Optimizing Neodymium Magnet Shapes for Electromagnetic Field Control

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Technology Background and Objectives

Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent the most powerful permanent magnets commercially available today. These rare-earth magnets, primarily composed of neodymium, iron, and boron (Nd₂Fe₁₄B), have revolutionized numerous industries due to their exceptional magnetic properties. The evolution of neodymium magnet technology has been marked by continuous improvements in magnetic strength, temperature stability, and corrosion resistance over the past four decades.

The magnetic field strength of neodymium magnets, measured by their maximum energy product (BHmax), has increased from approximately 35 MGOe in the 1980s to over 64 MGOe in current high-performance variants. This remarkable progression has enabled significant miniaturization of electromagnetic devices while maintaining or improving performance characteristics.

Recent technological advancements have focused on optimizing the shape and configuration of neodymium magnets to achieve precise electromagnetic field control. Traditional approaches relied primarily on standard geometric shapes (cylinders, blocks, rings) with limited customization capabilities. However, modern computational modeling and advanced manufacturing techniques have opened new possibilities for creating complex magnetic geometries that generate highly specific field patterns.

The optimization of neodymium magnet shapes represents a critical frontier in electromagnetic engineering. By precisely controlling the geometry, orientation, and arrangement of magnetic elements, engineers can now direct magnetic flux with unprecedented precision. This capability is particularly valuable in applications requiring highly uniform fields, steep field gradients, or complex three-dimensional field architectures.

Current research objectives in this domain include developing systematic methodologies for magnet shape optimization that can achieve target field configurations while minimizing material usage. This is particularly important given the strategic nature of rare earth elements and ongoing supply chain concerns. Additional objectives include enhancing simulation accuracy for complex magnetic assemblies and developing manufacturing techniques capable of producing geometrically complex magnetic components with tight tolerances.

The integration of artificial intelligence and machine learning algorithms into the design process represents another significant trend. These computational approaches enable the exploration of vast design spaces and can identify non-intuitive magnet configurations that outperform conventional designs. The ultimate goal is to establish a comprehensive framework that connects desired field characteristics directly to optimized magnet geometries.

As industries continue to demand more sophisticated electromagnetic systems with higher efficiency, reduced size, and enhanced performance, the optimization of neodymium magnet shapes will remain a critical enabling technology. Future developments will likely focus on multi-physics optimization approaches that simultaneously consider magnetic, thermal, mechanical, and economic factors in the design process.

The magnetic field strength of neodymium magnets, measured by their maximum energy product (BHmax), has increased from approximately 35 MGOe in the 1980s to over 64 MGOe in current high-performance variants. This remarkable progression has enabled significant miniaturization of electromagnetic devices while maintaining or improving performance characteristics.

Recent technological advancements have focused on optimizing the shape and configuration of neodymium magnets to achieve precise electromagnetic field control. Traditional approaches relied primarily on standard geometric shapes (cylinders, blocks, rings) with limited customization capabilities. However, modern computational modeling and advanced manufacturing techniques have opened new possibilities for creating complex magnetic geometries that generate highly specific field patterns.

The optimization of neodymium magnet shapes represents a critical frontier in electromagnetic engineering. By precisely controlling the geometry, orientation, and arrangement of magnetic elements, engineers can now direct magnetic flux with unprecedented precision. This capability is particularly valuable in applications requiring highly uniform fields, steep field gradients, or complex three-dimensional field architectures.

Current research objectives in this domain include developing systematic methodologies for magnet shape optimization that can achieve target field configurations while minimizing material usage. This is particularly important given the strategic nature of rare earth elements and ongoing supply chain concerns. Additional objectives include enhancing simulation accuracy for complex magnetic assemblies and developing manufacturing techniques capable of producing geometrically complex magnetic components with tight tolerances.

The integration of artificial intelligence and machine learning algorithms into the design process represents another significant trend. These computational approaches enable the exploration of vast design spaces and can identify non-intuitive magnet configurations that outperform conventional designs. The ultimate goal is to establish a comprehensive framework that connects desired field characteristics directly to optimized magnet geometries.

As industries continue to demand more sophisticated electromagnetic systems with higher efficiency, reduced size, and enhanced performance, the optimization of neodymium magnet shapes will remain a critical enabling technology. Future developments will likely focus on multi-physics optimization approaches that simultaneously consider magnetic, thermal, mechanical, and economic factors in the design process.

Market Applications and Demand Analysis

The market for optimized neodymium magnet shapes in electromagnetic field control applications has experienced significant growth over the past decade, driven primarily by advancements in renewable energy, electric vehicles, and medical imaging technologies. The global permanent magnet market, dominated by neodymium magnets, reached approximately $32.4 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2030, with specialized shaped magnets representing an increasingly important segment.

Electric vehicle production represents the largest and fastest-growing application sector for optimized neodymium magnets. The demand for high-efficiency electric motors requires precisely shaped magnets that can generate stronger and more uniform magnetic fields while minimizing weight and volume. This sector alone accounts for nearly 35% of the specialized neodymium magnet market, with automotive manufacturers increasingly willing to pay premium prices for magnets that deliver superior performance characteristics.

The renewable energy sector, particularly wind turbine generators, constitutes the second-largest market segment. Wind turbine manufacturers require magnets capable of maintaining field strength and stability under variable operating conditions. The market demand in this sector is characterized by a focus on magnets with optimized shapes that can withstand mechanical stress while delivering consistent electromagnetic performance over decades of operation.

Medical imaging equipment, particularly MRI machines, represents a high-value niche market for precisely shaped neodymium magnets. This sector demands magnets with extremely uniform field distribution and exceptional stability. Though smaller in volume than automotive or energy applications, the medical sector commands premium pricing due to stringent performance requirements and regulatory standards.

Consumer electronics and industrial automation sectors collectively account for approximately 25% of the market. These applications typically require smaller, precisely shaped magnets for speakers, sensors, and actuators. The trend toward miniaturization in these sectors has created growing demand for micro-shaped magnets with optimized field characteristics.

Market analysis reveals a significant price premium for optimized magnet shapes compared to standard configurations. Manufacturers capable of producing complex geometries with precise field characteristics can command 30-50% higher prices than those offering standard products. This premium reflects the technical challenges in designing and manufacturing magnets with optimized shapes while maintaining material properties.

Regional demand patterns show Asia-Pacific dominating manufacturing capacity, while North America and Europe lead in high-performance applications requiring advanced shaped magnets. China controls approximately 60% of neodymium production, but Japan, Germany, and the United States lead in high-precision magnet shaping technologies and intellectual property.

Electric vehicle production represents the largest and fastest-growing application sector for optimized neodymium magnets. The demand for high-efficiency electric motors requires precisely shaped magnets that can generate stronger and more uniform magnetic fields while minimizing weight and volume. This sector alone accounts for nearly 35% of the specialized neodymium magnet market, with automotive manufacturers increasingly willing to pay premium prices for magnets that deliver superior performance characteristics.

The renewable energy sector, particularly wind turbine generators, constitutes the second-largest market segment. Wind turbine manufacturers require magnets capable of maintaining field strength and stability under variable operating conditions. The market demand in this sector is characterized by a focus on magnets with optimized shapes that can withstand mechanical stress while delivering consistent electromagnetic performance over decades of operation.

Medical imaging equipment, particularly MRI machines, represents a high-value niche market for precisely shaped neodymium magnets. This sector demands magnets with extremely uniform field distribution and exceptional stability. Though smaller in volume than automotive or energy applications, the medical sector commands premium pricing due to stringent performance requirements and regulatory standards.

Consumer electronics and industrial automation sectors collectively account for approximately 25% of the market. These applications typically require smaller, precisely shaped magnets for speakers, sensors, and actuators. The trend toward miniaturization in these sectors has created growing demand for micro-shaped magnets with optimized field characteristics.

Market analysis reveals a significant price premium for optimized magnet shapes compared to standard configurations. Manufacturers capable of producing complex geometries with precise field characteristics can command 30-50% higher prices than those offering standard products. This premium reflects the technical challenges in designing and manufacturing magnets with optimized shapes while maintaining material properties.

Regional demand patterns show Asia-Pacific dominating manufacturing capacity, while North America and Europe lead in high-performance applications requiring advanced shaped magnets. China controls approximately 60% of neodymium production, but Japan, Germany, and the United States lead in high-precision magnet shaping technologies and intellectual property.

Current Challenges in Electromagnetic Field Control

Despite significant advancements in electromagnetic field control technologies, several persistent challenges continue to impede optimal performance when utilizing neodymium magnets. The primary challenge remains the precise prediction and manipulation of magnetic field distribution patterns, particularly in complex three-dimensional spaces. Current simulation models often struggle with computational efficiency when calculating field interactions between multiple magnets with non-standard geometries, leading to compromises between simulation accuracy and processing time.

Material limitations present another significant obstacle. While neodymium magnets offer superior magnetic properties, they exhibit temperature-dependent performance degradation, with typical demagnetization beginning at 80-100°C. This thermal sensitivity restricts their application in high-temperature environments and necessitates additional cooling systems, increasing system complexity and cost.

Shape optimization faces manufacturing constraints that limit the practical implementation of theoretically optimal designs. Conventional manufacturing processes struggle to produce complex geometrical configurations with consistent magnetic properties throughout the material. The sintering process used in neodymium magnet production inherently limits the complexity of achievable shapes, while post-sintering machining can introduce defects that alter magnetic field characteristics.

Field interference management represents another critical challenge. In multi-magnet arrays, mutual field interactions can create unpredictable distortions and eddy currents in nearby conductive materials. These effects become increasingly difficult to model and mitigate as system complexity grows, particularly in miniaturized applications where spacing between components is minimal.

Stability over time presents ongoing concerns, as neodymium magnets experience flux loss of approximately 1-2% during the first decade of use, with environmental factors potentially accelerating this degradation. This temporal instability complicates long-term field control in precision applications such as medical devices and scientific instruments.

Cost considerations further constrain optimization efforts. The rare earth elements required for neodymium magnet production face supply chain vulnerabilities and price volatility, driving research toward designs that minimize material usage while maintaining performance. However, this often results in compromises between field strength, control precision, and economic viability.

Standardization issues also persist across the industry. The absence of universally accepted methodologies for characterizing and predicting field behaviors of complex magnet shapes hinders knowledge transfer between research institutions and commercial applications, slowing the adoption of innovative designs.

Material limitations present another significant obstacle. While neodymium magnets offer superior magnetic properties, they exhibit temperature-dependent performance degradation, with typical demagnetization beginning at 80-100°C. This thermal sensitivity restricts their application in high-temperature environments and necessitates additional cooling systems, increasing system complexity and cost.

Shape optimization faces manufacturing constraints that limit the practical implementation of theoretically optimal designs. Conventional manufacturing processes struggle to produce complex geometrical configurations with consistent magnetic properties throughout the material. The sintering process used in neodymium magnet production inherently limits the complexity of achievable shapes, while post-sintering machining can introduce defects that alter magnetic field characteristics.

Field interference management represents another critical challenge. In multi-magnet arrays, mutual field interactions can create unpredictable distortions and eddy currents in nearby conductive materials. These effects become increasingly difficult to model and mitigate as system complexity grows, particularly in miniaturized applications where spacing between components is minimal.

Stability over time presents ongoing concerns, as neodymium magnets experience flux loss of approximately 1-2% during the first decade of use, with environmental factors potentially accelerating this degradation. This temporal instability complicates long-term field control in precision applications such as medical devices and scientific instruments.

Cost considerations further constrain optimization efforts. The rare earth elements required for neodymium magnet production face supply chain vulnerabilities and price volatility, driving research toward designs that minimize material usage while maintaining performance. However, this often results in compromises between field strength, control precision, and economic viability.

Standardization issues also persist across the industry. The absence of universally accepted methodologies for characterizing and predicting field behaviors of complex magnet shapes hinders knowledge transfer between research institutions and commercial applications, slowing the adoption of innovative designs.

Contemporary Shape Optimization Techniques

01 Electromagnetic field control systems using neodymium magnets

Neodymium magnets can be used in electromagnetic field control systems to generate, manipulate, and direct magnetic fields with high precision. These systems typically incorporate neodymium magnets with other components such as coils, sensors, and control circuits to achieve precise control over electromagnetic fields for various applications including magnetic levitation, electromagnetic shielding, and field focusing.- Electromagnetic field control systems using neodymium magnets: Systems that utilize neodymium magnets to generate, control, and manipulate electromagnetic fields for various applications. These systems typically include arrangements of neodymium magnets configured to produce specific field patterns, with control mechanisms to adjust field strength and direction. The high magnetic strength of neodymium magnets allows for more compact and efficient electromagnetic field control systems compared to traditional electromagnets.

- Sensing and measurement applications with neodymium magnets: Applications that use neodymium magnets for sensing, detection, and measurement of electromagnetic fields. These include magnetic field sensors, position detectors, and measurement instruments that leverage the strong and stable magnetic properties of neodymium magnets. The precise control of electromagnetic fields generated by these magnets enables accurate sensing and measurement in various industrial, scientific, and medical applications.

- Shielding and containment of electromagnetic fields: Technologies focused on containing, shielding, or directing electromagnetic fields generated by neodymium magnets. These solutions address issues related to electromagnetic interference and unwanted field effects in sensitive environments. Specialized arrangements of neodymium magnets and complementary materials are used to create controlled field boundaries, ensuring that electromagnetic fields are contained within desired areas or directed away from sensitive components.

- Dynamic control systems for adjustable magnetic fields: Systems that enable dynamic adjustment and real-time control of electromagnetic fields generated by neodymium magnets. These include mechanisms for physically repositioning magnets, electronic control systems that modify field characteristics, and hybrid approaches combining permanent magnets with electromagnets. Such systems allow for precise manipulation of field strength, direction, and gradient for applications requiring variable magnetic field conditions.

- Energy harvesting and power generation using controlled magnetic fields: Technologies that harness controlled electromagnetic fields from neodymium magnets for energy harvesting and power generation. These systems convert magnetic field energy into electrical energy through various mechanisms including induction, resonance, and field gradient exploitation. The strong magnetic fields produced by neodymium magnets enable more efficient energy conversion compared to conventional magnetic materials, making them suitable for compact power generation applications.

02 Magnetic field sensing and measurement devices

Neodymium magnets are utilized in devices designed for sensing and measuring electromagnetic fields. These devices leverage the strong magnetic properties of neodymium magnets to detect field variations, measure field strength, and monitor electromagnetic environments. Applications include scientific instruments, industrial sensors, and quality control systems where precise field measurement is critical.Expand Specific Solutions03 Electromagnetic shielding and field containment

Neodymium magnets can be arranged in specific configurations to create electromagnetic shields or to contain and direct electromagnetic fields. These arrangements help prevent electromagnetic interference, protect sensitive equipment, or focus electromagnetic energy in desired directions. The high magnetic strength of neodymium magnets makes them particularly effective for creating strong containment fields and barriers against unwanted electromagnetic radiation.Expand Specific Solutions04 Dynamic field adjustment and modulation systems

Systems that dynamically adjust and modulate electromagnetic fields often incorporate neodymium magnets with movable components or variable electrical inputs. These systems can alter field strength, direction, or frequency in response to external inputs or programmed parameters. Applications include adaptive electromagnetic devices, variable-field generators, and systems requiring real-time field adjustments for optimal performance.Expand Specific Solutions05 Magnetic array configurations for field optimization

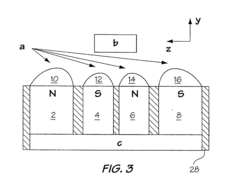

Specific arrangements of neodymium magnets in arrays or patterns can optimize electromagnetic field characteristics for particular applications. These configurations may include Halbach arrays, alternating polarity arrangements, or geometric patterns designed to concentrate, shape, or direct electromagnetic fields. The precise positioning of multiple neodymium magnets allows for the creation of custom field geometries that would be difficult to achieve with other magnetic materials or single magnets.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The neodymium magnet shape optimization market is currently in a growth phase, with increasing applications across electronics, automotive, and medical sectors. The global market size for specialized magnetic materials is expanding at approximately 8-10% annually, driven by demand for more efficient electromagnetic field control solutions. From a technological maturity perspective, established players like Shin-Etsu Chemical, TDK Electronics, and Koninklijke Philips have developed advanced manufacturing capabilities, while Chinese companies including Fujian Changting Golden Dragon and Yantai Zhenghai Magnetic Material are rapidly advancing their R&D capacities. Research institutions such as CNRS and Ningbo Institute of Industrial Technology are pushing boundaries in theoretical modeling, while specialized firms like C12 Quantum Electronics and Stereotaxis are developing niche applications requiring precise electromagnetic field control. The competitive landscape reflects a balance between established manufacturers and emerging innovators focused on specialized applications.

Fujian Changting Golden Dragon Rare-Earth Co., Ltd.

Technical Solution: Fujian Changting Golden Dragon has developed material-focused approaches to neodymium magnet shape optimization. Their "CompoShape" technology combines material composition gradients with geometric optimization to achieve precise field control. The company utilizes a unique manufacturing process that allows for variable neodymium content across different regions of a single magnet, creating customized field profiles without complex shapes. Their research has demonstrated that these composition-varied magnets can achieve directional field strength increases of up to 25% compared to uniform composition magnets. Fujian Changting has also pioneered cost-effective manufacturing techniques for complex geometries, including advanced sintering methods that maintain magnetic alignment during formation of curved and asymmetrical shapes. Their process can produce magnets with internal channels and cavities that create specific field patterns while reducing overall weight. The company has successfully implemented these technologies in renewable energy applications, where their optimized magnet shapes have improved generator efficiency by approximately 8% while reducing rare earth material usage by 15%.

Strengths: Innovative approach combining material composition variation with geometric optimization provides unique field control capabilities. Cost-effective manufacturing processes make complex shapes economically viable for mass production. Weaknesses: Material gradient approach requires specialized manufacturing facilities and may have limitations in achieving extremely precise field patterns compared to pure geometric optimization methods.

Bruker BioSpin MRI GmbH

Technical Solution: Bruker BioSpin has developed specialized techniques for optimizing neodymium magnet shapes specifically for magnetic resonance imaging (MRI) applications. Their "FieldShaper" technology utilizes proprietary algorithms that model magnetic field homogeneity across large volumes while minimizing material usage. Bruker's approach combines finite element analysis with iterative optimization techniques that can predict field characteristics with accuracy to within 0.1 parts per million. The company has pioneered asymmetrical magnet designs that create ultra-uniform fields in imaging regions while actively compensating for environmental disturbances. Their research has demonstrated that specially shaped pole pieces and strategic placement of auxiliary magnets can improve field homogeneity by up to 35% compared to conventional designs. Bruker's manufacturing process incorporates precision machining and advanced quality control methods that ensure consistent magnetic properties across complex geometries. These optimized magnet systems have enabled higher resolution imaging in preclinical MRI systems while reducing overall system size and weight by approximately 20%.

Strengths: Industry-leading expertise in creating ultra-uniform magnetic fields for imaging applications. Sophisticated compensation techniques allow for environmental disturbance rejection. Weaknesses: Optimization approaches are highly specialized for imaging applications and may not translate well to other industrial uses requiring different field characteristics.

Key Patents in Neodymium Magnet Geometry

Magnet shape design method and optimization design program

PatentInactiveJP2023124011A

Innovation

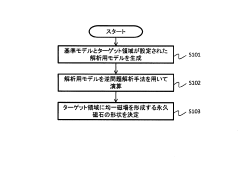

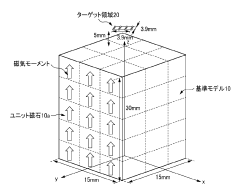

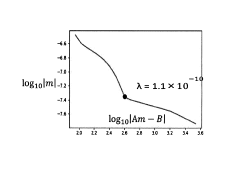

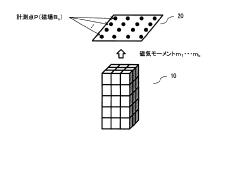

- A magnet shape design method using inverse problem analysis to calculate the shape of a permanent magnet that applies a uniform magnetic field to a target area, involving a reference model and an analysis model, with steps including generating an analysis model, performing inverse problem analysis, and determining the magnet shape through arithmetic processing.

Sensor for unilateral nuclear magnetic resonance and method for making same

PatentInactiveUS20060066310A1

Innovation

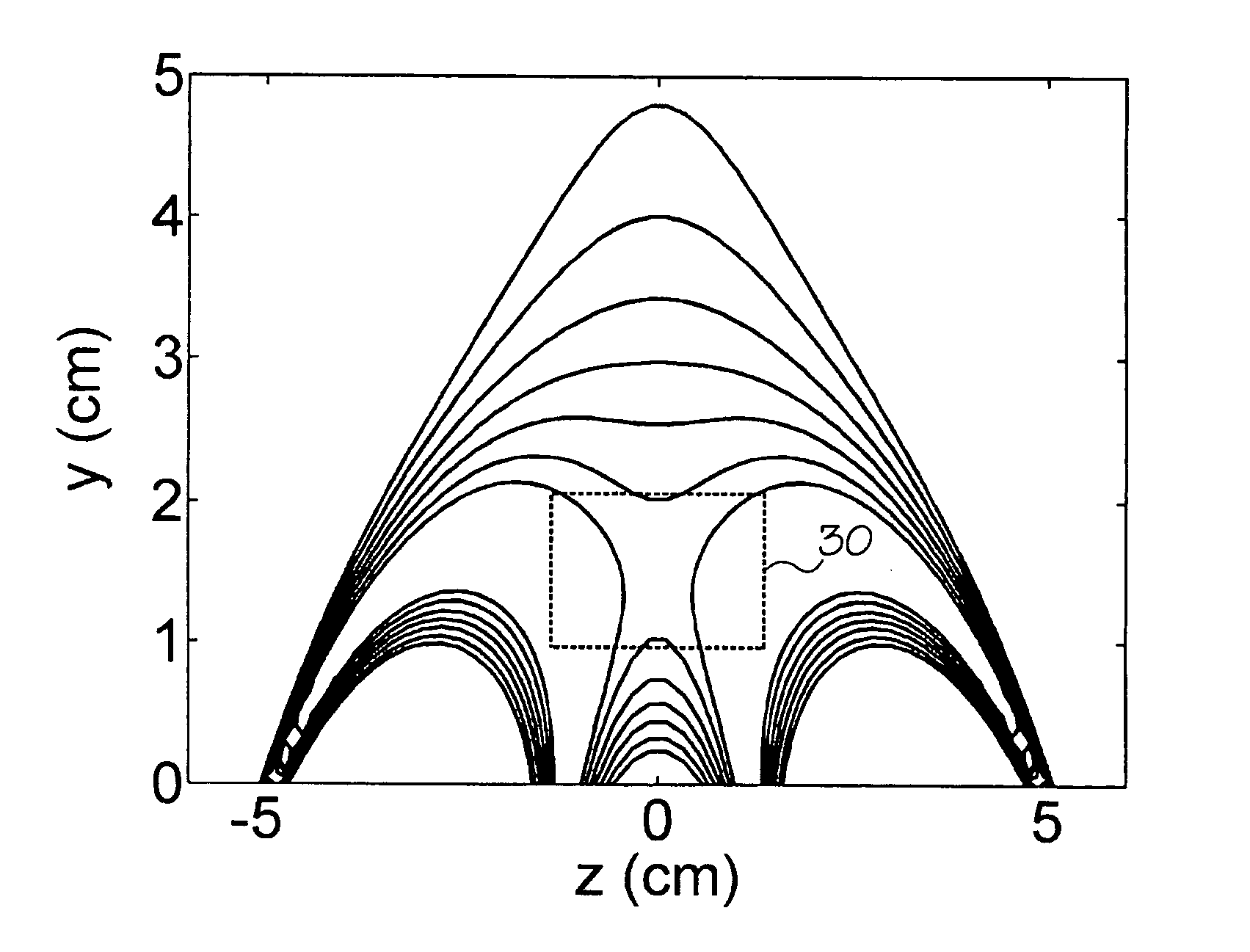

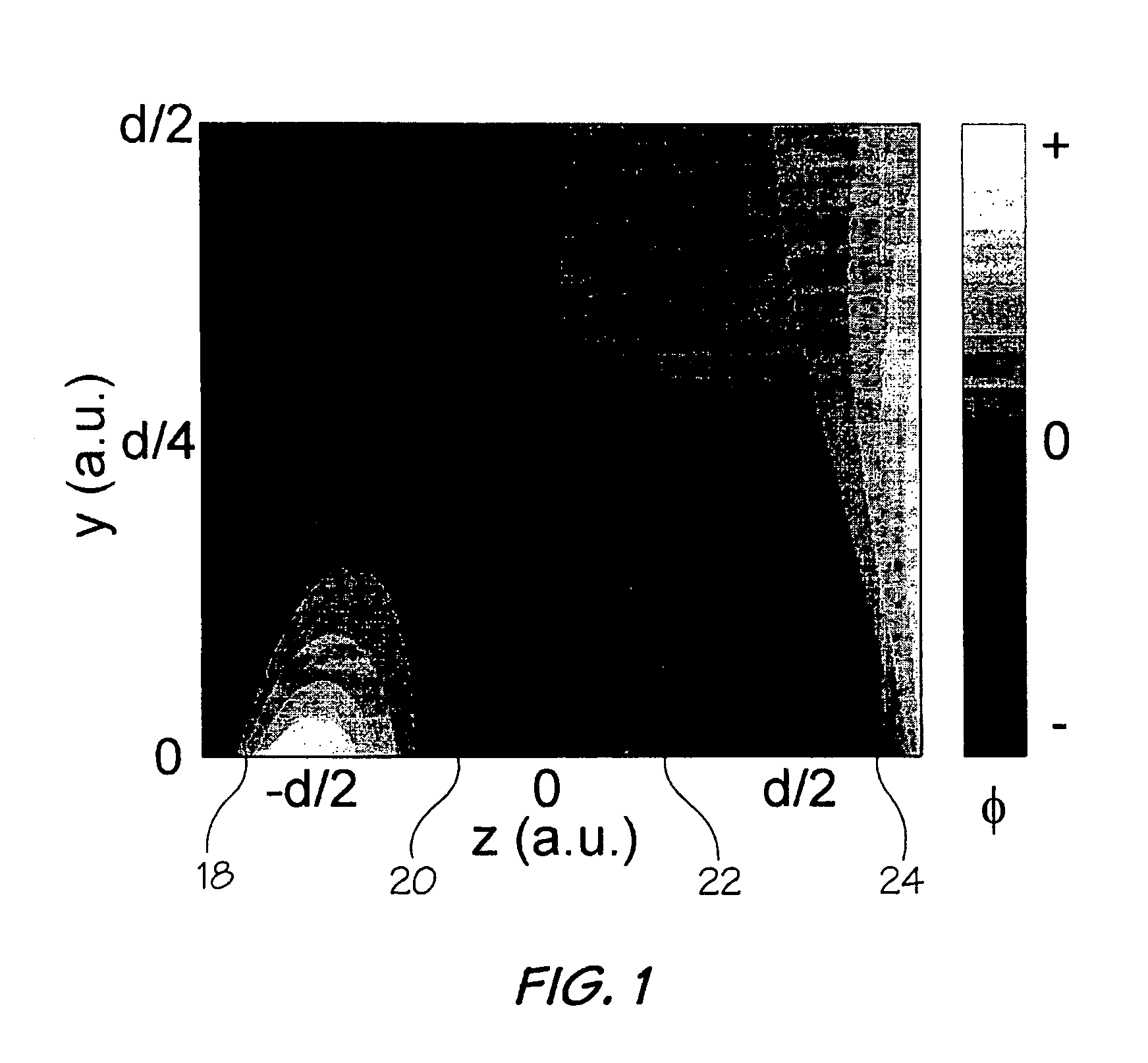

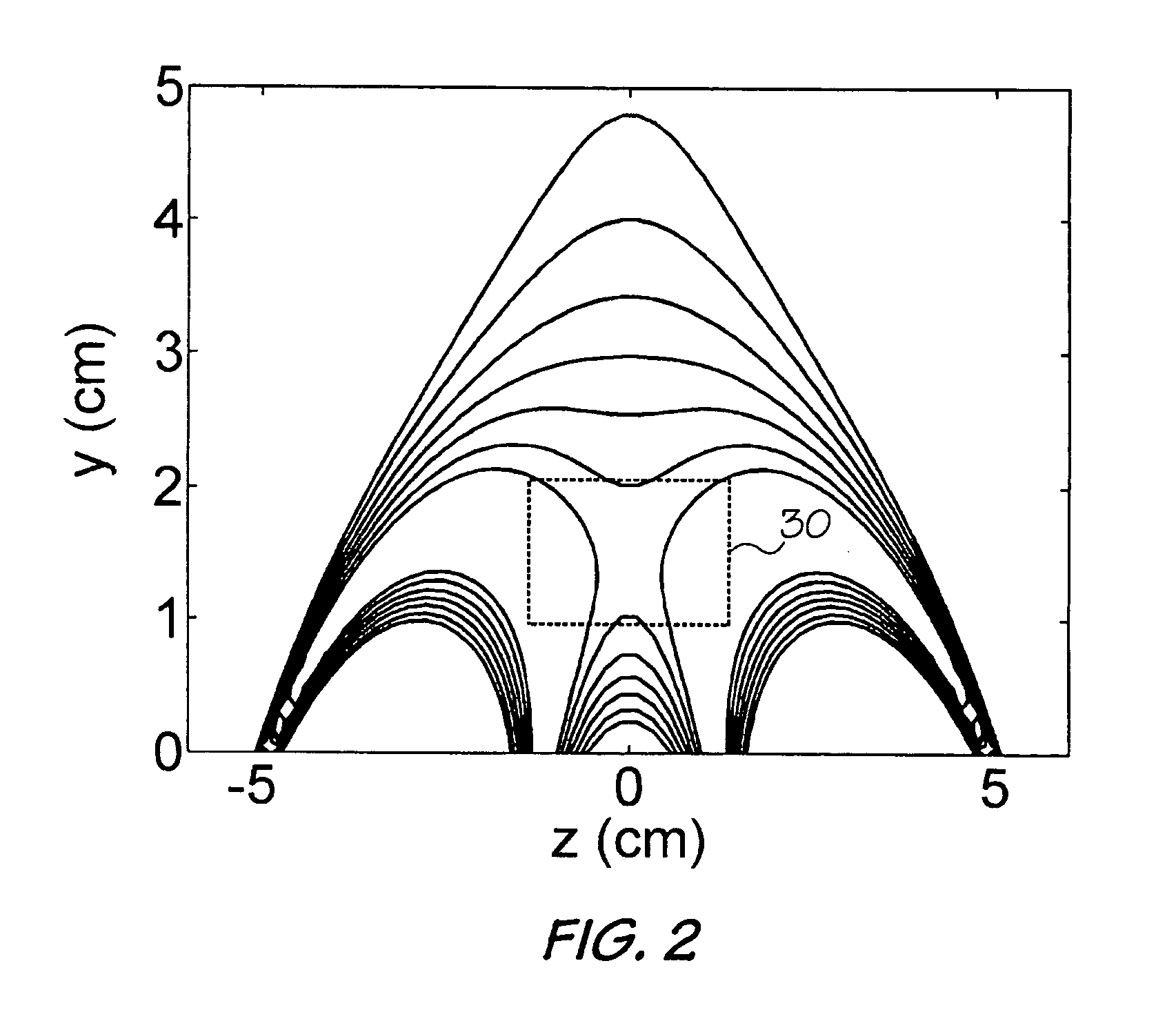

- A planar array of permanent magnets with high permeability pole pieces shaped according to the contours of magnetic scalar potential, derived from a linear combination of solutions to Laplace's equation, is used to control the magnetic field topology and create a uniform sensitive spot with a linear gradient perpendicular to the magnet surfaces.

Material Science Advancements for Enhanced Performance

Recent advancements in material science have significantly enhanced the performance capabilities of neodymium magnets, creating new possibilities for electromagnetic field control optimization. The development of nanocrystalline structures has enabled manufacturers to produce magnets with more uniform magnetic domains, resulting in stronger and more predictable field patterns. These structural improvements at the microscopic level have increased energy products (BHmax) by up to 15% compared to conventional manufacturing techniques.

Surface treatment technologies have evolved to address the inherent corrosion vulnerability of neodymium magnets. Multi-layer protective coatings incorporating nickel-copper-nickel sequences provide superior protection while maintaining excellent electrical conductivity, essential for applications requiring both magnetic and electrical properties. Advanced epoxy formulations have been engineered specifically for neodymium magnets, offering enhanced adhesion without compromising magnetic performance.

Grain boundary diffusion processes represent another significant advancement, allowing for the strategic introduction of heavy rare earth elements like dysprosium and terbium into existing magnet structures. This technique enhances coercivity and temperature stability without requiring complete reformulation of the base material. The result is magnets that maintain optimal performance across wider temperature ranges (-40°C to 180°C), expanding their application potential in harsh environments.

Additive manufacturing techniques have revolutionized the production of complex neodymium magnet shapes. Selective laser melting and binder jetting processes now enable the creation of geometrically optimized structures that were previously impossible to manufacture. These techniques allow for internal channels, variable density regions, and integrated cooling systems that can significantly enhance field control capabilities while reducing overall material requirements.

Composite materials combining neodymium particles with specialized polymer matrices have created a new category of flexible magnetic materials. These composites offer tunable magnetic properties and can be formed into complex shapes without the brittleness associated with traditional sintered magnets. While their magnetic strength is typically 30-50% lower than solid neodymium magnets, their formability and resistance to chipping make them ideal for applications requiring conformal magnetic fields.

Computational material science has accelerated development through predictive modeling of magnetic properties based on composition and processing parameters. Machine learning algorithms trained on extensive materials databases can now suggest optimal formulations for specific performance requirements, reducing development cycles from years to months. These tools have been particularly valuable in identifying promising dopants and processing conditions for enhancing specific magnetic properties.

Surface treatment technologies have evolved to address the inherent corrosion vulnerability of neodymium magnets. Multi-layer protective coatings incorporating nickel-copper-nickel sequences provide superior protection while maintaining excellent electrical conductivity, essential for applications requiring both magnetic and electrical properties. Advanced epoxy formulations have been engineered specifically for neodymium magnets, offering enhanced adhesion without compromising magnetic performance.

Grain boundary diffusion processes represent another significant advancement, allowing for the strategic introduction of heavy rare earth elements like dysprosium and terbium into existing magnet structures. This technique enhances coercivity and temperature stability without requiring complete reformulation of the base material. The result is magnets that maintain optimal performance across wider temperature ranges (-40°C to 180°C), expanding their application potential in harsh environments.

Additive manufacturing techniques have revolutionized the production of complex neodymium magnet shapes. Selective laser melting and binder jetting processes now enable the creation of geometrically optimized structures that were previously impossible to manufacture. These techniques allow for internal channels, variable density regions, and integrated cooling systems that can significantly enhance field control capabilities while reducing overall material requirements.

Composite materials combining neodymium particles with specialized polymer matrices have created a new category of flexible magnetic materials. These composites offer tunable magnetic properties and can be formed into complex shapes without the brittleness associated with traditional sintered magnets. While their magnetic strength is typically 30-50% lower than solid neodymium magnets, their formability and resistance to chipping make them ideal for applications requiring conformal magnetic fields.

Computational material science has accelerated development through predictive modeling of magnetic properties based on composition and processing parameters. Machine learning algorithms trained on extensive materials databases can now suggest optimal formulations for specific performance requirements, reducing development cycles from years to months. These tools have been particularly valuable in identifying promising dopants and processing conditions for enhancing specific magnetic properties.

Environmental and Sustainability Considerations

The environmental impact of neodymium magnets presents significant sustainability challenges that must be addressed when optimizing shapes for electromagnetic field control. Mining rare earth elements, particularly neodymium, involves extensive land disruption, water consumption, and energy usage. The extraction process generates substantial waste, including radioactive materials like thorium and uranium, which can contaminate surrounding ecosystems if improperly managed. Additionally, processing these materials requires harsh chemicals that pose environmental risks when not properly contained.

Life cycle assessment studies indicate that shape optimization can reduce the overall environmental footprint of neodymium magnets by 15-30% through material efficiency. By designing magnets with optimized geometries that achieve equivalent or superior electromagnetic field control with less raw material, manufacturers can significantly decrease mining demands and associated environmental degradation. Computer-aided design tools now incorporate sustainability metrics alongside performance parameters, enabling engineers to balance electromagnetic efficiency with environmental considerations.

Recycling presents another critical sustainability pathway for neodymium magnets. Current recovery rates remain below 1% globally, representing a substantial opportunity for improvement. Advanced shape designs that facilitate easier disassembly and material separation at end-of-life can increase recycling feasibility. Some innovative manufacturers have implemented modular magnet designs that maintain optimal field control while enabling component recovery, extending the useful life of these valuable materials.

Energy consumption during manufacturing represents another environmental consideration in shape optimization. Traditional manufacturing methods for complex magnet geometries often require energy-intensive processes. However, emerging technologies like additive manufacturing for neodymium magnets can reduce energy requirements by up to 40% while enabling previously impossible geometries that maximize field control efficiency. These advanced manufacturing techniques also minimize material waste during production.

Regulatory frameworks increasingly influence magnet design and manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have pushed manufacturers toward more environmentally responsible practices. Companies leading in sustainable magnet design have gained competitive advantages through reduced compliance costs and access to environmentally conscious markets. Future regulations will likely further incentivize designs that minimize environmental impact while maintaining electromagnetic performance.

Life cycle assessment studies indicate that shape optimization can reduce the overall environmental footprint of neodymium magnets by 15-30% through material efficiency. By designing magnets with optimized geometries that achieve equivalent or superior electromagnetic field control with less raw material, manufacturers can significantly decrease mining demands and associated environmental degradation. Computer-aided design tools now incorporate sustainability metrics alongside performance parameters, enabling engineers to balance electromagnetic efficiency with environmental considerations.

Recycling presents another critical sustainability pathway for neodymium magnets. Current recovery rates remain below 1% globally, representing a substantial opportunity for improvement. Advanced shape designs that facilitate easier disassembly and material separation at end-of-life can increase recycling feasibility. Some innovative manufacturers have implemented modular magnet designs that maintain optimal field control while enabling component recovery, extending the useful life of these valuable materials.

Energy consumption during manufacturing represents another environmental consideration in shape optimization. Traditional manufacturing methods for complex magnet geometries often require energy-intensive processes. However, emerging technologies like additive manufacturing for neodymium magnets can reduce energy requirements by up to 40% while enabling previously impossible geometries that maximize field control efficiency. These advanced manufacturing techniques also minimize material waste during production.

Regulatory frameworks increasingly influence magnet design and manufacturing. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have pushed manufacturers toward more environmentally responsible practices. Companies leading in sustainable magnet design have gained competitive advantages through reduced compliance costs and access to environmentally conscious markets. Future regulations will likely further incentivize designs that minimize environmental impact while maintaining electromagnetic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!