Neodymium Magnet Cost Effectiveness in Green Energy Projects

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Evolution and Green Energy Goals

Neodymium magnets have evolved significantly since their discovery in the 1980s by General Motors and Sumitomo Special Metals. Initially developed as a solution to the high cost and limited availability of samarium-cobalt magnets, neodymium-iron-boron (NdFeB) magnets quickly became the strongest permanent magnets commercially available. Their superior magnetic properties, including high remanence, coercivity, and energy product, have made them indispensable in various applications, particularly in green energy technologies.

The evolution of neodymium magnets has been characterized by continuous improvements in manufacturing processes, resulting in enhanced performance and reliability. Early production challenges related to corrosion resistance and temperature stability have been largely overcome through advanced coating technologies and compositional adjustments. The addition of dysprosium and terbium has significantly improved high-temperature performance, extending the operational range of these magnets in demanding environments.

Market trends indicate a growing demand for neodymium magnets in renewable energy systems, particularly wind turbines and electric vehicles. The direct-drive wind turbine design, which eliminates the need for a gearbox, relies heavily on neodymium magnets to achieve higher efficiency and reliability. Similarly, permanent magnet synchronous motors in electric vehicles depend on these magnets for optimal power-to-weight ratios and energy efficiency.

The green energy sector has established ambitious goals that directly impact neodymium magnet development. These include reducing rare earth content while maintaining or improving magnetic performance, developing recycling technologies to recover neodymium from end-of-life products, and finding alternative magnet compositions that reduce dependence on critical rare earth elements.

Cost-effectiveness remains a central concern in neodymium magnet applications for green energy. The volatile pricing of rare earth elements, particularly during the 2011 rare earth crisis, has prompted research into more economically sustainable solutions. Industry objectives now focus on optimizing magnet designs to use less material without compromising performance, developing manufacturing processes with lower energy consumption, and establishing more diverse supply chains to mitigate geopolitical risks.

Looking forward, the technical roadmap for neodymium magnets in green energy applications emphasizes several key objectives: increasing maximum operating temperatures to improve efficiency in motor applications, enhancing corrosion resistance for offshore wind installations, and developing magnets with reduced or no heavy rare earth content. These goals align with broader sustainability targets, including reducing the carbon footprint of magnet production and supporting circular economy principles through improved recyclability.

The evolution of neodymium magnets has been characterized by continuous improvements in manufacturing processes, resulting in enhanced performance and reliability. Early production challenges related to corrosion resistance and temperature stability have been largely overcome through advanced coating technologies and compositional adjustments. The addition of dysprosium and terbium has significantly improved high-temperature performance, extending the operational range of these magnets in demanding environments.

Market trends indicate a growing demand for neodymium magnets in renewable energy systems, particularly wind turbines and electric vehicles. The direct-drive wind turbine design, which eliminates the need for a gearbox, relies heavily on neodymium magnets to achieve higher efficiency and reliability. Similarly, permanent magnet synchronous motors in electric vehicles depend on these magnets for optimal power-to-weight ratios and energy efficiency.

The green energy sector has established ambitious goals that directly impact neodymium magnet development. These include reducing rare earth content while maintaining or improving magnetic performance, developing recycling technologies to recover neodymium from end-of-life products, and finding alternative magnet compositions that reduce dependence on critical rare earth elements.

Cost-effectiveness remains a central concern in neodymium magnet applications for green energy. The volatile pricing of rare earth elements, particularly during the 2011 rare earth crisis, has prompted research into more economically sustainable solutions. Industry objectives now focus on optimizing magnet designs to use less material without compromising performance, developing manufacturing processes with lower energy consumption, and establishing more diverse supply chains to mitigate geopolitical risks.

Looking forward, the technical roadmap for neodymium magnets in green energy applications emphasizes several key objectives: increasing maximum operating temperatures to improve efficiency in motor applications, enhancing corrosion resistance for offshore wind installations, and developing magnets with reduced or no heavy rare earth content. These goals align with broader sustainability targets, including reducing the carbon footprint of magnet production and supporting circular economy principles through improved recyclability.

Market Demand Analysis for Rare Earth Magnets

The global market for rare earth magnets, particularly neodymium magnets, has experienced substantial growth driven by the rapid expansion of green energy technologies. Current market valuations place the rare earth permanent magnet market at approximately $16.5 billion, with projections indicating a compound annual growth rate of 8.5% through 2030. This growth trajectory is primarily fueled by increasing demand from wind turbine generators, electric vehicles, and energy-efficient industrial motors.

Wind energy represents one of the largest demand sectors, with each modern utility-scale wind turbine requiring up to 600 kg of neodymium magnets for direct drive generators. The global wind energy capacity additions are expected to reach 110 GW annually by 2025, creating sustained demand for these critical components. This sector alone accounts for roughly 23% of the total rare earth magnet consumption.

The electric vehicle market presents an even more dramatic growth vector, with neodymium magnets being essential components in permanent magnet motors and generators. Each electric vehicle requires approximately 1-2 kg of neodymium magnets, and with global EV sales projected to reach 26 million units by 2030, this represents a significant demand driver. Industry analysts forecast that the automotive sector will consume nearly 40% of global neodymium magnet production by 2025.

Supply constraints remain a critical market factor, with China controlling approximately 85% of global rare earth processing capacity and 92% of magnet manufacturing. This concentration has created significant price volatility, with neodymium prices fluctuating between $50-120 per kilogram over the past five years. Recent geopolitical tensions have further highlighted supply chain vulnerabilities, prompting increased investment in alternative sourcing strategies.

Regional market analysis reveals emerging demand centers in Europe and North America, where green energy initiatives and industrial policies are creating new consumption hubs. The European Union's Green Deal and the United States' Inflation Reduction Act both include provisions that incentivize domestic production of clean energy components, including rare earth magnets, potentially reshaping traditional supply chains.

Price sensitivity analysis indicates that while neodymium magnets represent only 3-5% of total costs for wind turbines and 5-7% for electric vehicles, their price volatility can significantly impact project economics. Cost-effectiveness calculations show that despite higher initial costs compared to conventional alternatives, the performance benefits of neodymium magnets typically yield positive returns on investment through improved efficiency and reduced maintenance requirements in green energy applications.

Wind energy represents one of the largest demand sectors, with each modern utility-scale wind turbine requiring up to 600 kg of neodymium magnets for direct drive generators. The global wind energy capacity additions are expected to reach 110 GW annually by 2025, creating sustained demand for these critical components. This sector alone accounts for roughly 23% of the total rare earth magnet consumption.

The electric vehicle market presents an even more dramatic growth vector, with neodymium magnets being essential components in permanent magnet motors and generators. Each electric vehicle requires approximately 1-2 kg of neodymium magnets, and with global EV sales projected to reach 26 million units by 2030, this represents a significant demand driver. Industry analysts forecast that the automotive sector will consume nearly 40% of global neodymium magnet production by 2025.

Supply constraints remain a critical market factor, with China controlling approximately 85% of global rare earth processing capacity and 92% of magnet manufacturing. This concentration has created significant price volatility, with neodymium prices fluctuating between $50-120 per kilogram over the past five years. Recent geopolitical tensions have further highlighted supply chain vulnerabilities, prompting increased investment in alternative sourcing strategies.

Regional market analysis reveals emerging demand centers in Europe and North America, where green energy initiatives and industrial policies are creating new consumption hubs. The European Union's Green Deal and the United States' Inflation Reduction Act both include provisions that incentivize domestic production of clean energy components, including rare earth magnets, potentially reshaping traditional supply chains.

Price sensitivity analysis indicates that while neodymium magnets represent only 3-5% of total costs for wind turbines and 5-7% for electric vehicles, their price volatility can significantly impact project economics. Cost-effectiveness calculations show that despite higher initial costs compared to conventional alternatives, the performance benefits of neodymium magnets typically yield positive returns on investment through improved efficiency and reduced maintenance requirements in green energy applications.

Global Neodymium Supply Chain Challenges

The global neodymium supply chain faces significant challenges that directly impact the cost-effectiveness of green energy projects. China currently dominates the market, controlling approximately 85% of global rare earth processing capacity and producing over 70% of the world's neodymium magnets. This concentration creates substantial geopolitical vulnerabilities and price volatility risks for international markets, particularly affecting wind turbine and electric vehicle manufacturers.

Supply constraints have become increasingly evident as demand for neodymium magnets in renewable energy applications continues to surge. Market analysts project that neodymium demand could increase by 150-300% by 2030, primarily driven by the expansion of wind energy and electric mobility sectors. This growing supply-demand gap has resulted in price fluctuations exceeding 200% during certain periods over the past decade.

Environmental and social challenges further complicate the supply chain. Conventional rare earth mining and processing generate significant environmental impacts, including radioactive waste, toxic effluents, and substantial carbon emissions. These environmental concerns have led to stricter regulations in many regions, limiting new mining operations and increasing compliance costs for existing facilities.

The processing infrastructure represents another critical bottleneck. Separation and refining of rare earth elements require specialized facilities and expertise that have historically been concentrated in China. Despite recent investments in alternative processing capabilities in countries like Australia, Malaysia, and the United States, developing competitive processing capacity requires substantial capital investment and extended timeframes.

Trade restrictions and export quotas have periodically disrupted global neodymium supplies. China has implemented various export limitations since 2010, citing environmental protection and resource conservation. These policies have triggered international trade disputes and prompted consumer nations to seek supply diversification strategies, though with limited success to date.

Recycling infrastructure remains underdeveloped despite the significant potential for recovering neodymium from end-of-life products. Current recycling rates for rare earth elements are estimated at less than 1% globally. Technical challenges in separating these elements from complex waste streams, combined with insufficient collection systems and economic disincentives, have hindered the development of circular economy solutions.

Financing challenges also affect supply chain development, with new mining projects facing extended approval processes and uncertain returns. The average lead time for developing a new rare earth mine exceeds 10 years, creating significant lag between investment decisions and production capacity increases. This timeline mismatch exacerbates supply shortages during periods of rapid demand growth in green energy sectors.

Supply constraints have become increasingly evident as demand for neodymium magnets in renewable energy applications continues to surge. Market analysts project that neodymium demand could increase by 150-300% by 2030, primarily driven by the expansion of wind energy and electric mobility sectors. This growing supply-demand gap has resulted in price fluctuations exceeding 200% during certain periods over the past decade.

Environmental and social challenges further complicate the supply chain. Conventional rare earth mining and processing generate significant environmental impacts, including radioactive waste, toxic effluents, and substantial carbon emissions. These environmental concerns have led to stricter regulations in many regions, limiting new mining operations and increasing compliance costs for existing facilities.

The processing infrastructure represents another critical bottleneck. Separation and refining of rare earth elements require specialized facilities and expertise that have historically been concentrated in China. Despite recent investments in alternative processing capabilities in countries like Australia, Malaysia, and the United States, developing competitive processing capacity requires substantial capital investment and extended timeframes.

Trade restrictions and export quotas have periodically disrupted global neodymium supplies. China has implemented various export limitations since 2010, citing environmental protection and resource conservation. These policies have triggered international trade disputes and prompted consumer nations to seek supply diversification strategies, though with limited success to date.

Recycling infrastructure remains underdeveloped despite the significant potential for recovering neodymium from end-of-life products. Current recycling rates for rare earth elements are estimated at less than 1% globally. Technical challenges in separating these elements from complex waste streams, combined with insufficient collection systems and economic disincentives, have hindered the development of circular economy solutions.

Financing challenges also affect supply chain development, with new mining projects facing extended approval processes and uncertain returns. The average lead time for developing a new rare earth mine exceeds 10 years, creating significant lag between investment decisions and production capacity increases. This timeline mismatch exacerbates supply shortages during periods of rapid demand growth in green energy sectors.

Current Cost-Optimization Solutions for Nd Magnets

01 Manufacturing processes for cost-effective neodymium magnets

Various manufacturing processes have been developed to improve the cost-effectiveness of neodymium magnets. These include optimized sintering methods, improved powder metallurgy techniques, and efficient recycling processes. These manufacturing innovations help reduce production costs while maintaining or enhancing the magnetic properties of neodymium magnets, making them more economically viable for various applications.- Manufacturing process optimization for cost reduction: Various manufacturing processes can be optimized to reduce the production cost of neodymium magnets. These include improved sintering techniques, efficient material utilization, and streamlined production workflows. By implementing advanced manufacturing methods, manufacturers can achieve higher yields and lower production costs while maintaining the magnetic properties of neodymium magnets.

- Alternative material compositions to reduce rare earth content: Developing alternative material compositions that reduce the amount of rare earth elements while maintaining magnetic performance can improve cost-effectiveness. These approaches include partial substitution of neodymium with more abundant elements, creating composite materials, or developing novel alloy formulations that require less expensive raw materials while delivering comparable magnetic properties.

- Recycling and reuse of neodymium magnet materials: Implementing effective recycling and reuse processes for neodymium magnets can significantly reduce costs. These methods include extracting rare earth elements from end-of-life products, reprocessing manufacturing waste, and refurbishing used magnets. By establishing circular economy approaches for these valuable materials, the overall cost-effectiveness of neodymium magnets can be improved.

- Design optimization for magnetic efficiency: Optimizing the design of magnetic systems can improve cost-effectiveness by using less magnetic material while achieving the same performance. This includes shape optimization, strategic placement of magnetic components, and innovative magnetic circuit designs that maximize the efficiency of the magnetic field. These approaches allow for reduced material usage while maintaining or improving functional performance.

- Surface treatment and coating technologies: Advanced surface treatments and coating technologies can extend the lifespan of neodymium magnets, improving their long-term cost-effectiveness. These treatments protect against corrosion, oxidation, and physical damage, thereby reducing replacement frequency and maintenance costs. Various coating materials and application methods can be tailored to specific operating environments and applications.

02 Alternative material compositions to reduce costs

Research has focused on developing alternative material compositions that can reduce the cost of neodymium magnets while maintaining performance. These include partial substitution of expensive rare earth elements with more abundant materials, development of composite structures, and optimization of the neodymium-iron-boron ratio. These alternative compositions help address the high cost of raw materials while ensuring adequate magnetic performance for specific applications.Expand Specific Solutions03 Energy-efficient applications enhancing cost-effectiveness

Neodymium magnets contribute to cost-effectiveness through their application in energy-efficient devices and systems. Their strong magnetic properties allow for smaller, more efficient electric motors, generators, and energy harvesting systems. The long-term operational cost savings achieved through improved energy efficiency often outweigh the initial higher cost of neodymium magnets compared to conventional alternatives.Expand Specific Solutions04 Recycling and reuse strategies for cost reduction

Recycling and reuse strategies have been developed to improve the cost-effectiveness of neodymium magnets. These include methods for recovering rare earth elements from end-of-life products, refurbishing used magnets, and reprocessing manufacturing waste. These approaches help reduce dependency on primary raw materials, mitigate supply chain risks, and lower the overall environmental impact and cost of neodymium magnet production.Expand Specific Solutions05 Design optimization for cost-effective applications

Design optimization techniques have been employed to enhance the cost-effectiveness of neodymium magnets in various applications. These include magnetic circuit optimization, shape and size optimization, and strategic placement of magnets to maximize performance while minimizing material usage. Advanced simulation and modeling tools help engineers design systems that achieve the required magnetic performance with the minimum amount of expensive neodymium material.Expand Specific Solutions

Key Industry Players and Market Competition

The neodymium magnet market in green energy projects is currently in a growth phase, with increasing demand driven by renewable energy applications. The market is expected to reach significant scale as green energy adoption accelerates globally. Technologically, companies like JL MAG Rare-Earth Co. and Baotou Tianhe Magnetics Technology are leading in high-performance neodymium magnet production, while research institutions such as Centre National de la Recherche Scientifique and University of Birmingham are advancing cost-effectiveness through material innovations. Major industrial players including General Electric, BMW, and LG Electronics are integrating these magnets into green energy systems, while companies like Guangdong Bangpu Recycling Technology are developing recycling solutions to address sustainability concerns and reduce long-term costs.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed a comprehensive cost-effectiveness approach for neodymium magnets in green energy applications, focusing on their high-performance NdFeB magnets with reduced heavy rare earth content. Their technology involves a grain boundary diffusion process that optimizes magnetic properties while minimizing rare earth usage by up to 30% compared to conventional methods. The company has implemented a vertical integration strategy from raw material procurement to finished magnet production, allowing for better cost control throughout the supply chain. Their magnets achieve energy products exceeding 42 MGOe while maintaining thermal stability up to 180°C, making them particularly suitable for wind turbine generators and electric vehicle motors. JL MAG has also pioneered recycling technologies that recover over 90% of rare earth elements from end-of-life products, creating a circular economy approach that further enhances cost-effectiveness while reducing environmental impact.

Strengths: Vertical integration provides superior cost control; advanced grain boundary diffusion technology reduces rare earth content while maintaining performance; established recycling capabilities create secondary material streams. Weaknesses: Still dependent on volatile rare earth markets despite mitigation strategies; higher initial production costs compared to ferrite alternatives; limited geographical diversification of production facilities increases supply chain vulnerability.

Nikko Metal Manufacturing Co. Ltd.

Technical Solution: Nikko Metal has developed a proprietary manufacturing process for neodymium magnets specifically optimized for green energy applications, focusing on cost reduction through microstructure engineering. Their approach involves precise control of crystal grain size and orientation, achieving uniform microstructures that maximize magnetic performance per unit of raw material. The company's "MAGFINE" technology incorporates a modified strip casting and hydrogen decrepitation process that reduces energy consumption during manufacturing by approximately 25% compared to conventional methods. Nikko's magnets feature enhanced corrosion resistance through advanced surface treatment technologies, extending service life in harsh renewable energy environments like offshore wind installations. Their manufacturing process also incorporates automated quality control systems that reduce rejection rates to below 2%, significantly improving yield and overall cost-effectiveness. Additionally, Nikko has developed specialized magnet designs with optimized shapes that reduce material usage while maintaining performance specifications for specific green energy applications.

Strengths: Advanced microstructure control techniques maximize performance-to-cost ratio; energy-efficient manufacturing processes reduce production costs; specialized designs minimize material usage for specific applications. Weaknesses: Limited production capacity compared to larger competitors; higher initial investment costs for specialized equipment; relatively narrow focus on high-end applications may limit market penetration in cost-sensitive segments.

Critical Patents in Neodymium Magnet Manufacturing

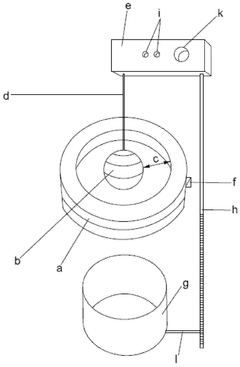

Electric power generation device

PatentWO2025165321A1

Innovation

- An electric power generation device utilizing nested neodymium magnets that convert rotational movement into electricity, with a cooling mechanism to prevent overheating and ensure continuous power generation.

Sustainability Impact Assessment

The sustainability impact of neodymium magnets in green energy projects extends far beyond simple economic calculations, encompassing environmental, social, and long-term ecological dimensions. When evaluating these rare earth permanent magnets, lifecycle assessment reveals significant environmental considerations at each stage - from mining and processing to eventual disposal or recycling.

Mining operations for neodymium create substantial environmental disruption, including habitat destruction, soil erosion, and potential contamination of water sources with radioactive materials like thorium and uranium that naturally occur alongside rare earth elements. Processing these materials requires energy-intensive separation techniques involving strong acids and organic solvents, generating toxic waste streams that demand careful management.

However, these environmental costs must be balanced against the sustainability benefits these magnets enable. In wind turbines, neodymium magnets significantly increase energy conversion efficiency, with direct-drive generators using these magnets eliminating the need for gearboxes, reducing maintenance requirements and extending operational lifespans. This translates to greater renewable energy generation per unit of environmental impact over the project lifetime.

Carbon footprint analysis demonstrates that despite the initial environmental burden, neodymium-based technologies in renewable energy applications typically achieve carbon payback within 6-18 months of operation, depending on installation location and energy mix. This represents a favorable sustainability profile compared to fossil fuel alternatives when evaluated across complete project lifespans.

Social sustainability factors also merit consideration, including labor conditions in mining regions and community impacts. Responsible sourcing initiatives are emerging to address these concerns, with certification systems being developed to verify ethical production practices throughout the supply chain.

Circular economy approaches are increasingly important for improving the sustainability profile of neodymium magnets. End-of-life recovery and recycling technologies are advancing, though currently at limited commercial scale. Promising techniques include hydrogen decrepitation and pyrometallurgical processes that can recover up to 90% of magnetic materials from end-of-life products, significantly reducing the need for virgin material extraction.

Future sustainability improvements will likely come from both technological advances in recycling and material science innovations that reduce required neodymium content while maintaining performance characteristics. Alternative magnet designs incorporating reduced rare earth content or more abundant elements represent an important research direction for enhancing long-term sustainability.

Mining operations for neodymium create substantial environmental disruption, including habitat destruction, soil erosion, and potential contamination of water sources with radioactive materials like thorium and uranium that naturally occur alongside rare earth elements. Processing these materials requires energy-intensive separation techniques involving strong acids and organic solvents, generating toxic waste streams that demand careful management.

However, these environmental costs must be balanced against the sustainability benefits these magnets enable. In wind turbines, neodymium magnets significantly increase energy conversion efficiency, with direct-drive generators using these magnets eliminating the need for gearboxes, reducing maintenance requirements and extending operational lifespans. This translates to greater renewable energy generation per unit of environmental impact over the project lifetime.

Carbon footprint analysis demonstrates that despite the initial environmental burden, neodymium-based technologies in renewable energy applications typically achieve carbon payback within 6-18 months of operation, depending on installation location and energy mix. This represents a favorable sustainability profile compared to fossil fuel alternatives when evaluated across complete project lifespans.

Social sustainability factors also merit consideration, including labor conditions in mining regions and community impacts. Responsible sourcing initiatives are emerging to address these concerns, with certification systems being developed to verify ethical production practices throughout the supply chain.

Circular economy approaches are increasingly important for improving the sustainability profile of neodymium magnets. End-of-life recovery and recycling technologies are advancing, though currently at limited commercial scale. Promising techniques include hydrogen decrepitation and pyrometallurgical processes that can recover up to 90% of magnetic materials from end-of-life products, significantly reducing the need for virgin material extraction.

Future sustainability improvements will likely come from both technological advances in recycling and material science innovations that reduce required neodymium content while maintaining performance characteristics. Alternative magnet designs incorporating reduced rare earth content or more abundant elements represent an important research direction for enhancing long-term sustainability.

Geopolitical Factors Affecting Rare Earth Markets

The geopolitical landscape surrounding rare earth elements, particularly neodymium used in high-performance magnets, significantly impacts the cost-effectiveness of green energy projects. China currently dominates the global rare earth supply chain, controlling approximately 85% of processing capacity despite holding only about one-third of known reserves. This market concentration creates substantial supply vulnerabilities for Western nations developing renewable energy technologies that rely heavily on neodymium magnets, such as wind turbines and electric vehicle motors.

Trade tensions between China and Western economies have repeatedly affected rare earth markets, with notable price volatility following export restrictions implemented in 2010-2011 and during recent US-China trade disputes. These geopolitical frictions have prompted price increases of up to 750% during peak tension periods, directly impacting the economic viability of green energy projects and extending payback periods for renewable investments.

National security concerns have further complicated the market, with many countries now classifying rare earth elements as strategic resources. The United States, European Union, Australia, and Japan have all implemented policies aimed at reducing dependency on Chinese supplies, including the US Inflation Reduction Act which provides substantial incentives for domestic rare earth processing and magnet manufacturing. These initiatives, while necessary for supply security, often increase short-term costs for green energy implementations.

Environmental and labor regulations create additional geopolitical disparities in production costs. China's historically less stringent environmental oversight has contributed to its cost advantage, though recent policy shifts toward stricter environmental standards are gradually leveling this disparity. Meanwhile, emerging rare earth producers in Vietnam, Malaysia, and African nations face varying regulatory environments that influence production costs and market stability.

Supply chain resilience strategies are reshaping the global rare earth landscape, with Japan, Australia, and the United States forming strategic partnerships to develop alternative supply sources. The Mountain Pass mine in California and Australia's Lynas Corporation represent significant non-Chinese production capacity, though processing capabilities remain limited outside China. These diversification efforts, while promising for long-term stability, require substantial capital investment that temporarily increases neodymium magnet costs for green energy applications.

The intersection of climate policy and resource nationalism further complicates the market, as nations simultaneously pursue decarbonization goals while attempting to secure domestic supply chains for critical minerals. This tension creates policy inconsistencies that can disrupt market predictability and complicate long-term cost projections for green energy projects dependent on neodymium magnets.

Trade tensions between China and Western economies have repeatedly affected rare earth markets, with notable price volatility following export restrictions implemented in 2010-2011 and during recent US-China trade disputes. These geopolitical frictions have prompted price increases of up to 750% during peak tension periods, directly impacting the economic viability of green energy projects and extending payback periods for renewable investments.

National security concerns have further complicated the market, with many countries now classifying rare earth elements as strategic resources. The United States, European Union, Australia, and Japan have all implemented policies aimed at reducing dependency on Chinese supplies, including the US Inflation Reduction Act which provides substantial incentives for domestic rare earth processing and magnet manufacturing. These initiatives, while necessary for supply security, often increase short-term costs for green energy implementations.

Environmental and labor regulations create additional geopolitical disparities in production costs. China's historically less stringent environmental oversight has contributed to its cost advantage, though recent policy shifts toward stricter environmental standards are gradually leveling this disparity. Meanwhile, emerging rare earth producers in Vietnam, Malaysia, and African nations face varying regulatory environments that influence production costs and market stability.

Supply chain resilience strategies are reshaping the global rare earth landscape, with Japan, Australia, and the United States forming strategic partnerships to develop alternative supply sources. The Mountain Pass mine in California and Australia's Lynas Corporation represent significant non-Chinese production capacity, though processing capabilities remain limited outside China. These diversification efforts, while promising for long-term stability, require substantial capital investment that temporarily increases neodymium magnet costs for green energy applications.

The intersection of climate policy and resource nationalism further complicates the market, as nations simultaneously pursue decarbonization goals while attempting to secure domestic supply chains for critical minerals. This tension creates policy inconsistencies that can disrupt market predictability and complicate long-term cost projections for green energy projects dependent on neodymium magnets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!