have gradually reduced these obstacles, making neodymium-based audio solutions increasingly accessible.

Current technical trends indicate growing interest in optimizing neodymium magnet implementations specifically for low-noise applications. This focus stems from the increasing consumer and professional demand for higher fidelity audio reproduction with minimal distortion across the frequency spectrum. The pursuit of noise reduction has become particularly critical as audio devices continue to shrink in size while expectations for sound quality continue to rise.

The primary technical objective of this research is to identify optimal design methodologies for implementing neodymium magnets in audio devices with a specific focus on minimizing noise generation. This encompasses several interconnected goals: understanding the fundamental mechanisms of noise production in neodymium-based transducers; evaluating existing noise mitigation techniques; and developing novel approaches to magnetic circuit design that leverage neodymium's unique properties while addressing its limitations.

Secondary objectives include exploring cost-effective manufacturing processes that maintain tight tolerances necessary for low-noise performance, investigating sustainable sourcing options given the geopolitical complexities surrounding rare earth elements, and assessing the long-term stability of various neodymium compounds under typical operating conditions in audio devices.

The scope of this investigation extends beyond purely magnetic considerations to include the interaction between neodymium magnets and other components in the audio signal chain. This holistic approach recognizes that achieving truly low-noise performance requires addressing electromagnetic interference, mechanical resonance, and thermal management as an integrated system rather than isolated challenges.

By establishing a comprehensive understanding of both the historical context and current technical landscape, this research aims to provide actionable insights for audio engineers and product developers seeking to implement neodymium magnets in next-generation low-noise audio devices across various price points and application scenarios.

The evolution of neodymium magnet technology in audio applications has followed a clear trajectory from initial adoption in high-end professional equipment to widespread implementation across consumer audio devices. Early challenges included cost barriers and manufacturing complexities, but economies of scale and production refinements have gradually reduced these obstacles, making neodymium-based audio solutions increasingly accessible.

Current technical trends indicate growing interest in optimizing neodymium magnet implementations specifically for low-noise applications. This focus stems from the increasing consumer and professional demand for higher fidelity audio reproduction with minimal distortion across the frequency spectrum. The pursuit of noise reduction has become particularly critical as audio devices continue to shrink in size while expectations for sound quality continue to rise.

The primary technical objective of this research is to identify optimal design methodologies for implementing neodymium magnets in audio devices with a specific focus on minimizing noise generation. This encompasses several interconnected goals: understanding the fundamental mechanisms of noise production in neodymium-based transducers; evaluating existing noise mitigation techniques; and developing novel approaches to magnetic circuit design that leverage neodymium's unique properties while addressing its limitations.

Secondary objectives include exploring cost-effective manufacturing processes that maintain tight tolerances necessary for low-noise performance, investigating sustainable sourcing options given the geopolitical complexities surrounding rare earth elements, and assessing the long-term stability of various neodymium compounds under typical operating conditions in audio devices.

The scope of this investigation extends beyond purely magnetic considerations to include the interaction between neodymium magnets and other components in the audio signal chain. This holistic approach recognizes that achieving truly low-noise performance requires addressing electromagnetic interference, mechanical resonance, and thermal management as an integrated system rather than isolated challenges.

By establishing a comprehensive understanding of both the historical context and current technical landscape, this research aims to provide actionable insights for audio engineers and product developers seeking to implement neodymium magnets in next-generation low-noise audio devices across various price points and application scenarios.

Market Analysis for Low-Noise Audio Applications

The low-noise audio device market has experienced significant growth over the past decade, driven by increasing consumer demand for high-fidelity sound reproduction across various applications. The global premium audio market, which encompasses low-noise devices, was valued at approximately $14 billion in 2022 and is projected to reach $22 billion by 2027, representing a compound annual growth rate of 9.5%.

Consumer segments driving this growth include audiophiles, professional sound engineers, music producers, and increasingly, everyday consumers seeking enhanced audio experiences. The COVID-19 pandemic accelerated this trend as consumers invested more in home entertainment systems and personal audio equipment during lockdowns, creating a sustained demand pattern that has continued post-pandemic.

Within the low-noise audio segment, headphones and earphones constitute the largest product category, accounting for roughly 40% of market share. Home theater systems and professional studio equipment follow at 25% and 20% respectively. Portable speakers and specialized audio components make up the remaining 15%.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12% annually, driven by rising disposable incomes and increasing adoption of premium audio products in China, Japan, and South Korea.

The implementation of neodymium magnets in audio devices addresses specific market demands for miniaturization without compromising sound quality. This technology enables manufacturers to develop thinner, lighter devices while maintaining or improving audio performance—a key selling point in today's portable-focused consumer market.

Industry analysis indicates that devices featuring neodymium magnet technology command a price premium of 15-30% compared to conventional alternatives, suggesting strong value perception among consumers. This premium positioning has attracted major manufacturers including Sony, Bose, Sennheiser, and Harman International, who have incorporated neodymium technology across their product lines.

Market research shows that consumers prioritize three key factors when purchasing low-noise audio devices: sound quality (cited by 78% of respondents), comfort/ergonomics (65%), and durability (52%). Devices utilizing neodymium magnets can address all three concerns through improved acoustic performance, reduced weight, and robust construction.

The forecast for neodymium-based audio technology remains strong, with particular growth expected in true wireless earbuds, high-resolution headphones, and compact home audio systems—all segments where the size-to-performance ratio is critical to market success.

Consumer segments driving this growth include audiophiles, professional sound engineers, music producers, and increasingly, everyday consumers seeking enhanced audio experiences. The COVID-19 pandemic accelerated this trend as consumers invested more in home entertainment systems and personal audio equipment during lockdowns, creating a sustained demand pattern that has continued post-pandemic.

Within the low-noise audio segment, headphones and earphones constitute the largest product category, accounting for roughly 40% of market share. Home theater systems and professional studio equipment follow at 25% and 20% respectively. Portable speakers and specialized audio components make up the remaining 15%.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%), Asia-Pacific (25%), and rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth rate at 12% annually, driven by rising disposable incomes and increasing adoption of premium audio products in China, Japan, and South Korea.

The implementation of neodymium magnets in audio devices addresses specific market demands for miniaturization without compromising sound quality. This technology enables manufacturers to develop thinner, lighter devices while maintaining or improving audio performance—a key selling point in today's portable-focused consumer market.

Industry analysis indicates that devices featuring neodymium magnet technology command a price premium of 15-30% compared to conventional alternatives, suggesting strong value perception among consumers. This premium positioning has attracted major manufacturers including Sony, Bose, Sennheiser, and Harman International, who have incorporated neodymium technology across their product lines.

Market research shows that consumers prioritize three key factors when purchasing low-noise audio devices: sound quality (cited by 78% of respondents), comfort/ergonomics (65%), and durability (52%). Devices utilizing neodymium magnets can address all three concerns through improved acoustic performance, reduced weight, and robust construction.

The forecast for neodymium-based audio technology remains strong, with particular growth expected in true wireless earbuds, high-resolution headphones, and compact home audio systems—all segments where the size-to-performance ratio is critical to market success.

Current Challenges in Magnetic Interference Reduction

The implementation of neodymium magnets in audio devices presents significant challenges related to magnetic interference. Despite their superior magnetic properties and compact size advantages, these powerful magnets generate magnetic fields that can severely impact audio signal integrity. When placed near sensitive audio components such as voice coils, transformers, or signal paths, they create unwanted electromagnetic interference (EMI) that manifests as audible noise, hum, or distortion in the audio output.

A primary technical obstacle is the containment of magnetic flux leakage. Neodymium magnets produce strong magnetic fields that extend well beyond their physical boundaries, affecting nearby components even without direct contact. This characteristic makes shielding particularly difficult, especially in compact audio devices where space constraints limit implementation of traditional isolation techniques.

The temperature sensitivity of neodymium magnets compounds these challenges. Their magnetic properties degrade at elevated temperatures, with significant performance loss occurring above 80°C. This thermal instability can lead to inconsistent audio performance across different operating conditions, particularly in devices that generate heat during extended operation.

Mechanical integration presents another set of difficulties. The brittleness of neodymium magnets makes them susceptible to chipping or cracking during assembly or operation, potentially releasing magnetic particles that can interfere with moving components or create short circuits in electronic pathways. Their strong attractive forces also complicate manufacturing processes, requiring specialized handling equipment and assembly techniques.

Current shielding solutions using mu-metal or permalloy materials add significant weight and cost to audio devices, contradicting the miniaturization trend in consumer electronics. Additionally, these shields often require precise placement and careful design to avoid creating secondary interference problems through field redirection rather than true containment.

The proximity effect between multiple neodymium magnets in complex audio systems creates unpredictable field interactions that can be difficult to model during the design phase. This leads to costly trial-and-error development cycles and potential performance inconsistencies between production units.

Regulatory compliance adds another layer of complexity, as electronic devices must meet electromagnetic compatibility (EMC) standards that limit radiated and conducted emissions. The strong fields from neodymium magnets can potentially cause devices to fail these certification requirements, necessitating extensive redesign or additional shielding measures.

A primary technical obstacle is the containment of magnetic flux leakage. Neodymium magnets produce strong magnetic fields that extend well beyond their physical boundaries, affecting nearby components even without direct contact. This characteristic makes shielding particularly difficult, especially in compact audio devices where space constraints limit implementation of traditional isolation techniques.

The temperature sensitivity of neodymium magnets compounds these challenges. Their magnetic properties degrade at elevated temperatures, with significant performance loss occurring above 80°C. This thermal instability can lead to inconsistent audio performance across different operating conditions, particularly in devices that generate heat during extended operation.

Mechanical integration presents another set of difficulties. The brittleness of neodymium magnets makes them susceptible to chipping or cracking during assembly or operation, potentially releasing magnetic particles that can interfere with moving components or create short circuits in electronic pathways. Their strong attractive forces also complicate manufacturing processes, requiring specialized handling equipment and assembly techniques.

Current shielding solutions using mu-metal or permalloy materials add significant weight and cost to audio devices, contradicting the miniaturization trend in consumer electronics. Additionally, these shields often require precise placement and careful design to avoid creating secondary interference problems through field redirection rather than true containment.

The proximity effect between multiple neodymium magnets in complex audio systems creates unpredictable field interactions that can be difficult to model during the design phase. This leads to costly trial-and-error development cycles and potential performance inconsistencies between production units.

Regulatory compliance adds another layer of complexity, as electronic devices must meet electromagnetic compatibility (EMC) standards that limit radiated and conducted emissions. The strong fields from neodymium magnets can potentially cause devices to fail these certification requirements, necessitating extensive redesign or additional shielding measures.

Current Magnetic Shielding and Isolation Techniques

01 Noise reduction in neodymium magnet applications

Various techniques are employed to reduce noise generated by neodymium magnets in different applications. These include using damping materials, optimizing magnet placement, and implementing vibration isolation systems. The noise reduction methods are particularly important in devices where neodymium magnets interact with other components, causing unwanted acoustic emissions. These solutions help minimize operational noise while maintaining the magnetic performance.- Noise reduction in magnetic assemblies: Various techniques are employed to reduce noise in neodymium magnet assemblies, particularly in motors and generators. These include optimizing the magnet arrangement, using damping materials, and implementing specific mounting configurations to minimize vibration and resonance effects. These approaches help to reduce the characteristic humming or buzzing noise often associated with neodymium magnets in operation.

- Magnetic shielding and isolation techniques: Shielding and isolation methods are used to contain the magnetic fields of neodymium magnets, which can help reduce noise caused by magnetic interactions with surrounding components. These techniques include using ferromagnetic materials for shielding, creating air gaps, and implementing isolation mounts to prevent the transmission of vibrations that generate noise.

- Structural modifications for acoustic performance: Specific structural modifications to devices containing neodymium magnets can significantly improve acoustic performance. These include changes to the housing design, incorporation of acoustic baffles, and modification of component geometry to reduce resonance. Such modifications are particularly important in applications like speakers, headphones, and automotive components where noise control is critical.

- Surface treatment and coating of magnets: Various surface treatments and coatings can be applied to neodymium magnets to reduce noise generation. These include anti-vibration coatings, specialized adhesives, and surface texturing that can dampen vibrations. These treatments help to minimize the friction and impact between magnets and adjacent components, thereby reducing operational noise.

- Electronic control systems for noise management: Advanced electronic control systems can be implemented to manage and reduce noise in devices using neodymium magnets. These systems include adaptive frequency control, phase modulation techniques, and feedback mechanisms that adjust the operation of magnetic components to minimize noise generation. Such approaches are particularly effective in precision instruments and consumer electronics where noise can affect performance and user experience.

02 Structural modifications to minimize magnetic vibration

Structural modifications in devices using neodymium magnets can significantly reduce noise caused by magnetic vibration. These modifications include redesigning mounting brackets, incorporating buffer layers between magnets and surrounding structures, and using specialized housing designs. By altering the physical structure around the magnets, the transmission of vibrations can be minimized, resulting in quieter operation of magnetic assemblies.Expand Specific Solutions03 Coating and surface treatment of neodymium magnets

Applying specific coatings and surface treatments to neodymium magnets can help reduce noise generation. These treatments modify the surface properties of the magnets, affecting how they interact with surrounding components. Specialized coatings can dampen vibrations at the source, provide electrical insulation that prevents eddy currents (which can cause noise), and protect against corrosion that might alter magnetic performance over time and lead to increased noise.Expand Specific Solutions04 Magnetic circuit design for noise control

Optimizing the design of magnetic circuits that incorporate neodymium magnets can significantly reduce operational noise. This includes careful arrangement of magnetic poles, using flux guides to direct magnetic fields, and implementing magnetic shielding. By controlling how magnetic flux interacts with surrounding components, designers can minimize the forces that cause vibration and noise while maintaining or even enhancing the desired magnetic performance.Expand Specific Solutions05 Electronic control systems for noise management

Electronic control systems can be implemented to manage and reduce noise in devices using neodymium magnets. These systems may include active noise cancellation, controlled power supply to electromagnets working with permanent magnets, and feedback mechanisms that adjust operation based on detected vibration. By dynamically controlling the magnetic forces and resulting mechanical movements, these systems can significantly reduce the noise generated during operation.Expand Specific Solutions

Leading Manufacturers and Audio Industry Landscape

The implementation of neodymium magnets in low-noise audio devices is currently in a growth phase, with the market expanding due to increasing demand for high-fidelity audio products. The global market size is estimated to reach significant value as companies leverage these powerful magnets to enhance audio performance. In terms of technical maturity, industry leaders like GoerTek, Sony, and Pioneer have made substantial advancements, developing proprietary technologies that minimize magnetic interference and vibration. Companies such as Yamaha, Harman, and AAC Acoustic Technologies are also contributing innovative solutions, while specialized magnetic material providers like Fujian Changting Golden Dragon Rare-Earth and Tianjin Topmag Magnet Group support the supply chain with high-quality neodymium components for audio applications.

GoerTek Inc.

Technical Solution: GoerTek has developed a comprehensive approach to implementing neodymium magnets in their audio devices through their "Precision Magnetic Field Control" (PMFC) technology. Their implementation focuses on optimizing the magnetic circuit design to minimize distortion and noise while maximizing efficiency. GoerTek utilizes computer-aided magnetic field simulation to design precisely shaped neodymium magnet structures that create highly uniform magnetic fields across the voice coil gap. Their approach includes a proprietary "dual-layer magnetic isolation" system where the primary neodymium magnets are surrounded by a secondary magnetic structure that contains stray fields and prevents interference with nearby components. GoerTek has also developed specialized manufacturing techniques for creating composite neodymium magnets with tailored magnetic properties in different regions, allowing for more precise control of the magnetic field shape. Their most advanced implementations incorporate active temperature compensation systems that adjust driver parameters in real-time to maintain consistent performance as the magnets' properties change with temperature variations. Additionally, GoerTek employs precision CNC machining to create complex pole piece geometries that work in conjunction with the neodymium magnets to optimize flux distribution.

Strengths: GoerTek's implementation achieves excellent power efficiency while maintaining very low distortion, making their solutions particularly well-suited for battery-powered audio devices. Their temperature compensation systems ensure consistent performance across varying environmental conditions. Weaknesses: The complex magnetic structures and active compensation systems add cost and complexity to the manufacturing process, and their solutions often require more sophisticated control electronics than simpler magnetic implementations.

Sony Group Corp.

Technical Solution: Sony has developed proprietary neodymium magnet implementations for their high-end audio devices, focusing on minimizing electromagnetic interference while maximizing acoustic performance. Their approach involves using specially designed neodymium magnet structures with copper-clad aluminum wire voice coils that reduce moving mass while maintaining high magnetic flux density. Sony's implementation includes advanced magnetic shielding techniques using mu-metal barriers that contain stray magnetic fields, preventing interference with nearby electronic components. Additionally, they've pioneered a process called "magnetic circuit optimization" where the neodymium magnets are precisely positioned and oriented to create an ideal magnetic field shape for driver movement, resulting in significantly reduced mechanical noise and distortion. Their latest designs incorporate dual-layer neodymium magnets with specialized damping materials between layers to absorb vibrations that could translate into audible noise.

Strengths: Sony's implementation achieves exceptional signal-to-noise ratios while maintaining compact form factors, ideal for portable high-resolution audio players and headphones. Their magnetic shielding techniques effectively eliminate interference issues common in densely packed audio devices. Weaknesses: The specialized manufacturing processes required for their optimized magnetic circuits increase production costs significantly, and the complex magnet arrangements are difficult to mass-produce with consistent quality.

Key Patents in Neodymium Magnet Audio Implementation

Acoustic device

PatentWO2024075415A1

Innovation

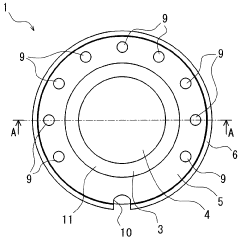

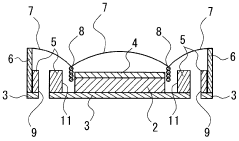

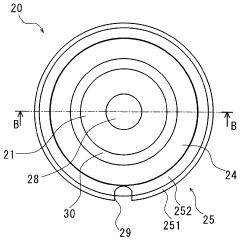

- The magnetic circuit is designed with components such as a cylindrical magnet, bottom yoke, ring yoke, and pole piece formed by compression molding soft magnetic powder, with through holes and a protective layer to reduce eddy currents and distortion, using a sintered neodymium magnet for improved magnetic properties.

Material Science Advancements for Audio Magnets

The field of material science has witnessed remarkable advancements in magnetic materials, particularly in the development of neodymium magnets for audio applications. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have revolutionized audio device engineering due to their exceptional magnetic properties. Recent innovations have focused on optimizing these materials specifically for low-noise audio implementations.

Material scientists have developed specialized coating technologies that significantly reduce surface irregularities in neodymium magnets. These coatings, including advanced nickel-copper-nickel multilayers and epoxy resin treatments, minimize micro-vibrations that can contribute to unwanted noise in audio reproduction. The precision of these coatings has reached nanometer-scale uniformity, ensuring consistent magnetic field generation.

Crystalline structure modifications represent another critical advancement. By controlling the orientation of magnetic domains during the manufacturing process, researchers have created neodymium magnets with more uniform magnetic fields. This structural optimization reduces magnetic flux variations that typically manifest as audio distortion, particularly in high-fidelity applications where signal-to-noise ratio is paramount.

Thermal stability enhancements have addressed one of the traditional limitations of neodymium magnets. New dysprosium and terbium doping techniques have improved temperature coefficients, maintaining consistent magnetic performance across wider operating temperature ranges. This stability is crucial for audio devices that generate heat during extended operation, as it prevents thermal-induced magnetic field fluctuations that can introduce noise.

Size reduction capabilities have progressed substantially, with manufacturers now able to produce high-performance neodymium magnets at microscale dimensions without sacrificing magnetic strength. This miniaturization enables more precise placement within audio transducers, optimizing the magnetic circuit while reducing mechanical interference that contributes to noise generation.

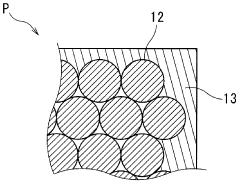

Composite magnetic materials represent the cutting edge of current research. By combining neodymium with other magnetic and non-magnetic materials in precisely engineered structures, scientists have created magnets with customized magnetic field geometries. These composites can shape the magnetic field to interact optimally with voice coils and other audio components, minimizing stray fields that induce noise in nearby electronic components.

Manufacturing precision has also improved dramatically, with advanced sintering and pressing techniques ensuring greater consistency between production batches. This uniformity is essential for audio applications where matched pairs of drivers require identical magnetic characteristics to maintain proper stereo imaging and minimize channel-specific noise artifacts.

Material scientists have developed specialized coating technologies that significantly reduce surface irregularities in neodymium magnets. These coatings, including advanced nickel-copper-nickel multilayers and epoxy resin treatments, minimize micro-vibrations that can contribute to unwanted noise in audio reproduction. The precision of these coatings has reached nanometer-scale uniformity, ensuring consistent magnetic field generation.

Crystalline structure modifications represent another critical advancement. By controlling the orientation of magnetic domains during the manufacturing process, researchers have created neodymium magnets with more uniform magnetic fields. This structural optimization reduces magnetic flux variations that typically manifest as audio distortion, particularly in high-fidelity applications where signal-to-noise ratio is paramount.

Thermal stability enhancements have addressed one of the traditional limitations of neodymium magnets. New dysprosium and terbium doping techniques have improved temperature coefficients, maintaining consistent magnetic performance across wider operating temperature ranges. This stability is crucial for audio devices that generate heat during extended operation, as it prevents thermal-induced magnetic field fluctuations that can introduce noise.

Size reduction capabilities have progressed substantially, with manufacturers now able to produce high-performance neodymium magnets at microscale dimensions without sacrificing magnetic strength. This miniaturization enables more precise placement within audio transducers, optimizing the magnetic circuit while reducing mechanical interference that contributes to noise generation.

Composite magnetic materials represent the cutting edge of current research. By combining neodymium with other magnetic and non-magnetic materials in precisely engineered structures, scientists have created magnets with customized magnetic field geometries. These composites can shape the magnetic field to interact optimally with voice coils and other audio components, minimizing stray fields that induce noise in nearby electronic components.

Manufacturing precision has also improved dramatically, with advanced sintering and pressing techniques ensuring greater consistency between production batches. This uniformity is essential for audio applications where matched pairs of drivers require identical magnetic characteristics to maintain proper stereo imaging and minimize channel-specific noise artifacts.

Environmental and Sustainability Considerations

The implementation of neodymium magnets in low-noise audio devices raises significant environmental and sustainability concerns that must be addressed throughout the product lifecycle. Neodymium, a rare earth element, is primarily mined in China, which controls approximately 85% of global production. The extraction process involves environmentally damaging practices including open-pit mining, acid leaching, and the generation of toxic waste containing radioactive thorium and uranium. These processes contribute to soil degradation, water pollution, and habitat destruction in mining regions.

Manufacturing neodymium magnets requires substantial energy inputs, particularly during the sintering process where temperatures reach 1000-1200°C. The coating processes often involve nickel, zinc, or epoxy treatments that utilize potentially harmful chemicals. Additionally, the carbon footprint associated with global transportation of raw materials and finished components further impacts the environmental profile of these audio devices.

From a resource conservation perspective, the limited global supply of neodymium presents long-term sustainability challenges. Current estimates suggest that accessible reserves may face significant constraints within the next 30-50 years at current consumption rates. This scarcity has prompted research into recycling methodologies and alternative magnetic materials with lower environmental impacts.

Recycling neodymium magnets from audio devices presents technical challenges due to their small size and integration with other components. Current recovery rates remain below 1% globally, though emerging technologies show promise for improved reclamation. Manufacturers implementing design-for-disassembly principles can significantly enhance end-of-life recyclability of these components.

Regulatory frameworks are evolving to address these concerns. The European Union's RoHS and REACH regulations impose restrictions on hazardous substances, while the Dodd-Frank Act requires disclosure of conflict minerals. Companies developing low-noise audio devices with neodymium magnets must navigate these requirements while anticipating stricter future regulations.

Forward-thinking manufacturers are exploring several sustainability strategies, including reduced magnet size through optimized design, partial substitution with less critical materials, implementation of closed-loop recycling programs, and investment in responsible sourcing initiatives. Some companies have established supplier certification programs that verify environmental compliance and ethical labor practices throughout the supply chain.

Manufacturing neodymium magnets requires substantial energy inputs, particularly during the sintering process where temperatures reach 1000-1200°C. The coating processes often involve nickel, zinc, or epoxy treatments that utilize potentially harmful chemicals. Additionally, the carbon footprint associated with global transportation of raw materials and finished components further impacts the environmental profile of these audio devices.

From a resource conservation perspective, the limited global supply of neodymium presents long-term sustainability challenges. Current estimates suggest that accessible reserves may face significant constraints within the next 30-50 years at current consumption rates. This scarcity has prompted research into recycling methodologies and alternative magnetic materials with lower environmental impacts.

Recycling neodymium magnets from audio devices presents technical challenges due to their small size and integration with other components. Current recovery rates remain below 1% globally, though emerging technologies show promise for improved reclamation. Manufacturers implementing design-for-disassembly principles can significantly enhance end-of-life recyclability of these components.

Regulatory frameworks are evolving to address these concerns. The European Union's RoHS and REACH regulations impose restrictions on hazardous substances, while the Dodd-Frank Act requires disclosure of conflict minerals. Companies developing low-noise audio devices with neodymium magnets must navigate these requirements while anticipating stricter future regulations.

Forward-thinking manufacturers are exploring several sustainability strategies, including reduced magnet size through optimized design, partial substitution with less critical materials, implementation of closed-loop recycling programs, and investment in responsible sourcing initiatives. Some companies have established supplier certification programs that verify environmental compliance and ethical labor practices throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!