Best Bonding Adhesives for Neodymium Magnets in Robotics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Adhesive Technology Background and Objectives

Neodymium magnets have revolutionized robotics since their commercial introduction in the 1980s. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer exceptional magnetic strength-to-weight ratios, making them indispensable in modern robotic systems. The evolution of adhesive technologies for these magnets has paralleled advancements in robotics, transitioning from basic epoxy systems to sophisticated formulations designed specifically for challenging operational environments.

The historical trajectory of neodymium magnet bonding technology reveals significant milestones. Early applications relied on general-purpose industrial adhesives, which often failed to address the unique challenges posed by these powerful magnets. The 1990s saw the emergence of specialized epoxy systems with improved temperature resistance, while the 2000s brought innovations in cyanoacrylate and acrylic adhesives tailored for rapid assembly processes in robotics manufacturing.

Current technological trends indicate a shift toward adhesives that not only provide strong mechanical bonds but also address specific challenges in robotics applications. These include vibration resistance, thermal cycling stability, and compatibility with increasingly miniaturized components. The industry is witnessing growing demand for adhesives that can maintain bond integrity across extreme temperature ranges, from cryogenic environments to high-temperature operation zones common in advanced robotics.

The primary technical objective of this research is to identify and evaluate optimal bonding solutions for neodymium magnets in diverse robotics applications. This includes assessing adhesive performance across various environmental conditions, mechanical stress scenarios, and long-term reliability requirements. Additionally, we aim to explore emerging adhesive technologies that may offer superior performance characteristics for next-generation robotic systems.

Secondary objectives include developing a comprehensive understanding of failure mechanisms in magnet-adhesive interfaces, establishing standardized testing protocols for evaluating bond strength in robotics-specific applications, and identifying environmentally sustainable adhesive alternatives that maintain performance standards while reducing ecological impact.

The scope encompasses both current commercial adhesive systems and emerging technologies in research phases. This includes traditional epoxy systems, modified acrylics, cyanoacrylates, polyurethanes, silicones, and novel hybrid formulations. Special attention will be given to adhesives that address the unique challenges of bonding neodymium magnets to diverse substrate materials commonly used in robotics, including various metals, polymers, ceramics, and composite materials.

This research aims to bridge the gap between theoretical adhesive performance and practical application requirements in the rapidly evolving field of robotics, ultimately providing actionable insights for both immediate implementation and future development pathways.

The historical trajectory of neodymium magnet bonding technology reveals significant milestones. Early applications relied on general-purpose industrial adhesives, which often failed to address the unique challenges posed by these powerful magnets. The 1990s saw the emergence of specialized epoxy systems with improved temperature resistance, while the 2000s brought innovations in cyanoacrylate and acrylic adhesives tailored for rapid assembly processes in robotics manufacturing.

Current technological trends indicate a shift toward adhesives that not only provide strong mechanical bonds but also address specific challenges in robotics applications. These include vibration resistance, thermal cycling stability, and compatibility with increasingly miniaturized components. The industry is witnessing growing demand for adhesives that can maintain bond integrity across extreme temperature ranges, from cryogenic environments to high-temperature operation zones common in advanced robotics.

The primary technical objective of this research is to identify and evaluate optimal bonding solutions for neodymium magnets in diverse robotics applications. This includes assessing adhesive performance across various environmental conditions, mechanical stress scenarios, and long-term reliability requirements. Additionally, we aim to explore emerging adhesive technologies that may offer superior performance characteristics for next-generation robotic systems.

Secondary objectives include developing a comprehensive understanding of failure mechanisms in magnet-adhesive interfaces, establishing standardized testing protocols for evaluating bond strength in robotics-specific applications, and identifying environmentally sustainable adhesive alternatives that maintain performance standards while reducing ecological impact.

The scope encompasses both current commercial adhesive systems and emerging technologies in research phases. This includes traditional epoxy systems, modified acrylics, cyanoacrylates, polyurethanes, silicones, and novel hybrid formulations. Special attention will be given to adhesives that address the unique challenges of bonding neodymium magnets to diverse substrate materials commonly used in robotics, including various metals, polymers, ceramics, and composite materials.

This research aims to bridge the gap between theoretical adhesive performance and practical application requirements in the rapidly evolving field of robotics, ultimately providing actionable insights for both immediate implementation and future development pathways.

Market Demand Analysis for Robotic Magnetic Bonding Solutions

The robotics industry is experiencing unprecedented growth, with the global robotics market projected to reach $260 billion by 2030. Within this expanding ecosystem, the demand for reliable magnetic bonding solutions has become increasingly critical. Neodymium magnets, known for their exceptional strength-to-weight ratio, have become fundamental components in modern robotics systems, creating a specialized market for adhesive solutions that can effectively secure these powerful magnets.

Market research indicates that the specific segment for robotic magnetic bonding solutions is growing at a compound annual growth rate of 12.7%, outpacing the broader adhesives market. This accelerated growth is primarily driven by the rapid expansion of collaborative robots (cobots), autonomous mobile robots (AMRs), and precision manufacturing robotics that rely heavily on neodymium magnets for actuation, sensing, and attachment mechanisms.

The automotive robotics sector represents the largest consumer of these specialized bonding solutions, accounting for approximately 34% of the market share. This dominance stems from the increasing automation in vehicle assembly lines where robots with magnetic end effectors require reliable adhesive solutions that can withstand high-speed operations and variable environmental conditions.

Consumer electronics manufacturing follows closely, representing 28% of the market demand. In this sector, the miniaturization trend has intensified the need for adhesives that can bond smaller yet more powerful magnets in confined spaces while maintaining thermal stability during operation.

Healthcare robotics has emerged as the fastest-growing segment, with a 19.5% annual growth rate. Surgical robots, rehabilitation devices, and medical automation systems require exceptionally reliable magnetic bonding solutions that can withstand sterilization processes while maintaining precise magnetic positioning.

Market analysis reveals several key demand drivers: First, there is growing pressure for adhesives that can perform under extreme temperature fluctuations, as robots increasingly operate in varied environments from industrial freezers to high-temperature manufacturing settings. Second, vibration resistance has become a critical requirement, particularly for robots operating at high speeds or in mobile applications.

Environmental regulations are significantly reshaping market demands, with over 65% of end-users now prioritizing adhesive solutions with low volatile organic compound (VOC) emissions. This shift has accelerated the development of water-based and solvent-free formulations specifically designed for neodymium magnet applications in robotics.

The market also shows increasing demand for "smart" adhesive solutions that incorporate indicators for bond integrity monitoring, allowing predictive maintenance of robotic systems before magnetic component failures occur. This trend aligns with the broader Industry 4.0 movement toward condition-based maintenance strategies in robotics.

Market research indicates that the specific segment for robotic magnetic bonding solutions is growing at a compound annual growth rate of 12.7%, outpacing the broader adhesives market. This accelerated growth is primarily driven by the rapid expansion of collaborative robots (cobots), autonomous mobile robots (AMRs), and precision manufacturing robotics that rely heavily on neodymium magnets for actuation, sensing, and attachment mechanisms.

The automotive robotics sector represents the largest consumer of these specialized bonding solutions, accounting for approximately 34% of the market share. This dominance stems from the increasing automation in vehicle assembly lines where robots with magnetic end effectors require reliable adhesive solutions that can withstand high-speed operations and variable environmental conditions.

Consumer electronics manufacturing follows closely, representing 28% of the market demand. In this sector, the miniaturization trend has intensified the need for adhesives that can bond smaller yet more powerful magnets in confined spaces while maintaining thermal stability during operation.

Healthcare robotics has emerged as the fastest-growing segment, with a 19.5% annual growth rate. Surgical robots, rehabilitation devices, and medical automation systems require exceptionally reliable magnetic bonding solutions that can withstand sterilization processes while maintaining precise magnetic positioning.

Market analysis reveals several key demand drivers: First, there is growing pressure for adhesives that can perform under extreme temperature fluctuations, as robots increasingly operate in varied environments from industrial freezers to high-temperature manufacturing settings. Second, vibration resistance has become a critical requirement, particularly for robots operating at high speeds or in mobile applications.

Environmental regulations are significantly reshaping market demands, with over 65% of end-users now prioritizing adhesive solutions with low volatile organic compound (VOC) emissions. This shift has accelerated the development of water-based and solvent-free formulations specifically designed for neodymium magnet applications in robotics.

The market also shows increasing demand for "smart" adhesive solutions that incorporate indicators for bond integrity monitoring, allowing predictive maintenance of robotic systems before magnetic component failures occur. This trend aligns with the broader Industry 4.0 movement toward condition-based maintenance strategies in robotics.

Current Adhesive Technologies and Challenges for Neodymium Magnets

The adhesive bonding of neodymium magnets in robotics applications presents unique challenges due to the specific properties of these powerful magnets. Currently, several adhesive technologies dominate the market, each with distinct advantages and limitations. Epoxy-based adhesives remain the most widely used solution, particularly two-part epoxy systems that offer excellent strength, temperature resistance, and durability. These adhesives typically provide shear strengths of 20-30 MPa and can withstand operating temperatures between -40°C and 150°C, making them suitable for most robotics applications.

Cyanoacrylates (super glues) represent another common solution, valued for their rapid curing time—often less than 60 seconds—and good initial bond strength. However, they demonstrate limitations in gap-filling capabilities and may become brittle over time, particularly when exposed to temperature fluctuations common in robotic operations.

Polyurethane adhesives have gained popularity for applications requiring some flexibility, offering good vibration resistance and moderate temperature performance. Their elongation properties (typically 100-300%) help absorb mechanical shock, though they generally provide lower overall bond strength compared to epoxies.

Acrylic adhesives present a balance between strength and flexibility, with improved impact resistance compared to epoxies. Modern structural acrylics can achieve shear strengths up to 25 MPa while maintaining some flexibility, making them increasingly popular in dynamic robotic applications.

Despite these options, significant challenges persist in neodymium magnet bonding. The strong magnetic fields generated by these magnets can interfere with proper adhesive application and positioning during the bonding process. Engineers often must develop specialized fixtures and techniques to counteract magnetic forces during assembly.

Surface preparation remains critical yet problematic. Neodymium magnets typically have nickel-copper-nickel protective coatings that require specific surface treatments to achieve optimal adhesion. Standard abrasion techniques may damage these protective layers, potentially compromising the magnet's corrosion resistance.

Temperature management presents another major challenge. The significant difference in thermal expansion coefficients between neodymium magnets and common substrate materials (like aluminum or plastics) creates stress at the bond line during temperature fluctuations. This thermal mismatch can lead to premature bond failure, particularly in applications experiencing wide temperature variations.

Long-term durability concerns also persist. The combination of vibration, thermal cycling, and potential exposure to moisture or chemicals in robotics applications can accelerate adhesive degradation. Current adhesives often demonstrate adequate initial strength but may fail prematurely under these combined stresses over extended periods.

Cyanoacrylates (super glues) represent another common solution, valued for their rapid curing time—often less than 60 seconds—and good initial bond strength. However, they demonstrate limitations in gap-filling capabilities and may become brittle over time, particularly when exposed to temperature fluctuations common in robotic operations.

Polyurethane adhesives have gained popularity for applications requiring some flexibility, offering good vibration resistance and moderate temperature performance. Their elongation properties (typically 100-300%) help absorb mechanical shock, though they generally provide lower overall bond strength compared to epoxies.

Acrylic adhesives present a balance between strength and flexibility, with improved impact resistance compared to epoxies. Modern structural acrylics can achieve shear strengths up to 25 MPa while maintaining some flexibility, making them increasingly popular in dynamic robotic applications.

Despite these options, significant challenges persist in neodymium magnet bonding. The strong magnetic fields generated by these magnets can interfere with proper adhesive application and positioning during the bonding process. Engineers often must develop specialized fixtures and techniques to counteract magnetic forces during assembly.

Surface preparation remains critical yet problematic. Neodymium magnets typically have nickel-copper-nickel protective coatings that require specific surface treatments to achieve optimal adhesion. Standard abrasion techniques may damage these protective layers, potentially compromising the magnet's corrosion resistance.

Temperature management presents another major challenge. The significant difference in thermal expansion coefficients between neodymium magnets and common substrate materials (like aluminum or plastics) creates stress at the bond line during temperature fluctuations. This thermal mismatch can lead to premature bond failure, particularly in applications experiencing wide temperature variations.

Long-term durability concerns also persist. The combination of vibration, thermal cycling, and potential exposure to moisture or chemicals in robotics applications can accelerate adhesive degradation. Current adhesives often demonstrate adequate initial strength but may fail prematurely under these combined stresses over extended periods.

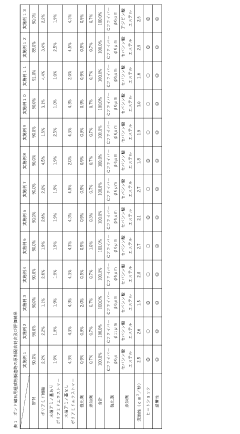

Comparative Analysis of Current Adhesive Solutions for Robotics

01 Epoxy-based adhesives for neodymium magnets

Epoxy-based adhesives are widely used for bonding neodymium magnets due to their excellent adhesion properties and high bonding strength. These adhesives typically contain epoxy resins that provide strong mechanical bonds and resistance to environmental factors. The formulations may include hardeners, fillers, and other additives to enhance specific properties such as thermal stability, electrical conductivity, or flexibility. Epoxy adhesives offer good gap-filling capabilities and can withstand the mechanical stresses associated with magnetic forces.- Epoxy-based adhesives for neodymium magnets: Epoxy-based adhesives provide excellent bonding strength for neodymium magnets due to their strong mechanical properties and resistance to environmental factors. These adhesives typically contain epoxy resins that form cross-linked structures when cured, resulting in high tensile and shear strength. The formulations may include hardeners, fillers, and other additives to enhance specific properties such as thermal conductivity, flexibility, or cure speed. Epoxy adhesives are particularly suitable for applications requiring high mechanical stability and long-term durability.

- Cyanoacrylate adhesives for rapid bonding: Cyanoacrylate adhesives, commonly known as instant adhesives, provide rapid bonding capabilities for neodymium magnets. These adhesives polymerize quickly when exposed to moisture on the surface of the materials being bonded, forming strong bonds within seconds to minutes. They are particularly useful for applications requiring fast assembly times and offer good adhesion to metal surfaces. While they may not provide the same level of long-term durability as epoxy adhesives in some environments, their rapid cure time makes them ideal for certain manufacturing processes where speed is essential.

- Specialized formulations for high-temperature applications: Specialized adhesive formulations designed for high-temperature applications ensure that neodymium magnet bonds maintain their strength under elevated temperature conditions. These adhesives typically incorporate heat-resistant polymers, ceramic fillers, or silicone-based compounds that can withstand temperatures well above standard operating conditions without degradation. The formulations are engineered to address the thermal expansion mismatch between magnets and substrates, preventing bond failure during thermal cycling. These adhesives are crucial for applications in automotive, electronics, and industrial environments where components may be exposed to significant temperature variations.

- Surface treatment methods to enhance bonding strength: Various surface treatment methods can significantly enhance the bonding strength between adhesives and neodymium magnets. These treatments include mechanical abrasion, chemical etching, plasma treatment, and application of primers or coupling agents. By increasing surface roughness, removing contaminants, or creating reactive sites on the magnet surface, these methods improve the mechanical interlocking and chemical bonding between the adhesive and the magnet. Proper surface preparation is often as important as the choice of adhesive itself in achieving optimal bond strength and durability.

- Testing and measurement of bond strength: Various testing methodologies and measurement techniques are employed to evaluate the bonding strength of adhesives used with neodymium magnets. These include shear strength tests, tensile tests, impact resistance evaluations, and environmental aging assessments. Advanced analytical techniques such as finite element analysis may be used to predict bond performance under various stress conditions. Standardized testing protocols ensure consistent evaluation of adhesive performance across different applications and environments, allowing for proper selection of bonding systems based on specific requirements for mechanical strength, temperature resistance, and durability.

02 Cyanoacrylate adhesives for rapid bonding

Cyanoacrylate adhesives, commonly known as instant or super glues, provide rapid bonding solutions for neodymium magnets. These adhesives polymerize quickly when exposed to moisture, forming strong bonds within seconds to minutes. This makes them particularly useful for applications requiring fast assembly times. While they may not offer the same level of ultimate bond strength as epoxy systems, their rapid curing and ease of application make them suitable for many consumer and industrial applications where immediate handling strength is required.Expand Specific Solutions03 High-temperature resistant adhesive formulations

Specialized adhesive formulations designed to withstand elevated temperatures are crucial for neodymium magnet applications in high-temperature environments. These adhesives typically incorporate silicone, polyimide, or modified epoxy chemistries that maintain their bonding strength at temperatures exceeding 150°C. Such formulations are essential for automotive, aerospace, and industrial applications where magnets may be exposed to significant thermal cycling or continuous high-temperature operation. These adhesives often contain ceramic fillers or other additives that enhance thermal stability and prevent bond degradation.Expand Specific Solutions04 Surface treatment methods to enhance adhesion

Various surface treatment methods can significantly improve the adhesion between neodymium magnets and adhesives. These include mechanical abrasion, chemical etching, plasma treatment, and application of specialized primers. Surface treatments remove contaminants, increase surface area, and create chemical functionalities that promote stronger interactions with adhesives. Properly prepared magnet surfaces can dramatically increase bond strength and durability, particularly in challenging environmental conditions or when bonding to difficult substrates like nickel-plated neodymium magnets.Expand Specific Solutions05 Conductive adhesives for electronic applications

Electrically and thermally conductive adhesives provide specialized bonding solutions for neodymium magnets in electronic applications. These adhesives typically contain metallic fillers such as silver, copper, or nickel particles dispersed in an epoxy or silicone matrix. The conductive properties allow for heat dissipation and electrical grounding while maintaining strong mechanical bonds. These adhesives are particularly important in applications such as speakers, sensors, and other electronic devices where the magnet must be both securely bonded and integrated into an electrical or thermal management system.Expand Specific Solutions

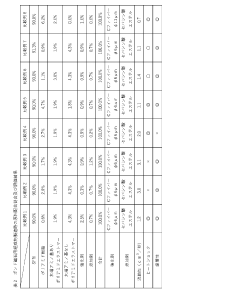

Leading Manufacturers and Suppliers in Magnetic Bonding Industry

The robotics adhesive bonding market for neodymium magnets is in a growth phase, driven by expanding automation and robotics applications. The market is characterized by specialized adhesive solutions from established chemical companies like Henkel AG and ThreeBond Co., alongside magnet manufacturers such as VACUUMSCHMELZE, JL MAG Rare-Earth, and NEOMAX. Technical maturity varies across applications, with companies like ThreeBond and Henkel leading in specialized adhesive formulations that address thermal expansion challenges and magnetic field interference. Research institutions like CNRS and Jilin University contribute to innovation, while automotive giants Toyota and Mitsubishi Electric drive demand through robotics applications. The market shows increasing integration between adhesive manufacturers and magnet producers to develop optimized bonding solutions.

ThreeBond Co., Ltd.

Technical Solution: ThreeBond has engineered specialized anaerobic and epoxy-based adhesive systems for neodymium magnet applications in robotics. Their ThreeBond 2273E is a high-performance, one-component epoxy adhesive specifically designed for bonding neodymium magnets to various substrates used in robotic joints and actuators. The adhesive features a proprietary curing mechanism that minimizes stress on the brittle magnet material during the curing process, reducing the risk of micro-fractures. ThreeBond's formulation includes thermal stabilizers that maintain bond integrity across operating temperatures from -40°C to 150°C, crucial for robotics applications that experience significant temperature fluctuations. Their technology also incorporates electrically insulating properties with a volume resistivity exceeding 1.0×10^14 Ω·cm, preventing unwanted electrical pathways in sensitive electronic components. The company's adhesives achieve shear strengths of 25-30 MPa on properly prepared neodymium surfaces, with specialized primers available for challenging bonding scenarios[2].

Strengths: Excellent thermal cycling resistance; proprietary stress-minimizing cure process; good electrical insulation properties; specialized formulations for different robotic environments. Weaknesses: Requires specific surface preparation protocols; premium pricing compared to general-purpose adhesives; some formulations have limited shelf life requiring refrigerated storage.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed specialized adhesive solutions specifically for neodymium magnet bonding in robotics applications. Their LOCTITE EA 9466 epoxy adhesive system provides high strength bonding with excellent resistance to shock, vibration, and thermal cycling - critical factors in robotic applications. The company's technology incorporates modified epoxy chemistry with nano-fillers that enhance the adhesive's ability to bond to metallic surfaces while maintaining flexibility to accommodate the different thermal expansion rates between magnets and mounting substrates. Henkel's adhesives feature working times of 60 minutes and achieve handling strength within 4-6 hours, with full cure properties developing within 24 hours at room temperature. Their formulations also include corrosion inhibitors that protect the highly reactive neodymium material from environmental degradation, extending the service life of robotic components[1].

Strengths: Superior resistance to thermal cycling (-40°C to 120°C); excellent vibration dampening properties; integrated corrosion protection for neodymium magnets; global technical support network. Weaknesses: Higher cost compared to standard industrial adhesives; requires careful surface preparation; some formulations have limited pot life requiring precise application timing.

Key Technical Innovations in Neodymium Magnet Bonding

Heat-curable resin composition

PatentWO2016093253A1

Innovation

- A thermosetting resin composition comprising epoxy resin, cyanate ester resin, a curing agent with modified amine compounds and phenolic resin, and a polyol compound with low viscosity, which provides rapid curing, excellent storage stability, peeling resistance, and bending properties, ensuring stable fixation of neodymium magnets.

Composition for bonded magnet, bonded magnet, and integrally molded component

PatentWO2024128242A1

Innovation

- A composition comprising 88.0% to 91.0% samarium-iron-nitrogen magnet powder, 3.0% to 7.0% polyamide elastomer, 0.5% to 2.0% carbon fibers, and 0.3% to 1.0% carboxylic acid ester, with a polyamide 12 resin, optimized to achieve fluidity of 1.5 cm³/second or more, enhancing moldability and thermal shock resistance.

Environmental and Temperature Considerations for Magnetic Bonds

Environmental factors and temperature variations significantly impact the performance and durability of adhesive bonds between neodymium magnets and robotic components. The operating environment of robotics systems can range from controlled indoor settings to harsh outdoor conditions, necessitating careful consideration of adhesive selection based on environmental exposure.

Temperature fluctuations pose a primary challenge for magnetic bonds in robotics. Neodymium magnets have a relatively low Curie temperature (310-400°C) and can lose magnetic properties when exposed to high temperatures. More critically, the coefficient of thermal expansion differs between magnets, adhesives, and substrate materials, creating stress at bonding interfaces during temperature cycles.

Humidity and moisture exposure represent another critical environmental factor. Many robotics applications may encounter water, condensation, or high humidity environments. Standard epoxy adhesives can absorb moisture over time, potentially compromising bond integrity through hydrolysis or plasticization effects. For underwater or high-humidity robotic applications, specialized moisture-resistant adhesives such as polyurethane or silicone-based formulations offer superior performance.

Chemical resistance becomes essential when robots operate in environments with exposure to oils, solvents, cleaning agents, or other chemicals. Epoxy-based adhesives generally provide good chemical resistance, while cyanoacrylates may degrade rapidly when exposed to certain solvents or high alkalinity. For robotics in chemical processing or industrial cleaning environments, fluoropolymer-modified adhesives offer enhanced chemical resistance.

UV radiation exposure presents challenges for outdoor robotic applications. Prolonged UV exposure can degrade many adhesive systems, particularly those based on polyurethanes or acrylics. UV-stabilized formulations or adhesives with protective overlays should be considered for outdoor robotics to prevent bond deterioration over time.

Vibration and mechanical stress resistance varies significantly among adhesive types. Robotics frequently experience vibration, shock, and cyclic loading during operation. Rigid adhesives like epoxies provide high strength but may crack under repeated stress, while flexible adhesives like polyurethanes or silicones offer better vibration damping but lower overall bond strength.

Thermal cycling capability is particularly important for robotics operating across varying temperature conditions. Repeated heating and cooling cycles create cumulative stress at the bond interface. Modified epoxies with flexibility enhancers or specialized thermally-conductive adhesives can better accommodate these stresses while maintaining bond integrity over numerous thermal cycles.

Temperature fluctuations pose a primary challenge for magnetic bonds in robotics. Neodymium magnets have a relatively low Curie temperature (310-400°C) and can lose magnetic properties when exposed to high temperatures. More critically, the coefficient of thermal expansion differs between magnets, adhesives, and substrate materials, creating stress at bonding interfaces during temperature cycles.

Humidity and moisture exposure represent another critical environmental factor. Many robotics applications may encounter water, condensation, or high humidity environments. Standard epoxy adhesives can absorb moisture over time, potentially compromising bond integrity through hydrolysis or plasticization effects. For underwater or high-humidity robotic applications, specialized moisture-resistant adhesives such as polyurethane or silicone-based formulations offer superior performance.

Chemical resistance becomes essential when robots operate in environments with exposure to oils, solvents, cleaning agents, or other chemicals. Epoxy-based adhesives generally provide good chemical resistance, while cyanoacrylates may degrade rapidly when exposed to certain solvents or high alkalinity. For robotics in chemical processing or industrial cleaning environments, fluoropolymer-modified adhesives offer enhanced chemical resistance.

UV radiation exposure presents challenges for outdoor robotic applications. Prolonged UV exposure can degrade many adhesive systems, particularly those based on polyurethanes or acrylics. UV-stabilized formulations or adhesives with protective overlays should be considered for outdoor robotics to prevent bond deterioration over time.

Vibration and mechanical stress resistance varies significantly among adhesive types. Robotics frequently experience vibration, shock, and cyclic loading during operation. Rigid adhesives like epoxies provide high strength but may crack under repeated stress, while flexible adhesives like polyurethanes or silicones offer better vibration damping but lower overall bond strength.

Thermal cycling capability is particularly important for robotics operating across varying temperature conditions. Repeated heating and cooling cycles create cumulative stress at the bond interface. Modified epoxies with flexibility enhancers or specialized thermally-conductive adhesives can better accommodate these stresses while maintaining bond integrity over numerous thermal cycles.

Durability and Longevity Testing Methodologies for Robotic Applications

Testing the durability and longevity of adhesive bonds between neodymium magnets and various substrates in robotic applications requires comprehensive methodologies that simulate real-world conditions. The primary testing approaches include thermal cycling tests, which subject bonded assemblies to temperature fluctuations between -40°C and 85°C to evaluate bond integrity under thermal stress. These tests typically run for 500-1000 cycles to identify potential delamination or bond weakening.

Vibration testing represents another critical methodology, where bonded magnet assemblies undergo frequencies ranging from 10Hz to 2000Hz at varying amplitudes. This simulates the operational vibrations robots experience during movement and interaction with environments. Advanced testing protocols often combine vibration with thermal cycling to create more realistic stress conditions.

Humidity resistance testing exposes bonded assemblies to controlled environments of 85% relative humidity at 85°C for periods of 500-1000 hours. This methodology is particularly important for robots operating in outdoor or humid industrial settings where moisture ingress can compromise adhesive performance.

Impact and shock testing evaluates sudden force resistance by subjecting bonded assemblies to standardized impacts, typically measuring from 5G to 50G depending on the intended application. For precision robotics, even minor displacement after impact can significantly affect performance, making this test particularly valuable.

Chemical resistance testing exposes bonded assemblies to common industrial fluids, cleaning agents, and environmental contaminants. This methodology typically involves immersion or vapor exposure for predetermined periods, followed by bond strength evaluation to identify potential degradation pathways.

Accelerated aging tests attempt to compress years of environmental exposure into weeks or months by intensifying UV radiation, temperature, and humidity cycles. The industry standard often involves 1000-2000 hours of exposure, with periodic evaluation of bond strength retention.

Fatigue testing applies cyclic loading to bonded assemblies, typically running for millions of cycles at loads representing 30-70% of ultimate bond strength. This methodology is particularly relevant for robotic joints and end-effectors where repeated movements create continuous stress on magnetic bonds.

Standardized pull and shear testing complements these methodologies by providing quantitative measurements of bond strength before and after environmental exposure. These tests follow ASTM or ISO standards and establish baseline performance metrics against which degradation can be measured.

Vibration testing represents another critical methodology, where bonded magnet assemblies undergo frequencies ranging from 10Hz to 2000Hz at varying amplitudes. This simulates the operational vibrations robots experience during movement and interaction with environments. Advanced testing protocols often combine vibration with thermal cycling to create more realistic stress conditions.

Humidity resistance testing exposes bonded assemblies to controlled environments of 85% relative humidity at 85°C for periods of 500-1000 hours. This methodology is particularly important for robots operating in outdoor or humid industrial settings where moisture ingress can compromise adhesive performance.

Impact and shock testing evaluates sudden force resistance by subjecting bonded assemblies to standardized impacts, typically measuring from 5G to 50G depending on the intended application. For precision robotics, even minor displacement after impact can significantly affect performance, making this test particularly valuable.

Chemical resistance testing exposes bonded assemblies to common industrial fluids, cleaning agents, and environmental contaminants. This methodology typically involves immersion or vapor exposure for predetermined periods, followed by bond strength evaluation to identify potential degradation pathways.

Accelerated aging tests attempt to compress years of environmental exposure into weeks or months by intensifying UV radiation, temperature, and humidity cycles. The industry standard often involves 1000-2000 hours of exposure, with periodic evaluation of bond strength retention.

Fatigue testing applies cyclic loading to bonded assemblies, typically running for millions of cycles at loads representing 30-70% of ultimate bond strength. This methodology is particularly relevant for robotic joints and end-effectors where repeated movements create continuous stress on magnetic bonds.

Standardized pull and shear testing complements these methodologies by providing quantitative measurements of bond strength before and after environmental exposure. These tests follow ASTM or ISO standards and establish baseline performance metrics against which degradation can be measured.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!