Neodymium Magnet Density Analysis in Space-Constrained Applications

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Evolution and Application Goals

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant breakthrough in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), have evolved dramatically over the past four decades, transforming numerous industries through their exceptional magnetic properties. The evolution trajectory has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance.

Initially, neodymium magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). Through refined manufacturing processes and compositional adjustments, contemporary high-performance variants now achieve energy products exceeding 52 MGOe, approaching the theoretical maximum of 64 MGOe. This progression has enabled unprecedented miniaturization while maintaining or enhancing magnetic performance.

The technological evolution of neodymium magnets has been driven by several key factors. Material science advancements have improved microstructure control, enhancing coercivity and remanence. Coating technologies have evolved from simple nickel plating to sophisticated multi-layer systems incorporating epoxy, zinc, gold, and specialized polymers, significantly improving corrosion resistance and extending operational lifespans in challenging environments.

Manufacturing processes have similarly advanced, transitioning from basic sintering methods to sophisticated techniques including hot deformation, spark plasma sintering, and precision die-upset processes. These innovations have enabled more precise control over magnetic domain alignment, resulting in magnets with more uniform and directionally optimized magnetic fields.

In space-constrained applications, the primary technical goal centers on maximizing magnetic force density—the ratio of magnetic performance to physical volume. This objective necessitates optimizing several interdependent factors: maximizing energy product (BHmax), minimizing weight, ensuring thermal stability across operational temperature ranges, and maintaining mechanical integrity under application-specific stresses.

Secondary technical goals include enhancing demagnetization resistance in high-temperature environments, improving mechanical properties to prevent brittle fracture during installation or operation, and developing more environmentally sustainable manufacturing processes that reduce dependence on critical rare earth elements through partial substitution with more abundant materials.

The forward-looking technical objectives for neodymium magnets in space-constrained applications focus on achieving magnetic density increases of 15-20% within the next five years while simultaneously improving temperature stability to function reliably at operating temperatures up to 200°C without significant demagnetization. Additional goals include developing magnets with customizable field geometries to optimize performance in specific application environments and creating advanced simulation tools that accurately predict magnetic performance in complex multi-material assemblies.

Initially, neodymium magnets offered magnetic energy products of approximately 35 MGOe (megagauss-oersteds). Through refined manufacturing processes and compositional adjustments, contemporary high-performance variants now achieve energy products exceeding 52 MGOe, approaching the theoretical maximum of 64 MGOe. This progression has enabled unprecedented miniaturization while maintaining or enhancing magnetic performance.

The technological evolution of neodymium magnets has been driven by several key factors. Material science advancements have improved microstructure control, enhancing coercivity and remanence. Coating technologies have evolved from simple nickel plating to sophisticated multi-layer systems incorporating epoxy, zinc, gold, and specialized polymers, significantly improving corrosion resistance and extending operational lifespans in challenging environments.

Manufacturing processes have similarly advanced, transitioning from basic sintering methods to sophisticated techniques including hot deformation, spark plasma sintering, and precision die-upset processes. These innovations have enabled more precise control over magnetic domain alignment, resulting in magnets with more uniform and directionally optimized magnetic fields.

In space-constrained applications, the primary technical goal centers on maximizing magnetic force density—the ratio of magnetic performance to physical volume. This objective necessitates optimizing several interdependent factors: maximizing energy product (BHmax), minimizing weight, ensuring thermal stability across operational temperature ranges, and maintaining mechanical integrity under application-specific stresses.

Secondary technical goals include enhancing demagnetization resistance in high-temperature environments, improving mechanical properties to prevent brittle fracture during installation or operation, and developing more environmentally sustainable manufacturing processes that reduce dependence on critical rare earth elements through partial substitution with more abundant materials.

The forward-looking technical objectives for neodymium magnets in space-constrained applications focus on achieving magnetic density increases of 15-20% within the next five years while simultaneously improving temperature stability to function reliably at operating temperatures up to 200°C without significant demagnetization. Additional goals include developing magnets with customizable field geometries to optimize performance in specific application environments and creating advanced simulation tools that accurately predict magnetic performance in complex multi-material assemblies.

Market Demand for High-Density Magnets in Miniaturized Devices

The market for high-density neodymium magnets in miniaturized devices has experienced significant growth over the past decade, driven primarily by the increasing demand for smaller, lighter, and more powerful electronic devices. This trend is particularly evident in consumer electronics, medical devices, automotive systems, and aerospace applications where space constraints are critical design factors.

Consumer electronics represent the largest market segment, with smartphones, wearables, and portable audio devices requiring compact yet powerful magnetic components. The global smartphone market alone, with annual shipments exceeding 1.3 billion units, creates substantial demand for high-density magnets used in speakers, vibration motors, and camera autofocus mechanisms. Wearable technology, growing at a compound annual rate of 15%, further intensifies this demand.

Medical device miniaturization presents another significant market opportunity. Implantable devices, hearing aids, and portable diagnostic equipment increasingly rely on high-density magnets. The medical device market values precision and reliability over cost, making it a premium segment for specialized magnetic solutions. The global medical device market, valued at approximately 430 billion dollars, continues to prioritize miniaturization as a key innovation driver.

Automotive applications represent a rapidly expanding market for high-density magnets in space-constrained environments. Modern vehicles contain numerous small sensors, actuators, and electric motors that benefit from neodymium magnets' superior magnetic properties. The transition toward electric vehicles further accelerates this trend, as these vehicles require multiple compact motor systems throughout their design.

Market research indicates that manufacturers are willing to pay premium prices for magnets that offer higher energy density (measured in MGOe) when facing severe space constraints. This price elasticity creates opportunities for advanced material formulations and manufacturing processes that can deliver incremental improvements in magnetic performance per unit volume.

Regional analysis shows Asia-Pacific dominating manufacturing capacity, with China producing over 80% of global rare earth magnets. However, concerns about supply chain security have prompted increased investment in alternative production facilities in North America and Europe, particularly for high-specification magnets used in critical applications.

Market forecasts project continued growth in demand for high-density magnets in miniaturized applications, with particular acceleration in emerging technologies such as microrobotics, next-generation hearing devices, and augmented reality hardware. These applications push the boundaries of current magnetic materials, creating market pull for ongoing research and development in neodymium magnet density optimization.

Consumer electronics represent the largest market segment, with smartphones, wearables, and portable audio devices requiring compact yet powerful magnetic components. The global smartphone market alone, with annual shipments exceeding 1.3 billion units, creates substantial demand for high-density magnets used in speakers, vibration motors, and camera autofocus mechanisms. Wearable technology, growing at a compound annual rate of 15%, further intensifies this demand.

Medical device miniaturization presents another significant market opportunity. Implantable devices, hearing aids, and portable diagnostic equipment increasingly rely on high-density magnets. The medical device market values precision and reliability over cost, making it a premium segment for specialized magnetic solutions. The global medical device market, valued at approximately 430 billion dollars, continues to prioritize miniaturization as a key innovation driver.

Automotive applications represent a rapidly expanding market for high-density magnets in space-constrained environments. Modern vehicles contain numerous small sensors, actuators, and electric motors that benefit from neodymium magnets' superior magnetic properties. The transition toward electric vehicles further accelerates this trend, as these vehicles require multiple compact motor systems throughout their design.

Market research indicates that manufacturers are willing to pay premium prices for magnets that offer higher energy density (measured in MGOe) when facing severe space constraints. This price elasticity creates opportunities for advanced material formulations and manufacturing processes that can deliver incremental improvements in magnetic performance per unit volume.

Regional analysis shows Asia-Pacific dominating manufacturing capacity, with China producing over 80% of global rare earth magnets. However, concerns about supply chain security have prompted increased investment in alternative production facilities in North America and Europe, particularly for high-specification magnets used in critical applications.

Market forecasts project continued growth in demand for high-density magnets in miniaturized applications, with particular acceleration in emerging technologies such as microrobotics, next-generation hearing devices, and augmented reality hardware. These applications push the boundaries of current magnetic materials, creating market pull for ongoing research and development in neodymium magnet density optimization.

Current Limitations and Challenges in Space-Constrained Magnetic Systems

The miniaturization trend in modern electronics and mechanical systems has placed significant constraints on the implementation of magnetic components, particularly those utilizing neodymium magnets. Despite their superior magnetic properties, neodymium magnets face several critical limitations when deployed in space-constrained applications. The primary challenge stems from the fundamental inverse relationship between magnetic field strength and size reduction, creating a technical bottleneck that engineers must navigate.

Temperature sensitivity represents another major limitation, as neodymium magnets experience significant performance degradation at elevated temperatures. In compact systems where heat dissipation is already problematic, this characteristic becomes particularly troublesome. Standard NdFeB magnets begin losing magnetic properties at approximately 80°C, with irreversible losses occurring above 150°C. This thermal constraint severely limits their application in miniaturized high-performance systems where operating temperatures frequently exceed these thresholds.

Mechanical fragility compounds these challenges, as neodymium magnets are inherently brittle and susceptible to chipping, cracking, and shattering when subjected to mechanical stress. This vulnerability becomes more pronounced in space-constrained applications where magnets must be manufactured with increasingly thin profiles, further compromising their structural integrity. The resulting trade-off between magnetic performance and mechanical robustness presents a significant engineering dilemma.

Corrosion susceptibility introduces additional complexity, particularly in applications exposed to humid or corrosive environments. While protective coatings offer some mitigation, these add to the dimensional footprint of the magnet, directly conflicting with space constraints. The coating thickness, typically ranging from 10-25 microns, becomes proportionally significant as magnet dimensions decrease, effectively reducing the volume available for active magnetic material.

Manufacturing precision limitations also emerge as magnets approach sub-millimeter dimensions. Current production technologies struggle to maintain consistent magnetic properties and dimensional accuracy at extremely small scales. This variability introduces performance inconsistencies that become increasingly problematic in precision applications requiring predictable magnetic field characteristics.

Economic considerations further complicate implementation, as the cost-per-unit-volume increases dramatically for miniaturized neodymium magnets due to more complex manufacturing processes, higher material waste, and increased quality control requirements. This cost escalation often forces designers to compromise between optimal magnetic performance and project budget constraints.

Finally, the environmental impact and regulatory challenges surrounding rare earth mining and processing create supply chain vulnerabilities that disproportionately affect space-constrained applications requiring high-performance magnets. These factors collectively necessitate innovative approaches to magnetic system design that can overcome the current limitations while meeting the demanding requirements of modern miniaturized applications.

Temperature sensitivity represents another major limitation, as neodymium magnets experience significant performance degradation at elevated temperatures. In compact systems where heat dissipation is already problematic, this characteristic becomes particularly troublesome. Standard NdFeB magnets begin losing magnetic properties at approximately 80°C, with irreversible losses occurring above 150°C. This thermal constraint severely limits their application in miniaturized high-performance systems where operating temperatures frequently exceed these thresholds.

Mechanical fragility compounds these challenges, as neodymium magnets are inherently brittle and susceptible to chipping, cracking, and shattering when subjected to mechanical stress. This vulnerability becomes more pronounced in space-constrained applications where magnets must be manufactured with increasingly thin profiles, further compromising their structural integrity. The resulting trade-off between magnetic performance and mechanical robustness presents a significant engineering dilemma.

Corrosion susceptibility introduces additional complexity, particularly in applications exposed to humid or corrosive environments. While protective coatings offer some mitigation, these add to the dimensional footprint of the magnet, directly conflicting with space constraints. The coating thickness, typically ranging from 10-25 microns, becomes proportionally significant as magnet dimensions decrease, effectively reducing the volume available for active magnetic material.

Manufacturing precision limitations also emerge as magnets approach sub-millimeter dimensions. Current production technologies struggle to maintain consistent magnetic properties and dimensional accuracy at extremely small scales. This variability introduces performance inconsistencies that become increasingly problematic in precision applications requiring predictable magnetic field characteristics.

Economic considerations further complicate implementation, as the cost-per-unit-volume increases dramatically for miniaturized neodymium magnets due to more complex manufacturing processes, higher material waste, and increased quality control requirements. This cost escalation often forces designers to compromise between optimal magnetic performance and project budget constraints.

Finally, the environmental impact and regulatory challenges surrounding rare earth mining and processing create supply chain vulnerabilities that disproportionately affect space-constrained applications requiring high-performance magnets. These factors collectively necessitate innovative approaches to magnetic system design that can overcome the current limitations while meeting the demanding requirements of modern miniaturized applications.

Current Methodologies for Magnet Density Analysis in Limited Spaces

01 Density characteristics of neodymium magnets

Neodymium magnets, also known as NdFeB magnets, have a high density compared to other types of permanent magnets. The typical density of neodymium magnets ranges from 7.4 to 7.8 g/cm³, depending on the specific composition and manufacturing process. This high density contributes to their compact size and strong magnetic properties, making them suitable for applications where space is limited but high magnetic performance is required.- Density characteristics of neodymium magnets: Neodymium magnets, also known as NdFeB magnets, have a high density compared to other types of permanent magnets. The typical density of neodymium magnets ranges from 7.4 to 7.8 g/cm³, depending on the specific composition and manufacturing process. This high density contributes to their compact size and strong magnetic properties, making them suitable for applications where space is limited but high magnetic strength is required.

- Manufacturing processes affecting density: Various manufacturing processes can affect the density of neodymium magnets. Sintering is a common method that achieves high density through high-temperature compaction of neodymium alloy powders. Hot pressing and isostatic pressing techniques can further increase density by reducing porosity. The cooling rate during solidification also impacts the crystalline structure and resulting density. Optimizing these manufacturing parameters is crucial for achieving the desired magnetic properties and density specifications.

- Density variations in neodymium magnet compositions: The density of neodymium magnets varies depending on their specific composition. Addition of elements such as dysprosium, terbium, or cobalt can alter the density while enhancing properties like temperature resistance or corrosion resistance. Magnets with higher rare earth content generally have higher density. Different grades of neodymium magnets (N35, N42, N52, etc.) have slightly different densities corresponding to their magnetic strength. These compositional variations allow manufacturers to tailor magnets for specific applications with optimal density-to-strength ratios.

- Density measurement techniques for neodymium magnets: Several techniques are employed to measure the density of neodymium magnets accurately. Archimedes' principle using liquid displacement is commonly used for determining the density of irregularly shaped magnets. Gas pycnometry provides precise measurements by detecting the volume of gas displaced by the magnet. X-ray diffraction can analyze the crystalline structure to calculate theoretical density. Quality control processes often include density measurements to ensure consistency in manufacturing and to verify that magnets meet specified standards.

- Applications leveraging neodymium magnet density: The high density of neodymium magnets makes them valuable in numerous applications. In electric motors and generators, their density-to-strength ratio enables compact, powerful designs. Wind turbines utilize dense neodymium magnets to maximize power generation efficiency in limited spaces. Consumer electronics benefit from miniaturization possibilities while maintaining strong magnetic fields. Medical devices such as MRI machines leverage the high density for powerful, precise magnetic fields. Automotive applications include sensors, motors, and speakers where space constraints demand high-density magnetic materials.

02 Manufacturing processes affecting density

Various manufacturing processes can affect the density of neodymium magnets. Sintering is the most common method, which involves compacting neodymium alloy powder and then heating it to form a dense solid. The sintering parameters, including temperature, pressure, and time, significantly influence the final density of the magnet. Alternative manufacturing methods such as hot pressing, injection molding, and bonding with polymers can produce neodymium magnets with different densities, typically ranging from 5.0 to 7.8 g/cm³.Expand Specific Solutions03 Density optimization for specific applications

The density of neodymium magnets can be optimized for specific applications by adjusting the composition and manufacturing process. For high-performance applications requiring maximum magnetic strength, higher density magnets are preferred. In contrast, for applications where weight is a critical factor, the density can be reduced by incorporating lightweight materials or creating composite structures. This optimization allows for tailored magnetic solutions in various industries including automotive, electronics, and renewable energy.Expand Specific Solutions04 Relationship between density and magnetic properties

There is a direct relationship between the density of neodymium magnets and their magnetic properties. Higher density generally correlates with stronger magnetic performance, including higher remanence, coercivity, and maximum energy product. This relationship is due to the increased amount of magnetic material per unit volume. However, beyond a certain threshold, further increases in density may not significantly improve magnetic properties and could lead to brittleness or other mechanical issues. Understanding this relationship is crucial for designing magnets with optimal performance characteristics.Expand Specific Solutions05 Density measurement and quality control

Accurate measurement of neodymium magnet density is essential for quality control in manufacturing processes. Various methods are employed, including the Archimedes principle, gas pycnometry, and dimensional analysis combined with precise weighing. These measurements help ensure consistency in production and verify that magnets meet specified density requirements. Advanced techniques such as X-ray tomography can also be used to detect internal voids or inhomogeneities that might affect the effective density and performance of the magnets.Expand Specific Solutions

Leading Manufacturers and Research Institutions in High-Density Magnetics

The neodymium magnet density analysis market for space-constrained applications is in a growth phase, with increasing demand driven by miniaturization trends across industries. The market is projected to reach significant value as high-performance magnets become essential in compact electronic devices, automotive systems, and medical equipment. Leading players include established manufacturers like Shin-Etsu Chemical, Neo Performance Materials, and Beijing Zhong Ke San Huan High-Tech, alongside automotive giants Toyota and Nissan who are integrating these technologies. Research institutions such as CNRS and Technical University of Denmark are advancing material science innovations, while companies like Magnequench and Fujian Changting Golden Dragon Rare-Earth focus on specialized applications requiring high magnetic density in limited spaces.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed a specialized high-density neodymium magnet production system targeting space-constrained industrial and consumer applications. Their "NanoGrain" technology employs a modified strip casting process that produces exceptionally fine-grained microstructures (average grain size <2μm), enabling higher density and improved mechanical properties. The company's vacuum sintering techniques achieve near-theoretical density (>99.5%) while maintaining precise dimensional control for miniaturized applications. Their patented rare earth element distribution technology creates optimized magnetic domains that maximize energy product in minimal volumes. For automotive sensor applications, San Huan has developed specialized coating technologies that provide corrosion resistance without adding significant volume, maintaining high magnetic performance in harsh environments. Their manufacturing capabilities include precision-shaped magnets with tolerances as tight as ±0.02mm, essential for space-constrained mechanisms in consumer electronics, automotive systems, and medical devices.

Strengths: Exceptional material density and dimensional precision; cost-effective manufacturing at scale; advanced corrosion protection systems suitable for harsh environments. Weaknesses: Limited customization for extremely small volumes; somewhat lower temperature stability than top competitors; less extensive technical support for application engineering.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu has developed proprietary NEOMAX® neodymium magnets with ultra-high density formulations specifically engineered for space-constrained applications. Their technology employs a unique grain boundary diffusion process that allows for increased magnetic flux density while maintaining minimal volume. The company's advanced sintering techniques create magnets with energy products exceeding 55 MGOe, representing some of the highest density-to-volume ratios in the industry. For aerospace and satellite applications, Shin-Etsu has pioneered thermal stability enhancements that maintain magnetic properties in extreme temperature environments (-60°C to +180°C) while achieving up to 30% size reduction compared to conventional magnets. Their patented dysprosium gradient technology concentrates heavy rare earth elements at grain boundaries rather than throughout the material, optimizing magnetic coercivity without compromising remanence.

Strengths: Industry-leading magnetic flux density-to-volume ratio; exceptional thermal stability in extreme environments; reduced dysprosium usage while maintaining performance. Weaknesses: Higher production costs compared to standard neodymium magnets; limited customization options for very small form factors; potential supply chain vulnerabilities due to rare earth material dependencies.

Critical Patents and Research in Neodymium Magnet Miniaturization

Method for strengthening neodymium-iron-boron magnet by means of grain boundary diffusion, and grain-boundary-strengthened neodymium-iron-boron magnet

PatentWO2025129994A1

Innovation

- 采用多次晶界扩散处理方法,通过提供不同重稀土含量的扩散源进行低温、中温和高温晶界扩散处理,结合退火处理,调控磁体内部微观结构,提升磁体的矫顽力和温度稳定性。

Production method of rare earth magnet

PatentInactiveEP2444985A1

Innovation

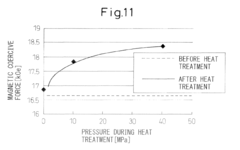

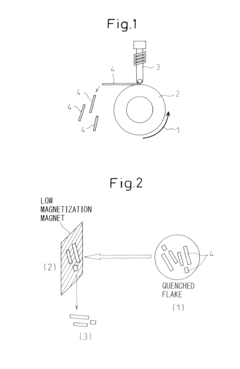

- A heat treatment method with pressurization is applied to rare earth magnets, allowing diffusion or fluidization of the grain boundary phase at temperatures that prevent coarsening of crystal grains, using additives like Ga, Al, and Cu to lower the melting point of the grain boundary phase and enhance magnetic coercive force.

Thermal Management Strategies for Compact Neodymium Magnet Applications

Thermal management represents a critical challenge in the application of neodymium magnets within space-constrained environments. As these powerful permanent magnets continue to find applications in increasingly compact devices, their thermal characteristics demand sophisticated management strategies to maintain performance and longevity.

The fundamental thermal challenge with neodymium magnets stems from their temperature sensitivity, with typical maximum operating temperatures ranging from 80°C to 200°C depending on grade. When exposed to temperatures exceeding their maximum rating, these magnets experience irreversible demagnetization, compromising their functional properties and system reliability.

Space-constrained applications present unique thermal challenges due to limited heat dissipation pathways and concentrated thermal loads. In high-density arrangements, the proximity of multiple magnets can create thermal hotspots, exacerbating temperature management difficulties. This is particularly evident in miniaturized motors, actuators, and sensors where thermal design space is severely limited.

Passive cooling strategies represent the first line of defense in thermal management. These include strategic material selection for surrounding components, incorporation of thermal interface materials (TIMs), and implementation of heat spreaders to distribute thermal energy more effectively. Advanced thermal simulation techniques allow engineers to optimize these passive elements without increasing spatial requirements.

Active cooling approaches become necessary in high-performance applications where passive methods prove insufficient. Miniaturized forced-air cooling systems, liquid cooling channels, and thermoelectric coolers offer viable solutions despite spatial limitations. Recent innovations in micro-cooling technologies have enabled the integration of active thermal management in increasingly compact form factors.

Material innovations have significantly expanded thermal management options. Development of high-temperature neodymium magnet grades (such as N33UH and N35AH) with improved thermal stability allows operation at elevated temperatures without demagnetization. Additionally, composite magnet structures incorporating thermally conductive materials enhance heat dissipation while maintaining magnetic performance.

System-level thermal design represents perhaps the most effective approach, integrating thermal considerations from the earliest design stages. This includes strategic positioning of heat-sensitive components, creation of thermal isolation zones, and implementation of thermal venting pathways that work within spatial constraints while maximizing cooling efficiency.

Future directions in thermal management for compact neodymium magnet applications include development of self-cooling magnetic materials, integration of phase-change materials for thermal buffering, and implementation of AI-driven thermal management systems capable of predictive temperature control in dynamic operating environments.

The fundamental thermal challenge with neodymium magnets stems from their temperature sensitivity, with typical maximum operating temperatures ranging from 80°C to 200°C depending on grade. When exposed to temperatures exceeding their maximum rating, these magnets experience irreversible demagnetization, compromising their functional properties and system reliability.

Space-constrained applications present unique thermal challenges due to limited heat dissipation pathways and concentrated thermal loads. In high-density arrangements, the proximity of multiple magnets can create thermal hotspots, exacerbating temperature management difficulties. This is particularly evident in miniaturized motors, actuators, and sensors where thermal design space is severely limited.

Passive cooling strategies represent the first line of defense in thermal management. These include strategic material selection for surrounding components, incorporation of thermal interface materials (TIMs), and implementation of heat spreaders to distribute thermal energy more effectively. Advanced thermal simulation techniques allow engineers to optimize these passive elements without increasing spatial requirements.

Active cooling approaches become necessary in high-performance applications where passive methods prove insufficient. Miniaturized forced-air cooling systems, liquid cooling channels, and thermoelectric coolers offer viable solutions despite spatial limitations. Recent innovations in micro-cooling technologies have enabled the integration of active thermal management in increasingly compact form factors.

Material innovations have significantly expanded thermal management options. Development of high-temperature neodymium magnet grades (such as N33UH and N35AH) with improved thermal stability allows operation at elevated temperatures without demagnetization. Additionally, composite magnet structures incorporating thermally conductive materials enhance heat dissipation while maintaining magnetic performance.

System-level thermal design represents perhaps the most effective approach, integrating thermal considerations from the earliest design stages. This includes strategic positioning of heat-sensitive components, creation of thermal isolation zones, and implementation of thermal venting pathways that work within spatial constraints while maximizing cooling efficiency.

Future directions in thermal management for compact neodymium magnet applications include development of self-cooling magnetic materials, integration of phase-change materials for thermal buffering, and implementation of AI-driven thermal management systems capable of predictive temperature control in dynamic operating environments.

Environmental and Supply Chain Considerations for Rare Earth Magnets

The environmental impact of neodymium magnets extends throughout their lifecycle, from mining to disposal. Rare earth mining operations, particularly in China which controls approximately 85% of global production, generate significant environmental concerns including soil erosion, water contamination, and the release of toxic byproducts such as radioactive thorium and uranium. The extraction and processing of neodymium requires substantial energy inputs and produces considerable greenhouse gas emissions, with estimates suggesting that producing one ton of rare earth elements generates 1-1.4 tons of radioactive waste.

Supply chain vulnerabilities present critical challenges for space-constrained applications relying on neodymium magnets. Market concentration in China creates geopolitical risks, as evidenced by the 2010-2011 rare earth crisis when export restrictions caused price increases exceeding 300%. This market volatility continues to impact industries dependent on high-density magnets, particularly those requiring miniaturized components where substitution is technically unfeasible.

Recycling infrastructure for rare earth magnets remains underdeveloped despite their classification as critical materials by numerous governments. Current recovery rates are estimated below 1% globally, representing a significant sustainability gap. Emerging technologies for magnet recycling, including hydrogen decrepitation and pyrometallurgical processes, show promise but face economic barriers to widespread implementation.

Alternative sourcing strategies are developing in response to these challenges. Projects in the United States, Australia, and Canada aim to establish more environmentally responsible mining operations with reduced chemical usage and improved waste management. Meanwhile, research into reduced-dysprosium formulations maintains performance while decreasing dependence on the most supply-constrained rare earth elements.

Regulatory frameworks increasingly influence the neodymium magnet supply chain. The European Union's Conflict Minerals Regulation and various national critical materials strategies are reshaping sourcing requirements. For space-constrained applications, these regulations may necessitate comprehensive supply chain documentation and potentially limit certain sourcing options, adding complexity to procurement processes.

Life cycle assessment studies indicate that despite their environmental production impact, neodymium magnets in high-efficiency applications often demonstrate net environmental benefits through operational energy savings. This creates a complex sustainability calculation for designers of space-constrained systems, who must balance immediate environmental impacts against long-term performance benefits.

Supply chain vulnerabilities present critical challenges for space-constrained applications relying on neodymium magnets. Market concentration in China creates geopolitical risks, as evidenced by the 2010-2011 rare earth crisis when export restrictions caused price increases exceeding 300%. This market volatility continues to impact industries dependent on high-density magnets, particularly those requiring miniaturized components where substitution is technically unfeasible.

Recycling infrastructure for rare earth magnets remains underdeveloped despite their classification as critical materials by numerous governments. Current recovery rates are estimated below 1% globally, representing a significant sustainability gap. Emerging technologies for magnet recycling, including hydrogen decrepitation and pyrometallurgical processes, show promise but face economic barriers to widespread implementation.

Alternative sourcing strategies are developing in response to these challenges. Projects in the United States, Australia, and Canada aim to establish more environmentally responsible mining operations with reduced chemical usage and improved waste management. Meanwhile, research into reduced-dysprosium formulations maintains performance while decreasing dependence on the most supply-constrained rare earth elements.

Regulatory frameworks increasingly influence the neodymium magnet supply chain. The European Union's Conflict Minerals Regulation and various national critical materials strategies are reshaping sourcing requirements. For space-constrained applications, these regulations may necessitate comprehensive supply chain documentation and potentially limit certain sourcing options, adding complexity to procurement processes.

Life cycle assessment studies indicate that despite their environmental production impact, neodymium magnets in high-efficiency applications often demonstrate net environmental benefits through operational energy savings. This creates a complex sustainability calculation for designers of space-constrained systems, who must balance immediate environmental impacts against long-term performance benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!