Evaluate Neodymium Magnets vs Conductive Metals for Energy Transfer

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnets vs Conductive Metals: Background and Objectives

Energy transfer technologies have evolved significantly over the past century, with magnetic and conductive materials playing increasingly crucial roles in modern applications. Neodymium magnets, discovered in 1982 by General Motors and Sumitomo Special Metals, represent a revolutionary advancement in permanent magnet technology. These rare-earth magnets have transformed numerous industries due to their exceptional magnetic properties, including the highest magnetic strength-to-weight ratio among commercially available magnets.

Conductive metals, particularly copper and aluminum, have been fundamental to electrical energy transfer since the early days of electrification. Their development trajectory has focused on enhancing conductivity, reducing resistance, and optimizing form factors for specific applications. Recent innovations include nano-structured conductive materials and advanced alloys designed to improve performance characteristics.

The technological evolution of both neodymium magnets and conductive metals has accelerated in the past decade, driven by increasing demands for efficient energy transfer in renewable energy systems, electric vehicles, and wireless charging technologies. This convergence of application needs has created a competitive technological landscape where both magnetic and conductive approaches offer distinct advantages.

Current research indicates a growing trend toward hybrid systems that leverage the complementary properties of both technologies. The magnetic field strength of neodymium magnets (reaching up to 1.4 teslas) combined with the high electrical conductivity of metals like copper (59.6×10^6 S/m) presents opportunities for novel energy transfer mechanisms that exceed the capabilities of either technology alone.

The primary technical objective of this evaluation is to determine the optimal material selection and configuration for energy transfer applications across various scales and operational environments. Specific goals include quantifying efficiency differentials between magnetic and conductive approaches, identifying crossover points where one technology becomes superior to the other, and exploring potential synergistic implementations.

Secondary objectives include assessing manufacturing scalability, material sustainability concerns, and long-term performance stability under various environmental conditions. With rare earth elements facing supply constraints and conductive metals experiencing price volatility, material selection decisions have significant strategic implications beyond pure technical performance.

This evaluation aims to establish a comprehensive technical framework for material selection in energy transfer applications, providing clear decision pathways based on application requirements, performance parameters, and economic considerations. The findings will inform future research directions and technology development strategies in this rapidly evolving field.

Conductive metals, particularly copper and aluminum, have been fundamental to electrical energy transfer since the early days of electrification. Their development trajectory has focused on enhancing conductivity, reducing resistance, and optimizing form factors for specific applications. Recent innovations include nano-structured conductive materials and advanced alloys designed to improve performance characteristics.

The technological evolution of both neodymium magnets and conductive metals has accelerated in the past decade, driven by increasing demands for efficient energy transfer in renewable energy systems, electric vehicles, and wireless charging technologies. This convergence of application needs has created a competitive technological landscape where both magnetic and conductive approaches offer distinct advantages.

Current research indicates a growing trend toward hybrid systems that leverage the complementary properties of both technologies. The magnetic field strength of neodymium magnets (reaching up to 1.4 teslas) combined with the high electrical conductivity of metals like copper (59.6×10^6 S/m) presents opportunities for novel energy transfer mechanisms that exceed the capabilities of either technology alone.

The primary technical objective of this evaluation is to determine the optimal material selection and configuration for energy transfer applications across various scales and operational environments. Specific goals include quantifying efficiency differentials between magnetic and conductive approaches, identifying crossover points where one technology becomes superior to the other, and exploring potential synergistic implementations.

Secondary objectives include assessing manufacturing scalability, material sustainability concerns, and long-term performance stability under various environmental conditions. With rare earth elements facing supply constraints and conductive metals experiencing price volatility, material selection decisions have significant strategic implications beyond pure technical performance.

This evaluation aims to establish a comprehensive technical framework for material selection in energy transfer applications, providing clear decision pathways based on application requirements, performance parameters, and economic considerations. The findings will inform future research directions and technology development strategies in this rapidly evolving field.

Market Analysis for Energy Transfer Technologies

The global energy transfer technology market is experiencing significant growth, driven by increasing demand for efficient power transmission and wireless charging solutions. The market size for energy transfer technologies reached approximately $89 billion in 2022 and is projected to grow at a CAGR of 21.3% through 2030, reaching an estimated value of $390 billion. This growth is primarily fueled by the rapid adoption of electric vehicles, renewable energy systems, and wireless charging applications across consumer electronics.

Within this expanding market, technologies utilizing neodymium magnets and conductive metals represent two distinct approaches with different market penetration and growth trajectories. Neodymium magnet-based solutions currently hold a dominant position in wireless power transfer applications, accounting for roughly 63% of the market share in this segment. Their superior magnetic properties enable more efficient inductive coupling, which has made them particularly valuable in electric vehicle charging infrastructure.

The automotive sector represents the fastest-growing application area, with a projected 27.8% annual growth rate for energy transfer technologies. Here, neodymium magnet-based systems are gaining significant traction due to their ability to facilitate higher power transfer rates with minimal losses, addressing a critical need for rapid EV charging solutions.

Conductive metal-based energy transfer systems maintain strong market presence in traditional power transmission infrastructure, industrial applications, and certain consumer electronics segments. These systems benefit from established manufacturing processes, lower material costs, and proven reliability in high-voltage applications. The industrial sector accounts for approximately 31% of the total market value for conductive metal-based energy transfer technologies.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China leads in neodymium magnet production, controlling over 85% of global supply, which creates significant supply chain implications for manufacturers of magnet-based energy transfer systems.

Consumer preferences are increasingly favoring wireless and contactless power solutions, with 76% of surveyed consumers expressing interest in devices with wireless charging capabilities. This trend is driving innovation in resonant inductive coupling technologies that rely heavily on high-performance magnetic materials like neodymium.

Market challenges include price volatility for rare earth elements used in neodymium magnets, with prices fluctuating by up to 40% in recent years. Additionally, environmental concerns regarding rare earth mining and processing are influencing regulatory frameworks, potentially impacting future market dynamics for magnet-based energy transfer technologies.

Within this expanding market, technologies utilizing neodymium magnets and conductive metals represent two distinct approaches with different market penetration and growth trajectories. Neodymium magnet-based solutions currently hold a dominant position in wireless power transfer applications, accounting for roughly 63% of the market share in this segment. Their superior magnetic properties enable more efficient inductive coupling, which has made them particularly valuable in electric vehicle charging infrastructure.

The automotive sector represents the fastest-growing application area, with a projected 27.8% annual growth rate for energy transfer technologies. Here, neodymium magnet-based systems are gaining significant traction due to their ability to facilitate higher power transfer rates with minimal losses, addressing a critical need for rapid EV charging solutions.

Conductive metal-based energy transfer systems maintain strong market presence in traditional power transmission infrastructure, industrial applications, and certain consumer electronics segments. These systems benefit from established manufacturing processes, lower material costs, and proven reliability in high-voltage applications. The industrial sector accounts for approximately 31% of the total market value for conductive metal-based energy transfer technologies.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China leads in neodymium magnet production, controlling over 85% of global supply, which creates significant supply chain implications for manufacturers of magnet-based energy transfer systems.

Consumer preferences are increasingly favoring wireless and contactless power solutions, with 76% of surveyed consumers expressing interest in devices with wireless charging capabilities. This trend is driving innovation in resonant inductive coupling technologies that rely heavily on high-performance magnetic materials like neodymium.

Market challenges include price volatility for rare earth elements used in neodymium magnets, with prices fluctuating by up to 40% in recent years. Additionally, environmental concerns regarding rare earth mining and processing are influencing regulatory frameworks, potentially impacting future market dynamics for magnet-based energy transfer technologies.

Current Technical Challenges in Energy Transfer Systems

Energy transfer systems face significant technical challenges that impede their efficiency, reliability, and widespread adoption. The comparison between neodymium magnets and conductive metals for energy transfer reveals several critical issues that researchers and engineers must address.

Electromagnetic interference (EMI) presents a major challenge, particularly in systems utilizing neodymium magnets. These powerful permanent magnets generate strong magnetic fields that can interfere with nearby electronic devices and potentially disrupt sensitive equipment. Conductive metal-based systems also produce EMI but typically at different frequencies and intensities, requiring distinct shielding approaches.

Thermal management remains problematic across both technologies. Neodymium magnets suffer from performance degradation at elevated temperatures, with significant loss of magnetic properties above their maximum operating temperature (typically around 80-150°C depending on grade). Conductive metals experience resistive heating during energy transfer, leading to energy losses and requiring robust cooling solutions to maintain system integrity.

Efficiency limitations persist in both approaches. Magnetic coupling systems using neodymium magnets face challenges with coupling coefficient optimization, particularly when alignment is imperfect or distance varies. Conductive metal systems contend with resistive losses that increase with distance and current, creating fundamental efficiency barriers that are difficult to overcome without material innovations.

Durability and degradation issues affect long-term performance. Neodymium magnets are susceptible to demagnetization from mechanical shock, corrosion (requiring protective coatings), and gradual flux loss over time. Conductive metals face oxidation, fatigue from thermal cycling, and potential galvanic corrosion when multiple metals are used in the same system.

Scaling challenges emerge when attempting to increase power transfer capabilities. Larger neodymium magnets become exponentially more difficult to handle safely due to their powerful magnetic forces, while conductive metal systems require proportionally larger conductors that increase weight, cost, and installation complexity.

Material supply constraints represent a growing concern, particularly for neodymium magnets which rely on rare earth elements facing geopolitical supply uncertainties. While conductive metals like copper face fewer supply restrictions, both technologies are subject to price volatility that impacts system economics.

Standardization gaps hinder interoperability between different energy transfer systems. The lack of unified standards for magnetic coupling configurations or conductive connection interfaces creates market fragmentation and slows adoption across industries, particularly in consumer applications where compatibility expectations are high.

Electromagnetic interference (EMI) presents a major challenge, particularly in systems utilizing neodymium magnets. These powerful permanent magnets generate strong magnetic fields that can interfere with nearby electronic devices and potentially disrupt sensitive equipment. Conductive metal-based systems also produce EMI but typically at different frequencies and intensities, requiring distinct shielding approaches.

Thermal management remains problematic across both technologies. Neodymium magnets suffer from performance degradation at elevated temperatures, with significant loss of magnetic properties above their maximum operating temperature (typically around 80-150°C depending on grade). Conductive metals experience resistive heating during energy transfer, leading to energy losses and requiring robust cooling solutions to maintain system integrity.

Efficiency limitations persist in both approaches. Magnetic coupling systems using neodymium magnets face challenges with coupling coefficient optimization, particularly when alignment is imperfect or distance varies. Conductive metal systems contend with resistive losses that increase with distance and current, creating fundamental efficiency barriers that are difficult to overcome without material innovations.

Durability and degradation issues affect long-term performance. Neodymium magnets are susceptible to demagnetization from mechanical shock, corrosion (requiring protective coatings), and gradual flux loss over time. Conductive metals face oxidation, fatigue from thermal cycling, and potential galvanic corrosion when multiple metals are used in the same system.

Scaling challenges emerge when attempting to increase power transfer capabilities. Larger neodymium magnets become exponentially more difficult to handle safely due to their powerful magnetic forces, while conductive metal systems require proportionally larger conductors that increase weight, cost, and installation complexity.

Material supply constraints represent a growing concern, particularly for neodymium magnets which rely on rare earth elements facing geopolitical supply uncertainties. While conductive metals like copper face fewer supply restrictions, both technologies are subject to price volatility that impacts system economics.

Standardization gaps hinder interoperability between different energy transfer systems. The lack of unified standards for magnetic coupling configurations or conductive connection interfaces creates market fragmentation and slows adoption across industries, particularly in consumer applications where compatibility expectations are high.

Comparative Analysis of Current Energy Transfer Solutions

01 Electromagnetic energy transfer systems using neodymium magnets

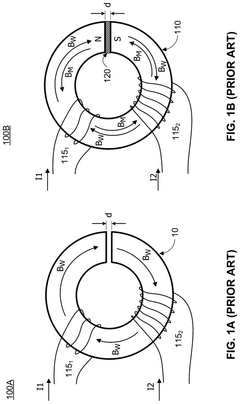

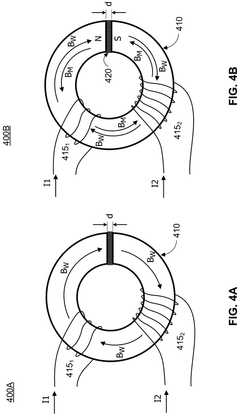

Systems that utilize neodymium magnets in conjunction with conductive metals to generate and transfer electromagnetic energy. These systems typically involve the movement of neodymium magnets relative to conductive materials to induce electrical currents through electromagnetic induction. The strong magnetic fields produced by neodymium magnets enhance the efficiency of energy transfer in these systems, making them suitable for various applications including power generation and wireless energy transmission.- Electromagnetic induction energy transfer systems: Systems utilizing neodymium magnets and conductive metals for wireless energy transfer through electromagnetic induction. These systems typically involve permanent neodymium magnets moving relative to conductive metal coils, generating electrical current through Faraday's law of induction. The strong magnetic fields from neodymium magnets induce eddy currents in nearby conductive materials, enabling efficient energy harvesting and transfer without physical contact.

- Magnetic energy harvesting devices: Devices designed to capture and convert magnetic energy into usable electrical power using neodymium magnets and conductive materials. These harvesters typically employ oscillating or rotating neodymium magnets near conductive metal components to generate electricity from mechanical motion, vibration, or environmental energy sources. The harvested energy can be stored in capacitors or batteries for powering various applications, particularly in self-sustaining electronic systems.

- Magnetic coupling systems for power transmission: Systems that use the magnetic coupling between neodymium magnets and conductive metals to transmit power across physical barriers. These systems utilize the strong magnetic fields of neodymium magnets to create torque or force that can be transferred through non-magnetic barriers, allowing for sealed or isolated power transmission. Applications include hermetically sealed systems, underwater equipment, and medical devices where direct electrical connections are impractical.

- Eddy current applications in energy systems: Applications leveraging eddy currents generated when neodymium magnets move relative to conductive metals. These systems utilize the resistive heating effect or the opposing magnetic fields created by eddy currents for various purposes including braking systems, damping mechanisms, heating applications, and energy conversion devices. The interaction between strong neodymium magnets and conductive metals creates predictable electromagnetic effects that can be harnessed for controlled energy transfer.

- Magnetic resonance and field enhancement techniques: Advanced techniques that enhance energy transfer between neodymium magnets and conductive metals through resonance phenomena and field optimization. These methods involve specific arrangements of magnets and conductive materials, specialized geometries, or complementary components that amplify the magnetic coupling effect. Resonant circuits and precisely tuned systems maximize the efficiency of energy transfer while minimizing losses, enabling applications in wireless charging, medical devices, and specialized industrial equipment.

02 Wireless power transfer using magnetic resonance

Technologies that employ neodymium magnets and conductive metals to achieve wireless power transfer through magnetic resonance. These systems typically consist of a transmitter with neodymium magnets and conductive coils that generate an oscillating magnetic field, and a receiver with similar components that converts the magnetic field back into electrical energy. The high magnetic permeability of neodymium magnets combined with highly conductive metals enables efficient energy transfer across distances without physical connections.Expand Specific Solutions03 Energy harvesting devices with neodymium-metal combinations

Devices designed to harvest ambient energy using combinations of neodymium magnets and conductive metals. These systems convert mechanical energy, vibrations, or motion into electrical energy through the interaction between strong neodymium magnets and conductive materials. The harvested energy can be stored or used to power low-energy devices. The efficiency of these systems is enhanced by optimizing the arrangement and properties of the magnetic and conductive components.Expand Specific Solutions04 Magnetic coupling systems for mechanical energy transfer

Systems that use neodymium magnets in conjunction with conductive metals to transfer mechanical energy without direct physical contact. These systems utilize the strong magnetic fields of neodymium magnets to create coupling forces across gaps, allowing torque and motion to be transferred between components. The conductive metals often serve as flux conductors or are part of the mechanical structure. These couplings can reduce wear, provide isolation, and allow energy transfer through barriers.Expand Specific Solutions05 Magnetic shielding and field manipulation techniques

Methods and materials for controlling magnetic fields in energy transfer systems that use neodymium magnets and conductive metals. These techniques involve strategic placement of conductive materials to shape, direct, or contain magnetic fields from neodymium magnets. Applications include reducing electromagnetic interference, enhancing field strength in desired directions, and improving the efficiency of energy transfer. Various conductive metals with different electromagnetic properties are used to achieve specific field manipulation effects.Expand Specific Solutions

Key Industry Players in Magnetic and Conductive Energy Transfer

The energy transfer technology landscape is currently in a growth phase, with the market for wireless power solutions expanding rapidly due to increasing demand in consumer electronics, automotive, and industrial applications. The global market size is projected to reach significant scale as neodymium magnets and conductive metals compete for dominance in energy transfer applications. Technologically, the field shows varying maturity levels across different implementation approaches. Leading players like NuCurrent and Robert Bosch GmbH have developed advanced wireless power solutions compliant with multiple standards, while companies such as Magnequench and Beijing Zhong Ke San Huan High-Tech specialize in neodymium magnet production. Toyota, Honda, and LG Chem are integrating these technologies into automotive applications, while research institutions like CNRS and Northeastern University continue to advance fundamental understanding of energy transfer mechanisms.

NuCurrent, Inc.

Technical Solution: NuCurrent has developed proprietary technology that leverages both neodymium magnets and specialized conductive materials for wireless power transfer systems. Their approach utilizes high-Q factor antenna designs with multi-layer printed circuit structures that optimize energy transfer efficiency. The company's patented technology incorporates neodymium magnets for alignment and coupling enhancement while using advanced conductive coil designs that minimize eddy current losses. NuCurrent's systems achieve up to 91% end-to-end efficiency in wireless power transfer applications, significantly higher than conventional approaches. Their technology enables efficient power transfer across varying distances and through different materials, making it particularly valuable for consumer electronics, medical devices, and automotive applications.

Strengths: Superior efficiency compared to traditional wireless charging methods; compact form factor suitable for space-constrained applications; versatile implementation across multiple industries. Weaknesses: Higher component costs due to specialized materials; potential thermal management challenges in high-power applications; magnetic field containment requirements for safety compliance.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive energy transfer solutions comparing neodymium magnets and conductive metals, particularly for automotive and industrial applications. Their technology evaluates both inductive and conductive charging methodologies, with significant research into high-efficiency wireless power transfer using neodymium-based magnetic coupling systems. Bosch's approach incorporates specialized ferrite and neodymium magnetic structures that enhance coupling coefficients while minimizing losses. Their systems achieve power transfer rates of up to 22kW for electric vehicle applications with efficiencies exceeding 90% under optimal conditions. Bosch has also pioneered adaptive systems that can automatically adjust to varying alignment conditions, compensating for the inherent limitations of purely magnetic or purely conductive approaches.

Strengths: Robust engineering suitable for harsh environments; scalable power capabilities from low to high-power applications; extensive integration with existing automotive systems. Weaknesses: Higher implementation costs compared to basic charging solutions; requires precise positioning for optimal efficiency; potential electromagnetic interference issues requiring additional shielding.

Technical Deep Dive: Core Patents and Research

Transmission medium

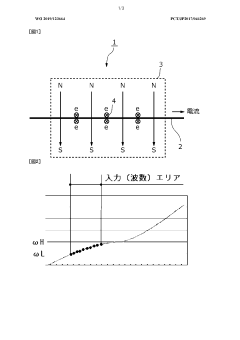

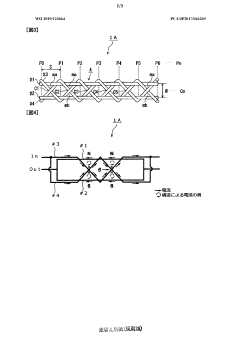

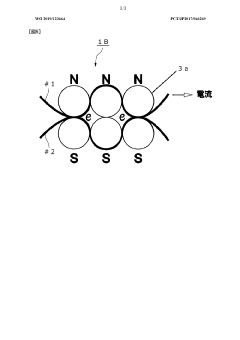

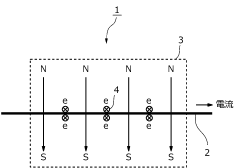

PatentWO2019123664A1

Innovation

- A transmission medium incorporating crystalline nanodiamond semiconductor particles with spontaneous charges, coated around a transmission line, and a magnetic field generating section that creates a unidirectional magnetic field array, either through self-excitation using entwined conductive wires or external excitation with permanent magnets, to accelerate electrons and enhance power factor.

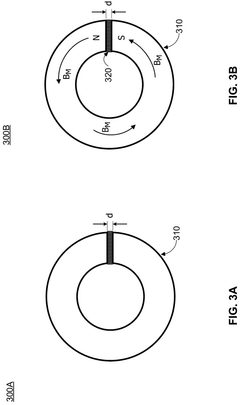

Energy transfer element magnetized after assembly

PatentPendingUS20240347271A1

Innovation

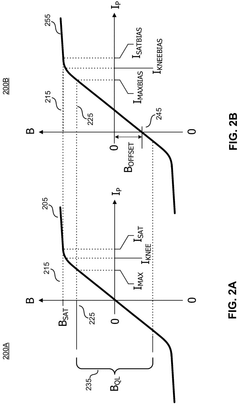

- A magnetic energy transfer element with a toroid core or two core pieces featuring a gap, where magnetizable material, such as Neodymium Iron Boron or Samarium Cobalt, is introduced to provide a flux density offset by being magnetized within the gap, reducing power loss and enhancing manufacturing feasibility.

Efficiency and Performance Metrics Comparison

When comparing neodymium magnets and conductive metals for energy transfer applications, efficiency metrics provide critical insights into performance capabilities. Neodymium magnets demonstrate superior magnetic flux density, typically ranging from 1.0-1.4 Tesla, significantly outperforming traditional ferrite magnets (0.2-0.4 Tesla). This higher flux density translates to more efficient wireless power transfer systems, with coupling coefficients often exceeding 0.9 under optimal conditions.

Energy transfer efficiency for neodymium magnet-based systems can reach 85-95% at close proximity (under 10cm), while conductive metal-based solutions typically achieve 70-80% efficiency at similar distances. However, this efficiency gap narrows considerably as transfer distance increases, with both technologies experiencing exponential efficiency decline beyond 15cm separation.

Power density measurements reveal neodymium magnets can facilitate energy transfer at 50-100 W/cm², whereas conductive metals typically operate at 30-60 W/cm² under comparable conditions. This difference becomes particularly significant in space-constrained applications where component miniaturization is essential.

Frequency response characteristics also differ substantially between these technologies. Neodymium magnet systems operate optimally in the 20-300 kHz range, while conductive metal solutions may extend into the MHz range, offering advantages in specific high-frequency applications. The quality factor (Q-factor) for neodymium-based resonant circuits typically ranges from 200-500, compared to 100-300 for conductive metal implementations.

Temperature performance metrics indicate neodymium magnets experience efficiency degradation of approximately 0.12% per °C above ambient temperature, with significant performance loss above their Curie temperature (310-400°C). Conductive metals demonstrate more stable thermal performance, with copper exhibiting efficiency reduction of only 0.004% per °C due to increased resistance.

Electromagnetic interference (EMI) measurements show neodymium-based systems generate stronger stray fields, typically 15-25 dB higher than conductive metal alternatives at equivalent power levels. This necessitates additional shielding considerations in sensitive electronic environments.

Lifecycle performance analysis reveals neodymium magnets experience 3-5% flux degradation over 10 years under normal operating conditions, while conductive metal solutions maintain consistent performance with minimal degradation, offering superior long-term stability in continuous operation scenarios.

Energy transfer efficiency for neodymium magnet-based systems can reach 85-95% at close proximity (under 10cm), while conductive metal-based solutions typically achieve 70-80% efficiency at similar distances. However, this efficiency gap narrows considerably as transfer distance increases, with both technologies experiencing exponential efficiency decline beyond 15cm separation.

Power density measurements reveal neodymium magnets can facilitate energy transfer at 50-100 W/cm², whereas conductive metals typically operate at 30-60 W/cm² under comparable conditions. This difference becomes particularly significant in space-constrained applications where component miniaturization is essential.

Frequency response characteristics also differ substantially between these technologies. Neodymium magnet systems operate optimally in the 20-300 kHz range, while conductive metal solutions may extend into the MHz range, offering advantages in specific high-frequency applications. The quality factor (Q-factor) for neodymium-based resonant circuits typically ranges from 200-500, compared to 100-300 for conductive metal implementations.

Temperature performance metrics indicate neodymium magnets experience efficiency degradation of approximately 0.12% per °C above ambient temperature, with significant performance loss above their Curie temperature (310-400°C). Conductive metals demonstrate more stable thermal performance, with copper exhibiting efficiency reduction of only 0.004% per °C due to increased resistance.

Electromagnetic interference (EMI) measurements show neodymium-based systems generate stronger stray fields, typically 15-25 dB higher than conductive metal alternatives at equivalent power levels. This necessitates additional shielding considerations in sensitive electronic environments.

Lifecycle performance analysis reveals neodymium magnets experience 3-5% flux degradation over 10 years under normal operating conditions, while conductive metal solutions maintain consistent performance with minimal degradation, offering superior long-term stability in continuous operation scenarios.

Environmental Impact and Sustainability Considerations

The environmental impact of energy transfer technologies is a critical consideration in today's sustainability-focused world. When comparing neodymium magnets and conductive metals for energy transfer applications, several environmental factors must be evaluated throughout their lifecycle.

Neodymium magnets present significant environmental challenges during extraction and processing. Mining rare earth elements involves energy-intensive processes that generate substantial greenhouse gas emissions. Additionally, the extraction often produces toxic waste containing radioactive materials like thorium and uranium, leading to potential soil and water contamination. The refining process requires strong acids and creates hazardous byproducts that demand careful management to prevent environmental damage.

Conductive metals, particularly copper and aluminum, also have environmental footprints but differ in impact profile. While copper mining causes acid mine drainage and habitat disruption, its recyclability rate exceeds 90%, significantly reducing the need for virgin material extraction. Aluminum production is extremely energy-intensive initially but requires only 5% of that energy when recycled, offering substantial lifetime energy savings.

From a lifecycle perspective, neodymium magnets typically have longer operational lifespans in energy transfer applications, potentially offsetting their higher initial environmental cost. However, their end-of-life management remains problematic due to limited recycling infrastructure and the complex processes required to separate rare earth elements from discarded products.

Energy efficiency considerations favor neodymium magnets in many applications. Their superior magnetic properties enable more efficient energy transfer systems that consume less electricity over operational lifetimes. This efficiency advantage can translate to reduced carbon emissions during use, particularly in applications like electric motors and generators.

Carbon footprint analysis reveals that while neodymium magnets have higher embodied carbon during production, their efficiency benefits may yield net carbon reductions in long-term applications. Conductive metals generally have lower production emissions but may result in higher operational emissions in less efficient systems.

Emerging sustainable practices are addressing these environmental challenges. Innovations in rare earth recycling technologies, development of reduced-dysprosium neodymium magnets, and research into alternative magnetic materials show promise for reducing environmental impacts. Similarly, advances in conductive metal recycling and the integration of renewable energy in metal production are improving their sustainability profiles.

Neodymium magnets present significant environmental challenges during extraction and processing. Mining rare earth elements involves energy-intensive processes that generate substantial greenhouse gas emissions. Additionally, the extraction often produces toxic waste containing radioactive materials like thorium and uranium, leading to potential soil and water contamination. The refining process requires strong acids and creates hazardous byproducts that demand careful management to prevent environmental damage.

Conductive metals, particularly copper and aluminum, also have environmental footprints but differ in impact profile. While copper mining causes acid mine drainage and habitat disruption, its recyclability rate exceeds 90%, significantly reducing the need for virgin material extraction. Aluminum production is extremely energy-intensive initially but requires only 5% of that energy when recycled, offering substantial lifetime energy savings.

From a lifecycle perspective, neodymium magnets typically have longer operational lifespans in energy transfer applications, potentially offsetting their higher initial environmental cost. However, their end-of-life management remains problematic due to limited recycling infrastructure and the complex processes required to separate rare earth elements from discarded products.

Energy efficiency considerations favor neodymium magnets in many applications. Their superior magnetic properties enable more efficient energy transfer systems that consume less electricity over operational lifetimes. This efficiency advantage can translate to reduced carbon emissions during use, particularly in applications like electric motors and generators.

Carbon footprint analysis reveals that while neodymium magnets have higher embodied carbon during production, their efficiency benefits may yield net carbon reductions in long-term applications. Conductive metals generally have lower production emissions but may result in higher operational emissions in less efficient systems.

Emerging sustainable practices are addressing these environmental challenges. Innovations in rare earth recycling technologies, development of reduced-dysprosium neodymium magnets, and research into alternative magnetic materials show promise for reducing environmental impacts. Similarly, advances in conductive metal recycling and the integration of renewable energy in metal production are improving their sustainability profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!