How to Reduce Eddy Currents in Neodymium Magnet Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Eddy Current Reduction Background and Objectives

Eddy currents, discovered by French physicist Léon Foucault in 1851, represent a significant challenge in applications utilizing neodymium magnets. These currents form when conductive materials experience changing magnetic fields, creating circular electrical flows that generate opposing magnetic fields. This phenomenon, governed by Faraday's law of induction and Lenz's law, results in energy losses through heat dissipation and magnetic field weakening, particularly problematic in high-performance applications.

The evolution of eddy current management has paralleled the development of magnetic materials. Early mitigation strategies emerged in transformer design during the late 19th century with laminated iron cores. The mid-20th century saw significant advancements with the introduction of ferrites and powder metallurgy techniques. The discovery of rare-earth magnets in the 1970s and 1980s, particularly neodymium-iron-boron (NdFeB) magnets, revolutionized permanent magnet applications but simultaneously intensified eddy current challenges due to their exceptional magnetic strength.

Recent technological trends show increasing focus on nanoscale material engineering, composite magnetic structures, and advanced simulation techniques to predict and minimize eddy current effects. The integration of computational electromagnetics with material science has enabled more sophisticated approaches to eddy current reduction, moving beyond traditional methods like lamination and powder metallurgy.

The primary objective of this technical research is to comprehensively evaluate existing and emerging methodologies for reducing eddy currents in neodymium magnet applications. Specifically, we aim to identify optimal material compositions, structural designs, and manufacturing techniques that minimize energy losses while maintaining the superior magnetic properties of neodymium magnets.

Secondary objectives include quantifying the performance improvements achievable through various eddy current reduction strategies across different application domains, particularly in electric motors, generators, transformers, and magnetic resonance imaging (MRI) systems. Additionally, we seek to establish a technical roadmap for future research directions, highlighting promising approaches for breakthrough innovations in eddy current management.

The significance of this research extends beyond immediate performance gains. As industries increasingly prioritize energy efficiency and sustainability, reducing eddy current losses represents a critical pathway to developing more environmentally friendly electromagnetic systems. Furthermore, as neodymium magnets continue to play a central role in renewable energy technologies and electric mobility solutions, advances in eddy current reduction will directly contribute to broader technological and environmental objectives.

The evolution of eddy current management has paralleled the development of magnetic materials. Early mitigation strategies emerged in transformer design during the late 19th century with laminated iron cores. The mid-20th century saw significant advancements with the introduction of ferrites and powder metallurgy techniques. The discovery of rare-earth magnets in the 1970s and 1980s, particularly neodymium-iron-boron (NdFeB) magnets, revolutionized permanent magnet applications but simultaneously intensified eddy current challenges due to their exceptional magnetic strength.

Recent technological trends show increasing focus on nanoscale material engineering, composite magnetic structures, and advanced simulation techniques to predict and minimize eddy current effects. The integration of computational electromagnetics with material science has enabled more sophisticated approaches to eddy current reduction, moving beyond traditional methods like lamination and powder metallurgy.

The primary objective of this technical research is to comprehensively evaluate existing and emerging methodologies for reducing eddy currents in neodymium magnet applications. Specifically, we aim to identify optimal material compositions, structural designs, and manufacturing techniques that minimize energy losses while maintaining the superior magnetic properties of neodymium magnets.

Secondary objectives include quantifying the performance improvements achievable through various eddy current reduction strategies across different application domains, particularly in electric motors, generators, transformers, and magnetic resonance imaging (MRI) systems. Additionally, we seek to establish a technical roadmap for future research directions, highlighting promising approaches for breakthrough innovations in eddy current management.

The significance of this research extends beyond immediate performance gains. As industries increasingly prioritize energy efficiency and sustainability, reducing eddy current losses represents a critical pathway to developing more environmentally friendly electromagnetic systems. Furthermore, as neodymium magnets continue to play a central role in renewable energy technologies and electric mobility solutions, advances in eddy current reduction will directly contribute to broader technological and environmental objectives.

Market Analysis for Low-Loss Neodymium Magnet Applications

The global market for low-loss neodymium magnets is experiencing robust growth, driven primarily by increasing demand in electric vehicles, renewable energy systems, and advanced electronics. The market size for neodymium magnets reached approximately $15 billion in 2022, with low-loss applications representing a growing segment estimated at $4.2 billion. Industry analysts project a compound annual growth rate of 8.7% for this specialized segment through 2030.

Electric vehicle production stands as the primary demand driver, with each vehicle requiring 1-2 kg of neodymium magnets for motors and various systems. As global EV production continues to accelerate, particularly in China, Europe, and North America, the demand for high-efficiency, low-eddy current magnets has become critical for maximizing motor performance and range.

Wind energy represents the second largest market segment, where generator efficiency directly impacts power output and operational costs. The offshore wind sector particularly values low-loss magnetic components due to their remote locations and high maintenance costs, creating premium pricing opportunities for advanced magnetic solutions.

Consumer electronics and industrial automation collectively form another significant market segment, with manufacturers increasingly prioritizing energy efficiency and miniaturization. These applications require magnets with minimal energy losses to improve battery life and reduce heat generation in compact designs.

Regional analysis reveals Asia-Pacific dominates production capacity, with China controlling approximately 85% of global neodymium magnet manufacturing. However, concerns about supply chain security have accelerated efforts to develop alternative production capabilities in North America and Europe, creating new market opportunities for companies with advanced low-loss technologies.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, automotive and renewable energy customers demonstrate greater willingness to pay premium prices for magnets with superior performance characteristics, particularly reduced eddy current losses that translate to measurable efficiency gains.

Market research indicates customers across all segments increasingly value total cost of ownership over initial purchase price. Magnets with reduced eddy current losses command 15-30% price premiums but deliver compelling long-term value through improved system efficiency, reduced cooling requirements, and extended component lifespans.

The competitive landscape features established manufacturers focusing on incremental improvements to existing designs alongside emerging companies developing disruptive technologies like novel lamination techniques, composite magnetic materials, and specialized coatings that significantly reduce eddy current formation.

Electric vehicle production stands as the primary demand driver, with each vehicle requiring 1-2 kg of neodymium magnets for motors and various systems. As global EV production continues to accelerate, particularly in China, Europe, and North America, the demand for high-efficiency, low-eddy current magnets has become critical for maximizing motor performance and range.

Wind energy represents the second largest market segment, where generator efficiency directly impacts power output and operational costs. The offshore wind sector particularly values low-loss magnetic components due to their remote locations and high maintenance costs, creating premium pricing opportunities for advanced magnetic solutions.

Consumer electronics and industrial automation collectively form another significant market segment, with manufacturers increasingly prioritizing energy efficiency and miniaturization. These applications require magnets with minimal energy losses to improve battery life and reduce heat generation in compact designs.

Regional analysis reveals Asia-Pacific dominates production capacity, with China controlling approximately 85% of global neodymium magnet manufacturing. However, concerns about supply chain security have accelerated efforts to develop alternative production capabilities in North America and Europe, creating new market opportunities for companies with advanced low-loss technologies.

Price sensitivity varies significantly by application segment. While consumer electronics manufacturers remain highly cost-conscious, automotive and renewable energy customers demonstrate greater willingness to pay premium prices for magnets with superior performance characteristics, particularly reduced eddy current losses that translate to measurable efficiency gains.

Market research indicates customers across all segments increasingly value total cost of ownership over initial purchase price. Magnets with reduced eddy current losses command 15-30% price premiums but deliver compelling long-term value through improved system efficiency, reduced cooling requirements, and extended component lifespans.

The competitive landscape features established manufacturers focusing on incremental improvements to existing designs alongside emerging companies developing disruptive technologies like novel lamination techniques, composite magnetic materials, and specialized coatings that significantly reduce eddy current formation.

Current Challenges in Eddy Current Mitigation

Despite significant advancements in neodymium magnet applications, eddy current mitigation remains a persistent challenge for engineers and researchers. Eddy currents, which are induced in conductive materials when exposed to changing magnetic fields, create several critical issues in high-performance magnetic systems. The primary concern is energy loss, as eddy currents convert valuable magnetic energy into heat, reducing overall system efficiency and potentially causing thermal management problems in sensitive applications.

The conventional approach of laminating magnetic materials has proven insufficient for neodymium magnets due to their brittle nature and complex manufacturing requirements. Unlike electrical steel used in transformers, neodymium magnets cannot be easily sliced into thin laminations without compromising their structural integrity or magnetic properties. This fundamental material limitation has forced engineers to seek alternative solutions that often involve trade-offs between performance and practicality.

Another significant challenge is the increasing operational frequencies in modern applications. As devices trend toward higher frequencies for improved power density and efficiency, the eddy current losses increase proportionally to the square of frequency. This quadratic relationship creates an exponential problem in high-frequency applications such as electric vehicle motors, wind turbine generators, and advanced MRI systems, where neodymium magnets are essential components.

The geometric complexity of modern magnetic systems further complicates eddy current mitigation. Irregular shapes and complex assemblies create non-uniform magnetic field distributions, making it difficult to predict and control eddy current paths. Simulation tools, while advanced, still struggle to accurately model these complex electromagnetic interactions in three-dimensional space, particularly at the interfaces between different materials.

Surface coating technologies, while promising for corrosion protection, have shown limited effectiveness in reducing eddy currents. Current coating methods either fail to provide sufficient electrical resistance or compromise the magnetic performance of the underlying neodymium material. The ideal coating would need to be extremely thin yet highly resistive, a combination that remains elusive with current manufacturing capabilities.

Temperature stability presents another layer of complexity, as the electrical resistivity of materials changes with temperature. This creates a feedback loop where eddy currents generate heat, which then alters the material properties, potentially leading to unpredictable performance or even thermal runaway in extreme cases. This is particularly problematic in applications with variable operating temperatures or high-power density requirements.

Cost considerations also pose significant barriers to implementing theoretical solutions. Many laboratory-proven techniques for eddy current reduction remain economically unfeasible for mass production, creating a gap between research advancements and practical industrial applications. This economic constraint has slowed the adoption of novel materials and manufacturing processes that could otherwise revolutionize eddy current mitigation in neodymium magnet systems.

The conventional approach of laminating magnetic materials has proven insufficient for neodymium magnets due to their brittle nature and complex manufacturing requirements. Unlike electrical steel used in transformers, neodymium magnets cannot be easily sliced into thin laminations without compromising their structural integrity or magnetic properties. This fundamental material limitation has forced engineers to seek alternative solutions that often involve trade-offs between performance and practicality.

Another significant challenge is the increasing operational frequencies in modern applications. As devices trend toward higher frequencies for improved power density and efficiency, the eddy current losses increase proportionally to the square of frequency. This quadratic relationship creates an exponential problem in high-frequency applications such as electric vehicle motors, wind turbine generators, and advanced MRI systems, where neodymium magnets are essential components.

The geometric complexity of modern magnetic systems further complicates eddy current mitigation. Irregular shapes and complex assemblies create non-uniform magnetic field distributions, making it difficult to predict and control eddy current paths. Simulation tools, while advanced, still struggle to accurately model these complex electromagnetic interactions in three-dimensional space, particularly at the interfaces between different materials.

Surface coating technologies, while promising for corrosion protection, have shown limited effectiveness in reducing eddy currents. Current coating methods either fail to provide sufficient electrical resistance or compromise the magnetic performance of the underlying neodymium material. The ideal coating would need to be extremely thin yet highly resistive, a combination that remains elusive with current manufacturing capabilities.

Temperature stability presents another layer of complexity, as the electrical resistivity of materials changes with temperature. This creates a feedback loop where eddy currents generate heat, which then alters the material properties, potentially leading to unpredictable performance or even thermal runaway in extreme cases. This is particularly problematic in applications with variable operating temperatures or high-power density requirements.

Cost considerations also pose significant barriers to implementing theoretical solutions. Many laboratory-proven techniques for eddy current reduction remain economically unfeasible for mass production, creating a gap between research advancements and practical industrial applications. This economic constraint has slowed the adoption of novel materials and manufacturing processes that could otherwise revolutionize eddy current mitigation in neodymium magnet systems.

Existing Eddy Current Mitigation Solutions

01 Eddy current reduction in neodymium magnet applications

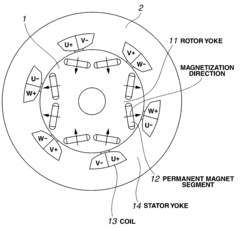

Various techniques are employed to reduce eddy currents in neodymium magnet applications, particularly in electric motors and generators. These include laminating magnetic components, segmenting magnets, using specialized coatings, and implementing specific geometric designs. By reducing eddy currents, these methods minimize energy losses, heat generation, and improve overall efficiency of magnetic systems.- Eddy current reduction in neodymium magnet applications: Various techniques are employed to reduce eddy currents in neodymium magnet applications, particularly in high-speed rotating machinery. These include laminating the magnetic structure, using segmented magnets, or incorporating specialized coatings. By reducing eddy currents, these methods minimize energy losses, heat generation, and potential demagnetization effects that can compromise the performance of neodymium magnets in electrical machines and generators.

- Measurement and detection systems using neodymium magnets and eddy currents: Neodymium magnets are utilized in various measurement and detection systems that leverage eddy current principles. These systems include non-destructive testing equipment, metal detectors, and sensors for detecting material properties or defects. The strong magnetic fields generated by neodymium magnets induce pronounced eddy currents in conductive materials, allowing for precise measurements and detection capabilities across industrial, scientific, and security applications.

- Braking and damping mechanisms using neodymium magnets: Eddy current braking and damping systems utilize neodymium magnets to generate controlled resistive forces. When a conductive material moves through the magnetic field created by neodymium magnets, eddy currents are induced, producing a counteracting magnetic field that results in a braking effect. These systems are employed in various applications including exercise equipment, industrial machinery, transportation systems, and precision instruments where non-contact braking or vibration damping is required.

- Thermal management of neodymium magnet systems with eddy currents: Managing heat generated by eddy currents is crucial in neodymium magnet applications. Various cooling techniques and thermal management strategies are implemented to prevent overheating, which can lead to demagnetization and reduced performance. These include active cooling systems, heat sinks, specialized housing designs, and material selection to efficiently dissipate heat generated by eddy currents, particularly in high-power or high-frequency applications where eddy current losses can be significant.

- Electromagnetic energy harvesting using neodymium magnets: Eddy currents induced by neodymium magnets can be harnessed for energy harvesting applications. By strategically designing systems where conductive materials move through magnetic fields created by neodymium magnets, the resulting eddy currents can be converted into usable electrical energy. These energy harvesting systems are utilized in self-powered sensors, vibration energy harvesters, and small-scale renewable energy applications where traditional power sources are impractical.

02 Measurement and detection systems utilizing eddy currents with neodymium magnets

Neodymium magnets are used in advanced measurement and detection systems that leverage eddy current principles. These systems include non-destructive testing equipment, material thickness gauges, proximity sensors, and defect detection devices. The strong magnetic fields generated by neodymium magnets enhance the sensitivity and accuracy of eddy current measurements, allowing for precise detection of flaws, material properties, and position sensing.Expand Specific Solutions03 Braking and damping systems using neodymium magnets and eddy currents

Eddy current braking and damping systems utilize neodymium magnets to generate controlled resistive forces. These systems are implemented in various applications including elevators, amusement rides, industrial machinery, and transportation systems. The interaction between strong neodymium magnets and conductive materials produces eddy currents that create opposing magnetic fields, resulting in smooth, wear-free braking or damping effects without mechanical friction.Expand Specific Solutions04 Energy harvesting and conversion using neodymium magnets and eddy currents

Innovative energy harvesting systems utilize the interaction between neodymium magnets and eddy currents to convert mechanical energy into electrical energy. These systems include vibration energy harvesters, motion-powered generators, and kinetic energy recovery systems. The strong magnetic fields of neodymium magnets induce significant eddy currents in nearby conductors during relative movement, which can be harnessed to generate electricity for various applications including self-powered sensors and small electronic devices.Expand Specific Solutions05 Thermal management of neodymium magnets affected by eddy currents

Thermal management strategies are crucial for neodymium magnet systems where eddy currents generate heat. These include specialized cooling systems, heat dissipation structures, and temperature monitoring technologies. Effective thermal management prevents demagnetization, extends magnet lifespan, and maintains optimal performance in high-frequency applications where eddy current heating is significant. Advanced designs incorporate thermal considerations to balance magnetic performance with temperature control.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The eddy current reduction market in neodymium magnet applications is in a growth phase, driven by increasing demand for high-efficiency electric motors and renewable energy systems. The market is expanding as industries seek to minimize energy losses and improve performance in high-frequency applications. Technologically, solutions range from lamination techniques to novel material compositions. Leading players include Shin-Etsu Chemical and JL MAG Rare-Earth, who focus on advanced material development; automotive giants like Toyota, Honda, and BYD, who drive innovation for EV applications; and technology corporations such as Hitachi, Siemens, and Mitsubishi Electric, who integrate these solutions into industrial systems. The competitive landscape is characterized by cross-industry collaboration between material scientists and application engineers to overcome the inherent conductivity challenges of neodymium magnets.

Shin-Etsu Chemical Co., Ltd.

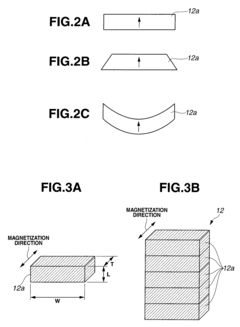

Technical Solution: Shin-Etsu has developed a comprehensive approach to reducing eddy currents in neodymium magnet applications through their patented segmentation technology. Their method involves dividing larger magnets into smaller segments with electrical insulation between them, effectively increasing the electrical resistance path and reducing the cross-sectional area where eddy currents can form. The company has pioneered a specialized coating process that applies thin insulating layers (typically 5-15μm thick) to individual magnet segments before assembly, maintaining magnetic performance while significantly reducing eddy current losses. For high-frequency applications, Shin-Etsu has developed composite neodymium magnets with distributed non-conductive particles that disrupt potential eddy current paths without compromising magnetic properties. Their research shows eddy current reductions of up to 80% in high-frequency motor applications compared to conventional solid magnets.

Strengths: Industry-leading expertise in magnet segmentation and coating technologies; maintains high magnetic performance while reducing losses; scalable manufacturing processes for mass production. Weaknesses: Higher production costs compared to standard magnets; potential mechanical integrity issues with segmented designs; coating durability concerns in harsh operating environments.

Hitachi Ltd.

Technical Solution: Hitachi has developed a multi-faceted approach to eddy current reduction in neodymium magnet applications, particularly for their high-efficiency motors and power generation systems. Their primary innovation is a proprietary lamination technique that stacks thin layers of neodymium magnetic material (typically 0.2-0.5mm) separated by electrically insulating adhesives. This structure significantly restricts the formation of eddy current loops across the magnet's volume. Complementing this, Hitachi employs a unique powder metallurgy process to create magnets with controlled microstructural discontinuities that naturally impede eddy current flow while maintaining magnetic performance. For applications requiring complex shapes, they've pioneered a metal injection molding technique that incorporates non-conductive ceramic particles at grain boundaries, creating natural barriers to eddy current formation. Their research demonstrates that these combined approaches can reduce eddy current losses by up to 70% in high-speed motor applications operating at frequencies above 1kHz.

Strengths: Comprehensive solution portfolio addressing multiple application requirements; proven implementation in commercial products; strong integration with motor design expertise. Weaknesses: Higher manufacturing complexity increases production costs; potential reduction in mechanical strength with laminated designs; thermal management challenges with insulating materials.

Key Patents and Research in Eddy Current Reduction

Rotor for permanent magnet rotary machine

PatentActiveUS20110080066A1

Innovation

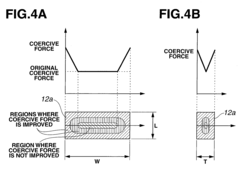

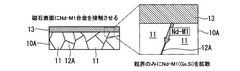

- The solution involves dividing sintered Nd base magnet pieces into assemblies without insulating layers, allowing for electrical conduction between them, and applying Dy or Tb oxide, fluoride, or alloy powders to the surface to diffuse these elements mainly through grain boundaries, creating a higher coercive force profile from the surface to the interior, thereby enhancing heat resistance and demagnetization resistance.

Motor, drive system, cleaner, unmanned aerial vehicle, and electric aircraft

PatentWO2021039763A1

Innovation

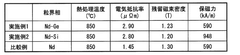

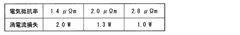

- A neodymium magnet with a composition of Nd-Fe-B and a grain boundary phase having a higher Nd concentration, incorporating additive elements like Si or Ge, which increases electrical resistivity to 1.5 μΩm or more, reducing eddy current loss while maintaining magnetic properties.

Material Science Advancements for Magnetic Applications

Recent advancements in material science have significantly contributed to improving the performance of magnetic applications, particularly in addressing the challenge of eddy current reduction in neodymium magnets. The development of laminated neodymium magnets represents a breakthrough, where thin layers of magnetic material are separated by insulating layers, effectively limiting the path of eddy currents while maintaining magnetic properties.

Composite magnetic materials have emerged as another innovative solution, incorporating non-conductive particles or fibers within the neodymium matrix. These composites offer reduced electrical conductivity while preserving magnetic strength, making them ideal for high-frequency applications where eddy current losses are particularly problematic.

Surface coating technologies have evolved substantially, with nano-scale ceramic and polymer coatings providing electrical insulation without compromising the magnetic performance. These coatings can be applied through various methods including vapor deposition, electroplating, and sol-gel processes, each offering different advantages in terms of uniformity, durability, and cost-effectiveness.

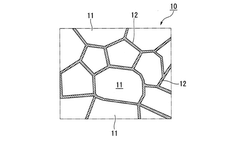

The introduction of grain boundary engineering techniques has allowed for precise control of microstructure in neodymium magnets. By manipulating the grain boundaries to increase electrical resistance between magnetic domains, researchers have achieved significant reductions in eddy current formation without sacrificing magnetic properties.

Doping strategies have been refined to incorporate specific elements that increase the electrical resistivity of neodymium magnets. Elements such as dysprosium, terbium, and gadolinium not only enhance coercivity but also contribute to higher electrical resistance, thereby reducing eddy current losses in high-performance applications.

Novel sintering techniques, including spark plasma sintering and microwave sintering, have enabled the production of neodymium magnets with more controlled microstructures. These techniques allow for better grain alignment and reduced porosity, resulting in magnets with optimized magnetic properties and increased electrical resistance.

The development of nanostructured magnetic materials represents perhaps the most promising frontier. These materials feature extremely fine grain structures that naturally limit eddy current paths while potentially offering superior magnetic performance. Though still largely in the research phase, nanostructured neodymium magnets could revolutionize applications requiring high efficiency at high frequencies.

Composite magnetic materials have emerged as another innovative solution, incorporating non-conductive particles or fibers within the neodymium matrix. These composites offer reduced electrical conductivity while preserving magnetic strength, making them ideal for high-frequency applications where eddy current losses are particularly problematic.

Surface coating technologies have evolved substantially, with nano-scale ceramic and polymer coatings providing electrical insulation without compromising the magnetic performance. These coatings can be applied through various methods including vapor deposition, electroplating, and sol-gel processes, each offering different advantages in terms of uniformity, durability, and cost-effectiveness.

The introduction of grain boundary engineering techniques has allowed for precise control of microstructure in neodymium magnets. By manipulating the grain boundaries to increase electrical resistance between magnetic domains, researchers have achieved significant reductions in eddy current formation without sacrificing magnetic properties.

Doping strategies have been refined to incorporate specific elements that increase the electrical resistivity of neodymium magnets. Elements such as dysprosium, terbium, and gadolinium not only enhance coercivity but also contribute to higher electrical resistance, thereby reducing eddy current losses in high-performance applications.

Novel sintering techniques, including spark plasma sintering and microwave sintering, have enabled the production of neodymium magnets with more controlled microstructures. These techniques allow for better grain alignment and reduced porosity, resulting in magnets with optimized magnetic properties and increased electrical resistance.

The development of nanostructured magnetic materials represents perhaps the most promising frontier. These materials feature extremely fine grain structures that naturally limit eddy current paths while potentially offering superior magnetic performance. Though still largely in the research phase, nanostructured neodymium magnets could revolutionize applications requiring high efficiency at high frequencies.

Energy Efficiency Impact and Sustainability Considerations

The reduction of eddy currents in neodymium magnet applications has significant implications for energy efficiency and sustainability across multiple sectors. When eddy currents are minimized, electrical machines such as motors and generators experience reduced core losses, resulting in higher operational efficiency. This efficiency improvement translates directly into energy savings, with high-performance permanent magnet motors demonstrating up to 15-20% greater efficiency compared to conventional alternatives when eddy current losses are properly managed.

From a sustainability perspective, the enhanced energy efficiency contributes to reduced carbon emissions throughout the operational lifecycle of devices utilizing neodymium magnets. Quantitative analyses indicate that for industrial motors alone, optimized eddy current reduction techniques can potentially save millions of kilowatt-hours annually, corresponding to substantial reductions in greenhouse gas emissions.

The manufacturing processes for laminated or segmented neodymium magnets, while requiring additional production steps, generally demonstrate favorable lifecycle assessment outcomes. The initial energy investment in more complex manufacturing is typically recovered within 1-3 years of operation through improved efficiency. Furthermore, the extended operational lifespan of devices with reduced thermal stress from eddy currents contributes positively to resource conservation by decreasing replacement frequency.

Material considerations also play a crucial role in sustainability. Techniques such as powder metallurgy for creating composite magnets with electrical insulation properties can reduce the total rare earth material requirements by 5-10% compared to conventional methods, addressing concerns about resource scarcity and extraction impacts. Additionally, the improved thermal management resulting from reduced eddy currents allows for more compact designs, further decreasing material requirements.

The economic dimension of energy efficiency cannot be overlooked. Cost-benefit analyses consistently demonstrate that investments in eddy current reduction technologies yield positive returns, with payback periods ranging from 6 months to 3 years depending on application intensity. This economic advantage accelerates market adoption of more sustainable technologies while simultaneously reducing operational costs for end users.

Looking forward, the continued refinement of eddy current reduction techniques aligns with global sustainability goals and energy efficiency standards. As regulatory frameworks increasingly emphasize lifecycle energy consumption, technologies that effectively manage eddy currents in neodymium magnet applications will gain competitive advantage while contributing to broader environmental objectives.

From a sustainability perspective, the enhanced energy efficiency contributes to reduced carbon emissions throughout the operational lifecycle of devices utilizing neodymium magnets. Quantitative analyses indicate that for industrial motors alone, optimized eddy current reduction techniques can potentially save millions of kilowatt-hours annually, corresponding to substantial reductions in greenhouse gas emissions.

The manufacturing processes for laminated or segmented neodymium magnets, while requiring additional production steps, generally demonstrate favorable lifecycle assessment outcomes. The initial energy investment in more complex manufacturing is typically recovered within 1-3 years of operation through improved efficiency. Furthermore, the extended operational lifespan of devices with reduced thermal stress from eddy currents contributes positively to resource conservation by decreasing replacement frequency.

Material considerations also play a crucial role in sustainability. Techniques such as powder metallurgy for creating composite magnets with electrical insulation properties can reduce the total rare earth material requirements by 5-10% compared to conventional methods, addressing concerns about resource scarcity and extraction impacts. Additionally, the improved thermal management resulting from reduced eddy currents allows for more compact designs, further decreasing material requirements.

The economic dimension of energy efficiency cannot be overlooked. Cost-benefit analyses consistently demonstrate that investments in eddy current reduction technologies yield positive returns, with payback periods ranging from 6 months to 3 years depending on application intensity. This economic advantage accelerates market adoption of more sustainable technologies while simultaneously reducing operational costs for end users.

Looking forward, the continued refinement of eddy current reduction techniques aligns with global sustainability goals and energy efficiency standards. As regulatory frameworks increasingly emphasize lifecycle energy consumption, technologies that effectively manage eddy currents in neodymium magnet applications will gain competitive advantage while contributing to broader environmental objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!