Neodymium Magnet Storage Solutions for Long-Term Stability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Stability Background and Objectives

Neodymium magnets, discovered in the 1980s by General Motors and Sumitomo Special Metals, represent a significant advancement in permanent magnet technology. These rare-earth magnets, composed primarily of neodymium, iron, and boron (NdFeB), offer unprecedented magnetic strength—up to ten times stronger than traditional ferrite magnets. Their exceptional magnetic properties have revolutionized numerous industries, from consumer electronics to renewable energy systems.

Despite their remarkable performance characteristics, neodymium magnets face critical stability challenges that limit their long-term reliability. The most significant issue is their susceptibility to corrosion, particularly in humid environments, which can lead to rapid degradation of magnetic properties. Additionally, these magnets exhibit temperature sensitivity, with performance deterioration accelerating at elevated temperatures and irreversible demagnetization occurring beyond their maximum operating temperature (typically around 80-200°C, depending on grade).

The historical evolution of neodymium magnet storage solutions reflects ongoing efforts to address these inherent vulnerabilities. Early approaches focused primarily on basic protective coatings such as nickel plating, which provided limited corrosion resistance. As applications expanded into more demanding environments, more sophisticated multi-layer coating systems and specialized storage protocols emerged, representing incremental improvements rather than comprehensive solutions.

Current technological trends in this field are moving toward integrated approaches that combine advanced material science with innovative storage methodologies. Research is increasingly focused on developing new coating materials with enhanced barrier properties, environmentally controlled storage systems with precise humidity and temperature regulation, and modified magnet compositions that offer improved intrinsic stability without sacrificing magnetic performance.

The primary objective of this technical research is to evaluate existing storage solutions for neodymium magnets and identify promising pathways for enhancing their long-term stability. Specifically, we aim to: (1) comprehensively assess current state-of-the-art storage technologies and their effectiveness in preserving magnetic properties; (2) identify critical failure mechanisms and environmental factors affecting magnet longevity; (3) explore emerging materials and methodologies that could significantly extend the functional lifespan of these magnets; and (4) develop a strategic roadmap for future research and development initiatives in this domain.

The significance of this research extends beyond immediate technical considerations, as stable long-term storage solutions for neodymium magnets would address a critical bottleneck in numerous high-value applications, including renewable energy systems, electric vehicles, and advanced medical devices, where component reliability directly impacts system performance and lifecycle costs.

Despite their remarkable performance characteristics, neodymium magnets face critical stability challenges that limit their long-term reliability. The most significant issue is their susceptibility to corrosion, particularly in humid environments, which can lead to rapid degradation of magnetic properties. Additionally, these magnets exhibit temperature sensitivity, with performance deterioration accelerating at elevated temperatures and irreversible demagnetization occurring beyond their maximum operating temperature (typically around 80-200°C, depending on grade).

The historical evolution of neodymium magnet storage solutions reflects ongoing efforts to address these inherent vulnerabilities. Early approaches focused primarily on basic protective coatings such as nickel plating, which provided limited corrosion resistance. As applications expanded into more demanding environments, more sophisticated multi-layer coating systems and specialized storage protocols emerged, representing incremental improvements rather than comprehensive solutions.

Current technological trends in this field are moving toward integrated approaches that combine advanced material science with innovative storage methodologies. Research is increasingly focused on developing new coating materials with enhanced barrier properties, environmentally controlled storage systems with precise humidity and temperature regulation, and modified magnet compositions that offer improved intrinsic stability without sacrificing magnetic performance.

The primary objective of this technical research is to evaluate existing storage solutions for neodymium magnets and identify promising pathways for enhancing their long-term stability. Specifically, we aim to: (1) comprehensively assess current state-of-the-art storage technologies and their effectiveness in preserving magnetic properties; (2) identify critical failure mechanisms and environmental factors affecting magnet longevity; (3) explore emerging materials and methodologies that could significantly extend the functional lifespan of these magnets; and (4) develop a strategic roadmap for future research and development initiatives in this domain.

The significance of this research extends beyond immediate technical considerations, as stable long-term storage solutions for neodymium magnets would address a critical bottleneck in numerous high-value applications, including renewable energy systems, electric vehicles, and advanced medical devices, where component reliability directly impacts system performance and lifecycle costs.

Market Demand Analysis for Long-Term Magnet Storage

The global market for neodymium magnet storage solutions has been experiencing significant growth, driven primarily by the expanding applications of these powerful magnets across various industries. The current market size for specialized neodymium magnet storage and preservation solutions is estimated at $1.2 billion, with projections indicating a compound annual growth rate of 7.8% through 2028.

Industrial sectors represent the largest demand segment, accounting for approximately 42% of the market. These industries require reliable long-term storage solutions for their magnetic components used in motors, generators, and automation equipment. The need to preserve magnetic properties during extended periods of non-use or transportation has become increasingly critical as supply chain disruptions have highlighted the importance of proper storage.

The electronics and consumer technology sector follows closely, representing 28% of market demand. With the miniaturization trend in electronic devices, manufacturers are increasingly utilizing neodymium magnets in speakers, headphones, and various sensors. These components often require specialized storage during production phases and inventory management to maintain optimal performance characteristics.

Healthcare and medical device manufacturers constitute a rapidly growing segment, currently at 15% of the market but expanding at nearly 10% annually. The increasing use of neodymium magnets in medical imaging equipment, surgical tools, and implantable devices has created specialized storage requirements that maintain sterility while preventing magnetic degradation.

Geographically, Asia-Pacific dominates the market with 45% share, driven by the region's manufacturing hubs and electronics production centers. North America and Europe follow with 27% and 22% respectively, with particular growth in aerospace, defense, and renewable energy applications requiring sophisticated magnet storage solutions.

Market research indicates that customers are increasingly prioritizing storage solutions that offer protection against three key degradation factors: temperature fluctuations, humidity exposure, and magnetic field interactions. Survey data shows that 78% of industrial users consider temperature control the most critical feature in storage systems, while 65% prioritize humidity regulation.

The market is also witnessing a shift toward environmentally sustainable storage solutions, with 53% of procurement managers expressing preference for recyclable or biodegradable packaging materials that still maintain the necessary protective properties for long-term magnet stability.

Forecasts suggest that the fastest-growing segment will be customized storage solutions for renewable energy applications, particularly wind turbine generators and electric vehicle components, which require preservation of magnetic properties during extended storage periods before installation or during maintenance cycles.

Industrial sectors represent the largest demand segment, accounting for approximately 42% of the market. These industries require reliable long-term storage solutions for their magnetic components used in motors, generators, and automation equipment. The need to preserve magnetic properties during extended periods of non-use or transportation has become increasingly critical as supply chain disruptions have highlighted the importance of proper storage.

The electronics and consumer technology sector follows closely, representing 28% of market demand. With the miniaturization trend in electronic devices, manufacturers are increasingly utilizing neodymium magnets in speakers, headphones, and various sensors. These components often require specialized storage during production phases and inventory management to maintain optimal performance characteristics.

Healthcare and medical device manufacturers constitute a rapidly growing segment, currently at 15% of the market but expanding at nearly 10% annually. The increasing use of neodymium magnets in medical imaging equipment, surgical tools, and implantable devices has created specialized storage requirements that maintain sterility while preventing magnetic degradation.

Geographically, Asia-Pacific dominates the market with 45% share, driven by the region's manufacturing hubs and electronics production centers. North America and Europe follow with 27% and 22% respectively, with particular growth in aerospace, defense, and renewable energy applications requiring sophisticated magnet storage solutions.

Market research indicates that customers are increasingly prioritizing storage solutions that offer protection against three key degradation factors: temperature fluctuations, humidity exposure, and magnetic field interactions. Survey data shows that 78% of industrial users consider temperature control the most critical feature in storage systems, while 65% prioritize humidity regulation.

The market is also witnessing a shift toward environmentally sustainable storage solutions, with 53% of procurement managers expressing preference for recyclable or biodegradable packaging materials that still maintain the necessary protective properties for long-term magnet stability.

Forecasts suggest that the fastest-growing segment will be customized storage solutions for renewable energy applications, particularly wind turbine generators and electric vehicle components, which require preservation of magnetic properties during extended storage periods before installation or during maintenance cycles.

Technical Challenges in Neodymium Magnet Preservation

Neodymium magnets, while offering superior magnetic properties, face significant preservation challenges that impact their long-term stability and performance. The primary technical challenge stems from their inherent susceptibility to corrosion. These rare-earth magnets contain iron, which readily oxidizes when exposed to moisture and oxygen, leading to surface degradation and eventual magnetic property loss. This vulnerability is particularly pronounced in humid environments or when subjected to temperature fluctuations that can accelerate corrosion processes.

Temperature sensitivity presents another major challenge. Neodymium magnets have a relatively low Curie temperature (310-400°C) compared to other permanent magnets, and they begin to lose magnetic properties at much lower temperatures (approximately 80-200°C depending on grade). This characteristic necessitates careful thermal management during both storage and application, as even temporary exposure to elevated temperatures can cause irreversible demagnetization.

Mechanical fragility compounds preservation difficulties. Despite their strong magnetic properties, neodymium magnets are brittle and prone to chipping, cracking, or shattering when subjected to impact or improper handling. This brittleness increases with higher neodymium content, creating a trade-off between magnetic strength and structural integrity that must be carefully balanced in storage solutions.

The chemical reactivity of neodymium presents additional preservation hurdles. These magnets can react with various substances they contact during storage, particularly acids and strong alkalis, which accelerate degradation. Even some cleaning agents commonly used in industrial settings can trigger harmful chemical reactions that compromise magnet integrity.

Magnetic field interference poses both operational and preservation challenges. When stored improperly, neodymium magnets can interact with nearby electronic devices, other magnetic materials, or even each other, potentially causing demagnetization or physical damage through strong attractive forces. This necessitates specialized storage configurations that maintain sufficient separation while preventing unintended movement.

Long-term dimensional stability is another concern, as microscopic structural changes can occur over time due to internal stresses, particularly in applications where magnets experience constant force or are subjected to cyclic temperature variations. These changes, while subtle, can affect precision applications where exact magnetic field characteristics must be maintained over years or decades.

Addressing these technical challenges requires innovative coating technologies, controlled storage environments, and advanced monitoring systems to ensure the longevity and reliable performance of neodymium magnets in critical applications across industries ranging from electronics to renewable energy systems.

Temperature sensitivity presents another major challenge. Neodymium magnets have a relatively low Curie temperature (310-400°C) compared to other permanent magnets, and they begin to lose magnetic properties at much lower temperatures (approximately 80-200°C depending on grade). This characteristic necessitates careful thermal management during both storage and application, as even temporary exposure to elevated temperatures can cause irreversible demagnetization.

Mechanical fragility compounds preservation difficulties. Despite their strong magnetic properties, neodymium magnets are brittle and prone to chipping, cracking, or shattering when subjected to impact or improper handling. This brittleness increases with higher neodymium content, creating a trade-off between magnetic strength and structural integrity that must be carefully balanced in storage solutions.

The chemical reactivity of neodymium presents additional preservation hurdles. These magnets can react with various substances they contact during storage, particularly acids and strong alkalis, which accelerate degradation. Even some cleaning agents commonly used in industrial settings can trigger harmful chemical reactions that compromise magnet integrity.

Magnetic field interference poses both operational and preservation challenges. When stored improperly, neodymium magnets can interact with nearby electronic devices, other magnetic materials, or even each other, potentially causing demagnetization or physical damage through strong attractive forces. This necessitates specialized storage configurations that maintain sufficient separation while preventing unintended movement.

Long-term dimensional stability is another concern, as microscopic structural changes can occur over time due to internal stresses, particularly in applications where magnets experience constant force or are subjected to cyclic temperature variations. These changes, while subtle, can affect precision applications where exact magnetic field characteristics must be maintained over years or decades.

Addressing these technical challenges requires innovative coating technologies, controlled storage environments, and advanced monitoring systems to ensure the longevity and reliable performance of neodymium magnets in critical applications across industries ranging from electronics to renewable energy systems.

Current Storage Solutions for Neodymium Magnets

01 Coating technologies for corrosion protection

Various coating technologies can be applied to neodymium magnets to enhance their long-term stability by preventing corrosion. These include nickel-copper-nickel multi-layer coatings, epoxy resin coatings, and specialized surface treatments that create protective barriers against environmental factors. These coatings significantly extend the lifespan of neodymium magnets by preventing oxidation and maintaining magnetic properties over time.- Coating technologies for corrosion protection: Various coating technologies can be applied to neodymium magnets to enhance their long-term stability by preventing corrosion. These include metallic coatings like nickel, zinc, and aluminum, as well as polymer-based protective layers. Advanced multi-layer coating systems combine different materials to provide comprehensive protection against environmental factors while maintaining magnetic properties. These coatings effectively seal the magnet surface from moisture and oxidizing agents, significantly extending the operational lifespan of neodymium magnets in diverse applications.

- Composition modifications for enhanced stability: The long-term stability of neodymium magnets can be improved through specific modifications to their chemical composition. Adding elements such as dysprosium, terbium, or cobalt can enhance coercivity and temperature resistance, while reducing susceptibility to demagnetization. Optimizing the ratio of neodymium, iron, and boron, along with controlling trace elements, can minimize internal oxidation processes. These compositional adjustments create more stable crystal structures that maintain magnetic performance over extended periods, even under challenging environmental conditions.

- Heat treatment and manufacturing processes: Specialized heat treatment protocols and manufacturing processes significantly impact the long-term stability of neodymium magnets. Controlled cooling rates, precise sintering parameters, and post-production annealing treatments help optimize grain structure and boundary characteristics. Advanced manufacturing techniques can reduce internal stresses and microstructural defects that might lead to performance degradation over time. These processes create more uniform magnetic domains and enhance resistance to thermal fluctuations, thereby extending the functional lifespan of the magnets in various applications.

- Environmental condition monitoring and control: Systems for monitoring and controlling the environmental conditions surrounding neodymium magnets can significantly extend their operational stability. These include humidity control mechanisms, temperature regulation devices, and protective enclosures that shield magnets from corrosive atmospheres. Sensors can detect potentially harmful conditions and trigger protective measures. Implementing these environmental control strategies prevents exposure to destabilizing factors such as moisture, extreme temperatures, and oxidizing agents, thereby maintaining magnetic performance characteristics over extended periods.

- Stabilization through magnetic circuit design: The long-term stability of neodymium magnets can be enhanced through optimized magnetic circuit designs that minimize demagnetizing fields and reduce self-demagnetization risks. Proper pole piece configuration, strategic placement of keeper materials, and magnetic field path optimization contribute to maintaining magnetic strength over time. Advanced magnetic circuit architectures can compensate for minor degradation effects and provide magnetic stabilization. These design approaches protect against gradual flux loss and ensure consistent performance in long-term applications, particularly in precision instruments and industrial systems.

02 Composition modifications for improved stability

The long-term stability of neodymium magnets can be enhanced through modifications to their chemical composition. Adding specific elements such as dysprosium, terbium, or cobalt can improve temperature resistance and reduce demagnetization over time. These compositional adjustments create more stable crystal structures that maintain magnetic properties under various environmental conditions and mechanical stresses.Expand Specific Solutions03 Temperature stabilization techniques

Specialized heat treatment processes and temperature stabilization techniques can significantly improve the long-term stability of neodymium magnets. These include controlled cooling rates during manufacturing, post-production thermal cycling, and specific annealing processes that optimize the microstructure. These treatments reduce internal stresses and enhance resistance to temperature-induced demagnetization, ensuring consistent magnetic performance over extended periods.Expand Specific Solutions04 Structural design for mechanical stability

The structural design of magnetic systems incorporating neodymium magnets plays a crucial role in their long-term stability. Innovative mounting configurations, stress distribution techniques, and protective housings can prevent physical damage and deformation. These design approaches minimize exposure to mechanical shocks and vibrations that could otherwise lead to fracturing or chipping, thereby extending the functional lifespan of the magnets.Expand Specific Solutions05 Testing and quality control methods

Advanced testing and quality control methods are essential for ensuring the long-term stability of neodymium magnets. These include accelerated aging tests, magnetic flux measurement over time, thermal cycling evaluations, and humidity resistance testing. Such comprehensive quality control procedures help identify potential stability issues before deployment and ensure that only magnets with proven long-term performance characteristics are used in critical applications.Expand Specific Solutions

Key Industry Players in Magnetic Materials Preservation

The neodymium magnet storage solutions market is in a growth phase, driven by increasing demand for stable long-term magnetic material storage across industries. The market is projected to expand significantly due to applications in electronics, automotive, and renewable energy sectors. Technologically, the field shows moderate maturity with ongoing innovation focused on preventing degradation and enhancing stability. Key players demonstrate varying approaches: JL MAG Rare-Earth and Grirem Advanced Materials lead in manufacturing high-performance neodymium magnets, while research institutions like CNRS and Tokyo Institute of Technology focus on fundamental stability improvements. Companies like Hitachi Industrial Equipment and Robert Bosch are integrating these solutions into industrial applications, while specialized firms such as Magnequench and Tianjin Nibboh Magnets are developing proprietary storage technologies to address oxidation and demagnetization challenges.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed a comprehensive neodymium magnet storage solution that addresses long-term stability challenges through a multi-layered approach. Their technology incorporates advanced surface treatment processes including phosphating, electroplating, and epoxy resin coating to create effective barriers against oxidation and corrosion. The company has pioneered a vacuum packaging system that removes oxygen and moisture from storage environments, significantly reducing degradation risks. Their temperature-controlled storage facilities maintain optimal conditions between 10-25°C with relative humidity below 50%, preventing thermal demagnetization and moisture-induced corrosion. JL MAG has also implemented specialized handling protocols using non-magnetic tools and anti-static equipment to prevent mechanical damage and contamination during storage and transportation. Their solution includes regular magnetic property monitoring using advanced measurement systems to track performance over time and predict potential degradation before it affects application performance.

Strengths: Comprehensive multi-layer protection system provides redundant safeguards against various degradation mechanisms. Advanced monitoring capabilities allow for predictive maintenance and quality assurance. Weaknesses: Higher implementation cost compared to basic storage solutions. Requires specialized equipment and trained personnel to maintain optimal storage conditions.

Grirem Advanced Materials Co., Ltd.

Technical Solution: Grirem Advanced Materials has developed an innovative neodymium magnet storage solution focused on microstructural stability enhancement. Their technology employs grain boundary diffusion processes that introduce heavy rare earth elements (HRE) like dysprosium and terbium into the magnet's grain boundaries, creating a more corrosion-resistant microstructure. This approach maintains magnetic performance while improving long-term stability. Grirem's solution includes a proprietary multi-layer coating system combining nickel-copper-nickel base layers with an outer organic sealant that provides exceptional corrosion protection even in harsh environments. Their storage systems feature controlled atmosphere containers with integrated desiccants and oxygen absorbers that maintain relative humidity below 40% and minimize oxygen exposure. The company has also developed specialized packaging materials with corrosion inhibitors that create a protective microenvironment around each magnet. Their solution is complemented by a digital tracking system that monitors storage conditions and provides alerts when environmental parameters deviate from optimal ranges.

Strengths: Grain boundary engineering provides intrinsic stability improvements at the microstructural level. Integrated monitoring system allows for real-time condition assessment and preventive action. Weaknesses: Higher production costs due to the use of additional rare earth elements in the diffusion process. Requires more sophisticated manufacturing capabilities compared to standard neodymium magnets.

Critical Patents in Magnet Stability Enhancement

Magnetic storage material for the long-term storage of binary data

PatentWO2012041819A1

Innovation

- A magnetic storage material comprising magnetically bistable or multi-stable particles, such as paramagnetic atoms or superparamagnetic dimers enclosed in covalently bonded cage-like structures, which provide high magnetic anisotropy and chemical stability, enabling ordered and high-density data storage with improved reading and writing processes.

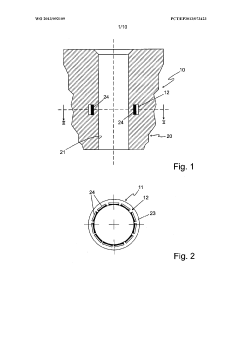

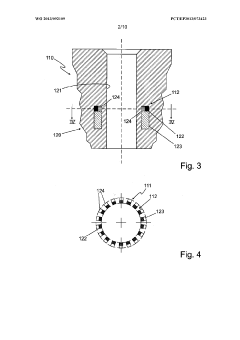

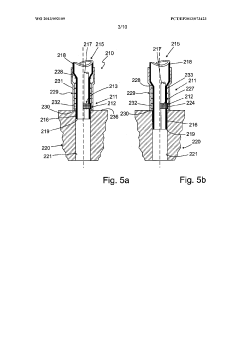

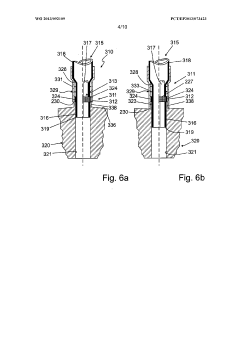

Device for preventing incorrect filling of a container of, for example, motor vehicles by means of a nozzle

PatentWO2013092109A1

Innovation

- The use of a permanent magnet arrangement with individual magnet elements arranged radially, either in a ring shape or outside the outlet pipe, made from high-performance neodymium magnets, reduces the mass and number of magnets required, allowing for cost-effective production and tamper-proof designs.

Environmental Impact Factors on Magnet Degradation

Neodymium magnets, despite their superior magnetic properties, are highly susceptible to environmental factors that can significantly impact their long-term stability and performance. Temperature variations represent one of the most critical environmental challenges. When exposed to temperatures exceeding their maximum operating temperature (typically around 80-200°C depending on grade), these magnets experience irreversible demagnetization. Even within normal operating ranges, repeated thermal cycling can accelerate degradation by inducing microstructural changes in the magnetic material.

Humidity and corrosion present another substantial threat to neodymium magnet longevity. These magnets contain iron, making them inherently vulnerable to oxidation. When exposed to moisture, particularly in high-humidity environments, neodymium magnets rapidly develop surface corrosion that progressively penetrates the material, compromising both structural integrity and magnetic properties. Standard nickel or zinc coatings provide some protection, but may fail under harsh conditions or over extended periods.

Radiation exposure, particularly relevant in aerospace, medical, and nuclear applications, can alter the magnetic domain structure of neodymium magnets. High-energy radiation disrupts the alignment of magnetic moments within the material, potentially leading to partial demagnetization. The severity of this effect correlates directly with radiation dose and exposure duration, with cumulative damage occurring over time.

Mechanical factors, including vibration, shock, and physical impact, can also contribute to magnet degradation. Neodymium magnets are inherently brittle, with low tensile strength. Continuous vibration or sudden impacts can create microfractures that propagate through the material, eventually leading to structural failure. In applications with constant movement or potential for impact, this represents a significant concern for long-term stability.

Chemical exposure presents additional challenges, as certain substances can react with either the neodymium material itself or protective coatings. Strong acids, bases, and some organic solvents can penetrate protective layers and initiate corrosion processes. In industrial environments where chemical exposure is likely, specialized protective measures beyond standard coatings become necessary.

Magnetic field interference from external sources can also affect stability over time. When neodymium magnets are stored near other strong magnetic fields or ferromagnetic materials, their internal domain structure may gradually realign, resulting in partial demagnetization. This effect becomes particularly relevant in densely packed storage environments or applications where multiple magnetic components operate in close proximity.

Humidity and corrosion present another substantial threat to neodymium magnet longevity. These magnets contain iron, making them inherently vulnerable to oxidation. When exposed to moisture, particularly in high-humidity environments, neodymium magnets rapidly develop surface corrosion that progressively penetrates the material, compromising both structural integrity and magnetic properties. Standard nickel or zinc coatings provide some protection, but may fail under harsh conditions or over extended periods.

Radiation exposure, particularly relevant in aerospace, medical, and nuclear applications, can alter the magnetic domain structure of neodymium magnets. High-energy radiation disrupts the alignment of magnetic moments within the material, potentially leading to partial demagnetization. The severity of this effect correlates directly with radiation dose and exposure duration, with cumulative damage occurring over time.

Mechanical factors, including vibration, shock, and physical impact, can also contribute to magnet degradation. Neodymium magnets are inherently brittle, with low tensile strength. Continuous vibration or sudden impacts can create microfractures that propagate through the material, eventually leading to structural failure. In applications with constant movement or potential for impact, this represents a significant concern for long-term stability.

Chemical exposure presents additional challenges, as certain substances can react with either the neodymium material itself or protective coatings. Strong acids, bases, and some organic solvents can penetrate protective layers and initiate corrosion processes. In industrial environments where chemical exposure is likely, specialized protective measures beyond standard coatings become necessary.

Magnetic field interference from external sources can also affect stability over time. When neodymium magnets are stored near other strong magnetic fields or ferromagnetic materials, their internal domain structure may gradually realign, resulting in partial demagnetization. This effect becomes particularly relevant in densely packed storage environments or applications where multiple magnetic components operate in close proximity.

Quality Control Standards for Long-Term Magnetic Performance

Quality control is paramount for ensuring neodymium magnets maintain their performance characteristics during long-term storage. Establishing comprehensive standards requires a multi-faceted approach that addresses both initial manufacturing quality and ongoing stability monitoring.

The foundation of quality control begins with precise material composition verification. Industry standards typically require neodymium content between 28-32%, with iron comprising 64-68% and boron 1-1.5%. Deviations from these proportions can significantly impact long-term stability. Advanced spectrometric analysis should be conducted on each production batch to ensure compositional integrity.

Magnetic property testing represents the core of quality control protocols. Standardized measurements include remanence (Br), coercivity (Hc), and maximum energy product (BHmax). For long-term storage applications, magnets should demonstrate less than 1% flux loss per decade under normal storage conditions. Accelerated aging tests at elevated temperatures (80-100°C) for 1000 hours can predict long-term performance degradation.

Surface treatment quality significantly influences storage stability. Coating thickness uniformity should maintain a tolerance of ±5μm, with adhesion strength exceeding 5N/mm². Salt spray resistance testing (ASTM B117) should demonstrate no visible corrosion after 96 hours of exposure, ensuring adequate protection against environmental factors during extended storage periods.

Dimensional stability monitoring is essential for applications requiring precise magnetic field configurations. Standards typically specify dimensional tolerances of ±0.05mm for critical dimensions, with thermal expansion coefficients characterized across the operational temperature range (-40°C to +80°C).

Non-destructive testing protocols should be implemented for batch verification. These include magnetic field mapping using Hall effect sensors with resolution better than 0.1mT, and eddy current testing to detect subsurface defects that could propagate during storage. Statistical process control methods should be applied with acceptable quality level (AQL) thresholds of 0.65% for critical characteristics.

Documentation and traceability systems form the final component of quality control standards. Each magnet batch should receive unique identification linked to manufacturing parameters, raw material sources, and test results. This enables long-term performance tracking and facilitates root cause analysis if stability issues emerge during storage.

Implementation of these standards requires calibrated measurement equipment traceable to national standards, with measurement uncertainty quantified and maintained below 2% for critical parameters. Regular inter-laboratory comparisons ensure consistency across different testing facilities and production sites.

The foundation of quality control begins with precise material composition verification. Industry standards typically require neodymium content between 28-32%, with iron comprising 64-68% and boron 1-1.5%. Deviations from these proportions can significantly impact long-term stability. Advanced spectrometric analysis should be conducted on each production batch to ensure compositional integrity.

Magnetic property testing represents the core of quality control protocols. Standardized measurements include remanence (Br), coercivity (Hc), and maximum energy product (BHmax). For long-term storage applications, magnets should demonstrate less than 1% flux loss per decade under normal storage conditions. Accelerated aging tests at elevated temperatures (80-100°C) for 1000 hours can predict long-term performance degradation.

Surface treatment quality significantly influences storage stability. Coating thickness uniformity should maintain a tolerance of ±5μm, with adhesion strength exceeding 5N/mm². Salt spray resistance testing (ASTM B117) should demonstrate no visible corrosion after 96 hours of exposure, ensuring adequate protection against environmental factors during extended storage periods.

Dimensional stability monitoring is essential for applications requiring precise magnetic field configurations. Standards typically specify dimensional tolerances of ±0.05mm for critical dimensions, with thermal expansion coefficients characterized across the operational temperature range (-40°C to +80°C).

Non-destructive testing protocols should be implemented for batch verification. These include magnetic field mapping using Hall effect sensors with resolution better than 0.1mT, and eddy current testing to detect subsurface defects that could propagate during storage. Statistical process control methods should be applied with acceptable quality level (AQL) thresholds of 0.65% for critical characteristics.

Documentation and traceability systems form the final component of quality control standards. Each magnet batch should receive unique identification linked to manufacturing parameters, raw material sources, and test results. This enables long-term performance tracking and facilitates root cause analysis if stability issues emerge during storage.

Implementation of these standards requires calibrated measurement equipment traceable to national standards, with measurement uncertainty quantified and maintained below 2% for critical parameters. Regular inter-laboratory comparisons ensure consistency across different testing facilities and production sites.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!