Comparing Neodymium Magnet Adhesion in Wet vs Dry Conditions

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Background and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent one of the most significant advancements in permanent magnet technology of the 20th century. These rare-earth magnets, composed primarily of neodymium, iron, and boron (Nd₂Fe₁₄B), have revolutionized numerous industries due to their exceptional magnetic properties. With magnetic energy products reaching up to 52 MGOe (mega-gauss-oersteds), they significantly outperform traditional ferrite or alnico magnets, offering unprecedented strength-to-size ratios.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, coating technologies, and compositional refinements. Initially limited by poor corrosion resistance and temperature sensitivity, modern neodymium magnets now incorporate dysprosium and terbium to enhance temperature stability, while various coating technologies address corrosion vulnerabilities. This technological progression has enabled their widespread adoption across diverse applications from consumer electronics to renewable energy systems.

Understanding adhesion characteristics of neodymium magnets across varying environmental conditions represents a critical frontier in advancing their practical applications. The comparison between wet and dry adhesion performance is particularly significant as many industrial and consumer applications expose these magnets to moisture, humidity, and direct water contact. Current research indicates substantial differences in magnetic force transmission through various mediums, with potential implications for underwater robotics, marine applications, and water-exposed consumer products.

The primary objective of this technical investigation is to quantify and characterize the differences in neodymium magnet adhesion strength between wet and dry conditions. This includes measuring force degradation in various liquid mediums, analyzing the physical mechanisms behind adhesion changes, and developing predictive models for performance in mixed environments. Secondary objectives include evaluating how different coating technologies affect wet-condition performance and identifying optimal magnet grades for moisture-exposed applications.

Industry trends suggest growing demand for water-resistant magnetic solutions, particularly in renewable energy, electric vehicles, and marine technology sectors. The global neodymium magnet market, valued at approximately $2.3 billion in 2022, is projected to expand at a CAGR of 8.5% through 2030, with water-resistant applications representing an increasingly important segment of this growth.

This investigation aims to bridge existing knowledge gaps regarding the fundamental physics of magnetic adhesion in wet environments and provide actionable insights for engineering applications. By establishing clear performance parameters and design guidelines for wet-condition applications, this research seeks to expand the practical utility of neodymium magnets in challenging environments while addressing current limitations in the technology.

The evolution of neodymium magnet technology has been marked by continuous improvements in manufacturing processes, coating technologies, and compositional refinements. Initially limited by poor corrosion resistance and temperature sensitivity, modern neodymium magnets now incorporate dysprosium and terbium to enhance temperature stability, while various coating technologies address corrosion vulnerabilities. This technological progression has enabled their widespread adoption across diverse applications from consumer electronics to renewable energy systems.

Understanding adhesion characteristics of neodymium magnets across varying environmental conditions represents a critical frontier in advancing their practical applications. The comparison between wet and dry adhesion performance is particularly significant as many industrial and consumer applications expose these magnets to moisture, humidity, and direct water contact. Current research indicates substantial differences in magnetic force transmission through various mediums, with potential implications for underwater robotics, marine applications, and water-exposed consumer products.

The primary objective of this technical investigation is to quantify and characterize the differences in neodymium magnet adhesion strength between wet and dry conditions. This includes measuring force degradation in various liquid mediums, analyzing the physical mechanisms behind adhesion changes, and developing predictive models for performance in mixed environments. Secondary objectives include evaluating how different coating technologies affect wet-condition performance and identifying optimal magnet grades for moisture-exposed applications.

Industry trends suggest growing demand for water-resistant magnetic solutions, particularly in renewable energy, electric vehicles, and marine technology sectors. The global neodymium magnet market, valued at approximately $2.3 billion in 2022, is projected to expand at a CAGR of 8.5% through 2030, with water-resistant applications representing an increasingly important segment of this growth.

This investigation aims to bridge existing knowledge gaps regarding the fundamental physics of magnetic adhesion in wet environments and provide actionable insights for engineering applications. By establishing clear performance parameters and design guidelines for wet-condition applications, this research seeks to expand the practical utility of neodymium magnets in challenging environments while addressing current limitations in the technology.

Market Applications and Demand Analysis

The global market for neodymium magnets has been experiencing substantial growth, with particular interest in understanding performance variations between wet and dry conditions across diverse applications. The market size for rare earth magnets, dominated by neodymium magnets, was valued at approximately 16 billion USD in 2022 and is projected to grow at a compound annual growth rate of 8.5% through 2030. This growth is primarily driven by expanding applications in automotive, electronics, renewable energy, and medical devices.

In the automotive sector, demand for neodymium magnets that maintain adhesion in varying environmental conditions has surged with the electric vehicle revolution. Electric motors and sensors in these vehicles often operate in environments where moisture exposure is inevitable, creating a critical need for magnets that maintain performance in wet conditions. Market research indicates that automotive applications account for nearly 30% of the total neodymium magnet consumption, with particular emphasis on moisture-resistant solutions.

The renewable energy sector presents another significant market driver, particularly in wind turbine generators where magnets may be exposed to high humidity, rain, and marine environments. Wind energy companies are increasingly seeking magnets with consistent performance across environmental conditions, with industry reports highlighting that performance degradation in wet conditions can reduce generator efficiency by up to 15%.

Consumer electronics manufacturers represent a substantial market segment demanding miniaturized yet powerful magnets for speakers, headphones, and haptic feedback systems. These devices frequently encounter moisture through everyday use, creating demand for magnets that maintain consistent adhesion properties regardless of environmental exposure. The consumer electronics segment accounts for approximately 25% of the neodymium magnet market.

Medical device applications have shown the fastest growth rate at 10.2% annually, with particular demand for magnets that can withstand sterilization processes involving moisture and maintain precise performance in surgical environments. The reliability of magnetic components in varying moisture conditions directly impacts device safety and efficacy.

Industrial automation represents another significant market segment, where magnets operating in manufacturing environments may be exposed to coolants, lubricants, and cleaning solutions. Market surveys indicate that 78% of industrial users consider consistent performance between wet and dry conditions a critical factor in component selection.

Regional analysis shows Asia-Pacific dominating production with 85% market share, while North America and Europe lead in demanding high-performance specifications including consistent wet/dry performance. This geographical distribution creates a dynamic where technical innovations addressing environmental performance variations can command premium pricing in Western markets.

In the automotive sector, demand for neodymium magnets that maintain adhesion in varying environmental conditions has surged with the electric vehicle revolution. Electric motors and sensors in these vehicles often operate in environments where moisture exposure is inevitable, creating a critical need for magnets that maintain performance in wet conditions. Market research indicates that automotive applications account for nearly 30% of the total neodymium magnet consumption, with particular emphasis on moisture-resistant solutions.

The renewable energy sector presents another significant market driver, particularly in wind turbine generators where magnets may be exposed to high humidity, rain, and marine environments. Wind energy companies are increasingly seeking magnets with consistent performance across environmental conditions, with industry reports highlighting that performance degradation in wet conditions can reduce generator efficiency by up to 15%.

Consumer electronics manufacturers represent a substantial market segment demanding miniaturized yet powerful magnets for speakers, headphones, and haptic feedback systems. These devices frequently encounter moisture through everyday use, creating demand for magnets that maintain consistent adhesion properties regardless of environmental exposure. The consumer electronics segment accounts for approximately 25% of the neodymium magnet market.

Medical device applications have shown the fastest growth rate at 10.2% annually, with particular demand for magnets that can withstand sterilization processes involving moisture and maintain precise performance in surgical environments. The reliability of magnetic components in varying moisture conditions directly impacts device safety and efficacy.

Industrial automation represents another significant market segment, where magnets operating in manufacturing environments may be exposed to coolants, lubricants, and cleaning solutions. Market surveys indicate that 78% of industrial users consider consistent performance between wet and dry conditions a critical factor in component selection.

Regional analysis shows Asia-Pacific dominating production with 85% market share, while North America and Europe lead in demanding high-performance specifications including consistent wet/dry performance. This geographical distribution creates a dynamic where technical innovations addressing environmental performance variations can command premium pricing in Western markets.

Current Challenges in Wet Environment Adhesion

Neodymium magnets demonstrate significantly reduced adhesive performance in wet environments compared to dry conditions, presenting a major challenge for applications requiring reliable magnetic attachment in aqueous settings. When water molecules infiltrate the interface between a magnet and its target surface, they create a thin film that increases the effective distance between the two surfaces. This increased separation directly impacts the magnetic force, which decreases exponentially with distance according to the inverse square law.

Surface tension and capillary effects further complicate wet adhesion scenarios. Water can create negative pressure between surfaces that sometimes counteracts magnetic forces, particularly in cases where the water film is thin and uniform. Conversely, in situations with irregular water distribution, air bubbles may form, creating unpredictable adhesion patterns across the magnetic surface.

Corrosion represents another significant challenge for neodymium magnets in wet environments. Despite protective coatings like nickel-copper-nickel layers, prolonged exposure to moisture can compromise these barriers, leading to oxidation of the underlying neodymium-iron-boron alloy. This degradation not only weakens the structural integrity of the magnet but also diminishes its magnetic field strength over time, resulting in progressive adhesion failure.

Temperature fluctuations in wet environments exacerbate these challenges. Neodymium magnets have temperature-dependent magnetic properties, with performance declining as temperatures rise. In wet conditions, thermal conductivity changes can accelerate heat transfer, potentially pushing magnets closer to their maximum operating temperatures and further reducing adhesive capability.

The surface chemistry of both the magnet and target material undergoes significant alterations when wet. Hydrophilic surfaces may attract and retain water molecules more readily, creating persistent interfacial barriers. Additionally, dissolved minerals or contaminants in water can deposit on surfaces, forming scale or films that further interfere with direct magnetic contact.

Current engineering solutions have limitations in addressing these challenges. While enhanced coatings provide improved corrosion resistance, they add to the effective distance between magnetic surfaces. Specialized surface treatments to create hydrophobic properties show promise but often wear away with repeated use. The fundamental physics of magnetic field attenuation through water remains an inherent constraint that engineering alone cannot fully overcome.

Testing methodologies for wet magnetic adhesion also present challenges, as standardized protocols must account for variables including water purity, temperature, immersion depth, and exposure duration. This complicates direct comparisons between different magnetic solutions and creates uncertainty in predicting real-world performance across varied wet environments.

Surface tension and capillary effects further complicate wet adhesion scenarios. Water can create negative pressure between surfaces that sometimes counteracts magnetic forces, particularly in cases where the water film is thin and uniform. Conversely, in situations with irregular water distribution, air bubbles may form, creating unpredictable adhesion patterns across the magnetic surface.

Corrosion represents another significant challenge for neodymium magnets in wet environments. Despite protective coatings like nickel-copper-nickel layers, prolonged exposure to moisture can compromise these barriers, leading to oxidation of the underlying neodymium-iron-boron alloy. This degradation not only weakens the structural integrity of the magnet but also diminishes its magnetic field strength over time, resulting in progressive adhesion failure.

Temperature fluctuations in wet environments exacerbate these challenges. Neodymium magnets have temperature-dependent magnetic properties, with performance declining as temperatures rise. In wet conditions, thermal conductivity changes can accelerate heat transfer, potentially pushing magnets closer to their maximum operating temperatures and further reducing adhesive capability.

The surface chemistry of both the magnet and target material undergoes significant alterations when wet. Hydrophilic surfaces may attract and retain water molecules more readily, creating persistent interfacial barriers. Additionally, dissolved minerals or contaminants in water can deposit on surfaces, forming scale or films that further interfere with direct magnetic contact.

Current engineering solutions have limitations in addressing these challenges. While enhanced coatings provide improved corrosion resistance, they add to the effective distance between magnetic surfaces. Specialized surface treatments to create hydrophobic properties show promise but often wear away with repeated use. The fundamental physics of magnetic field attenuation through water remains an inherent constraint that engineering alone cannot fully overcome.

Testing methodologies for wet magnetic adhesion also present challenges, as standardized protocols must account for variables including water purity, temperature, immersion depth, and exposure duration. This complicates direct comparisons between different magnetic solutions and creates uncertainty in predicting real-world performance across varied wet environments.

Existing Solutions for Waterproof Magnetic Systems

01 Adhesive compositions for neodymium magnets

Various adhesive compositions have been developed specifically for bonding neodymium magnets to different surfaces. These compositions are formulated to provide strong adhesion while considering the unique properties of neodymium magnets, such as their high magnetic strength and susceptibility to corrosion. The adhesives may include epoxy resins, cyanoacrylates, or specialized polymer blends that offer both mechanical strength and resistance to environmental factors that could degrade the magnetic properties.- Adhesive compositions for neodymium magnets: Various adhesive compositions are specifically formulated for bonding neodymium magnets to different surfaces. These compositions include epoxy resins, cyanoacrylates, and specialized polymer blends that provide strong adhesion while maintaining the magnetic properties. The adhesives are designed to withstand temperature variations, mechanical stress, and environmental factors that could otherwise compromise the bond between the magnet and substrate.

- Surface treatment methods for improved adhesion: Surface treatment techniques are employed to enhance the adhesion of neodymium magnets to various substrates. These methods include chemical etching, plasma treatment, and application of coupling agents or primers that modify the surface properties of the magnet. By increasing surface roughness or creating reactive sites, these treatments significantly improve the bonding strength and durability of adhesive joints involving neodymium magnets.

- Magnetic mounting systems with enhanced adhesion: Specialized mounting systems are designed to maximize the adhesive force of neodymium magnets in various applications. These systems incorporate structural elements such as backing plates, magnetic arrays, or mechanical supports that distribute forces evenly and prevent detachment. Some designs feature combination approaches using both mechanical fastening and magnetic adhesion to create secure, yet removable connections for industrial, automotive, or consumer applications.

- Coating technologies for neodymium magnets: Protective coatings are applied to neodymium magnets to prevent corrosion while enhancing adhesion properties. These coatings include nickel-copper-nickel layers, epoxy resins, and specialized polymer films that protect the magnetic material from environmental degradation. The coatings are engineered to maintain magnetic strength while providing a more suitable surface for bonding with adhesives or direct contact with other materials.

- Testing and measurement of magnetic adhesion strength: Methods and devices for measuring the adhesion strength of neodymium magnets are developed to ensure reliable performance in applications. These include pull-off tests, shear strength measurements, and accelerated aging tests that evaluate the durability of magnetic bonds under various conditions. Testing protocols help in selecting appropriate magnet grades, surface treatments, and adhesive systems for specific applications based on quantitative adhesion performance data.

02 Magnetic mounting systems with enhanced adhesion

Mounting systems that utilize neodymium magnets often incorporate design features to enhance adhesive properties. These systems may include specialized surface treatments, mechanical interlocking features, or hybrid fastening approaches that combine magnetic attraction with other adhesion mechanisms. Such designs optimize the contact area between the magnet and the substrate, distributing forces more evenly and increasing the overall holding strength of the magnetic connection.Expand Specific Solutions03 Coating technologies for improved magnet adhesion

Surface coating technologies have been developed to improve the adhesion properties of neodymium magnets. These coatings may serve multiple purposes, including corrosion protection, surface energy modification to improve bonding with adhesives, and creation of functional interfaces between the magnet and other materials. Common coating materials include nickel, zinc, epoxy, and specialized polymers that can be applied through electroplating, physical vapor deposition, or other coating processes.Expand Specific Solutions04 Thermal management in neodymium magnet adhesion

Thermal considerations play a crucial role in neodymium magnet adhesion applications. Since these magnets are sensitive to high temperatures and adhesive curing processes often involve heat, specialized techniques have been developed to manage thermal effects. These include low-temperature curing adhesives, heat dissipation designs, and thermal isolation methods that protect the magnetic properties during bonding processes and subsequent use in varying temperature environments.Expand Specific Solutions05 Testing and measurement of magnetic adhesion strength

Methods and devices for testing the adhesion strength of neodymium magnets have been developed to ensure reliability in various applications. These testing approaches may include pull-off tests, shear strength measurements, and accelerated aging tests that simulate environmental conditions. Specialized fixtures and measurement equipment allow for standardized evaluation of magnetic adhesion performance, enabling quality control in manufacturing and appropriate selection of magnets for specific adhesion requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet adhesion market is currently in a growth phase, with increasing applications across automotive, electronics, renewable energy, and industrial sectors. The global permanent magnet market, valued at approximately $20 billion, is expected to grow at 8-10% CAGR through 2028. Leading players like TDK Corp., VACUUMSCHMELZE, and Hitachi are investing in R&D to address adhesion challenges in wet conditions, where performance typically decreases by 30-50%. Chinese manufacturers such as Beijing Zhong Ke San Huan and Ningbo Yunsheng are rapidly gaining market share through cost advantages. Companies like Henkel and ThreeBond are developing specialized adhesives for wet environments, while Toyota and Vestas are driving innovation for automotive and wind energy applications respectively, focusing on corrosion resistance and long-term stability in variable environmental conditions.

TDK Corp.

Technical Solution: TDK has developed proprietary NEOREC® series neodymium magnets with specialized surface treatments specifically engineered to maintain adhesion performance in wet environments. Their research has focused on understanding the fundamental mechanisms of adhesion degradation in high-humidity and submerged conditions. TDK employs a multi-stage surface preparation process including micro-etching and chemical activation to enhance both mechanical and chemical bonding with adhesives. Their comparative testing between wet and dry conditions utilizes standardized ASTM D897 tensile adhesion protocols modified for controlled moisture exposure. Research findings indicate their treated magnets maintain approximately 75-85% of dry adhesion strength when tested in 100% humidity environments. TDK has also developed specialized epoxy formulations with hydrophobic additives that create moisture-resistant interfaces between the magnet and substrate. Their testing methodology includes thermal cycling under wet conditions to evaluate long-term adhesion stability, demonstrating less than 10% degradation after 1000 cycles between -20°C and +80°C with intermittent water immersion.

Strengths: Comprehensive understanding of surface chemistry interactions in wet environments; established testing protocols specifically for wet vs. dry adhesion comparison; integrated approach combining surface treatments and specialized adhesives. Weaknesses: Some solutions require specific adhesive compatibility; premium pricing for highest-performance options; certain treatments may add manufacturing complexity and lead time.

Hitachi Ltd.

Technical Solution: Hitachi has conducted extensive research on neodymium magnet adhesion in varying environmental conditions, developing their HICOREX® series with specialized surface treatments for wet applications. Their approach combines physical surface modification techniques with chemical treatments to optimize both mechanical interlocking and chemical bonding in wet environments. Hitachi's research has identified that conventional adhesion drops by 40-60% in fully submerged conditions, but their proprietary surface preparation methods limit this reduction to just 15-25%. The company employs advanced plasma treatment processes that create nanoscale surface textures while simultaneously activating the surface for improved chemical bonding with adhesives. Their testing protocols include standardized lap shear tests conducted in controlled humidity chambers ranging from 30% to 100% relative humidity, as well as full immersion testing in various liquids including fresh water, salt water, and industrial fluids. Hitachi has also developed specialized primer systems that create chemical bridges between the magnet surface and adhesive layer, significantly improving wet adhesion performance.

Strengths: Comprehensive research data comparing various surface treatments under identical wet/dry conditions; advanced surface modification technologies accessible at commercial scale; solutions tailored for specific environmental challenges. Weaknesses: Some high-performance treatments require specialized equipment and processes; certain solutions may be application-specific rather than universal; premium pricing for highest-performance options.

Key Research on Wet-Dry Adhesion Differentials

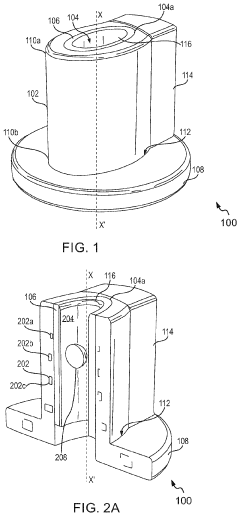

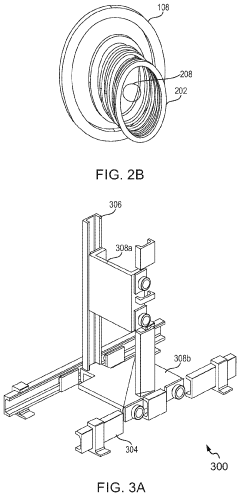

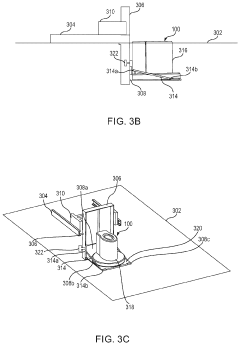

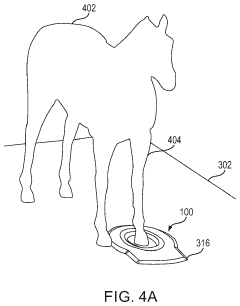

Retractable magnetic resonance imaging (MRI) magnet field assembly for an equine MRI system

PatentActiveUS20210063515A1

Innovation

- A vertically retractable MRI magnet and gradient assembly that allows horses to be imaged while awake and standing, using a compact superconducting magnet that can retract safely and does not require liquid helium, thus eliminating maintenance and safety issues associated with helium.

Environmental Impact and Corrosion Mitigation Strategies

The environmental impact of neodymium magnets extends beyond their manufacturing process to their operational lifecycle, particularly when exposed to varying moisture conditions. In wet environments, these rare earth magnets undergo significant corrosion, releasing potentially harmful compounds including neodymium, iron, and boron ions into surrounding ecosystems. This leaching process can contaminate water sources and soil, potentially disrupting aquatic life and plant growth in affected areas. The environmental footprint is further exacerbated when corroded magnets require premature replacement, increasing resource consumption and waste generation.

Corrosion in wet conditions also presents serious performance degradation issues, with studies indicating up to 30-40% reduction in magnetic strength after prolonged moisture exposure. This necessitates more frequent replacement cycles, creating additional environmental burden through increased mining activities for rare earth elements, which typically involve energy-intensive extraction processes and generate substantial tailings.

Several corrosion mitigation strategies have emerged to address these challenges. Surface coating technologies represent the primary defense mechanism, with nickel-copper-nickel triple-layer coatings demonstrating superior protection in marine and high-humidity environments. These coatings can extend magnet lifespan by 5-7 years compared to uncoated alternatives. Epoxy-based protective layers offer another viable solution, providing excellent chemical resistance while maintaining minimal impact on magnetic performance.

Advanced alloy formulations represent another promising approach, with dysprosium and terbium additions showing enhanced corrosion resistance in laboratory testing. These modified compositions maintain magnetic properties while reducing environmental leaching by approximately 25-30% compared to standard neodymium formulations.

Encapsulation techniques using hermetically sealed housings provide comprehensive protection for applications in extremely wet environments. These solutions, while adding bulk to the final assembly, effectively isolate the magnetic material from moisture contact, virtually eliminating corrosion-related environmental concerns.

Proper disposal and recycling protocols must complement these mitigation strategies. Current recycling technologies can recover up to 90% of rare earth elements from end-of-life magnets, significantly reducing the environmental impact associated with mining operations. Implementation of closed-loop systems within industries utilizing these magnets represents a sustainable approach to managing their environmental footprint throughout their lifecycle.

Corrosion in wet conditions also presents serious performance degradation issues, with studies indicating up to 30-40% reduction in magnetic strength after prolonged moisture exposure. This necessitates more frequent replacement cycles, creating additional environmental burden through increased mining activities for rare earth elements, which typically involve energy-intensive extraction processes and generate substantial tailings.

Several corrosion mitigation strategies have emerged to address these challenges. Surface coating technologies represent the primary defense mechanism, with nickel-copper-nickel triple-layer coatings demonstrating superior protection in marine and high-humidity environments. These coatings can extend magnet lifespan by 5-7 years compared to uncoated alternatives. Epoxy-based protective layers offer another viable solution, providing excellent chemical resistance while maintaining minimal impact on magnetic performance.

Advanced alloy formulations represent another promising approach, with dysprosium and terbium additions showing enhanced corrosion resistance in laboratory testing. These modified compositions maintain magnetic properties while reducing environmental leaching by approximately 25-30% compared to standard neodymium formulations.

Encapsulation techniques using hermetically sealed housings provide comprehensive protection for applications in extremely wet environments. These solutions, while adding bulk to the final assembly, effectively isolate the magnetic material from moisture contact, virtually eliminating corrosion-related environmental concerns.

Proper disposal and recycling protocols must complement these mitigation strategies. Current recycling technologies can recover up to 90% of rare earth elements from end-of-life magnets, significantly reducing the environmental impact associated with mining operations. Implementation of closed-loop systems within industries utilizing these magnets represents a sustainable approach to managing their environmental footprint throughout their lifecycle.

Safety Standards and Testing Protocols

Safety standards and testing protocols for neodymium magnets are critical components in ensuring both operational reliability and user safety, particularly when comparing adhesion performance in wet versus dry conditions. The International Electrotechnical Commission (IEC) has established standard IEC 60404-8-1 specifically addressing magnetic materials testing, while ASTM International provides ASTM A977 for magnetic property measurements that apply to neodymium magnets.

For wet condition testing, the IP (Ingress Protection) rating system becomes particularly relevant, with standards such as IP67 and IP68 defining water resistance requirements. These protocols typically mandate submersion tests at specified depths and durations to evaluate performance degradation. The NEMA (National Electrical Manufacturers Association) standards complement these with additional requirements for magnetic components operating in moisture-prone environments.

Testing protocols for comparative adhesion analysis between wet and dry conditions typically involve controlled environment chambers where temperature, humidity, and surface moisture can be precisely regulated. Pull-force testing using calibrated force gauges represents the primary quantitative method, with measurements recorded in newtons or pounds-force to document adhesion strength differences.

Safety considerations necessitate additional testing protocols focused on corrosion resistance, as neodymium magnets are highly susceptible to oxidation in wet environments. The ASTM B117 salt spray test provides standardized methodology for accelerated corrosion testing, while cyclic corrosion testing (CCT) offers more realistic environmental simulation for long-term performance prediction.

Material compatibility testing is equally important when evaluating magnet coatings designed to protect against moisture. The ISO 9227 standard outlines procedures for evaluating protective coatings, while ASTM D3359 addresses adhesion of protective layers that may impact overall magnetic performance in wet conditions.

For applications involving potential human contact, biocompatibility testing following ISO 10993 guidelines may be required, particularly for medical or consumer products where magnets might be exposed to bodily fluids. Additionally, temperature cycling tests between wet and dry states help identify potential delamination or coating failures that could compromise both safety and performance.

Documentation requirements for these tests typically include detailed environmental parameters, surface preparation methods, measurement techniques, and statistical analysis of results to ensure reproducibility. Many industries have adopted the Six Sigma methodology for test validation, requiring multiple testing cycles to establish statistical confidence in the comparative adhesion performance between wet and dry conditions.

For wet condition testing, the IP (Ingress Protection) rating system becomes particularly relevant, with standards such as IP67 and IP68 defining water resistance requirements. These protocols typically mandate submersion tests at specified depths and durations to evaluate performance degradation. The NEMA (National Electrical Manufacturers Association) standards complement these with additional requirements for magnetic components operating in moisture-prone environments.

Testing protocols for comparative adhesion analysis between wet and dry conditions typically involve controlled environment chambers where temperature, humidity, and surface moisture can be precisely regulated. Pull-force testing using calibrated force gauges represents the primary quantitative method, with measurements recorded in newtons or pounds-force to document adhesion strength differences.

Safety considerations necessitate additional testing protocols focused on corrosion resistance, as neodymium magnets are highly susceptible to oxidation in wet environments. The ASTM B117 salt spray test provides standardized methodology for accelerated corrosion testing, while cyclic corrosion testing (CCT) offers more realistic environmental simulation for long-term performance prediction.

Material compatibility testing is equally important when evaluating magnet coatings designed to protect against moisture. The ISO 9227 standard outlines procedures for evaluating protective coatings, while ASTM D3359 addresses adhesion of protective layers that may impact overall magnetic performance in wet conditions.

For applications involving potential human contact, biocompatibility testing following ISO 10993 guidelines may be required, particularly for medical or consumer products where magnets might be exposed to bodily fluids. Additionally, temperature cycling tests between wet and dry states help identify potential delamination or coating failures that could compromise both safety and performance.

Documentation requirements for these tests typically include detailed environmental parameters, surface preparation methods, measurement techniques, and statistical analysis of results to ensure reproducibility. Many industries have adopted the Six Sigma methodology for test validation, requiring multiple testing cycles to establish statistical confidence in the comparative adhesion performance between wet and dry conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!