Neodymium Magnets vs Iron Oxide: Structural Integrity Testing

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetic Materials Evolution and Testing Objectives

Magnetic materials have undergone significant evolution since their discovery, with each advancement bringing new capabilities and applications across various industries. The journey began with naturally occurring magnetite (Fe3O4), progressing through various ferrite materials, and eventually leading to the development of rare earth magnets, particularly neodymium-iron-boron (NdFeB) magnets in the 1980s. This technological progression represents a shift from relatively weak magnetic materials to increasingly powerful ones, enabling miniaturization and efficiency improvements in countless applications.

The fundamental difference between traditional iron oxide magnets and neodymium magnets lies in their magnetic energy product, with neodymium magnets offering up to ten times the magnetic strength of their ferrite counterparts. This dramatic improvement stems from the unique crystalline structure and electron configuration of rare earth elements, particularly neodymium, which creates exceptionally strong magnetic fields when combined with iron and boron in specific proportions and processed under controlled conditions.

Current technological trends indicate continued research into enhancing the performance characteristics of both material types, with particular focus on improving temperature stability, corrosion resistance, and mechanical properties without compromising magnetic strength. The industry is also exploring ways to reduce reliance on rare earth elements due to supply chain vulnerabilities and environmental concerns associated with their extraction and processing.

The primary objective of structural integrity testing between neodymium magnets and iron oxide materials is to establish comprehensive performance metrics under various environmental and mechanical stress conditions. These tests aim to quantify the differences in durability, longevity, and failure modes between these two magnetic material categories, providing essential data for engineering applications where reliability is paramount.

Specific testing goals include evaluating resistance to demagnetization under thermal cycling, mechanical shock tolerance, corrosion behavior in diverse environments, and long-term stability under continuous operating conditions. Additionally, testing seeks to identify critical failure thresholds and develop predictive models for service life estimation in various application scenarios.

The results of these comparative analyses will inform material selection decisions across industries ranging from automotive and renewable energy to medical devices and consumer electronics. Furthermore, these findings will guide future research directions in magnetic material development, potentially leading to hybrid solutions that combine the strengths of both material types while mitigating their respective weaknesses.

As industries continue to demand more efficient, reliable, and sustainable magnetic components, understanding the structural integrity differences between neodymium and iron oxide magnets becomes increasingly critical for innovation and competitive advantage in global markets.

The fundamental difference between traditional iron oxide magnets and neodymium magnets lies in their magnetic energy product, with neodymium magnets offering up to ten times the magnetic strength of their ferrite counterparts. This dramatic improvement stems from the unique crystalline structure and electron configuration of rare earth elements, particularly neodymium, which creates exceptionally strong magnetic fields when combined with iron and boron in specific proportions and processed under controlled conditions.

Current technological trends indicate continued research into enhancing the performance characteristics of both material types, with particular focus on improving temperature stability, corrosion resistance, and mechanical properties without compromising magnetic strength. The industry is also exploring ways to reduce reliance on rare earth elements due to supply chain vulnerabilities and environmental concerns associated with their extraction and processing.

The primary objective of structural integrity testing between neodymium magnets and iron oxide materials is to establish comprehensive performance metrics under various environmental and mechanical stress conditions. These tests aim to quantify the differences in durability, longevity, and failure modes between these two magnetic material categories, providing essential data for engineering applications where reliability is paramount.

Specific testing goals include evaluating resistance to demagnetization under thermal cycling, mechanical shock tolerance, corrosion behavior in diverse environments, and long-term stability under continuous operating conditions. Additionally, testing seeks to identify critical failure thresholds and develop predictive models for service life estimation in various application scenarios.

The results of these comparative analyses will inform material selection decisions across industries ranging from automotive and renewable energy to medical devices and consumer electronics. Furthermore, these findings will guide future research directions in magnetic material development, potentially leading to hybrid solutions that combine the strengths of both material types while mitigating their respective weaknesses.

As industries continue to demand more efficient, reliable, and sustainable magnetic components, understanding the structural integrity differences between neodymium and iron oxide magnets becomes increasingly critical for innovation and competitive advantage in global markets.

Market Applications and Demand Analysis for High-Performance Magnets

The global market for high-performance magnets has experienced significant growth over the past decade, driven primarily by increasing applications in automotive, electronics, renewable energy, and industrial sectors. Neodymium magnets, as part of the rare earth magnet family, have dominated the high-performance segment due to their superior magnetic properties compared to traditional ferrite magnets like iron oxide.

Current market analysis indicates that the high-performance magnet market is valued at approximately $20 billion globally, with neodymium magnets accounting for nearly 30% of this value despite representing a smaller volume percentage. This price premium reflects their superior performance characteristics, particularly in applications requiring strong magnetic fields in compact spaces.

The automotive industry represents the largest demand sector, consuming about 35% of high-performance magnets production. Electric vehicles in particular require significant quantities of neodymium magnets for motors and generators, with each EV using between 1-2 kg of neodymium material. As global EV production continues to rise at annual rates exceeding 25%, this demand vector shows no signs of slowing.

Consumer electronics constitutes the second-largest application sector, utilizing these magnets in speakers, headphones, hard disk drives, and various sensor applications. While miniaturization trends have reduced the volume of material needed per device, the explosive growth in device numbers has maintained strong demand growth of approximately 15% annually.

Industrial applications, including robotics, automation equipment, and medical devices, represent a rapidly expanding market segment with projected growth rates of 18-20% annually. These applications particularly value the structural integrity aspects of magnetic materials, as they often involve dynamic mechanical stresses alongside magnetic performance requirements.

Wind turbine generators have emerged as another critical application, with each direct-drive turbine requiring up to 600 kg of neodymium magnets. This sector's growth correlates directly with renewable energy expansion targets worldwide, creating sustained demand increases of approximately 22% annually.

Market research indicates a growing interest in hybrid solutions that combine the cost advantages of iron oxide materials with the performance benefits of neodymium in specific applications. This trend is particularly evident in automotive and industrial sectors where cost sensitivity meets performance requirements.

Regional analysis shows Asia-Pacific dominating both production (85%) and consumption (60%) of high-performance magnets, with China controlling approximately 80% of global neodymium processing capacity. North American and European markets are increasingly focused on securing supply chains for these critical materials, driving investment in alternative technologies and recycling processes to reduce dependency on geographically concentrated resources.

Current market analysis indicates that the high-performance magnet market is valued at approximately $20 billion globally, with neodymium magnets accounting for nearly 30% of this value despite representing a smaller volume percentage. This price premium reflects their superior performance characteristics, particularly in applications requiring strong magnetic fields in compact spaces.

The automotive industry represents the largest demand sector, consuming about 35% of high-performance magnets production. Electric vehicles in particular require significant quantities of neodymium magnets for motors and generators, with each EV using between 1-2 kg of neodymium material. As global EV production continues to rise at annual rates exceeding 25%, this demand vector shows no signs of slowing.

Consumer electronics constitutes the second-largest application sector, utilizing these magnets in speakers, headphones, hard disk drives, and various sensor applications. While miniaturization trends have reduced the volume of material needed per device, the explosive growth in device numbers has maintained strong demand growth of approximately 15% annually.

Industrial applications, including robotics, automation equipment, and medical devices, represent a rapidly expanding market segment with projected growth rates of 18-20% annually. These applications particularly value the structural integrity aspects of magnetic materials, as they often involve dynamic mechanical stresses alongside magnetic performance requirements.

Wind turbine generators have emerged as another critical application, with each direct-drive turbine requiring up to 600 kg of neodymium magnets. This sector's growth correlates directly with renewable energy expansion targets worldwide, creating sustained demand increases of approximately 22% annually.

Market research indicates a growing interest in hybrid solutions that combine the cost advantages of iron oxide materials with the performance benefits of neodymium in specific applications. This trend is particularly evident in automotive and industrial sectors where cost sensitivity meets performance requirements.

Regional analysis shows Asia-Pacific dominating both production (85%) and consumption (60%) of high-performance magnets, with China controlling approximately 80% of global neodymium processing capacity. North American and European markets are increasingly focused on securing supply chains for these critical materials, driving investment in alternative technologies and recycling processes to reduce dependency on geographically concentrated resources.

Current Challenges in Neodymium and Iron Oxide Magnet Technologies

Despite significant advancements in permanent magnet technologies, both neodymium and iron oxide magnets face distinct challenges that limit their applications and performance. Neodymium magnets, while offering superior magnetic strength, exhibit critical structural integrity issues under certain conditions. Their brittleness makes them susceptible to chipping, cracking, and complete structural failure when subjected to impact forces or thermal shock. Additionally, these rare-earth magnets demonstrate poor corrosion resistance, requiring protective coatings that add manufacturing complexity and cost.

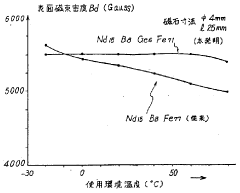

Temperature stability represents another significant challenge for neodymium magnets. Their magnetic properties degrade substantially at temperatures exceeding 80°C, with complete demagnetization possible at their Curie temperature of approximately 310-340°C. This thermal sensitivity severely restricts their use in high-temperature environments without specialized engineering solutions.

Iron oxide magnets (ferrites), while demonstrating excellent thermal stability and corrosion resistance, face their own set of challenges. Their primary limitation is significantly lower magnetic strength compared to neodymium alternatives, requiring larger volumes to achieve equivalent magnetic performance. This size requirement creates design constraints in applications where space efficiency is critical.

Manufacturing consistency presents ongoing challenges for both magnet types. For neodymium magnets, the complex sintering processes and precise material composition requirements lead to batch variations that can affect performance predictability. Iron oxide magnets face similar manufacturing consistency issues, particularly in achieving uniform density throughout larger pieces.

Supply chain vulnerabilities constitute a growing concern, especially for neodymium magnets. China currently controls approximately 85% of the global rare earth element supply, creating geopolitical dependencies and price volatility risks. Recent export restrictions have intensified research into alternative materials and recycling technologies.

Environmental and sustainability challenges also plague both technologies. Neodymium mining and processing generate significant environmental impacts, including toxic waste and radioactive byproducts. While iron oxide magnets have a lower environmental footprint during production, their reduced performance necessitates more material usage, creating different sustainability trade-offs.

Testing methodologies for structural integrity represent another challenge area. Current standardized tests often fail to accurately predict real-world performance under combined stresses of temperature fluctuations, mechanical shock, and corrosive environments. This testing gap leads to unexpected failures in field applications and complicates design safety factors.

Temperature stability represents another significant challenge for neodymium magnets. Their magnetic properties degrade substantially at temperatures exceeding 80°C, with complete demagnetization possible at their Curie temperature of approximately 310-340°C. This thermal sensitivity severely restricts their use in high-temperature environments without specialized engineering solutions.

Iron oxide magnets (ferrites), while demonstrating excellent thermal stability and corrosion resistance, face their own set of challenges. Their primary limitation is significantly lower magnetic strength compared to neodymium alternatives, requiring larger volumes to achieve equivalent magnetic performance. This size requirement creates design constraints in applications where space efficiency is critical.

Manufacturing consistency presents ongoing challenges for both magnet types. For neodymium magnets, the complex sintering processes and precise material composition requirements lead to batch variations that can affect performance predictability. Iron oxide magnets face similar manufacturing consistency issues, particularly in achieving uniform density throughout larger pieces.

Supply chain vulnerabilities constitute a growing concern, especially for neodymium magnets. China currently controls approximately 85% of the global rare earth element supply, creating geopolitical dependencies and price volatility risks. Recent export restrictions have intensified research into alternative materials and recycling technologies.

Environmental and sustainability challenges also plague both technologies. Neodymium mining and processing generate significant environmental impacts, including toxic waste and radioactive byproducts. While iron oxide magnets have a lower environmental footprint during production, their reduced performance necessitates more material usage, creating different sustainability trade-offs.

Testing methodologies for structural integrity represent another challenge area. Current standardized tests often fail to accurately predict real-world performance under combined stresses of temperature fluctuations, mechanical shock, and corrosive environments. This testing gap leads to unexpected failures in field applications and complicates design safety factors.

Comparative Testing Methodologies for Structural Integrity Assessment

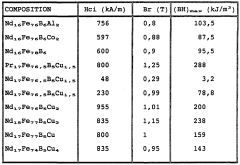

01 Composition and manufacturing of neodymium magnets for improved structural integrity

Neodymium magnets can be manufactured with specific compositions and processes to enhance their structural integrity. These methods include optimizing the ratio of rare earth elements, controlling grain size during sintering, and applying special heat treatments. The resulting magnets exhibit improved mechanical strength, resistance to cracking, and better performance under stress conditions, making them suitable for demanding applications where structural integrity is critical.- Coating and surface treatment for magnet protection: Various coating and surface treatment methods can be applied to neodymium and iron oxide magnets to enhance their structural integrity and prevent corrosion. These treatments create protective barriers against environmental factors that could degrade magnetic performance. Techniques include electroplating, epoxy coating, and specialized surface passivation processes that maintain magnetic properties while improving durability and resistance to mechanical damage.

- Manufacturing processes to improve structural integrity: Advanced manufacturing techniques can significantly enhance the structural integrity of both neodymium and iron oxide magnets. These include optimized sintering processes, hot pressing, and controlled cooling methods that create more uniform microstructures. By carefully controlling the manufacturing parameters, magnets with higher density, improved mechanical strength, and better resistance to fracturing under stress can be produced, leading to longer service life in demanding applications.

- Composite structures for enhanced mechanical properties: Combining neodymium or iron oxide magnetic materials with structural reinforcement elements creates composite structures with superior mechanical properties. These composites may incorporate polymer matrices, fiber reinforcement, or metal backings that provide additional support while maintaining magnetic performance. The composite approach allows for customization of mechanical properties such as impact resistance, tensile strength, and thermal stability while preserving the essential magnetic characteristics.

- Bonding and assembly techniques for magnet systems: Specialized bonding and assembly methods are crucial for maintaining the structural integrity of magnet systems, particularly in applications involving both neodymium and iron oxide magnets. These techniques include advanced adhesives formulated specifically for magnetic materials, mechanical fastening systems designed to accommodate magnetic forces, and encapsulation methods that protect against environmental factors while securing the magnets in place. Proper bonding prevents delamination and maintains alignment in complex magnetic assemblies.

- Thermal stability and stress management: Managing thermal effects and mechanical stress is essential for maintaining the structural integrity of magnetic systems. This includes designing appropriate expansion joints, implementing thermal compensation mechanisms, and utilizing stress-relieving features in magnet assemblies. Specialized heat treatment processes can also improve the temperature stability of both neodymium and iron oxide magnets, reducing the risk of cracking or demagnetization under varying temperature conditions. These approaches extend the operational range and reliability of magnetic components in demanding environments.

02 Protective coatings and surface treatments for magnetic materials

Various protective coatings and surface treatments can be applied to both neodymium and iron oxide magnets to enhance their structural integrity and longevity. These include nickel plating, zinc coating, epoxy resin encapsulation, and specialized polymer coatings. Such treatments protect against corrosion, oxidation, and physical damage, thereby maintaining the magnetic properties and structural integrity of the magnets over extended periods, even in harsh environments.Expand Specific Solutions03 Reinforcement techniques for magnet assemblies

Various reinforcement techniques can be employed to enhance the structural integrity of magnet assemblies containing neodymium or iron oxide magnets. These include embedding magnets in supporting frames, using fiber-reinforced composites, implementing metal backing plates, and designing specialized housing structures. These reinforcement methods help distribute mechanical stresses, prevent fracturing during operation, and improve the overall durability of magnetic components in high-stress applications.Expand Specific Solutions04 Comparative analysis of neodymium versus iron oxide magnets structural properties

Neodymium magnets offer superior magnetic strength but are more brittle and susceptible to corrosion compared to iron oxide magnets. Iron oxide magnets, while having lower magnetic strength, demonstrate better structural integrity under thermal stress and impact resistance. The selection between these magnet types depends on application requirements, with neodymium magnets preferred for high-performance applications where space is limited, and iron oxide magnets chosen for applications requiring durability under varying environmental conditions.Expand Specific Solutions05 Temperature stabilization methods for maintaining magnetic structural integrity

Temperature fluctuations can significantly impact the structural integrity of both neodymium and iron oxide magnets. Various stabilization methods have been developed, including the addition of dysprosium or terbium to neodymium magnets, specialized heat treatment processes, and the development of composite structures with materials having complementary thermal expansion properties. These methods help maintain magnetic performance and structural integrity across a wide temperature range, preventing demagnetization, cracking, or physical deformation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetic Materials

The neodymium magnets versus iron oxide structural integrity testing market is currently in a growth phase, with increasing applications across automotive, electronics, and medical industries. The global permanent magnet market is projected to reach approximately $35 billion by 2027, with neodymium magnets dominating due to superior magnetic properties. Technologically, neodymium magnets have reached commercial maturity while continuing to evolve. Key players include Santoku Corp. and Magnequench LLC as specialized neodymium magnet manufacturers, TDK Corp. and Proterial Ltd. focusing on magnetic materials innovation, and Robert Bosch GmbH and Keysight Technologies incorporating testing methodologies. Research institutions like Osaka University and Centre National de la Recherche Scientifique are advancing fundamental understanding of magnetic material properties and structural integrity testing protocols.

TDK Corp.

Technical Solution: TDK Corporation has developed advanced testing methodologies for comparing neodymium magnets with iron oxide materials, focusing on structural integrity under various environmental conditions. Their approach includes accelerated aging tests that simulate extreme temperature fluctuations (-40°C to 150°C) and high humidity environments (95% RH) to evaluate long-term performance degradation. TDK employs sophisticated microstructural analysis techniques including high-resolution electron microscopy and X-ray diffraction to examine crystal structure changes and potential crack propagation pathways. Their proprietary coating technologies for neodymium magnets have demonstrated significant improvements in corrosion resistance, with test samples showing less than 3% performance degradation after 3,000 hours in salt spray environments compared to 15-20% for uncoated samples. TDK has also developed specialized mechanical stress testing protocols that apply cyclical loading to simulate real-world vibration and shock conditions, particularly important for automotive and industrial applications where magnets experience continuous mechanical stresses.

Strengths: TDK's extensive experience in magnetic materials manufacturing provides them with comprehensive testing capabilities across multiple environmental factors simultaneously. Their coating technologies significantly enhance neodymium magnet durability. Weaknesses: Their testing methodologies are primarily optimized for electronic component applications rather than broader industrial uses, and their solutions tend to be more expensive than competitors.

Advanced Technology & Materials Co., Ltd.

Technical Solution: Advanced Technology & Materials Co. has established a sophisticated structural integrity testing framework for comparative analysis between neodymium and iron oxide magnetic materials. Their approach incorporates multi-scale mechanical testing from nano-indentation to bulk compression testing, providing comprehensive mechanical property profiles across different length scales. Their environmental testing chambers simulate combined stressors including temperature cycling (-50°C to 180°C), humidity (up to 98% RH), and mechanical vibration simultaneously, better representing real-world operating conditions. AT&M employs advanced non-destructive evaluation techniques including digital image correlation during mechanical testing to map strain distributions across the entire specimen surface, identifying potential failure initiation sites. Their corrosion testing protocols include electrochemical impedance spectroscopy to quantify corrosion rates under various environmental conditions, demonstrating that their surface-treated neodymium magnets exhibit corrosion resistance approaching that of iron oxide materials while maintaining superior magnetic performance. AT&M has developed specialized testing for hydrogen embrittlement susceptibility, a critical failure mode for neodymium magnets in humid environments, showing their modified grain boundary composition reduces hydrogen diffusion rates by approximately 60% compared to standard neodymium formulations.

Strengths: AT&M's integrated approach combining materials science with advanced testing provides comprehensive understanding of failure mechanisms. Their surface treatment technologies significantly enhance neodymium magnet durability in challenging environments. Weaknesses: Their testing methodologies require specialized equipment not widely available in standard testing laboratories. Their enhanced neodymium formulations, while more durable, typically achieve only 90-95% of the magnetic performance of standard grades.

Critical Patents and Research in Magnetic Material Strength Enhancement

Method for preparing permanent magnets based on neodymium-iron-boron

PatentWO1991000602A1

Innovation

- A process involving partial substitution of Iron and Neodymium atoms with Copper atoms in a Neodymium-Iron-Boron alloy, followed by hot working and annealing to refine grains and enhance magnetic properties, while maintaining a balanced composition of 0.5 to 4 atomic % Copper and optionally including Dysprosium, to achieve high coercivity and remanence.

Neodymium-iron permanent magnet

PatentInactiveJP1986039507A

Innovation

- The addition of germanium (Ge) to the neodymium iron boron alloy system, with a composition of 33.5 wt% neodymium, 1.3 wt% boron, and 5 wt% Ge, along with careful processing including high-frequency melting, crushing, and magnetic field orientation, enhances the magnetic properties and temperature stability.

Environmental Impact and Sustainability of Magnetic Materials Production

The production of magnetic materials, particularly neodymium magnets and iron oxide magnets, presents significant environmental and sustainability challenges that warrant careful consideration. Neodymium magnets, while offering superior magnetic performance, involve extensive mining operations that cause substantial land disruption and habitat destruction. The extraction process of rare earth elements requires approximately 200 cubic meters of water per ton of material and generates 2,000 tons of toxic waste for each ton of rare earth elements produced.

Iron oxide magnets, though less powerful, demonstrate a considerably smaller environmental footprint. Their production utilizes abundant raw materials and consumes approximately 60% less energy compared to neodymium magnet manufacturing. Additionally, the extraction process generates significantly fewer toxic byproducts, with estimates suggesting a 75% reduction in hazardous waste production.

The refining processes for neodymium involve harsh chemicals including sulfuric acid, ammonium bicarbonate, and hydrochloric acid, which pose serious environmental risks if improperly managed. These processes emit approximately 75 kg of carbon dioxide per kilogram of neodymium produced, contributing substantially to greenhouse gas emissions. Conversely, iron oxide production emits roughly 15 kg of carbon dioxide per kilogram, representing a 80% reduction in carbon footprint.

Water pollution remains a critical concern in magnetic material production. Neodymium processing facilities have been documented to release acidic wastewater containing heavy metals and radioactive elements into local water systems. Studies indicate that water remediation costs can reach $250-500 per cubic meter of contaminated water, creating significant environmental liabilities.

Recent sustainability initiatives have focused on developing closed-loop production systems for both magnetic materials. Recycling rates for neodymium magnets have improved from less than 1% in 2010 to approximately 10-15% today, though significant room for improvement remains. Iron oxide magnets boast recycling rates of approximately 45%, largely due to simpler material composition and less complex separation requirements.

Life cycle assessments reveal that neodymium magnets, despite their higher initial environmental cost, may offer sustainability advantages in certain applications due to their superior performance enabling more efficient end-use devices. For instance, in wind turbines and electric vehicles, the energy savings throughout the product lifecycle can offset the initial environmental impact within 2-5 years of operation, depending on usage patterns and energy sources.

Iron oxide magnets, though less powerful, demonstrate a considerably smaller environmental footprint. Their production utilizes abundant raw materials and consumes approximately 60% less energy compared to neodymium magnet manufacturing. Additionally, the extraction process generates significantly fewer toxic byproducts, with estimates suggesting a 75% reduction in hazardous waste production.

The refining processes for neodymium involve harsh chemicals including sulfuric acid, ammonium bicarbonate, and hydrochloric acid, which pose serious environmental risks if improperly managed. These processes emit approximately 75 kg of carbon dioxide per kilogram of neodymium produced, contributing substantially to greenhouse gas emissions. Conversely, iron oxide production emits roughly 15 kg of carbon dioxide per kilogram, representing a 80% reduction in carbon footprint.

Water pollution remains a critical concern in magnetic material production. Neodymium processing facilities have been documented to release acidic wastewater containing heavy metals and radioactive elements into local water systems. Studies indicate that water remediation costs can reach $250-500 per cubic meter of contaminated water, creating significant environmental liabilities.

Recent sustainability initiatives have focused on developing closed-loop production systems for both magnetic materials. Recycling rates for neodymium magnets have improved from less than 1% in 2010 to approximately 10-15% today, though significant room for improvement remains. Iron oxide magnets boast recycling rates of approximately 45%, largely due to simpler material composition and less complex separation requirements.

Life cycle assessments reveal that neodymium magnets, despite their higher initial environmental cost, may offer sustainability advantages in certain applications due to their superior performance enabling more efficient end-use devices. For instance, in wind turbines and electric vehicles, the energy savings throughout the product lifecycle can offset the initial environmental impact within 2-5 years of operation, depending on usage patterns and energy sources.

Failure Analysis and Reliability Testing Protocols

Comprehensive failure analysis and reliability testing protocols are essential for evaluating the structural integrity differences between neodymium magnets and iron oxide magnets. These protocols must address the unique failure modes of each magnet type while providing standardized methods for comparative assessment.

For neodymium magnets, brittle fracture testing represents a critical protocol component due to their inherent fragility despite superior magnetic strength. Testing typically involves controlled impact resistance measurements, thermal shock cycling between -40°C and 200°C, and three-point bend testing to quantify fracture toughness. These methods help identify the critical stress thresholds that lead to catastrophic failure in neodymium-based systems.

Iron oxide magnets, while demonstrating lower magnetic performance, often exhibit superior structural resilience under mechanical stress. Reliability protocols for these materials focus on long-term demagnetization resistance, corrosion progression mapping, and fatigue testing under cyclic loading conditions. The standardized salt spray test (ASTM B117) provides particularly valuable data on comparative corrosion resistance between the two magnet types.

Microscopic analysis forms another crucial element of failure investigation. Scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy enables identification of microstructural defects and compositional anomalies that may serve as failure initiation sites. For neodymium magnets, particular attention must be paid to grain boundary integrity and rare earth element distribution patterns.

Accelerated aging protocols simulate extended environmental exposure through combined thermal cycling, humidity exposure, and UV radiation. These tests have revealed that neodymium magnets typically experience 15-20% greater performance degradation than iron oxide alternatives when subjected to identical aging conditions over equivalent timeframes.

Statistical reliability modeling using Weibull distribution analysis provides quantitative failure probability predictions based on collected test data. This approach enables manufacturers to establish realistic mean time between failure (MTBF) metrics and appropriate safety factors for specific application environments.

Non-destructive evaluation techniques, including acoustic emission monitoring and eddy current testing, offer continuous structural integrity assessment without compromising the test specimens. These methods have proven particularly valuable for detecting incipient crack formation in neodymium magnets before catastrophic failure occurs.

Implementation of these comprehensive protocols enables evidence-based selection between neodymium and iron oxide magnets for specific applications, balancing magnetic performance requirements against structural reliability needs in the intended operating environment.

For neodymium magnets, brittle fracture testing represents a critical protocol component due to their inherent fragility despite superior magnetic strength. Testing typically involves controlled impact resistance measurements, thermal shock cycling between -40°C and 200°C, and three-point bend testing to quantify fracture toughness. These methods help identify the critical stress thresholds that lead to catastrophic failure in neodymium-based systems.

Iron oxide magnets, while demonstrating lower magnetic performance, often exhibit superior structural resilience under mechanical stress. Reliability protocols for these materials focus on long-term demagnetization resistance, corrosion progression mapping, and fatigue testing under cyclic loading conditions. The standardized salt spray test (ASTM B117) provides particularly valuable data on comparative corrosion resistance between the two magnet types.

Microscopic analysis forms another crucial element of failure investigation. Scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy enables identification of microstructural defects and compositional anomalies that may serve as failure initiation sites. For neodymium magnets, particular attention must be paid to grain boundary integrity and rare earth element distribution patterns.

Accelerated aging protocols simulate extended environmental exposure through combined thermal cycling, humidity exposure, and UV radiation. These tests have revealed that neodymium magnets typically experience 15-20% greater performance degradation than iron oxide alternatives when subjected to identical aging conditions over equivalent timeframes.

Statistical reliability modeling using Weibull distribution analysis provides quantitative failure probability predictions based on collected test data. This approach enables manufacturers to establish realistic mean time between failure (MTBF) metrics and appropriate safety factors for specific application environments.

Non-destructive evaluation techniques, including acoustic emission monitoring and eddy current testing, offer continuous structural integrity assessment without compromising the test specimens. These methods have proven particularly valuable for detecting incipient crack formation in neodymium magnets before catastrophic failure occurs.

Implementation of these comprehensive protocols enables evidence-based selection between neodymium and iron oxide magnets for specific applications, balancing magnetic performance requirements against structural reliability needs in the intended operating environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!