Characterizing Neodymium Magnet Load-Bearing Capacity in Structures

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant breakthrough in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have revolutionized numerous industries due to their exceptional magnetic properties. With magnetic energy products reaching up to 52 MGOe (mega-gauss-oersteds), they significantly outperform traditional ferrite or alnico magnets, offering unprecedented strength-to-weight ratios.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, material composition, and performance characteristics. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium additions to enhance high-temperature performance, while protective coatings address oxidation concerns. These advancements have expanded their application range considerably.

Understanding the load-bearing capacity of neodymium magnets in structural applications represents a critical frontier in materials engineering. While their magnetic properties are well-documented, comprehensive characterization of their mechanical behavior under various load conditions remains underdeveloped. This gap in knowledge has limited their integration into load-bearing structural components where both magnetic functionality and mechanical reliability are required.

The technical objectives of this research focus on establishing standardized methodologies for characterizing the load-bearing capacity of neodymium magnets across different structural configurations. This includes developing testing protocols for static and dynamic loading scenarios, investigating the relationship between magnetic field strength and mechanical performance, and quantifying the effects of environmental factors on long-term structural integrity.

Current trends indicate growing interest in utilizing neodymium magnets as active structural elements rather than merely as attachments or components within structures. This paradigm shift necessitates deeper understanding of their behavior under complex stress states, particularly in applications such as architectural systems, mechanical joints, and self-assembling structures where magnets simultaneously provide both connection force and functional properties.

The intersection of magnetic performance and structural engineering presents unique challenges. Magnetic forces must be accurately modeled alongside traditional mechanical forces, requiring new computational approaches and simulation methodologies. Additionally, the brittle nature of sintered neodymium magnets introduces fracture mechanics considerations that must be addressed when evaluating their load-bearing potential.

As industries move toward more integrated and multifunctional materials, characterizing the dual magnetic-mechanical properties of neodymium magnets will enable new design paradigms. The ultimate goal is to develop comprehensive design guidelines that allow engineers to confidently incorporate these powerful magnets into load-bearing applications while maintaining appropriate safety factors and performance predictability.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, material composition, and performance characteristics. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium additions to enhance high-temperature performance, while protective coatings address oxidation concerns. These advancements have expanded their application range considerably.

Understanding the load-bearing capacity of neodymium magnets in structural applications represents a critical frontier in materials engineering. While their magnetic properties are well-documented, comprehensive characterization of their mechanical behavior under various load conditions remains underdeveloped. This gap in knowledge has limited their integration into load-bearing structural components where both magnetic functionality and mechanical reliability are required.

The technical objectives of this research focus on establishing standardized methodologies for characterizing the load-bearing capacity of neodymium magnets across different structural configurations. This includes developing testing protocols for static and dynamic loading scenarios, investigating the relationship between magnetic field strength and mechanical performance, and quantifying the effects of environmental factors on long-term structural integrity.

Current trends indicate growing interest in utilizing neodymium magnets as active structural elements rather than merely as attachments or components within structures. This paradigm shift necessitates deeper understanding of their behavior under complex stress states, particularly in applications such as architectural systems, mechanical joints, and self-assembling structures where magnets simultaneously provide both connection force and functional properties.

The intersection of magnetic performance and structural engineering presents unique challenges. Magnetic forces must be accurately modeled alongside traditional mechanical forces, requiring new computational approaches and simulation methodologies. Additionally, the brittle nature of sintered neodymium magnets introduces fracture mechanics considerations that must be addressed when evaluating their load-bearing potential.

As industries move toward more integrated and multifunctional materials, characterizing the dual magnetic-mechanical properties of neodymium magnets will enable new design paradigms. The ultimate goal is to develop comprehensive design guidelines that allow engineers to confidently incorporate these powerful magnets into load-bearing applications while maintaining appropriate safety factors and performance predictability.

Market Analysis for Load-Bearing Magnetic Applications

The global market for load-bearing magnetic applications has experienced significant growth over the past decade, driven primarily by advancements in neodymium magnet technology. Current market valuations indicate that the industrial magnetic systems sector reached approximately 21.5 billion USD in 2022, with load-bearing applications representing roughly 3.8 billion USD of this total. Industry forecasts project a compound annual growth rate (CAGR) of 6.7% through 2028, outpacing many traditional industrial material markets.

The construction and architectural sectors have emerged as primary adopters of load-bearing magnetic solutions, particularly in modular building systems and temporary structural supports. This segment accounts for approximately 32% of the total market share, with applications ranging from magnetic formwork systems to decorative façade elements with structural functions. The manufacturing sector follows closely at 28%, implementing magnetic load-bearing systems in assembly lines, material handling, and precision equipment mounting.

Consumer demand for space-efficient furniture and multifunctional living solutions has created a rapidly expanding niche market for neodymium-based load-bearing systems in residential applications. This segment has shown the highest growth rate at 9.3% annually, albeit from a smaller base. Commercial applications in retail fixtures and displays represent another 17% of the market.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity, producing 68% of neodymium magnets used in load-bearing applications globally. However, North America and Europe lead in high-value application development and implementation, accounting for 58% of revenue generation despite lower production volumes. This geographic distribution highlights the value-added nature of engineering solutions rather than raw material production.

Market penetration faces several constraints, including cost barriers for widespread adoption, with neodymium magnet solutions typically commanding a 30-45% premium over conventional mechanical fastening systems. Safety concerns regarding potential magnetic field interference with electronic equipment and sudden demagnetization risks under extreme conditions have limited adoption in certain critical infrastructure applications.

Customer surveys indicate growing awareness of magnetic load-bearing solutions, with 73% of industrial procurement specialists reporting familiarity with these technologies compared to just 41% five years ago. However, only 28% report having implemented such solutions in their operations, suggesting significant untapped market potential as technical understanding improves and costs decrease through economies of scale.

The construction and architectural sectors have emerged as primary adopters of load-bearing magnetic solutions, particularly in modular building systems and temporary structural supports. This segment accounts for approximately 32% of the total market share, with applications ranging from magnetic formwork systems to decorative façade elements with structural functions. The manufacturing sector follows closely at 28%, implementing magnetic load-bearing systems in assembly lines, material handling, and precision equipment mounting.

Consumer demand for space-efficient furniture and multifunctional living solutions has created a rapidly expanding niche market for neodymium-based load-bearing systems in residential applications. This segment has shown the highest growth rate at 9.3% annually, albeit from a smaller base. Commercial applications in retail fixtures and displays represent another 17% of the market.

Regional analysis reveals that Asia-Pacific dominates manufacturing capacity, producing 68% of neodymium magnets used in load-bearing applications globally. However, North America and Europe lead in high-value application development and implementation, accounting for 58% of revenue generation despite lower production volumes. This geographic distribution highlights the value-added nature of engineering solutions rather than raw material production.

Market penetration faces several constraints, including cost barriers for widespread adoption, with neodymium magnet solutions typically commanding a 30-45% premium over conventional mechanical fastening systems. Safety concerns regarding potential magnetic field interference with electronic equipment and sudden demagnetization risks under extreme conditions have limited adoption in certain critical infrastructure applications.

Customer surveys indicate growing awareness of magnetic load-bearing solutions, with 73% of industrial procurement specialists reporting familiarity with these technologies compared to just 41% five years ago. However, only 28% report having implemented such solutions in their operations, suggesting significant untapped market potential as technical understanding improves and costs decrease through economies of scale.

Current Challenges in Magnetic Load-Bearing Systems

Despite significant advancements in magnetic technology, magnetic load-bearing systems face several critical challenges that limit their widespread implementation in structural applications. The primary obstacle remains the accurate characterization and prediction of neodymium magnets' load-bearing capacity under various environmental and operational conditions. Current testing methodologies often fail to account for the complex interplay between magnetic field strength degradation over time and structural integrity under dynamic loads.

Temperature sensitivity presents another significant challenge, as neodymium magnets experience substantial performance degradation at elevated temperatures. The magnetic flux density can decrease by up to 0.12% per degree Celsius above room temperature, with permanent demagnetization occurring around 80-200°C depending on the specific grade. This thermal vulnerability necessitates sophisticated thermal management systems in load-bearing applications, adding complexity and cost.

Long-term stability issues further complicate magnetic load-bearing system design. Neodymium magnets exhibit flux loss of approximately 1-2% during the first decade of use under normal conditions, but this can accelerate significantly under adverse conditions such as high temperatures, strong opposing magnetic fields, or mechanical shock. Current predictive models for this degradation lack sufficient validation across extended timeframes, creating uncertainty in lifetime performance estimates.

Mechanical brittleness of neodymium magnets poses additional engineering challenges. With tensile strength approximately 8-14% that of structural steel, these magnets require careful integration into load-bearing structures to prevent fracture. The current practice of encasing magnets in protective materials often reduces the effective magnetic force available for load-bearing applications.

Standardization remains inadequate across the industry, with inconsistent testing protocols and performance metrics making direct comparisons between different magnetic systems difficult. This lack of standardization impedes knowledge transfer and slows technological advancement in the field.

Economic considerations also present barriers, as high-performance neodymium magnets contain rare earth elements subject to significant price volatility and supply chain concerns. The cost-performance ratio often makes traditional mechanical fastening systems more economically viable for many applications despite the potential advantages of magnetic systems.

Finally, computational modeling limitations hinder design optimization. Current finite element analysis tools struggle to simultaneously model magnetic field interactions, structural mechanics, thermal effects, and long-term degradation with sufficient accuracy for critical load-bearing applications. This computational gap forces engineers to employ excessive safety factors, reducing the efficiency and economic viability of magnetic load-bearing systems.

Temperature sensitivity presents another significant challenge, as neodymium magnets experience substantial performance degradation at elevated temperatures. The magnetic flux density can decrease by up to 0.12% per degree Celsius above room temperature, with permanent demagnetization occurring around 80-200°C depending on the specific grade. This thermal vulnerability necessitates sophisticated thermal management systems in load-bearing applications, adding complexity and cost.

Long-term stability issues further complicate magnetic load-bearing system design. Neodymium magnets exhibit flux loss of approximately 1-2% during the first decade of use under normal conditions, but this can accelerate significantly under adverse conditions such as high temperatures, strong opposing magnetic fields, or mechanical shock. Current predictive models for this degradation lack sufficient validation across extended timeframes, creating uncertainty in lifetime performance estimates.

Mechanical brittleness of neodymium magnets poses additional engineering challenges. With tensile strength approximately 8-14% that of structural steel, these magnets require careful integration into load-bearing structures to prevent fracture. The current practice of encasing magnets in protective materials often reduces the effective magnetic force available for load-bearing applications.

Standardization remains inadequate across the industry, with inconsistent testing protocols and performance metrics making direct comparisons between different magnetic systems difficult. This lack of standardization impedes knowledge transfer and slows technological advancement in the field.

Economic considerations also present barriers, as high-performance neodymium magnets contain rare earth elements subject to significant price volatility and supply chain concerns. The cost-performance ratio often makes traditional mechanical fastening systems more economically viable for many applications despite the potential advantages of magnetic systems.

Finally, computational modeling limitations hinder design optimization. Current finite element analysis tools struggle to simultaneously model magnetic field interactions, structural mechanics, thermal effects, and long-term degradation with sufficient accuracy for critical load-bearing applications. This computational gap forces engineers to employ excessive safety factors, reducing the efficiency and economic viability of magnetic load-bearing systems.

Existing Methods for Characterizing Magnetic Load Capacity

01 Factors affecting load-bearing capacity of neodymium magnets

The load-bearing capacity of neodymium magnets is influenced by several factors including the grade of the magnet, its size and shape, temperature conditions, and the type of material it's attracting. Higher grade neodymium magnets (such as N52) offer stronger magnetic fields and thus higher load-bearing capacities. The geometry of the magnet also plays a crucial role, with larger surface areas typically providing greater holding force. Environmental conditions, particularly temperature, can significantly affect performance as neodymium magnets lose strength at higher temperatures.- Factors affecting load-bearing capacity of neodymium magnets: The load-bearing capacity of neodymium magnets is influenced by several factors including the grade of the magnet, its size and shape, temperature conditions, and the material of the surface it's attached to. Higher grade neodymium magnets (such as N52) offer stronger magnetic fields and thus higher load-bearing capacities. The geometry of the magnet also plays a crucial role, with larger surface areas generally providing greater holding force. Environmental factors like temperature can significantly reduce magnetic strength, as neodymium magnets lose performance at higher temperatures.

- Testing and measurement methods for load-bearing capacity: Various testing methodologies have been developed to accurately measure the load-bearing capacity of neodymium magnets. These include pull-force testing, where the force required to separate the magnet from a ferromagnetic surface is measured; shear force testing, which measures the resistance to lateral movement; and cyclic loading tests to determine long-term performance. Advanced measurement techniques employ specialized equipment like force gauges and computerized testing systems to provide precise data on magnetic holding strength under different conditions and orientations.

- Enhancement techniques for load-bearing capacity: Several methods can enhance the load-bearing capacity of neodymium magnets. These include using backing plates made of ferromagnetic materials to concentrate and direct the magnetic field, creating arrays or specific arrangements of multiple magnets to combine their forces, applying special coatings to protect against demagnetization, and optimizing the magnet's shape for specific applications. Some advanced techniques involve creating composite structures where neodymium magnets are integrated with other materials to maximize their holding strength while minimizing weight and size.

- Applications utilizing neodymium magnets' load-bearing capacity: The exceptional load-bearing capacity of neodymium magnets enables numerous industrial and commercial applications. These include magnetic mounting systems for tools and equipment, magnetic fasteners and closures in furniture and accessories, magnetic lifting devices for manufacturing and construction, magnetic bearings in high-performance machinery, and magnetic assemblies in automotive and aerospace components. The high strength-to-weight ratio of these magnets makes them particularly valuable in applications where space is limited but substantial holding force is required.

- Safety considerations and limitations of load-bearing applications: When utilizing neodymium magnets for load-bearing applications, several safety considerations must be addressed. These include the brittle nature of the magnets which can lead to breakage under impact or excessive stress, potential sudden failure without warning if load limits are exceeded, demagnetization risks due to environmental factors, and the need for safety factors in design calculations. Additionally, neodymium magnets can lose significant holding power at elevated temperatures, with some grades losing effectiveness above 80°C. Proper mounting techniques and regular inspection are essential for maintaining safe operation in critical load-bearing applications.

02 Testing and measurement methods for load-bearing capacity

Various testing methodologies have been developed to accurately measure the load-bearing capacity of neodymium magnets. These include pull-force testing, where the force required to separate the magnet from a ferromagnetic surface is measured; shear force testing, which measures the resistance to lateral movement; and cyclic loading tests to determine durability over time. Advanced measurement techniques utilize specialized equipment such as force gauges, tensile testing machines, and computerized measurement systems to provide precise data on magnetic holding strength under different conditions and applications.Expand Specific Solutions03 Mounting systems and fixtures for optimizing load capacity

Specialized mounting systems and fixtures can significantly enhance the load-bearing capacity of neodymium magnets. These include steel backing plates that help concentrate and direct the magnetic field, pot housings that protect the magnet while channeling magnetic force, and custom fixtures designed for specific load applications. The design of these mounting systems often incorporates features to maximize the contact area between the magnet and the attracted surface, as well as to distribute the load evenly across the magnetic interface, thereby preventing localized stress points that could cause failure.Expand Specific Solutions04 Surface treatments and coatings to enhance performance

Various surface treatments and coatings are applied to neodymium magnets to enhance their load-bearing capacity and durability. Nickel-copper-nickel coatings provide corrosion resistance while maintaining magnetic performance. Specialized polymer coatings can increase friction between the magnet and the surface, improving shear resistance. Some advanced treatments modify the surface structure of the magnet to optimize the magnetic field distribution at the interface. These treatments not only protect the brittle neodymium material from damage but also can focus the magnetic field to increase the effective holding force.Expand Specific Solutions05 Applications requiring high load-bearing capacity

Neodymium magnets with high load-bearing capacity find applications across numerous industries. In construction and manufacturing, they are used for temporary holding fixtures, lifting devices, and assembly aids. The automotive industry utilizes them in magnetic mounting systems, sensors, and specialized tools. Consumer products incorporate these magnets in furniture fasteners, door catches, and organizational systems. Industrial applications include magnetic separators, conveyor systems, and robotic end effectors. Each application requires specific considerations regarding the magnet's shape, size, grade, and mounting system to achieve optimal load-bearing performance while ensuring safety and reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet load-bearing capacity characterization market is currently in a growth phase, with increasing applications across automotive, renewable energy, and industrial sectors. The global permanent magnet market is projected to reach approximately $40 billion by 2027, with neodymium magnets representing the largest segment. Chinese companies dominate the competitive landscape, with JL MAG Rare-Earth, Ningbo Yunsheng, and Zhong Ke San Huan leading in manufacturing capacity and technological innovation. Japanese and European players like Seiko Instruments, Kobe Steel, and Robert Bosch contribute significant R&D advancements in high-performance applications. Research institutions including Tokyo University of Science and CNRS are driving fundamental breakthroughs in load-bearing capacity enhancement. The technology is maturing rapidly with industrial players like Vestas Wind Systems and Toyota Motor Corp integrating advanced neodymium magnets into their structural designs.

JL MAG Rare-Earth Co., Ltd.

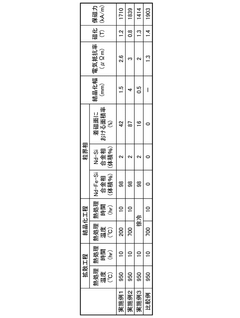

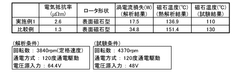

Technical Solution: JL MAG has developed advanced characterization methodologies for neodymium magnet load-bearing capacity in structural applications. Their approach combines finite element analysis (FEA) with experimental validation using specialized testing equipment that can measure magnetic forces up to 500N with precision of ±0.1N. The company has pioneered a multi-parameter assessment framework that evaluates both static and dynamic load capacities under varying temperature conditions (-40°C to 180°C), accounting for demagnetization risks. Their proprietary NdFeB-S series magnets feature enhanced mechanical properties through grain boundary diffusion technology, achieving 20-30% higher tensile strength compared to conventional neodymium magnets while maintaining magnetic performance. JL MAG's characterization system includes accelerated aging tests that predict long-term performance degradation under sustained loads, enabling more accurate service life predictions for structural applications.

Strengths: Comprehensive testing methodology that integrates mechanical and magnetic property analysis; advanced manufacturing techniques that enhance structural integrity without compromising magnetic performance. Weaknesses: Their characterization methods require specialized equipment not widely available in standard testing facilities; the testing protocols are time-intensive, potentially limiting throughput for mass production applications.

Yantai Zhenghai Magnetic Material Co., Ltd.

Technical Solution: Yantai Zhenghai has developed a systematic approach to characterizing neodymium magnet load-bearing capacity focused on industrial applications. Their methodology incorporates both theoretical modeling and practical testing protocols. The company utilizes advanced strain gauge technology to measure microscopic deformations under various load conditions, with sensitivity down to 0.1 microstrain. Their proprietary "ZH-LoadSim" software simulates complex stress distributions in magnetic assemblies, accounting for temperature variations, vibration, and shock loading scenarios. Yantai Zhenghai's characterization process includes specialized coating evaluation to determine how surface treatments affect mechanical properties, finding that their nickel-copper-nickel triple-layer coating increases load capacity by approximately 15% compared to uncoated magnets. The company has established standardized testing procedures that evaluate both compressive and tensile strength across different magnet grades, with particular attention to the relationship between magnetic field strength degradation and mechanical stress thresholds.

Strengths: Practical focus on industrial applications with real-world loading conditions; comprehensive coating analysis that addresses both mechanical protection and load capacity enhancement. Weaknesses: Their characterization methods primarily focus on static load scenarios with less emphasis on dynamic or cyclical loading conditions that may be critical in certain applications.

Critical Patents in Neodymium Magnet Load Testing

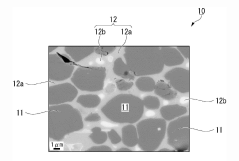

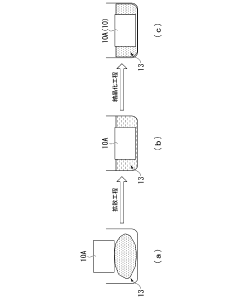

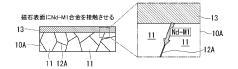

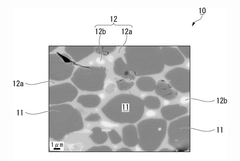

Neodymium magnet and neodymium magnet manufacturing method

PatentPendingJP2022132032A

Innovation

- A neodymium magnet with a material structure comprising a Nd-Fe-B main phase and a grain boundary phase enriched with Nd, containing an alloy of Fe and additional elements like Si, Ge, or Sn, is manufactured through a process involving diffusion and crystallization to enhance electrical resistivity without compromising magnetic properties.

Motor, drive system, cleaner, unmanned aerial vehicle, and electric aircraft

PatentWO2022181808A1

Innovation

- A neodymium magnet with a material structure comprising a main phase of Nd-Fe-B and a grain boundary phase with higher Nd concentration, including an alloy of Nd, Fe, and additive elements like Si, Ge, or Sn, which is diffused into the grain boundaries to enhance electrical resistivity without deteriorating magnetic properties.

Safety Standards for Magnetic Structural Applications

The implementation of neodymium magnets in structural applications necessitates adherence to comprehensive safety standards due to their powerful magnetic properties. Currently, several international organizations have established guidelines specifically addressing magnetic structural applications, including ASTM International's F2052 standard for measuring magnetic pull forces and the International Electrotechnical Commission's IEC 62464 guidelines for magnetic safety in medical environments.

Safety standards typically categorize magnetic structural applications based on risk levels, with critical infrastructure requiring more stringent compliance measures than consumer applications. These standards mandate specific testing protocols for load-bearing magnetic connections, including cyclic loading tests, temperature variation assessments, and long-term degradation analyses to ensure structural integrity over time.

The European Committee for Standardization (CEN) has developed EN 12472, which addresses corrosion resistance requirements for magnetic components in structures, particularly important for neodymium magnets which are susceptible to oxidation without proper coating. Additionally, the International Building Code (IBC) has recently incorporated provisions for magnetic fastening systems, requiring minimum safety factors of 3.0 for primary load-bearing applications.

Occupational safety considerations are equally important, with OSHA in the United States establishing exposure limits for workers handling large neodymium magnets. These regulations specify maximum field strength exposure durations and mandate protective equipment when working with magnetic assemblies exceeding certain field strengths, typically above 0.5 millitesla for extended periods.

Risk assessment frameworks for magnetic structural applications typically evaluate three primary factors: mechanical failure potential, magnetic field interference with sensitive equipment, and biological exposure risks. The IEEE Standard 1785 provides methodologies for quantifying these risks and implementing appropriate mitigation strategies in various environments.

For neodymium magnet applications specifically, certification processes often require documentation of magnet grade, coating specifications, and load capacity calculations validated through physical testing. The National Fire Protection Association (NFPA) has also addressed magnetic assemblies in their standards, particularly regarding fire resistance ratings and behavior during extreme temperature events, as neodymium magnets lose magnetic properties at temperatures exceeding their Curie point (approximately 320°C).

Emerging standards are beginning to address the unique challenges of dynamic loading in magnetic structural applications, with organizations like ISO developing new testing protocols that account for vibration, impact resistance, and seismic performance of magnetic connections in building systems.

Safety standards typically categorize magnetic structural applications based on risk levels, with critical infrastructure requiring more stringent compliance measures than consumer applications. These standards mandate specific testing protocols for load-bearing magnetic connections, including cyclic loading tests, temperature variation assessments, and long-term degradation analyses to ensure structural integrity over time.

The European Committee for Standardization (CEN) has developed EN 12472, which addresses corrosion resistance requirements for magnetic components in structures, particularly important for neodymium magnets which are susceptible to oxidation without proper coating. Additionally, the International Building Code (IBC) has recently incorporated provisions for magnetic fastening systems, requiring minimum safety factors of 3.0 for primary load-bearing applications.

Occupational safety considerations are equally important, with OSHA in the United States establishing exposure limits for workers handling large neodymium magnets. These regulations specify maximum field strength exposure durations and mandate protective equipment when working with magnetic assemblies exceeding certain field strengths, typically above 0.5 millitesla for extended periods.

Risk assessment frameworks for magnetic structural applications typically evaluate three primary factors: mechanical failure potential, magnetic field interference with sensitive equipment, and biological exposure risks. The IEEE Standard 1785 provides methodologies for quantifying these risks and implementing appropriate mitigation strategies in various environments.

For neodymium magnet applications specifically, certification processes often require documentation of magnet grade, coating specifications, and load capacity calculations validated through physical testing. The National Fire Protection Association (NFPA) has also addressed magnetic assemblies in their standards, particularly regarding fire resistance ratings and behavior during extreme temperature events, as neodymium magnets lose magnetic properties at temperatures exceeding their Curie point (approximately 320°C).

Emerging standards are beginning to address the unique challenges of dynamic loading in magnetic structural applications, with organizations like ISO developing new testing protocols that account for vibration, impact resistance, and seismic performance of magnetic connections in building systems.

Environmental Impact of Rare Earth Magnet Production

The production of rare earth magnets, particularly neodymium magnets, presents significant environmental challenges that must be considered when evaluating their application in load-bearing structures. The extraction and processing of rare earth elements like neodymium involve extensive mining operations that cause substantial land degradation, habitat destruction, and landscape alteration. These activities typically require the removal of large volumes of topsoil and rock, permanently changing local ecosystems and biodiversity patterns.

Water pollution represents another critical environmental concern in rare earth magnet production. The separation and refinement processes utilize substantial quantities of toxic chemicals, acids, and heavy metals that can contaminate groundwater and surface water systems. Studies indicate that for every ton of rare earth elements produced, approximately 2,000 tons of toxic waste may be generated, creating long-term environmental liabilities in production regions.

Air quality degradation occurs throughout the production chain, from mining dust to processing emissions. The smelting and separation phases release particulate matter, sulfur dioxide, and greenhouse gases. Additionally, radioactive elements like thorium and uranium, naturally occurring alongside rare earth deposits, present radiation hazards when brought to the surface during extraction operations.

Energy consumption in neodymium magnet production is exceptionally high, with estimates suggesting that processing one ton of rare earth oxides requires between 65,000-75,000 kWh of electricity. This intensive energy requirement translates to substantial carbon emissions, particularly in regions where coal remains the primary energy source for industrial operations.

The geographical concentration of rare earth processing, predominantly in China (controlling approximately 85-90% of global production), has led to localized environmental degradation hotspots. Regions like Baotou in Inner Mongolia have experienced severe environmental deterioration, including the formation of toxic lakes and elevated rates of respiratory and digestive diseases among local populations.

Recent regulatory developments have begun addressing these environmental impacts. China has implemented stricter environmental standards for rare earth processing, while alternative production methods are emerging, including recycling technologies, environmentally optimized extraction processes, and research into substitute materials. These developments are particularly relevant when considering neodymium magnets for structural applications, as the environmental footprint must be balanced against their superior load-bearing capabilities and potential for enabling more efficient structural designs.

Water pollution represents another critical environmental concern in rare earth magnet production. The separation and refinement processes utilize substantial quantities of toxic chemicals, acids, and heavy metals that can contaminate groundwater and surface water systems. Studies indicate that for every ton of rare earth elements produced, approximately 2,000 tons of toxic waste may be generated, creating long-term environmental liabilities in production regions.

Air quality degradation occurs throughout the production chain, from mining dust to processing emissions. The smelting and separation phases release particulate matter, sulfur dioxide, and greenhouse gases. Additionally, radioactive elements like thorium and uranium, naturally occurring alongside rare earth deposits, present radiation hazards when brought to the surface during extraction operations.

Energy consumption in neodymium magnet production is exceptionally high, with estimates suggesting that processing one ton of rare earth oxides requires between 65,000-75,000 kWh of electricity. This intensive energy requirement translates to substantial carbon emissions, particularly in regions where coal remains the primary energy source for industrial operations.

The geographical concentration of rare earth processing, predominantly in China (controlling approximately 85-90% of global production), has led to localized environmental degradation hotspots. Regions like Baotou in Inner Mongolia have experienced severe environmental deterioration, including the formation of toxic lakes and elevated rates of respiratory and digestive diseases among local populations.

Recent regulatory developments have begun addressing these environmental impacts. China has implemented stricter environmental standards for rare earth processing, while alternative production methods are emerging, including recycling technologies, environmentally optimized extraction processes, and research into substitute materials. These developments are particularly relevant when considering neodymium magnets for structural applications, as the environmental footprint must be balanced against their superior load-bearing capabilities and potential for enabling more efficient structural designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!