How to Reduce Neodymium Magnet Aging in Outdoor Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Aging Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer exceptional magnetic strength-to-weight ratios, making them indispensable in numerous modern applications ranging from consumer electronics to renewable energy systems and automotive components.

Despite their superior magnetic properties, neodymium magnets face a critical limitation: susceptibility to aging, particularly in outdoor environments. This aging process manifests as a gradual degradation of magnetic properties over time, resulting in diminished performance and potentially catastrophic failure in critical applications. The primary environmental factors accelerating this aging include temperature fluctuations, humidity, corrosive atmospheres, UV radiation, and mechanical stresses.

The economic implications of premature magnet aging are substantial, with global industries spending billions annually on replacement and maintenance. As neodymium magnets continue to play an increasingly vital role in green technologies such as wind turbines and electric vehicles, addressing their longevity has become not just an engineering challenge but also a sustainability imperative.

Historical approaches to mitigating neodymium magnet aging have evolved from basic nickel plating in the 1990s to more sophisticated multi-layer coating systems in recent years. The technological trajectory shows a clear shift from merely addressing corrosion resistance to comprehensive protection strategies that consider multiple degradation mechanisms simultaneously.

Current research indicates that magnet aging follows complex pathways involving surface oxidation, internal microstructural changes, and boundary phase alterations. Understanding these mechanisms at the atomic and microstructural levels has been greatly enhanced by advanced characterization techniques developed over the past decade, including high-resolution electron microscopy and neutron diffraction studies.

The primary objective of this technical investigation is to comprehensively evaluate existing and emerging technologies for reducing neodymium magnet aging in outdoor applications. Specifically, we aim to identify optimal protection strategies that balance performance, cost-effectiveness, and environmental sustainability while extending service life by at least 50% compared to current industry standards.

Secondary objectives include developing predictive models for magnet aging under various environmental conditions, establishing standardized accelerated testing protocols that correlate reliably with real-world performance, and exploring novel material compositions and processing techniques that inherently enhance aging resistance without compromising magnetic properties.

This research is particularly timely given the projected 300% increase in neodymium magnet demand by 2030, driven largely by renewable energy and electric vehicle sectors, coupled with ongoing supply chain vulnerabilities for rare earth materials.

Despite their superior magnetic properties, neodymium magnets face a critical limitation: susceptibility to aging, particularly in outdoor environments. This aging process manifests as a gradual degradation of magnetic properties over time, resulting in diminished performance and potentially catastrophic failure in critical applications. The primary environmental factors accelerating this aging include temperature fluctuations, humidity, corrosive atmospheres, UV radiation, and mechanical stresses.

The economic implications of premature magnet aging are substantial, with global industries spending billions annually on replacement and maintenance. As neodymium magnets continue to play an increasingly vital role in green technologies such as wind turbines and electric vehicles, addressing their longevity has become not just an engineering challenge but also a sustainability imperative.

Historical approaches to mitigating neodymium magnet aging have evolved from basic nickel plating in the 1990s to more sophisticated multi-layer coating systems in recent years. The technological trajectory shows a clear shift from merely addressing corrosion resistance to comprehensive protection strategies that consider multiple degradation mechanisms simultaneously.

Current research indicates that magnet aging follows complex pathways involving surface oxidation, internal microstructural changes, and boundary phase alterations. Understanding these mechanisms at the atomic and microstructural levels has been greatly enhanced by advanced characterization techniques developed over the past decade, including high-resolution electron microscopy and neutron diffraction studies.

The primary objective of this technical investigation is to comprehensively evaluate existing and emerging technologies for reducing neodymium magnet aging in outdoor applications. Specifically, we aim to identify optimal protection strategies that balance performance, cost-effectiveness, and environmental sustainability while extending service life by at least 50% compared to current industry standards.

Secondary objectives include developing predictive models for magnet aging under various environmental conditions, establishing standardized accelerated testing protocols that correlate reliably with real-world performance, and exploring novel material compositions and processing techniques that inherently enhance aging resistance without compromising magnetic properties.

This research is particularly timely given the projected 300% increase in neodymium magnet demand by 2030, driven largely by renewable energy and electric vehicle sectors, coupled with ongoing supply chain vulnerabilities for rare earth materials.

Market Demand Analysis for Durable Outdoor Magnets

The global market for durable outdoor magnets, particularly neodymium-based permanent magnets, has been experiencing robust growth driven by multiple sectors. The renewable energy sector, especially wind turbine generators, represents the largest demand segment with an annual growth rate of 15% since 2018. These applications require magnets that can withstand harsh outdoor conditions while maintaining performance over 20+ year lifespans.

Industrial automation and electric vehicle markets follow closely, with outdoor sensors, actuators, and motor systems demanding high-performance magnets resistant to environmental degradation. Market research indicates that premature magnet aging in outdoor applications costs industries approximately $2.3 billion annually in replacement and maintenance expenses.

Consumer electronics manufacturers are increasingly incorporating neodymium magnets in weather-resistant portable devices, creating a new demand segment growing at 12% annually. This trend is particularly evident in outdoor recreational equipment, where durability under varying weather conditions is paramount.

Geographic analysis reveals that Asia-Pacific dominates the production landscape with 85% of global neodymium magnet manufacturing, while North America and Europe represent the largest markets for high-performance, environmentally-stable magnetic solutions. This supply-demand geography creates significant opportunities for technological innovation in durability enhancement.

Market surveys indicate that customers are willing to pay a 15-30% premium for magnets with proven extended lifespan in outdoor environments, particularly when backed by performance guarantees. This price elasticity demonstrates the significant value placed on solving the aging problem.

The defense and aerospace sectors represent smaller but high-value market segments, where mission-critical applications demand exceptional reliability under extreme environmental conditions. These sectors often pioneer advanced solutions that eventually cascade to commercial applications.

Industry forecasts project the market for environmentally-resistant neodymium magnets to reach $7.8 billion by 2027, representing a compound annual growth rate of 8.4%. This growth trajectory is contingent upon technological advancements that effectively address the aging challenges in outdoor applications.

Customer requirements analysis reveals five critical performance demands: resistance to temperature fluctuations (-40°C to +150°C), humidity tolerance above 95% relative humidity, corrosion resistance in saline environments, UV stability, and mechanical shock resistance. Solutions addressing all five factors simultaneously command the highest market premium.

Industrial automation and electric vehicle markets follow closely, with outdoor sensors, actuators, and motor systems demanding high-performance magnets resistant to environmental degradation. Market research indicates that premature magnet aging in outdoor applications costs industries approximately $2.3 billion annually in replacement and maintenance expenses.

Consumer electronics manufacturers are increasingly incorporating neodymium magnets in weather-resistant portable devices, creating a new demand segment growing at 12% annually. This trend is particularly evident in outdoor recreational equipment, where durability under varying weather conditions is paramount.

Geographic analysis reveals that Asia-Pacific dominates the production landscape with 85% of global neodymium magnet manufacturing, while North America and Europe represent the largest markets for high-performance, environmentally-stable magnetic solutions. This supply-demand geography creates significant opportunities for technological innovation in durability enhancement.

Market surveys indicate that customers are willing to pay a 15-30% premium for magnets with proven extended lifespan in outdoor environments, particularly when backed by performance guarantees. This price elasticity demonstrates the significant value placed on solving the aging problem.

The defense and aerospace sectors represent smaller but high-value market segments, where mission-critical applications demand exceptional reliability under extreme environmental conditions. These sectors often pioneer advanced solutions that eventually cascade to commercial applications.

Industry forecasts project the market for environmentally-resistant neodymium magnets to reach $7.8 billion by 2027, representing a compound annual growth rate of 8.4%. This growth trajectory is contingent upon technological advancements that effectively address the aging challenges in outdoor applications.

Customer requirements analysis reveals five critical performance demands: resistance to temperature fluctuations (-40°C to +150°C), humidity tolerance above 95% relative humidity, corrosion resistance in saline environments, UV stability, and mechanical shock resistance. Solutions addressing all five factors simultaneously command the highest market premium.

Current Challenges in Outdoor Magnet Applications

Neodymium magnets face significant challenges when deployed in outdoor environments, primarily due to their susceptibility to various degradation mechanisms. Temperature fluctuations represent one of the most critical issues, as these magnets can experience irreversible flux losses when exposed to temperatures exceeding their maximum operating range. In harsh outdoor conditions, temperatures can vary dramatically between seasons and even within a single day, potentially accelerating demagnetization processes and reducing magnetic field strength over time.

Corrosion presents another major challenge, particularly in humid or coastal environments. Despite protective coatings like nickel, zinc, or epoxy, these barriers often deteriorate over time due to UV radiation, physical damage, or chemical exposure. Once the protective layer is compromised, the underlying neodymium material rapidly oxidizes, leading to significant performance degradation and structural integrity issues.

Mechanical stress from vibration, impact, or thermal expansion/contraction cycles can induce microcracks in the brittle magnetic material. These structural defects progressively worsen with continued exposure to environmental stressors, ultimately affecting magnetic domain alignment and reducing overall magnetic performance. This is particularly problematic in applications like wind turbines or outdoor machinery where constant vibration is unavoidable.

Radiation exposure, particularly UV radiation from sunlight, degrades both the protective coatings and the magnetic material itself. This photodegradation process accelerates other aging mechanisms and can lead to surface embrittlement and increased susceptibility to environmental damage. Additionally, in certain applications, exposure to electromagnetic fields from nearby equipment can potentially affect magnetic domain stability over extended periods.

The combination of these factors creates complex degradation pathways that are difficult to predict and mitigate. Current protective technologies often represent compromises between cost, durability, and magnetic performance. For instance, thicker protective coatings provide better environmental protection but reduce the effective magnetic strength at the surface and add to manufacturing costs.

Industry standards for outdoor magnetic applications remain inconsistent, with testing protocols often failing to accurately simulate real-world aging conditions. Accelerated aging tests frequently focus on single stressors rather than the combined effects of multiple environmental factors, leading to potential underestimation of field degradation rates. This gap between laboratory testing and actual performance creates significant challenges for engineers designing systems with long service life requirements.

Corrosion presents another major challenge, particularly in humid or coastal environments. Despite protective coatings like nickel, zinc, or epoxy, these barriers often deteriorate over time due to UV radiation, physical damage, or chemical exposure. Once the protective layer is compromised, the underlying neodymium material rapidly oxidizes, leading to significant performance degradation and structural integrity issues.

Mechanical stress from vibration, impact, or thermal expansion/contraction cycles can induce microcracks in the brittle magnetic material. These structural defects progressively worsen with continued exposure to environmental stressors, ultimately affecting magnetic domain alignment and reducing overall magnetic performance. This is particularly problematic in applications like wind turbines or outdoor machinery where constant vibration is unavoidable.

Radiation exposure, particularly UV radiation from sunlight, degrades both the protective coatings and the magnetic material itself. This photodegradation process accelerates other aging mechanisms and can lead to surface embrittlement and increased susceptibility to environmental damage. Additionally, in certain applications, exposure to electromagnetic fields from nearby equipment can potentially affect magnetic domain stability over extended periods.

The combination of these factors creates complex degradation pathways that are difficult to predict and mitigate. Current protective technologies often represent compromises between cost, durability, and magnetic performance. For instance, thicker protective coatings provide better environmental protection but reduce the effective magnetic strength at the surface and add to manufacturing costs.

Industry standards for outdoor magnetic applications remain inconsistent, with testing protocols often failing to accurately simulate real-world aging conditions. Accelerated aging tests frequently focus on single stressors rather than the combined effects of multiple environmental factors, leading to potential underestimation of field degradation rates. This gap between laboratory testing and actual performance creates significant challenges for engineers designing systems with long service life requirements.

Existing Anti-Aging Solutions for Outdoor Magnets

01 Thermal stability and aging mechanisms of neodymium magnets

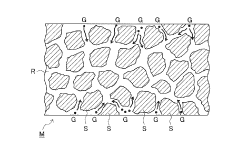

Neodymium magnets experience aging due to thermal effects that can degrade their magnetic properties over time. This aging process involves microstructural changes in the material, including grain boundary diffusion and oxidation. Understanding these mechanisms is crucial for predicting the long-term performance of these magnets in various applications, especially those exposed to elevated temperatures. Research focuses on quantifying the rate of magnetic flux loss and developing models to predict magnet lifespan under different operating conditions.- Thermal stability and aging mechanisms of neodymium magnets: Neodymium magnets experience aging due to thermal effects that can degrade their magnetic properties over time. This aging process involves microstructural changes, including grain boundary diffusion and oxidation, particularly at elevated temperatures. Research focuses on understanding these mechanisms to predict and mitigate performance degradation in applications where temperature stability is critical.

- Coating technologies to prevent aging and corrosion: Protective coatings are applied to neodymium magnets to prevent aging caused by environmental factors such as humidity, oxygen, and corrosive substances. These coatings include metallic layers (nickel, copper, zinc), epoxy resins, and advanced composite materials that form barriers against oxidation while maintaining magnetic performance. The coating techniques have evolved to provide longer service life in harsh operating conditions.

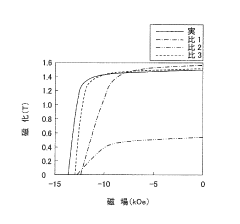

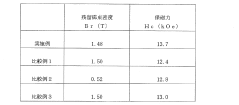

- Composition modifications to enhance aging resistance: Alloying elements are added to neodymium-iron-boron compositions to improve resistance to aging. Elements such as dysprosium, terbium, cobalt, and copper are incorporated to enhance coercivity retention and temperature stability. These compositional modifications strengthen the material against demagnetization at high temperatures and extend the useful lifetime of the magnets in demanding applications.

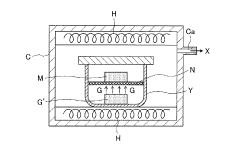

- Manufacturing processes to minimize aging effects: Specialized manufacturing techniques are developed to produce neodymium magnets with improved aging characteristics. These include optimized sintering parameters, grain boundary engineering, and post-production heat treatments that stabilize the magnetic microstructure. Advanced processing methods create more uniform grain structures that are less susceptible to time and temperature-dependent degradation.

- Testing and prediction methods for magnet aging: Accelerated aging tests and computational models are employed to predict the long-term performance of neodymium magnets. These methods involve exposing magnets to elevated temperatures for shorter periods to simulate years of normal operation, combined with magnetic property measurements. Advanced analytical techniques including electron microscopy and magnetic domain imaging help characterize aging mechanisms and validate prediction models for different application environments.

02 Coating and surface treatment methods to prevent aging

Various coating and surface treatment techniques have been developed to protect neodymium magnets from environmental factors that accelerate aging. These include nickel-copper-nickel plating, epoxy coatings, and specialized polymer layers that create barriers against moisture, oxygen, and corrosive substances. Advanced surface passivation methods can significantly extend magnet lifespan by preventing oxidation and corrosion of the base material, which are primary causes of magnetic property degradation over time.Expand Specific Solutions03 Composition modifications to improve aging resistance

Modifying the chemical composition of neodymium magnets by adding specific elements can enhance their resistance to aging. Elements such as dysprosium, terbium, cobalt, and copper are incorporated to improve coercivity retention at elevated temperatures and reduce susceptibility to oxidation. These compositional adjustments create more stable microstructures that maintain magnetic properties over longer periods, even under challenging environmental conditions.Expand Specific Solutions04 Testing and characterization methods for aging assessment

Specialized testing protocols have been developed to evaluate and predict the aging behavior of neodymium magnets. These include accelerated aging tests under controlled temperature and humidity conditions, magnetic flux measurement over time, and advanced microstructural analysis techniques. Methods such as pulse field magnetometry, vibrating sample magnetometry, and electron microscopy allow for detailed characterization of aging-related changes, enabling more accurate lifetime predictions for magnets in specific applications.Expand Specific Solutions05 Manufacturing processes to enhance aging resistance

Innovative manufacturing techniques can significantly improve the aging resistance of neodymium magnets. These include optimized sintering processes, grain boundary engineering, and controlled cooling rates that create more stable microstructures. Post-production treatments such as specific heat treatment protocols and magnetic field exposure during processing can also enhance long-term stability. These manufacturing improvements focus on creating more uniform internal structures with fewer defects that could serve as initiation points for aging-related degradation.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet aging reduction market in outdoor applications is in a growth phase, with increasing demand driven by renewable energy and electric vehicle sectors. The global permanent magnet market is projected to reach $40 billion by 2027, with neodymium magnets comprising a significant portion. Technical maturity varies across solutions, with companies like VACUUMSCHMELZE, TDK Corp, and JL MAG leading with advanced coating technologies. Chinese manufacturers including Baotou Tianhe Magnetics and Zhong Ke San Huan dominate production volume, while research institutions like Zhejiang University and CNRS are developing next-generation anti-aging solutions through surface modification and alloy optimization. Western companies like NIDEC and Honda focus on application-specific protective designs for harsh environments.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed a comprehensive approach to reducing neodymium magnet aging in outdoor applications through their JLMAG® high-performance series. Their technology combines metallurgical innovations with advanced surface protection systems. The company utilizes a grain boundary optimization process that precisely controls the microstructure of NdFeB magnets, creating refined grain boundaries that inherently resist oxidation and corrosion. For outdoor applications, JL MAG employs a triple-layer electroplating system (nickel-copper-nickel) with thicknesses optimized based on application requirements, followed by an epoxy or parylene conformal coating that provides additional moisture and chemical resistance. Their research has demonstrated that this combination can withstand over 1,000 hours in salt spray testing without significant degradation of magnetic properties. JL MAG has also developed heavy rare earth-efficient formulations that strategically place dysprosium and terbium at grain boundaries rather than throughout the material, improving temperature stability while minimizing resource usage. Their magnets have been successfully deployed in wind turbine generators, electric vehicle motors, and other demanding outdoor applications with extended service life expectations.

Strengths: Comprehensive protection combining metallurgical improvements and multi-layer surface treatments; proven performance in demanding outdoor applications; cost-effective use of heavy rare earth elements through targeted distribution. Weaknesses: Some advanced coating options add significant cost; production capacity constraints for highest-performance grades; coating thickness must be carefully controlled to maintain dimensional tolerances.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has developed advanced coating technologies specifically designed to reduce neodymium magnet aging in outdoor applications. Their VACODYM® series incorporates multi-layer protective coating systems that include electroplated nickel-copper-nickel layers followed by an organic epoxy topcoat. This combination provides superior corrosion resistance while maintaining magnetic properties in harsh environments. The company has also pioneered vacuum melting and casting processes that significantly reduce oxygen content in NdFeB magnets, minimizing internal oxidation pathways. Their proprietary grain boundary diffusion process introduces heavy rare earth elements (Dy, Tb) into the grain boundaries rather than the entire microstructure, creating a shell structure that enhances coercivity without sacrificing remanence. This technology allows their magnets to maintain performance at elevated temperatures (up to 200°C) while resisting demagnetization in outdoor conditions with significant temperature fluctuations.

Strengths: Industry-leading multi-layer coating technology provides exceptional corrosion resistance; grain boundary diffusion process optimizes use of heavy rare earth elements; vacuum processing minimizes internal oxidation pathways. Weakness: Higher production costs compared to standard magnets; coating processes add manufacturing complexity; some solutions require specialized equipment not widely available in the industry.

Key Patents and Research on Magnet Corrosion Prevention

Neodymium magnet and production method therefor

PatentInactiveJP2012174920A

Innovation

- A method involving the use of neodymium alloys with non-rare earth metals such as aluminum, copper, manganese, or iron for grain boundary diffusion under reduced pressure, reducing thermal energy and material costs while maintaining coercive force.

Environmental Impact Assessment of Coating Technologies

The coating technologies used to protect neodymium magnets in outdoor applications have varying environmental impacts that must be carefully assessed. Traditional coating methods such as nickel-copper-nickel plating involve heavy metals and chemical processes that generate hazardous waste streams requiring specialized disposal procedures. These processes typically consume significant amounts of water and energy, while also producing air emissions containing volatile organic compounds and metal particulates that can affect local air quality.

Epoxy-based coatings present a different environmental profile, with lower heavy metal content but higher organic solvent usage during application. The curing process for these coatings releases volatile organic compounds that contribute to photochemical smog formation. However, newer water-based epoxy formulations have reduced these emissions substantially, decreasing their environmental footprint by up to 70% compared to traditional solvent-based systems.

Parylene coating technology, which uses vapor deposition processes, offers environmental advantages through its nearly 100% material utilization efficiency and minimal waste generation. The process operates at room temperature, reducing energy consumption compared to high-temperature coating methods. Nevertheless, the precursor chemicals used in parylene deposition may present toxicity concerns if not properly contained and managed.

Emerging environmentally friendly alternatives include zinc-based coatings that provide comparable protection with significantly reduced environmental impact. Life cycle assessments indicate that zinc coatings reduce overall environmental impact by approximately 40% compared to nickel-based alternatives, primarily due to lower energy requirements and reduced toxicity profiles.

The manufacturing facilities implementing these coating technologies must address environmental compliance with increasingly stringent regulations worldwide. Water treatment systems, air scrubbers, and waste management protocols represent significant investments that coating facilities must make to minimize environmental impacts. Companies adopting closed-loop processing systems have demonstrated water usage reductions of up to 80% and waste generation reductions of 60%.

End-of-life considerations also factor into environmental impact assessments, as coated magnets eventually require disposal or recycling. Certain coating types can complicate recycling processes by introducing contaminants that must be separated before the rare earth materials can be recovered. Coatings designed with recyclability in mind can improve overall life cycle environmental performance by facilitating more efficient material recovery at end-of-life.

Epoxy-based coatings present a different environmental profile, with lower heavy metal content but higher organic solvent usage during application. The curing process for these coatings releases volatile organic compounds that contribute to photochemical smog formation. However, newer water-based epoxy formulations have reduced these emissions substantially, decreasing their environmental footprint by up to 70% compared to traditional solvent-based systems.

Parylene coating technology, which uses vapor deposition processes, offers environmental advantages through its nearly 100% material utilization efficiency and minimal waste generation. The process operates at room temperature, reducing energy consumption compared to high-temperature coating methods. Nevertheless, the precursor chemicals used in parylene deposition may present toxicity concerns if not properly contained and managed.

Emerging environmentally friendly alternatives include zinc-based coatings that provide comparable protection with significantly reduced environmental impact. Life cycle assessments indicate that zinc coatings reduce overall environmental impact by approximately 40% compared to nickel-based alternatives, primarily due to lower energy requirements and reduced toxicity profiles.

The manufacturing facilities implementing these coating technologies must address environmental compliance with increasingly stringent regulations worldwide. Water treatment systems, air scrubbers, and waste management protocols represent significant investments that coating facilities must make to minimize environmental impacts. Companies adopting closed-loop processing systems have demonstrated water usage reductions of up to 80% and waste generation reductions of 60%.

End-of-life considerations also factor into environmental impact assessments, as coated magnets eventually require disposal or recycling. Certain coating types can complicate recycling processes by introducing contaminants that must be separated before the rare earth materials can be recovered. Coatings designed with recyclability in mind can improve overall life cycle environmental performance by facilitating more efficient material recovery at end-of-life.

Material Science Advancements for Extreme Conditions

Recent advancements in material science have significantly contributed to addressing the challenge of neodymium magnet aging in outdoor applications. These developments focus on enhancing magnet resilience against extreme environmental conditions that accelerate degradation processes. Innovative coating technologies have emerged as a primary solution, with multi-layer protective systems combining organic and inorganic materials to create comprehensive barriers against moisture, temperature fluctuations, and corrosive elements.

Nano-structured coatings represent a breakthrough in this field, offering superior adhesion and protection while maintaining the magnetic properties of the underlying material. These coatings incorporate self-healing capabilities through the integration of microcapsules containing repair agents that activate when the coating integrity is compromised, extending service life in harsh outdoor environments.

Compositional modifications of neodymium magnets have also shown promising results. By incorporating specific rare earth elements such as dysprosium and terbium in precise quantities, researchers have developed magnets with enhanced coercivity at elevated temperatures, reducing flux losses during thermal cycling. Additionally, grain boundary diffusion techniques have improved the intrinsic resistance to demagnetization without requiring excessive amounts of costly heavy rare earth elements.

Surface treatment innovations include advanced passivation processes that create chemically stable oxide layers on magnet surfaces before applying traditional coatings. These treatments significantly enhance corrosion resistance by forming a robust foundation layer that bonds exceptionally well with subsequent protective coatings, creating a more durable protection system for outdoor exposure.

Microstructural engineering approaches have focused on optimizing grain size and alignment to minimize internal stress points that can serve as initiation sites for corrosion and cracking. Through controlled solidification and heat treatment protocols, magnets with more uniform microstructures demonstrate improved resistance to environmental degradation while maintaining optimal magnetic performance.

Hybrid material systems combining neodymium magnets with complementary materials in composite structures represent another frontier. These designs strategically position protective elements around the magnetic components, creating physical barriers against environmental factors while maintaining the functional properties of the magnetic system. Such approaches have proven particularly effective in applications exposed to marine environments or extreme temperature variations.

Computational modeling and accelerated aging test methodologies have advanced significantly, enabling more accurate prediction of magnet performance under various environmental conditions. These tools allow for rapid iteration in material development, reducing the time required to bring new protective solutions from laboratory to commercial implementation.

Nano-structured coatings represent a breakthrough in this field, offering superior adhesion and protection while maintaining the magnetic properties of the underlying material. These coatings incorporate self-healing capabilities through the integration of microcapsules containing repair agents that activate when the coating integrity is compromised, extending service life in harsh outdoor environments.

Compositional modifications of neodymium magnets have also shown promising results. By incorporating specific rare earth elements such as dysprosium and terbium in precise quantities, researchers have developed magnets with enhanced coercivity at elevated temperatures, reducing flux losses during thermal cycling. Additionally, grain boundary diffusion techniques have improved the intrinsic resistance to demagnetization without requiring excessive amounts of costly heavy rare earth elements.

Surface treatment innovations include advanced passivation processes that create chemically stable oxide layers on magnet surfaces before applying traditional coatings. These treatments significantly enhance corrosion resistance by forming a robust foundation layer that bonds exceptionally well with subsequent protective coatings, creating a more durable protection system for outdoor exposure.

Microstructural engineering approaches have focused on optimizing grain size and alignment to minimize internal stress points that can serve as initiation sites for corrosion and cracking. Through controlled solidification and heat treatment protocols, magnets with more uniform microstructures demonstrate improved resistance to environmental degradation while maintaining optimal magnetic performance.

Hybrid material systems combining neodymium magnets with complementary materials in composite structures represent another frontier. These designs strategically position protective elements around the magnetic components, creating physical barriers against environmental factors while maintaining the functional properties of the magnetic system. Such approaches have proven particularly effective in applications exposed to marine environments or extreme temperature variations.

Computational modeling and accelerated aging test methodologies have advanced significantly, enabling more accurate prediction of magnet performance under various environmental conditions. These tools allow for rapid iteration in material development, reducing the time required to bring new protective solutions from laboratory to commercial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!