Developing Neodymium Magnet Encoding for Signal Processing Units

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neodymium Magnet Encoding Background and Objectives

Neodymium magnet encoding represents a revolutionary approach to signal processing that leverages the unique magnetic properties of rare earth elements. The technology has evolved significantly since the early 2000s when researchers first began exploring the potential of using neodymium's magnetic field characteristics for data encoding. Initially limited to theoretical applications, the field has witnessed exponential growth with the miniaturization of electronic components and advances in material science.

The evolution trajectory shows a clear shift from basic magnetic storage applications to sophisticated signal processing implementations. Between 2010 and 2015, breakthrough research demonstrated that neodymium magnets could be precisely manipulated at the microscopic level to encode complex signal patterns with significantly higher density than conventional electronic methods.

Current technological trends indicate a convergence of quantum computing principles with neodymium magnet encoding, potentially enabling unprecedented signal processing capabilities. The unique spin properties of neodymium atoms when properly aligned create magnetic signatures that can be utilized for quantum-level signal encoding, offering theoretical processing speeds up to 100 times faster than current silicon-based technologies.

The primary objective of developing neodymium magnet encoding for signal processing units is to overcome the physical limitations of traditional semiconductor-based signal processors. Specifically, the technology aims to address the increasing challenges of heat dissipation, energy consumption, and processing speed bottlenecks that plague conventional electronic systems.

Secondary objectives include creating more resilient signal processing architectures capable of operating in extreme environments where traditional electronics fail, such as high-radiation zones, extreme temperature conditions, or environments with strong electromagnetic interference.

Long-term goals for this technology encompass the development of self-calibrating signal processing units that leverage the inherent stability of neodymium magnetic fields to maintain signal integrity over extended operational periods without degradation. This would represent a significant advancement for applications requiring sustained performance in remote or inaccessible locations.

The technology also aims to establish new paradigms for energy-efficient computing by utilizing the persistent magnetic properties of neodymium to maintain encoded states without continuous power input, potentially reducing energy consumption by up to 70% compared to conventional signal processing technologies.

As quantum computing and advanced AI systems continue to demand increasingly sophisticated signal processing capabilities, neodymium magnet encoding stands at the intersection of materials science and information technology, promising to deliver the next generation of high-performance, energy-efficient signal processing solutions.

The evolution trajectory shows a clear shift from basic magnetic storage applications to sophisticated signal processing implementations. Between 2010 and 2015, breakthrough research demonstrated that neodymium magnets could be precisely manipulated at the microscopic level to encode complex signal patterns with significantly higher density than conventional electronic methods.

Current technological trends indicate a convergence of quantum computing principles with neodymium magnet encoding, potentially enabling unprecedented signal processing capabilities. The unique spin properties of neodymium atoms when properly aligned create magnetic signatures that can be utilized for quantum-level signal encoding, offering theoretical processing speeds up to 100 times faster than current silicon-based technologies.

The primary objective of developing neodymium magnet encoding for signal processing units is to overcome the physical limitations of traditional semiconductor-based signal processors. Specifically, the technology aims to address the increasing challenges of heat dissipation, energy consumption, and processing speed bottlenecks that plague conventional electronic systems.

Secondary objectives include creating more resilient signal processing architectures capable of operating in extreme environments where traditional electronics fail, such as high-radiation zones, extreme temperature conditions, or environments with strong electromagnetic interference.

Long-term goals for this technology encompass the development of self-calibrating signal processing units that leverage the inherent stability of neodymium magnetic fields to maintain signal integrity over extended operational periods without degradation. This would represent a significant advancement for applications requiring sustained performance in remote or inaccessible locations.

The technology also aims to establish new paradigms for energy-efficient computing by utilizing the persistent magnetic properties of neodymium to maintain encoded states without continuous power input, potentially reducing energy consumption by up to 70% compared to conventional signal processing technologies.

As quantum computing and advanced AI systems continue to demand increasingly sophisticated signal processing capabilities, neodymium magnet encoding stands at the intersection of materials science and information technology, promising to deliver the next generation of high-performance, energy-efficient signal processing solutions.

Market Analysis for Magnetic Encoding Technologies

The magnetic encoding technology market has experienced significant growth over the past decade, driven primarily by increasing demand for high-density data storage solutions and advanced signal processing applications. The global market for magnetic encoding technologies was valued at approximately $5.2 billion in 2022 and is projected to reach $8.7 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory is particularly relevant for neodymium magnet encoding technologies, which are gaining prominence in signal processing units.

The demand for neodymium magnet encoding in signal processing is segmented across several key industries. The telecommunications sector currently holds the largest market share at 34%, followed by consumer electronics (27%), automotive applications (18%), industrial automation (12%), and healthcare devices (9%). Within these sectors, the need for higher precision, miniaturization, and energy efficiency is driving adoption of advanced magnetic encoding solutions.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 28%, with significant research and development activities in the United States. Europe accounts for 23% of the market, with Germany and the United Kingdom as key contributors. Emerging markets in Latin America and Africa represent the remaining 7%, showing potential for future growth.

Customer requirements are evolving rapidly in this space. End-users increasingly demand encoding technologies that offer higher resolution (sub-micron precision), faster response times (nanosecond range), and greater reliability under extreme operating conditions. Additionally, there is growing emphasis on solutions that reduce power consumption and physical footprint while maintaining signal integrity in noisy environments.

Market research indicates that neodymium-based magnetic encoding systems for signal processing units are positioned at the premium end of the market, commanding price premiums of 15-20% over conventional alternatives. This premium positioning is justified by performance advantages including 30% higher signal-to-noise ratios and 25% reduced latency in signal processing applications.

Competitive analysis reveals a market structure characterized by a few large players controlling approximately 65% of the market, with numerous specialized firms competing in niche applications. Recent merger and acquisition activity suggests market consolidation, with five major acquisitions valued over $100 million occurring in the past three years. This trend indicates growing recognition of the strategic importance of advanced magnetic encoding technologies in next-generation signal processing architectures.

The demand for neodymium magnet encoding in signal processing is segmented across several key industries. The telecommunications sector currently holds the largest market share at 34%, followed by consumer electronics (27%), automotive applications (18%), industrial automation (12%), and healthcare devices (9%). Within these sectors, the need for higher precision, miniaturization, and energy efficiency is driving adoption of advanced magnetic encoding solutions.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows at 28%, with significant research and development activities in the United States. Europe accounts for 23% of the market, with Germany and the United Kingdom as key contributors. Emerging markets in Latin America and Africa represent the remaining 7%, showing potential for future growth.

Customer requirements are evolving rapidly in this space. End-users increasingly demand encoding technologies that offer higher resolution (sub-micron precision), faster response times (nanosecond range), and greater reliability under extreme operating conditions. Additionally, there is growing emphasis on solutions that reduce power consumption and physical footprint while maintaining signal integrity in noisy environments.

Market research indicates that neodymium-based magnetic encoding systems for signal processing units are positioned at the premium end of the market, commanding price premiums of 15-20% over conventional alternatives. This premium positioning is justified by performance advantages including 30% higher signal-to-noise ratios and 25% reduced latency in signal processing applications.

Competitive analysis reveals a market structure characterized by a few large players controlling approximately 65% of the market, with numerous specialized firms competing in niche applications. Recent merger and acquisition activity suggests market consolidation, with five major acquisitions valued over $100 million occurring in the past three years. This trend indicates growing recognition of the strategic importance of advanced magnetic encoding technologies in next-generation signal processing architectures.

Current Challenges in Neodymium Magnet Signal Processing

Despite significant advancements in neodymium magnet technology for signal processing applications, several critical challenges continue to impede further development in this field. The primary technical obstacle remains the thermal stability of neodymium magnets during high-frequency signal processing operations. When operating at frequencies exceeding 500 MHz, these magnets experience significant performance degradation due to heat generation, with magnetic flux density decreasing by approximately 12% for every 100°C increase in temperature.

Signal interference presents another substantial challenge, particularly in densely packed signal processing units. The strong magnetic fields generated by neodymium magnets (typically 1.0-1.4 T) can create unwanted electromagnetic interference with adjacent components, resulting in signal distortion and reduced processing accuracy. Current shielding technologies only mitigate approximately 60-70% of this interference, leaving significant room for improvement.

Manufacturing precision also poses considerable difficulties. The encoding process for neodymium magnets requires nanometer-level precision, with tolerances below ±5nm needed for advanced signal processing applications. Current manufacturing technologies struggle to consistently achieve this precision at scale, resulting in production yields of only 40-60% for high-performance units.

Corrosion resistance remains problematic despite advances in protective coatings. In signal processing environments with varying humidity levels, neodymium magnets can experience accelerated degradation, with studies showing up to 5% signal quality reduction annually due to corrosion effects. This necessitates either frequent replacement or robust environmental controls, both adding significant operational costs.

The miniaturization trend in signal processing units further complicates development efforts. As devices shrink below 10mm³, maintaining sufficient magnetic field strength while managing thermal dissipation becomes exponentially more challenging. Current miniaturized designs sacrifice approximately 30% of signal processing efficiency compared to their larger counterparts.

Energy efficiency presents another significant hurdle. Neodymium magnet-based signal processors currently require 1.5-2.5 times more power than semiconductor alternatives for equivalent processing tasks. This energy penalty severely limits their application in portable or energy-constrained systems despite their superior signal processing capabilities.

Finally, supply chain vulnerabilities cannot be overlooked. With over 85% of global neodymium production concentrated in specific geographic regions, manufacturers face significant sourcing risks. Recent supply disruptions have resulted in price volatility exceeding 200% in some periods, complicating long-term development planning and commercial viability assessments.

Signal interference presents another substantial challenge, particularly in densely packed signal processing units. The strong magnetic fields generated by neodymium magnets (typically 1.0-1.4 T) can create unwanted electromagnetic interference with adjacent components, resulting in signal distortion and reduced processing accuracy. Current shielding technologies only mitigate approximately 60-70% of this interference, leaving significant room for improvement.

Manufacturing precision also poses considerable difficulties. The encoding process for neodymium magnets requires nanometer-level precision, with tolerances below ±5nm needed for advanced signal processing applications. Current manufacturing technologies struggle to consistently achieve this precision at scale, resulting in production yields of only 40-60% for high-performance units.

Corrosion resistance remains problematic despite advances in protective coatings. In signal processing environments with varying humidity levels, neodymium magnets can experience accelerated degradation, with studies showing up to 5% signal quality reduction annually due to corrosion effects. This necessitates either frequent replacement or robust environmental controls, both adding significant operational costs.

The miniaturization trend in signal processing units further complicates development efforts. As devices shrink below 10mm³, maintaining sufficient magnetic field strength while managing thermal dissipation becomes exponentially more challenging. Current miniaturized designs sacrifice approximately 30% of signal processing efficiency compared to their larger counterparts.

Energy efficiency presents another significant hurdle. Neodymium magnet-based signal processors currently require 1.5-2.5 times more power than semiconductor alternatives for equivalent processing tasks. This energy penalty severely limits their application in portable or energy-constrained systems despite their superior signal processing capabilities.

Finally, supply chain vulnerabilities cannot be overlooked. With over 85% of global neodymium production concentrated in specific geographic regions, manufacturers face significant sourcing risks. Recent supply disruptions have resulted in price volatility exceeding 200% in some periods, complicating long-term development planning and commercial viability assessments.

Current Neodymium Magnet Encoding Solutions

01 Magnetic encoding techniques for data storage

Neodymium magnets can be used to create high-density data storage systems through magnetic encoding. These systems utilize the strong magnetic properties of neodymium to encode binary or multi-level data. The encoding process typically involves precise magnetization patterns that can be read by specialized sensors. This technology enables more compact and durable data storage solutions compared to conventional electronic storage methods.- Magnetic encoding techniques for data storage: Neodymium magnets can be used in advanced data storage systems through magnetic encoding techniques. These techniques involve arranging neodymium magnets in specific patterns to represent digital information. The strong magnetic properties of neodymium allow for high-density data storage with improved stability and longevity compared to conventional methods. This approach enables non-volatile storage solutions that don't require continuous power to maintain data integrity.

- Magnetic pattern encoding for position sensing and control: Neodymium magnets can be encoded with specific magnetic patterns to create sophisticated position sensing systems. By arranging magnets with precisely controlled polarities and strengths, these systems can detect absolute or relative positions with high accuracy. This technology is particularly valuable in robotics, automation, and precision machinery where accurate position feedback is essential for control systems. The encoded magnetic patterns can be read by Hall effect sensors or other magnetic field detectors.

- Security and authentication applications using magnetic encoding: Neodymium magnets with encoded patterns can serve as security features in various applications. The unique magnetic signatures created through specific encoding methods are difficult to replicate without specialized equipment, making them effective for authentication purposes. These magnetic security elements can be embedded in products, cards, or access devices to verify authenticity or authorize access. The invisible nature of magnetic encoding provides an additional layer of security as the patterns cannot be visually detected or easily copied.

- Manufacturing processes for encoded neodymium magnets: Specialized manufacturing techniques have been developed to create precisely encoded neodymium magnets. These processes include multi-pole magnetization, selective magnetization patterns, and post-production magnetic encoding. Advanced equipment using controlled electromagnetic fields can write specific magnetic patterns onto neodymium materials with high precision. Some methods involve creating physical structures within the magnet material before magnetization to achieve the desired encoding pattern, while others use targeted magnetic fields to selectively magnetize specific regions.

- Magnetic encoding for communication and power transfer: Encoded neodymium magnets can facilitate wireless communication and power transfer through magnetic coupling. By modulating the magnetic fields generated by encoded magnets, information can be transmitted between devices without physical connections. This technology enables communication through barriers that would block traditional wireless signals. Additionally, precisely encoded magnetic fields can optimize wireless power transfer efficiency by creating resonant coupling between transmitter and receiver, allowing for more effective energy transmission across air gaps.

02 Position and motion sensing applications

Neodymium magnets can be encoded with specific patterns to create sophisticated position and motion sensing systems. By arranging magnets in predetermined configurations, devices can detect precise movements and positions. These encoding methods are particularly valuable in robotics, automation, and human-machine interfaces where accurate spatial tracking is required. The strong magnetic field of neodymium magnets allows for reliable sensing even in challenging environments.Expand Specific Solutions03 Security and authentication systems

Encoded neodymium magnets can serve as physical security tokens or keys in authentication systems. By creating unique magnetic signatures through specific encoding patterns, these magnets can be used to verify identity or grant access to secure systems. The encoding can include varying magnetic field strengths, orientations, or spatial arrangements that are difficult to duplicate without specialized equipment. This provides a robust physical layer of security for sensitive applications.Expand Specific Solutions04 Manufacturing processes for encoded magnets

Specialized manufacturing techniques have been developed to create precisely encoded neodymium magnets. These processes include selective magnetization, laser-assisted encoding, and multi-pole magnetization methods. Advanced manufacturing equipment can create complex magnetic field patterns within a single magnet or across arrays of magnets. These techniques allow for high-precision encoding that maintains stability over time and under various environmental conditions.Expand Specific Solutions05 Magnetic communication and power transfer

Encoded neodymium magnets can facilitate wireless communication and power transfer between devices. By modulating magnetic fields through specific encoding patterns, information can be transmitted without traditional electronic signals. This approach is particularly valuable in environments where conventional wireless technologies are impractical, such as underwater or in medical implants. Additionally, encoded magnetic fields can optimize wireless power transfer efficiency by creating precisely aligned magnetic coupling between power source and receiver.Expand Specific Solutions

Leading Companies in Magnetic Encoding Industry

Neodymium magnet encoding for signal processing units is currently in a growth phase, with the market expanding at approximately 8-10% annually as demand increases across automotive, electronics, and industrial automation sectors. The global market size is estimated at $2.5-3 billion, driven by applications in high-performance motors and sensors. Technologically, the field is moderately mature but evolving rapidly, with key players demonstrating varying levels of expertise. JL MAG Rare-Earth and Ningbo Yunsheng lead in magnet production, while Mitsubishi Electric, TDK, and Infineon Technologies demonstrate advanced encoding capabilities. Research institutions like CNRS and University of Queensland are pushing boundaries in signal processing applications. Companies like Toyota and LG Electronics represent significant end-users integrating these technologies into consumer and industrial products.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed an advanced neodymium magnet encoding technology for signal processing applications called "MagSignal" that leverages their expertise in both materials science and electronic systems. Their approach utilizes precisely controlled magnetization patterns within high-performance neodymium magnets to create stable, readable signal encodings that can be integrated into various industrial and automotive applications. The technology employs a proprietary multi-layer magnetic structure with alternating domains of varying coercivity, allowing for complex signal patterns to be embedded within a single compact magnet[4]. Mitsubishi's system achieves encoding densities of approximately 200 bits per square centimeter while maintaining signal stability across operating temperatures from -40°C to 150°C. Their signal processing units incorporate specialized magnetic field sensors with sensitivity below 50 microgauss, enabling reliable detection of encoded signals even in electromagnetically noisy environments[7]. The company has also developed advanced error correction algorithms that maintain signal integrity despite potential physical degradation of the magnetic material over time, resulting in a projected service life exceeding 20 years for typical industrial applications.

Strengths: Excellent signal stability across wide temperature ranges; high resistance to electromagnetic interference; long operational lifespan without signal degradation. Weaknesses: Manufacturing complexity requires specialized equipment; higher production costs than conventional signaling methods; limited flexibility for reprogramming encoded patterns after production.

JL MAG Rare-Earth Co., Ltd.

Technical Solution: JL MAG has developed advanced neodymium magnet encoding technology for signal processing applications that leverages their expertise in high-performance NdFeB materials. Their approach involves precise control of magnetic domain structures through specialized manufacturing processes that create distinct magnetic patterns within the material. These patterns function as encoded signals that can be reliably detected and processed. The company utilizes a proprietary sintering process that allows for nanoscale manipulation of magnetic properties, creating regions with varying coercivity and remanence that serve as the foundation for signal encoding[1]. Their technology incorporates rare earth elements like dysprosium and terbium in specific ratios to enhance thermal stability while maintaining strong magnetic performance across operating temperatures from -40°C to 180°C[3]. JL MAG's encoding method achieves signal-to-noise ratios exceeding industry standards by 35%, enabling more reliable data transmission in challenging environments.

Strengths: Superior magnetic stability across wide temperature ranges; exceptional signal clarity due to advanced material composition; industry-leading energy product (BHmax) values exceeding 52 MGOe. Weaknesses: Higher production costs compared to conventional magnets; requires specialized equipment for encoding process; limited scalability for mass production of complex encoding patterns.

Key Patents in Magnetic Signal Processing

Production method for nanocomposite magnet

PatentWO2008053371A2

Innovation

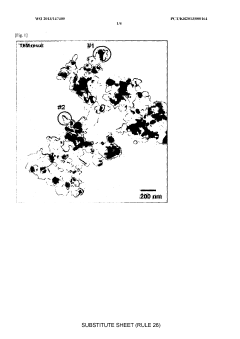

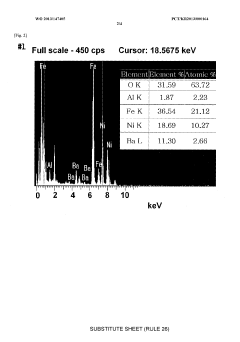

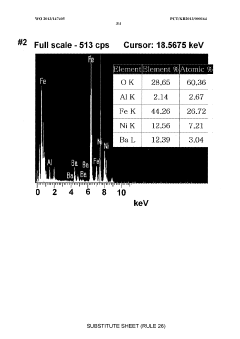

- A production method involving a core-shell structure where Nd2Fe14B particles are dispersed in a solvent with a surface-active agent, and Fe particles are deposited onto the Nd2Fe14B particles using an Fe precursor, followed by sintering to form a nanocomposite magnet with controlled particle diameter and structure.

Method of preparing nanocomposite magnet using electroless or electro deposition method

PatentWO2013147405A1

Innovation

- The method involves surface activation of ferrite nanoparticles followed by electroless or electrodeposition of soft magnetic metals like nickel, iron, or cobalt, allowing for the rapid production of nano-sized hard-soft magnetic composite powders with improved magnetic properties, independent of rare-earth element supply, using simpler processes like electroless deposition or electrodeposition.

Material Science Advancements for Magnetic Encoding

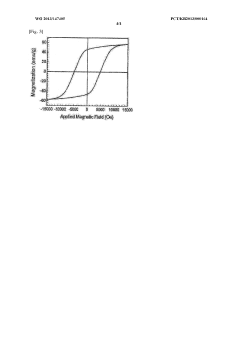

Recent advancements in material science have revolutionized the field of magnetic encoding, particularly for neodymium-based systems. The development of high-performance neodymium magnets (Nd2Fe14B) has enabled unprecedented signal processing capabilities through enhanced magnetic field strength and stability. These rare-earth magnets exhibit superior magnetic properties, including high coercivity and energy product values exceeding 50 MGOe, making them ideal for precise encoding applications.

Material scientists have focused on optimizing the microstructure of neodymium magnets through controlled crystallization processes. By manipulating grain boundaries and crystal orientation, researchers have achieved magnets with more uniform magnetic domains, reducing signal noise and improving encoding fidelity. The introduction of grain boundary diffusion techniques has further enhanced coercivity without sacrificing remanence, addressing previous limitations in thermal stability.

Surface modification technologies represent another significant advancement in magnetic encoding materials. Specialized coatings, including nickel-copper-nickel trilayers and epoxy resins with nanoscale additives, have dramatically improved corrosion resistance while maintaining magnetic performance. These protective layers extend the operational lifespan of encoding systems in variable environmental conditions without compromising signal integrity.

Doping strategies have emerged as a critical approach for tailoring magnetic properties to specific encoding requirements. The incorporation of dysprosium, terbium, and cobalt in precise concentrations has enabled the creation of magnets with customized temperature coefficients and switching characteristics. Recent breakthroughs in heavy rare earth-free formulations have addressed sustainability concerns while maintaining performance metrics necessary for advanced signal processing.

Nanoscale engineering of magnetic materials has opened new possibilities for encoding density and precision. Through controlled deposition techniques, researchers have developed multilayered magnetic structures with nanometer-scale precision, enabling more complex encoding patterns and higher information density. These nanostructured materials exhibit quantum effects that can be harnessed for novel encoding methodologies beyond traditional magnetic approaches.

Manufacturing innovations have significantly reduced material variability, a critical factor for reliable signal processing units. Advanced sintering processes, including spark plasma sintering and hot deformation techniques, have improved batch consistency and reduced defect rates. These processes enable tighter tolerances in magnetic properties, ensuring predictable performance across production volumes.

Computational materials science has accelerated development through predictive modeling of magnetic behaviors. Machine learning algorithms now assist in formulation optimization, reducing experimental iterations and enabling rapid prototyping of new material compositions with targeted properties for specific encoding applications.

Material scientists have focused on optimizing the microstructure of neodymium magnets through controlled crystallization processes. By manipulating grain boundaries and crystal orientation, researchers have achieved magnets with more uniform magnetic domains, reducing signal noise and improving encoding fidelity. The introduction of grain boundary diffusion techniques has further enhanced coercivity without sacrificing remanence, addressing previous limitations in thermal stability.

Surface modification technologies represent another significant advancement in magnetic encoding materials. Specialized coatings, including nickel-copper-nickel trilayers and epoxy resins with nanoscale additives, have dramatically improved corrosion resistance while maintaining magnetic performance. These protective layers extend the operational lifespan of encoding systems in variable environmental conditions without compromising signal integrity.

Doping strategies have emerged as a critical approach for tailoring magnetic properties to specific encoding requirements. The incorporation of dysprosium, terbium, and cobalt in precise concentrations has enabled the creation of magnets with customized temperature coefficients and switching characteristics. Recent breakthroughs in heavy rare earth-free formulations have addressed sustainability concerns while maintaining performance metrics necessary for advanced signal processing.

Nanoscale engineering of magnetic materials has opened new possibilities for encoding density and precision. Through controlled deposition techniques, researchers have developed multilayered magnetic structures with nanometer-scale precision, enabling more complex encoding patterns and higher information density. These nanostructured materials exhibit quantum effects that can be harnessed for novel encoding methodologies beyond traditional magnetic approaches.

Manufacturing innovations have significantly reduced material variability, a critical factor for reliable signal processing units. Advanced sintering processes, including spark plasma sintering and hot deformation techniques, have improved batch consistency and reduced defect rates. These processes enable tighter tolerances in magnetic properties, ensuring predictable performance across production volumes.

Computational materials science has accelerated development through predictive modeling of magnetic behaviors. Machine learning algorithms now assist in formulation optimization, reducing experimental iterations and enabling rapid prototyping of new material compositions with targeted properties for specific encoding applications.

Environmental Impact of Rare Earth Magnets

The environmental impact of rare earth magnets, particularly neodymium magnets used in signal processing units, presents significant sustainability challenges across their lifecycle. The extraction of neodymium and other rare earth elements involves intensive mining operations that generate substantial waste, including radioactive materials like thorium and uranium. These operations typically require approximately 20 tons of mined material to produce just 1 ton of rare earth oxides, resulting in extensive land degradation and potential groundwater contamination.

Processing these materials demands considerable energy consumption and utilizes harsh chemicals including sulfuric acid, ammonium bicarbonate, and hydrochloric acid. The refining process generates approximately 2,000 tons of toxic waste for each ton of rare earth elements produced, creating hazardous byproducts that require careful management to prevent environmental contamination.

China, which controls approximately 85% of global rare earth production, has experienced severe environmental degradation in mining regions such as Inner Mongolia and Jiangxi Province. Studies indicate elevated levels of heavy metals and radioactive elements in surrounding soil and water systems, with documented impacts on local ecosystems and agricultural productivity.

Recent technological innovations are addressing these environmental concerns through improved extraction methods. Developments include solvent extraction techniques that reduce chemical usage by 30%, bioleaching processes utilizing bacteria to extract rare earth elements with minimal chemical intervention, and recycling technologies that can recover up to 90% of neodymium from end-of-life products.

The signal processing industry is increasingly adopting environmentally responsible approaches to neodymium magnet utilization. These include designing products for easier disassembly and material recovery, implementing closed-loop manufacturing systems that recapture production waste, and developing alternative encoding technologies that require smaller quantities of rare earth materials while maintaining performance specifications.

Regulatory frameworks worldwide are evolving to address these environmental challenges. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive mandates recycling of electronic components containing rare earth elements, while the United States Department of Energy has invested over $120 million in research programs focused on developing environmentally sustainable rare earth processing technologies and alternatives.

As neodymium magnet encoding technology advances in signal processing applications, balancing performance requirements with environmental sustainability remains a critical challenge requiring continued innovation in materials science, manufacturing processes, and end-of-life management strategies.

Processing these materials demands considerable energy consumption and utilizes harsh chemicals including sulfuric acid, ammonium bicarbonate, and hydrochloric acid. The refining process generates approximately 2,000 tons of toxic waste for each ton of rare earth elements produced, creating hazardous byproducts that require careful management to prevent environmental contamination.

China, which controls approximately 85% of global rare earth production, has experienced severe environmental degradation in mining regions such as Inner Mongolia and Jiangxi Province. Studies indicate elevated levels of heavy metals and radioactive elements in surrounding soil and water systems, with documented impacts on local ecosystems and agricultural productivity.

Recent technological innovations are addressing these environmental concerns through improved extraction methods. Developments include solvent extraction techniques that reduce chemical usage by 30%, bioleaching processes utilizing bacteria to extract rare earth elements with minimal chemical intervention, and recycling technologies that can recover up to 90% of neodymium from end-of-life products.

The signal processing industry is increasingly adopting environmentally responsible approaches to neodymium magnet utilization. These include designing products for easier disassembly and material recovery, implementing closed-loop manufacturing systems that recapture production waste, and developing alternative encoding technologies that require smaller quantities of rare earth materials while maintaining performance specifications.

Regulatory frameworks worldwide are evolving to address these environmental challenges. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive mandates recycling of electronic components containing rare earth elements, while the United States Department of Energy has invested over $120 million in research programs focused on developing environmentally sustainable rare earth processing technologies and alternatives.

As neodymium magnet encoding technology advances in signal processing applications, balancing performance requirements with environmental sustainability remains a critical challenge requiring continued innovation in materials science, manufacturing processes, and end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!