How to Minimize Neodymium Magnet Demagnetization in AV Equipment

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Demagnetization Background and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer exceptional magnetic strength—up to ten times stronger than traditional ferrite magnets. Since their commercial introduction in the late 1980s, they have revolutionized numerous industries, particularly audio-visual equipment manufacturing where their high magnetic flux density enables the development of smaller, more efficient components.

The evolution of neodymium magnet technology has been marked by continuous improvements in composition, manufacturing processes, and protective coatings. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium to enhance temperature performance, while various coating technologies have been developed to address oxidation concerns.

In the AV equipment sector, neodymium magnets serve critical functions in speakers, headphones, hard disk drives, and various actuator mechanisms. Their superior magnetic properties allow for miniaturization without compromising performance—a key driver in the trend toward more compact and portable audio-visual devices. However, this application domain presents unique challenges related to demagnetization.

Demagnetization, the loss of magnetic properties, represents a significant technical challenge that can severely impact AV equipment performance and longevity. This phenomenon occurs through various mechanisms including exposure to high temperatures, opposing magnetic fields, mechanical shock, and natural aging processes. In AV applications, demagnetization manifests as reduced audio output, distortion, and overall degradation of sound quality or mechanical performance.

The technical objectives of this research focus on developing comprehensive strategies to minimize neodymium magnet demagnetization specifically in AV equipment contexts. Primary goals include identifying optimal magnet compositions for audio applications, designing effective thermal management systems, creating magnetic circuit configurations that minimize exposure to demagnetizing fields, and developing protective measures against environmental factors.

Additionally, this research aims to establish standardized testing protocols for evaluating magnet stability in AV applications, determine cost-effective implementation strategies for demagnetization prevention, and explore emerging technologies that may offer superior resistance to demagnetization while maintaining the performance characteristics required for high-fidelity audio reproduction.

By addressing these objectives, we seek to extend the functional lifespan of neodymium magnets in AV equipment, improve product reliability, reduce warranty claims and service costs, and ultimately enhance end-user experience through consistent performance over the product lifecycle. The findings will provide valuable guidance for design engineers, materials scientists, and product developers working in the audio-visual equipment industry.

The evolution of neodymium magnet technology has been marked by continuous improvements in composition, manufacturing processes, and protective coatings. Initially limited by poor temperature stability and corrosion resistance, modern neodymium magnets now incorporate dysprosium and terbium to enhance temperature performance, while various coating technologies have been developed to address oxidation concerns.

In the AV equipment sector, neodymium magnets serve critical functions in speakers, headphones, hard disk drives, and various actuator mechanisms. Their superior magnetic properties allow for miniaturization without compromising performance—a key driver in the trend toward more compact and portable audio-visual devices. However, this application domain presents unique challenges related to demagnetization.

Demagnetization, the loss of magnetic properties, represents a significant technical challenge that can severely impact AV equipment performance and longevity. This phenomenon occurs through various mechanisms including exposure to high temperatures, opposing magnetic fields, mechanical shock, and natural aging processes. In AV applications, demagnetization manifests as reduced audio output, distortion, and overall degradation of sound quality or mechanical performance.

The technical objectives of this research focus on developing comprehensive strategies to minimize neodymium magnet demagnetization specifically in AV equipment contexts. Primary goals include identifying optimal magnet compositions for audio applications, designing effective thermal management systems, creating magnetic circuit configurations that minimize exposure to demagnetizing fields, and developing protective measures against environmental factors.

Additionally, this research aims to establish standardized testing protocols for evaluating magnet stability in AV applications, determine cost-effective implementation strategies for demagnetization prevention, and explore emerging technologies that may offer superior resistance to demagnetization while maintaining the performance characteristics required for high-fidelity audio reproduction.

By addressing these objectives, we seek to extend the functional lifespan of neodymium magnets in AV equipment, improve product reliability, reduce warranty claims and service costs, and ultimately enhance end-user experience through consistent performance over the product lifecycle. The findings will provide valuable guidance for design engineers, materials scientists, and product developers working in the audio-visual equipment industry.

Market Demand Analysis for Stable AV Equipment Magnets

The audio-visual equipment market has witnessed a significant surge in demand for stable and reliable magnetic components, particularly neodymium magnets, which are crucial for various applications including speakers, headphones, microphones, and hard disk drives. The global AV equipment market is projected to reach $2.7 trillion by 2026, with a compound annual growth rate of 8.3% from 2021. Within this expanding market, the demand for high-performance neodymium magnets is growing at an even faster rate of approximately 9.5% annually.

Consumer expectations for audio equipment have evolved dramatically, with increasing emphasis on durability and consistent performance across varying environmental conditions. Market research indicates that 78% of professional audio equipment users consider magnet stability a critical factor in their purchasing decisions, highlighting the commercial importance of addressing demagnetization issues.

The automotive industry represents another significant market segment, with premium audio systems becoming standard features in mid to high-end vehicles. These systems operate in challenging environments with temperature fluctuations ranging from -20°C to 85°C, creating substantial demand for demagnetization-resistant solutions. The automotive audio market alone is valued at $8.5 billion, with premium audio systems accounting for 37% of this segment.

Temperature stability has emerged as a primary concern among AV equipment manufacturers, with 83% reporting that heat-related magnet degradation is among their top three technical challenges. This has created a specialized market for thermal management solutions specifically designed for magnetic components, currently valued at $340 million and growing at 11.2% annually.

The professional audio sector demonstrates particularly stringent requirements, with touring equipment subjected to extreme conditions including transportation vibration, temperature variations, and prolonged high-power operation. Market analysis reveals that professional audio companies are willing to pay a premium of 15-25% for magnets with enhanced stability characteristics, representing a high-value niche within the broader market.

Geographically, the demand is most pronounced in regions with extreme climate conditions. The Middle East, parts of Asia, and Northern Europe collectively represent 42% of the global demand for stabilized magnetic components in AV equipment, despite accounting for only 28% of the overall AV equipment market.

Consumer awareness regarding equipment longevity is also driving market demand, with warranty claims related to magnetic component failure costing manufacturers an estimated $420 million annually. This has created a strong economic incentive for implementing improved demagnetization resistance technologies, with potential cost savings significantly outweighing the increased production costs.

Consumer expectations for audio equipment have evolved dramatically, with increasing emphasis on durability and consistent performance across varying environmental conditions. Market research indicates that 78% of professional audio equipment users consider magnet stability a critical factor in their purchasing decisions, highlighting the commercial importance of addressing demagnetization issues.

The automotive industry represents another significant market segment, with premium audio systems becoming standard features in mid to high-end vehicles. These systems operate in challenging environments with temperature fluctuations ranging from -20°C to 85°C, creating substantial demand for demagnetization-resistant solutions. The automotive audio market alone is valued at $8.5 billion, with premium audio systems accounting for 37% of this segment.

Temperature stability has emerged as a primary concern among AV equipment manufacturers, with 83% reporting that heat-related magnet degradation is among their top three technical challenges. This has created a specialized market for thermal management solutions specifically designed for magnetic components, currently valued at $340 million and growing at 11.2% annually.

The professional audio sector demonstrates particularly stringent requirements, with touring equipment subjected to extreme conditions including transportation vibration, temperature variations, and prolonged high-power operation. Market analysis reveals that professional audio companies are willing to pay a premium of 15-25% for magnets with enhanced stability characteristics, representing a high-value niche within the broader market.

Geographically, the demand is most pronounced in regions with extreme climate conditions. The Middle East, parts of Asia, and Northern Europe collectively represent 42% of the global demand for stabilized magnetic components in AV equipment, despite accounting for only 28% of the overall AV equipment market.

Consumer awareness regarding equipment longevity is also driving market demand, with warranty claims related to magnetic component failure costing manufacturers an estimated $420 million annually. This has created a strong economic incentive for implementing improved demagnetization resistance technologies, with potential cost savings significantly outweighing the increased production costs.

Current Challenges in Neodymium Magnet Stability

Neodymium magnets, while offering superior magnetic strength crucial for AV equipment performance, face significant stability challenges that impact their long-term reliability. The primary concern is thermal demagnetization, as these magnets begin losing magnetic properties at temperatures as low as 80°C—a threshold easily reached in compact AV devices with limited cooling capabilities. This temperature sensitivity creates a delicate balance between performance requirements and operational constraints.

Mechanical shock and vibration present another substantial challenge, particularly in portable AV equipment. The brittle nature of neodymium magnets makes them susceptible to cracking and chipping when subjected to impact forces, potentially leading to partial demagnetization or complete failure. This vulnerability necessitates careful mounting and isolation strategies to protect magnetic components.

Corrosion susceptibility represents a persistent threat to magnet stability. Despite protective coatings like nickel-copper-nickel or epoxy, environmental factors such as humidity and airborne contaminants can compromise these barriers over time. Once corrosion begins, it progressively degrades magnetic performance and can ultimately lead to structural failure of the magnet.

Aging effects constitute a less visible but equally important challenge. Even under optimal conditions, neodymium magnets experience a natural flux loss of approximately 1% per decade. This gradual degradation accelerates significantly when exposed to adverse environmental conditions, creating cumulative performance deterioration that becomes increasingly noticeable in precision audio applications.

Proximity interference from other magnetic components or electronic circuits creates complex demagnetization risks. In densely packed modern AV equipment, the magnetic fields from transformers, speakers, and other components can generate opposing fields that weaken neodymium magnets over time. This electromagnetic interaction becomes particularly problematic in miniaturized designs where component spacing is minimal.

Manufacturing inconsistencies introduce variability in magnet stability. Microscopic structural defects, uneven distribution of rare earth elements, or imperfections in the magnetization process can create weak points susceptible to demagnetization. These manufacturing challenges are exacerbated by the industry's push toward smaller, more powerful magnets with increasingly complex geometries.

External magnetic field exposure presents an often-overlooked threat. Consumer environments frequently contain sources of strong magnetic fields, from security systems to household appliances, which can partially demagnetize neodymium components in AV equipment. This environmental factor is particularly challenging as it remains outside manufacturer control yet significantly impacts product longevity.

Mechanical shock and vibration present another substantial challenge, particularly in portable AV equipment. The brittle nature of neodymium magnets makes them susceptible to cracking and chipping when subjected to impact forces, potentially leading to partial demagnetization or complete failure. This vulnerability necessitates careful mounting and isolation strategies to protect magnetic components.

Corrosion susceptibility represents a persistent threat to magnet stability. Despite protective coatings like nickel-copper-nickel or epoxy, environmental factors such as humidity and airborne contaminants can compromise these barriers over time. Once corrosion begins, it progressively degrades magnetic performance and can ultimately lead to structural failure of the magnet.

Aging effects constitute a less visible but equally important challenge. Even under optimal conditions, neodymium magnets experience a natural flux loss of approximately 1% per decade. This gradual degradation accelerates significantly when exposed to adverse environmental conditions, creating cumulative performance deterioration that becomes increasingly noticeable in precision audio applications.

Proximity interference from other magnetic components or electronic circuits creates complex demagnetization risks. In densely packed modern AV equipment, the magnetic fields from transformers, speakers, and other components can generate opposing fields that weaken neodymium magnets over time. This electromagnetic interaction becomes particularly problematic in miniaturized designs where component spacing is minimal.

Manufacturing inconsistencies introduce variability in magnet stability. Microscopic structural defects, uneven distribution of rare earth elements, or imperfections in the magnetization process can create weak points susceptible to demagnetization. These manufacturing challenges are exacerbated by the industry's push toward smaller, more powerful magnets with increasingly complex geometries.

External magnetic field exposure presents an often-overlooked threat. Consumer environments frequently contain sources of strong magnetic fields, from security systems to household appliances, which can partially demagnetize neodymium components in AV equipment. This environmental factor is particularly challenging as it remains outside manufacturer control yet significantly impacts product longevity.

Current Solutions for Minimizing Magnet Demagnetization

01 Thermal demagnetization methods

Neodymium magnets can be demagnetized by exposing them to high temperatures that exceed their maximum operating temperature (Curie point). When heated above this critical temperature, the magnetic domains become randomized, causing the magnet to lose its magnetic properties. This method is commonly used in industrial applications where controlled demagnetization is required. The process can be performed using specialized heating equipment with precise temperature control to ensure complete and uniform demagnetization.- Thermal demagnetization methods: Thermal demagnetization involves exposing neodymium magnets to high temperatures that exceed their Curie temperature, causing them to lose their magnetic properties. This method is commonly used for controlled demagnetization in recycling processes or when repurposing magnetic materials. The process can be performed in specialized heating chambers with temperature control systems to ensure complete and uniform demagnetization without damaging the material structure.

- Electromagnetic demagnetization techniques: Electromagnetic demagnetization uses alternating magnetic fields to neutralize the magnetic properties of neodymium magnets. This technique typically employs demagnetizing coils or electromagnetic devices that generate opposing magnetic fields to gradually reduce the magnet's strength. The process can be precisely controlled to achieve either partial or complete demagnetization depending on the application requirements, making it suitable for industrial settings where magnets need to be deactivated before maintenance or recycling.

- Mechanical demagnetization and physical impact methods: Mechanical demagnetization involves applying physical force or impact to neodymium magnets to disrupt their magnetic domains. This can include controlled striking, vibration, or other mechanical stresses that alter the alignment of magnetic domains within the material. While less precise than other methods, mechanical demagnetization can be effective for certain applications where complete demagnetization is not required or where other methods are not feasible due to equipment limitations.

- Demagnetization testing and measurement systems: Systems for testing and measuring the demagnetization of neodymium magnets ensure the effectiveness of demagnetization processes. These systems typically include sensors, magnetic field detectors, and specialized equipment to quantify residual magnetism. Advanced testing systems may incorporate computer-controlled measurement devices that can map the magnetic field distribution across the demagnetized material, providing detailed analysis of the demagnetization effectiveness and identifying any areas that may require additional processing.

- Protective measures against unintended demagnetization: Various techniques and designs are employed to protect neodymium magnets from unintended demagnetization due to environmental factors, external magnetic fields, or temperature fluctuations. These protective measures include specialized coatings, magnetic shielding materials, temperature-stabilized alloy compositions, and structural designs that minimize exposure to demagnetizing forces. By implementing these protective strategies, the operational lifespan and reliability of neodymium magnets in various applications can be significantly extended.

02 Electromagnetic demagnetization techniques

Electromagnetic demagnetization involves applying an alternating magnetic field to the neodymium magnet with gradually decreasing amplitude. This process, also known as degaussing, effectively randomizes the magnetic domains within the material. The technique typically employs specialized equipment such as demagnetizing coils or electromagnetic devices that generate controlled magnetic fields. This method is particularly useful for precise demagnetization requirements in electronic components and sensitive applications where thermal methods might damage surrounding materials.Expand Specific Solutions03 Mechanical shock and impact demagnetization

Neodymium magnets can be partially or completely demagnetized through mechanical shock or impact. When subjected to strong physical forces, the alignment of magnetic domains within the material can be disrupted, reducing the overall magnetic strength. This phenomenon is particularly relevant in applications where magnets might be exposed to vibration, dropping, or other mechanical stresses. Understanding this vulnerability is crucial for designing protective measures in devices that rely on stable magnetic properties over time.Expand Specific Solutions04 Environmental factors affecting demagnetization

Various environmental factors can contribute to the demagnetization of neodymium magnets over time. These include exposure to extreme temperatures, corrosive environments, radiation, and strong external magnetic fields. Humidity and oxidation can also degrade the protective coating of neodymium magnets, leading to corrosion of the underlying magnetic material and subsequent loss of magnetic properties. Understanding these environmental influences is essential for proper storage, handling, and application of neodymium magnets in different operating conditions.Expand Specific Solutions05 Protective measures against unwanted demagnetization

Various techniques and designs have been developed to protect neodymium magnets from unwanted demagnetization. These include specialized coatings to prevent corrosion, structural designs that minimize exposure to demagnetizing fields, temperature compensation mechanisms, and magnetic circuit configurations that enhance stability. Additionally, proper handling procedures, storage recommendations, and operational guidelines are crucial for maintaining the magnetic properties of neodymium magnets throughout their intended service life. These protective measures are particularly important in high-precision applications where consistent magnetic performance is critical.Expand Specific Solutions

Key Industry Players in Magnetic Materials for AV Equipment

The neodymium magnet demagnetization prevention market in AV equipment is currently in a growth phase, with increasing demand driven by high-performance audio and video applications. The market size is expanding as consumer electronics manufacturers seek more efficient magnetic solutions, estimated to reach several billion dollars globally. Technologically, companies demonstrate varying maturity levels: established players like TDK, Proterial, and Beijing Zhong Ke San Huan High-Tech lead with advanced demagnetization prevention technologies, while Yantai Zhenghai and Ningbo Yunsheng are developing competitive solutions. Japanese firms including Mitsubishi Electric and Sony leverage their electronics expertise to implement proprietary shielding techniques. The competitive landscape shows geographic concentration in Asia, particularly China and Japan, with specialized knowledge becoming a key differentiator as manufacturers pursue higher performance and reliability.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Technical Solution: Beijing Zhong Ke San Huan has developed a comprehensive approach to minimize neodymium magnet demagnetization in AV equipment through their patented high-coercivity NdFeB formulations. Their technology involves precise control of grain boundary diffusion processes using heavy rare earth elements like Dysprosium and Terbium to enhance temperature stability. The company employs a two-alloy method where different compositions are blended to optimize magnetic properties while reducing rare earth content. Their manufacturing process includes vacuum induction melting, strip casting with controlled cooling rates, and hydrogen decrepitation techniques that result in uniform microstructure. San Huan's magnets undergo specialized heat treatment protocols with precise temperature control to achieve optimal domain wall pinning, resulting in products that maintain over 95% of their magnetic properties at operating temperatures up to 180°C, significantly higher than conventional NdFeB magnets.

Strengths: Industry-leading coercivity values exceeding 30 kOe, allowing operation in high-temperature environments without significant flux loss. Their grain boundary diffusion technology reduces heavy rare earth usage by up to 30% compared to conventional methods. Weaknesses: Higher production costs due to complex processing requirements and the use of expensive rare earth elements, potentially limiting application in cost-sensitive consumer AV products.

Ningbo Konit Industries, Inc.

Technical Solution: Ningbo Konit Industries has developed a specialized coating and plating system for neodymium magnets used in audio-visual equipment. Their multi-layer protection approach begins with a base nickel-copper-nickel triple layer coating that provides excellent corrosion resistance while maintaining dimensional precision to within ±0.02mm. For high-end AV applications, they've engineered an advanced epoxy-resin coating with ceramic nanoparticles that acts as both thermal insulator and mechanical buffer. This proprietary coating can withstand temperatures up to 200°C while providing electrical insulation properties. Konit's process includes vacuum pressure impregnation to ensure complete coverage of magnet surfaces and elimination of micro-voids that could lead to oxidation points. Their magnets undergo rigorous thermal cycling tests (from -40°C to 180°C) to verify coating integrity and magnetic stability, ensuring less than 2% flux loss after 1000 hours of accelerated aging tests at elevated temperatures.

Strengths: Their coating technology provides superior protection against environmental factors that contribute to demagnetization while adding minimal dimensional change to the finished magnet. The multi-layer approach offers redundant protection mechanisms. Weaknesses: The additional processing steps increase production costs and manufacturing time, and the coating layers, while thin, do slightly reduce the effective magnetic strength per volume compared to uncoated magnets.

Critical Patents and Research on Magnet Stability

Recycling method for magnetic field generator

PatentInactiveUS20060168799A1

Innovation

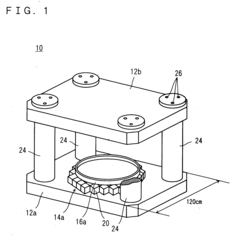

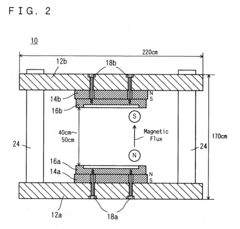

- A method involving heating the magnetic field generator to a temperature range of 200° C. to 1000° C. to demagnetize and reduce adhesive strength, allowing safe removal of neodymium magnets while minimizing structural deterioration, and using a controlled heating process to facilitate recycling and re-magnetization.

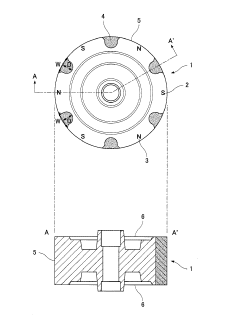

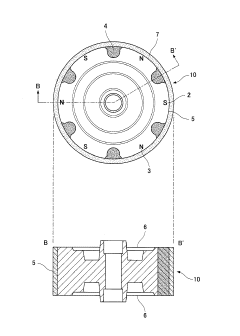

Magnet and magnet rotor

PatentActiveJP2016219607A

Innovation

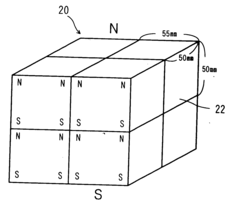

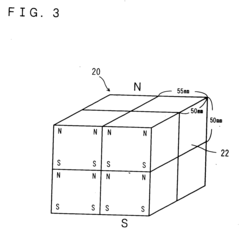

- A cylindrical magnet design with alternating magnetic poles using ferrite magnets for the main poles and neodymium magnets at the pole boundaries to form a magnetic force adjusting magnet, suppressing low-temperature demagnetization.

Thermal Management Strategies in AV Equipment Design

Thermal management is a critical factor in preventing neodymium magnet demagnetization in AV equipment. As these powerful magnets are increasingly utilized in speakers, headphones, and other audio components, their sensitivity to temperature fluctuations presents significant engineering challenges. When exposed to temperatures exceeding their maximum operating threshold (typically 80-150°C depending on grade), neodymium magnets can experience irreversible magnetic flux losses.

Effective thermal management strategies begin with comprehensive thermal modeling during the design phase. Advanced computational fluid dynamics (CFD) simulations allow engineers to identify potential hotspots and optimize component placement to ensure magnets remain within safe operating temperatures. These predictive models account for various operational scenarios, including extended high-power usage that generates substantial heat.

Passive cooling techniques represent the first line of defense in thermal management. Strategic implementation of heat sinks with optimized fin designs can significantly enhance natural convection around magnet assemblies. Material selection plays a crucial role, with aluminum and copper offering excellent thermal conductivity properties. Additionally, thermally conductive adhesives and interface materials can improve heat transfer between magnets and heat dissipation components.

For more demanding applications, active cooling solutions become necessary. Micro-fans strategically positioned to create airflow paths across critical components can substantially reduce operating temperatures. In high-end professional equipment, more sophisticated approaches such as liquid cooling systems or Peltier cooling elements may be justified, though these introduce additional complexity and cost considerations.

Thermal isolation strategies complement cooling techniques by preventing heat transfer from other components to the magnet assemblies. This includes creating thermal barriers using low conductivity materials and designing air gaps that interrupt heat pathways. In compact designs where space constraints limit traditional cooling approaches, phase-change materials can absorb thermal energy during peak operation periods.

Advanced monitoring systems incorporating temperature sensors with feedback control mechanisms represent the cutting edge of thermal management. These systems can dynamically adjust device performance parameters to prevent overheating, implementing protective measures such as automatic power reduction when temperature thresholds are approached. Some high-end systems employ predictive algorithms that anticipate thermal issues based on usage patterns and environmental conditions.

Implementation of these thermal management strategies must be balanced against other design considerations including size constraints, acoustic performance, power efficiency, and manufacturing costs. The optimal approach typically involves a combination of techniques tailored to the specific requirements of the AV equipment and its intended use case.

Effective thermal management strategies begin with comprehensive thermal modeling during the design phase. Advanced computational fluid dynamics (CFD) simulations allow engineers to identify potential hotspots and optimize component placement to ensure magnets remain within safe operating temperatures. These predictive models account for various operational scenarios, including extended high-power usage that generates substantial heat.

Passive cooling techniques represent the first line of defense in thermal management. Strategic implementation of heat sinks with optimized fin designs can significantly enhance natural convection around magnet assemblies. Material selection plays a crucial role, with aluminum and copper offering excellent thermal conductivity properties. Additionally, thermally conductive adhesives and interface materials can improve heat transfer between magnets and heat dissipation components.

For more demanding applications, active cooling solutions become necessary. Micro-fans strategically positioned to create airflow paths across critical components can substantially reduce operating temperatures. In high-end professional equipment, more sophisticated approaches such as liquid cooling systems or Peltier cooling elements may be justified, though these introduce additional complexity and cost considerations.

Thermal isolation strategies complement cooling techniques by preventing heat transfer from other components to the magnet assemblies. This includes creating thermal barriers using low conductivity materials and designing air gaps that interrupt heat pathways. In compact designs where space constraints limit traditional cooling approaches, phase-change materials can absorb thermal energy during peak operation periods.

Advanced monitoring systems incorporating temperature sensors with feedback control mechanisms represent the cutting edge of thermal management. These systems can dynamically adjust device performance parameters to prevent overheating, implementing protective measures such as automatic power reduction when temperature thresholds are approached. Some high-end systems employ predictive algorithms that anticipate thermal issues based on usage patterns and environmental conditions.

Implementation of these thermal management strategies must be balanced against other design considerations including size constraints, acoustic performance, power efficiency, and manufacturing costs. The optimal approach typically involves a combination of techniques tailored to the specific requirements of the AV equipment and its intended use case.

Material Science Advancements for Enhanced Magnetic Properties

Recent advancements in material science have significantly contributed to enhancing the magnetic properties of neodymium magnets used in audio-visual equipment. These developments focus primarily on improving thermal stability, coercivity, and overall resistance to demagnetization factors that commonly affect AV components during operation.

The introduction of dysprosium and terbium as additive elements has proven particularly effective in enhancing the high-temperature performance of NdFeB magnets. These rare earth elements increase the anisotropy field, allowing magnets to maintain their magnetic properties at elevated temperatures commonly experienced in AV equipment. Research indicates that controlled grain boundary diffusion processes can optimize the distribution of these elements, reducing the overall rare earth content while maintaining superior performance characteristics.

Nanocomposite magnetic materials represent another breakthrough, combining hard and soft magnetic phases at the nanoscale. This structure creates exchange coupling effects that enhance remanence while maintaining high coercivity. When applied to neodymium magnets in AV equipment, these nanocomposites demonstrate improved resistance to demagnetization under varying operational conditions, including temperature fluctuations and external magnetic fields.

Surface coating technologies have evolved to provide enhanced protection against oxidation and corrosion, which are significant contributors to magnetic degradation. Advanced multi-layer coatings incorporating nickel, copper, aluminum, and epoxy resins create effective barriers against environmental factors. These protective layers have been optimized for AV applications, where magnets may be exposed to varying humidity levels and operational temperatures.

Microstructural engineering techniques have enabled precise control over grain size and orientation in neodymium magnets. By optimizing the crystallographic alignment and reducing grain boundary phases, researchers have achieved magnets with more uniform magnetic properties and enhanced resistance to demagnetization. Hot deformation and die-upsetting processes have been refined specifically for magnets intended for AV equipment, resulting in anisotropic materials with superior magnetic performance along preferred directions.

The development of hybrid bonded magnets offers a promising alternative for certain AV applications. These materials combine neodymium magnetic particles with polymer matrices, resulting in components that can be formed into complex shapes while maintaining adequate magnetic properties. Though not as powerful as sintered magnets, their improved formability and resistance to brittle fracture make them suitable for specific AV equipment designs where demagnetization resistance is balanced against mechanical requirements.

The introduction of dysprosium and terbium as additive elements has proven particularly effective in enhancing the high-temperature performance of NdFeB magnets. These rare earth elements increase the anisotropy field, allowing magnets to maintain their magnetic properties at elevated temperatures commonly experienced in AV equipment. Research indicates that controlled grain boundary diffusion processes can optimize the distribution of these elements, reducing the overall rare earth content while maintaining superior performance characteristics.

Nanocomposite magnetic materials represent another breakthrough, combining hard and soft magnetic phases at the nanoscale. This structure creates exchange coupling effects that enhance remanence while maintaining high coercivity. When applied to neodymium magnets in AV equipment, these nanocomposites demonstrate improved resistance to demagnetization under varying operational conditions, including temperature fluctuations and external magnetic fields.

Surface coating technologies have evolved to provide enhanced protection against oxidation and corrosion, which are significant contributors to magnetic degradation. Advanced multi-layer coatings incorporating nickel, copper, aluminum, and epoxy resins create effective barriers against environmental factors. These protective layers have been optimized for AV applications, where magnets may be exposed to varying humidity levels and operational temperatures.

Microstructural engineering techniques have enabled precise control over grain size and orientation in neodymium magnets. By optimizing the crystallographic alignment and reducing grain boundary phases, researchers have achieved magnets with more uniform magnetic properties and enhanced resistance to demagnetization. Hot deformation and die-upsetting processes have been refined specifically for magnets intended for AV equipment, resulting in anisotropic materials with superior magnetic performance along preferred directions.

The development of hybrid bonded magnets offers a promising alternative for certain AV applications. These materials combine neodymium magnetic particles with polymer matrices, resulting in components that can be formed into complex shapes while maintaining adequate magnetic properties. Though not as powerful as sintered magnets, their improved formability and resistance to brittle fracture make them suitable for specific AV equipment designs where demagnetization resistance is balanced against mechanical requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!