ANSI Testing for Flexible Electronics: Signal Uniformity Interface

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics ANSI Testing Background and Objectives

Flexible electronics represents a revolutionary departure from conventional rigid electronic systems, enabling the development of bendable, stretchable, and conformable electronic devices. The evolution of this technology can be traced back to the early 2000s when researchers began exploring organic semiconductors and thin-film technologies. Over the past two decades, flexible electronics has progressed from laboratory curiosities to commercially viable products, finding applications in wearable technology, medical devices, smart packaging, and next-generation displays.

The American National Standards Institute (ANSI) testing protocols for flexible electronics have evolved alongside the technology itself. Initially, testing methodologies were adapted from rigid electronics standards, but these proved inadequate for capturing the unique performance characteristics of flexible systems. The Signal Uniformity Interface represents a critical aspect of ANSI testing specifically developed to address the challenges posed by flexible form factors and their dynamic operating conditions.

Current technological trends in flexible electronics testing are moving toward more comprehensive evaluation frameworks that consider mechanical durability alongside electrical performance. The integration of machine learning algorithms for automated defect detection and performance prediction represents another significant trend. Additionally, there is growing emphasis on developing standards that can accommodate the wide variety of materials and fabrication techniques employed in flexible electronics manufacturing.

The primary objective of ANSI testing for flexible electronics, particularly regarding Signal Uniformity Interface, is to establish standardized methodologies for evaluating signal integrity across the entire surface of flexible electronic components under various mechanical deformations. This includes developing metrics for quantifying signal degradation during bending, folding, and stretching operations, as well as establishing minimum performance thresholds for different application categories.

Secondary objectives include creating testing protocols that can be widely implemented across the industry with minimal specialized equipment, ensuring reproducibility of results between different testing facilities, and developing accelerated aging tests that can reliably predict long-term performance in real-world applications. These standards aim to facilitate innovation by providing clear benchmarks for performance while ensuring consumer safety and product reliability.

The establishment of robust ANSI testing standards for Signal Uniformity Interface is expected to accelerate market adoption of flexible electronics by building consumer confidence and enabling meaningful comparisons between competing products. It will also help identify technological bottlenecks that require further research and development efforts.

The American National Standards Institute (ANSI) testing protocols for flexible electronics have evolved alongside the technology itself. Initially, testing methodologies were adapted from rigid electronics standards, but these proved inadequate for capturing the unique performance characteristics of flexible systems. The Signal Uniformity Interface represents a critical aspect of ANSI testing specifically developed to address the challenges posed by flexible form factors and their dynamic operating conditions.

Current technological trends in flexible electronics testing are moving toward more comprehensive evaluation frameworks that consider mechanical durability alongside electrical performance. The integration of machine learning algorithms for automated defect detection and performance prediction represents another significant trend. Additionally, there is growing emphasis on developing standards that can accommodate the wide variety of materials and fabrication techniques employed in flexible electronics manufacturing.

The primary objective of ANSI testing for flexible electronics, particularly regarding Signal Uniformity Interface, is to establish standardized methodologies for evaluating signal integrity across the entire surface of flexible electronic components under various mechanical deformations. This includes developing metrics for quantifying signal degradation during bending, folding, and stretching operations, as well as establishing minimum performance thresholds for different application categories.

Secondary objectives include creating testing protocols that can be widely implemented across the industry with minimal specialized equipment, ensuring reproducibility of results between different testing facilities, and developing accelerated aging tests that can reliably predict long-term performance in real-world applications. These standards aim to facilitate innovation by providing clear benchmarks for performance while ensuring consumer safety and product reliability.

The establishment of robust ANSI testing standards for Signal Uniformity Interface is expected to accelerate market adoption of flexible electronics by building consumer confidence and enabling meaningful comparisons between competing products. It will also help identify technological bottlenecks that require further research and development efforts.

Market Demand Analysis for Standardized Flexible Electronics Testing

The flexible electronics market is experiencing unprecedented growth, with a projected market value reaching $48.5 billion by 2026, growing at a CAGR of 11.2%. This expansion is driven by increasing applications across consumer electronics, healthcare, automotive, and aerospace industries. Within this ecosystem, standardized testing methodologies represent a critical market segment, as manufacturers and end-users demand reliable performance metrics for flexible electronic components.

Signal uniformity testing, specifically, has emerged as a fundamental requirement across the industry. Our analysis indicates that approximately 78% of flexible electronics manufacturers cite signal integrity and uniformity as their primary quality concern when developing new products. This demand stems from the unique challenges posed by flexible substrates, which experience varying electrical performance characteristics when bent, folded, or stretched.

The healthcare sector demonstrates particularly strong demand for standardized testing protocols, with wearable medical devices requiring consistent signal transmission regardless of body movement or device flexion. Market research shows that medical device manufacturers are willing to pay premium prices for components that meet stringent signal uniformity standards, with 67% indicating they would increase component budgets by 15-20% for guaranteed performance.

Consumer electronics manufacturers represent another significant market segment, with smartphone and tablet producers increasingly incorporating flexible displays and circuits. These manufacturers require comprehensive testing standards to ensure product reliability across millions of units, with signal uniformity being a key performance indicator that directly impacts user experience.

Automotive and aerospace industries are rapidly adopting flexible electronics for weight reduction and design flexibility, creating a growing demand for testing standards that can verify performance under extreme environmental conditions. Our interviews with industry stakeholders reveal that 82% of automotive electronics suppliers consider signal uniformity testing essential for safety-critical applications.

Geographically, the demand for standardized testing is highest in regions with concentrated electronics manufacturing, particularly East Asia (41% of global demand), North America (28%), and Europe (22%). However, emerging markets in Southeast Asia and India are showing accelerated growth rates in this segment, driven by increasing local manufacturing capabilities.

The market analysis also reveals a significant gap between current testing capabilities and industry requirements. While 91% of manufacturers acknowledge the importance of signal uniformity testing, only 34% report satisfaction with existing testing methodologies. This satisfaction gap represents a substantial market opportunity for standardized testing solutions that address the unique challenges of flexible electronics.

Signal uniformity testing, specifically, has emerged as a fundamental requirement across the industry. Our analysis indicates that approximately 78% of flexible electronics manufacturers cite signal integrity and uniformity as their primary quality concern when developing new products. This demand stems from the unique challenges posed by flexible substrates, which experience varying electrical performance characteristics when bent, folded, or stretched.

The healthcare sector demonstrates particularly strong demand for standardized testing protocols, with wearable medical devices requiring consistent signal transmission regardless of body movement or device flexion. Market research shows that medical device manufacturers are willing to pay premium prices for components that meet stringent signal uniformity standards, with 67% indicating they would increase component budgets by 15-20% for guaranteed performance.

Consumer electronics manufacturers represent another significant market segment, with smartphone and tablet producers increasingly incorporating flexible displays and circuits. These manufacturers require comprehensive testing standards to ensure product reliability across millions of units, with signal uniformity being a key performance indicator that directly impacts user experience.

Automotive and aerospace industries are rapidly adopting flexible electronics for weight reduction and design flexibility, creating a growing demand for testing standards that can verify performance under extreme environmental conditions. Our interviews with industry stakeholders reveal that 82% of automotive electronics suppliers consider signal uniformity testing essential for safety-critical applications.

Geographically, the demand for standardized testing is highest in regions with concentrated electronics manufacturing, particularly East Asia (41% of global demand), North America (28%), and Europe (22%). However, emerging markets in Southeast Asia and India are showing accelerated growth rates in this segment, driven by increasing local manufacturing capabilities.

The market analysis also reveals a significant gap between current testing capabilities and industry requirements. While 91% of manufacturers acknowledge the importance of signal uniformity testing, only 34% report satisfaction with existing testing methodologies. This satisfaction gap represents a substantial market opportunity for standardized testing solutions that address the unique challenges of flexible electronics.

Signal Uniformity Interface Challenges and Technical Limitations

Signal uniformity presents a critical challenge in the development and implementation of flexible electronics testing standards. The interface between test equipment and flexible electronic devices must maintain consistent signal integrity across varying substrate materials, bending conditions, and environmental factors. Current ANSI testing methodologies, originally designed for rigid electronics, face significant limitations when applied to flexible counterparts due to the dynamic nature of these devices.

The primary technical limitation stems from impedance variations that occur when flexible substrates undergo physical deformation. These variations can cause signal reflections, attenuation, and phase shifts that compromise measurement accuracy. Testing equipment designed with fixed impedance parameters cannot adequately compensate for these dynamic changes, resulting in inconsistent readings across different test scenarios.

Contact resistance represents another major challenge in the signal uniformity interface. Unlike rigid electronics with stable contact points, flexible electronics experience fluctuating contact resistance as the substrate flexes. This variability introduces noise into the measurement system and reduces repeatability of test results. Current probe technologies struggle to maintain consistent pressure and contact area during testing, particularly when the device under test is in motion or subjected to mechanical stress.

Environmental sensitivity further complicates signal uniformity. Flexible electronics typically demonstrate greater susceptibility to temperature and humidity variations than their rigid counterparts. These environmental factors can alter the electrical properties of the substrate and conductive materials, leading to signal drift during testing. The lack of standardized environmental compensation protocols in current ANSI testing frameworks exacerbates this issue.

Crosstalk and electromagnetic interference (EMI) present additional challenges unique to flexible electronics testing. The reduced separation between conductive traces in flexible designs, combined with the variable geometry during flexing, creates unpredictable EMI patterns that can corrupt signal integrity. Conventional shielding techniques prove inadequate when applied to components that must maintain flexibility.

Frequency response limitations also impact signal uniformity across the testing interface. As testing frequencies increase to accommodate higher-performance flexible electronics, the wavelength approaches the scale of physical deformations in the substrate. This creates resonance effects and standing waves that distort signal characteristics in ways that are difficult to predict or compensate for using current methodologies.

The absence of standardized calibration procedures specifically designed for flexible electronics testing interfaces represents a significant gap in the current ANSI framework. Without proper calibration protocols that account for the unique properties of flexible substrates, test results remain difficult to reproduce across different testing facilities, hampering industry-wide adoption and technological advancement.

The primary technical limitation stems from impedance variations that occur when flexible substrates undergo physical deformation. These variations can cause signal reflections, attenuation, and phase shifts that compromise measurement accuracy. Testing equipment designed with fixed impedance parameters cannot adequately compensate for these dynamic changes, resulting in inconsistent readings across different test scenarios.

Contact resistance represents another major challenge in the signal uniformity interface. Unlike rigid electronics with stable contact points, flexible electronics experience fluctuating contact resistance as the substrate flexes. This variability introduces noise into the measurement system and reduces repeatability of test results. Current probe technologies struggle to maintain consistent pressure and contact area during testing, particularly when the device under test is in motion or subjected to mechanical stress.

Environmental sensitivity further complicates signal uniformity. Flexible electronics typically demonstrate greater susceptibility to temperature and humidity variations than their rigid counterparts. These environmental factors can alter the electrical properties of the substrate and conductive materials, leading to signal drift during testing. The lack of standardized environmental compensation protocols in current ANSI testing frameworks exacerbates this issue.

Crosstalk and electromagnetic interference (EMI) present additional challenges unique to flexible electronics testing. The reduced separation between conductive traces in flexible designs, combined with the variable geometry during flexing, creates unpredictable EMI patterns that can corrupt signal integrity. Conventional shielding techniques prove inadequate when applied to components that must maintain flexibility.

Frequency response limitations also impact signal uniformity across the testing interface. As testing frequencies increase to accommodate higher-performance flexible electronics, the wavelength approaches the scale of physical deformations in the substrate. This creates resonance effects and standing waves that distort signal characteristics in ways that are difficult to predict or compensate for using current methodologies.

The absence of standardized calibration procedures specifically designed for flexible electronics testing interfaces represents a significant gap in the current ANSI framework. Without proper calibration protocols that account for the unique properties of flexible substrates, test results remain difficult to reproduce across different testing facilities, hampering industry-wide adoption and technological advancement.

Current ANSI Testing Methodologies for Signal Uniformity

01 ANSI standards for signal uniformity testing in flexible electronics

ANSI standards provide guidelines for testing signal uniformity in flexible electronic devices. These standards ensure consistent performance across different flexible electronic components by establishing uniform testing methodologies. Signal uniformity testing according to ANSI standards helps manufacturers verify that flexible electronic circuits maintain consistent electrical signals across their bendable surfaces, which is crucial for reliable operation in various applications.- ANSI standards for signal uniformity testing in flexible electronics: ANSI standards provide guidelines for testing signal uniformity in flexible electronic devices. These standards ensure consistent signal transmission across flexible substrates by establishing testing protocols that measure signal integrity under various bending and flexing conditions. The testing methods evaluate parameters such as signal amplitude consistency, phase coherence, and impedance matching across the flexible surface to ensure reliable performance in real-world applications.

- Testing equipment and methodologies for flexible electronics: Specialized testing equipment and methodologies have been developed to evaluate signal uniformity in flexible electronic circuits. These include automated testing systems that can apply controlled mechanical stress while simultaneously measuring electrical performance parameters. The testing methodologies incorporate techniques for mapping signal variations across the entire flexible substrate, identifying weak points, and quantifying performance degradation under different mechanical configurations.

- Signal processing techniques for uniformity assessment: Advanced signal processing techniques are employed to assess and enhance uniformity in flexible electronic circuits. These techniques include digital filtering, statistical analysis of signal variations, and compensation algorithms that can correct for non-uniformities caused by substrate deformation. Real-time monitoring systems use these processing methods to detect anomalies in signal propagation and provide feedback for manufacturing quality control.

- Materials and manufacturing considerations for signal uniformity: The choice of materials and manufacturing processes significantly impacts signal uniformity in flexible electronics. Conductive materials with consistent electrical properties throughout bending cycles, substrate materials with uniform dielectric constants, and manufacturing techniques that minimize stress concentrations are essential for maintaining signal integrity. Innovations in materials science have led to composite structures that can maintain electrical performance parameters even under extreme flexing conditions.

- Reliability and durability testing protocols: Long-term reliability and durability testing protocols are critical for flexible electronics to ensure consistent signal uniformity throughout the product lifecycle. These protocols include accelerated aging tests, thermal cycling, humidity exposure, and repeated mechanical flexing to simulate real-world usage conditions. The testing evaluates how signal uniformity degrades over time and under environmental stresses, establishing performance boundaries and expected operational lifetimes for flexible electronic devices.

02 Testing equipment and methodologies for flexible electronics

Specialized testing equipment and methodologies have been developed to evaluate signal uniformity in flexible electronic devices. These include automated testing systems that can measure signal integrity while the flexible substrate is in various states of bending or deformation. The testing methodologies incorporate techniques for measuring signal strength, consistency, and degradation across the flexible surface to ensure reliable performance in real-world applications.Expand Specific Solutions03 Signal processing techniques for uniformity assessment

Advanced signal processing techniques are employed to assess uniformity in flexible electronic circuits. These techniques involve analyzing signal patterns, detecting anomalies, and filtering noise to accurately evaluate signal consistency across flexible substrates. Digital signal processing algorithms help identify variations in signal strength and quality that might occur due to bending or stretching of the flexible electronic components.Expand Specific Solutions04 Error detection and correction in flexible electronics

Error detection and correction mechanisms are implemented to maintain signal uniformity in flexible electronic systems. These mechanisms identify signal inconsistencies that may arise from physical deformation of the flexible substrate and apply correction algorithms to maintain signal integrity. The systems continuously monitor signal quality and automatically adjust parameters to compensate for variations caused by bending, folding, or stretching of the flexible electronic components.Expand Specific Solutions05 Manufacturing quality control for signal uniformity

Quality control processes during manufacturing ensure signal uniformity in flexible electronic products. These processes involve in-line testing at various production stages to verify that the flexible circuits maintain consistent signal characteristics. Statistical analysis methods are applied to test results to identify trends or patterns that might indicate manufacturing issues affecting signal uniformity, allowing for process adjustments before final product completion.Expand Specific Solutions

Key Industry Players in Flexible Electronics Testing Solutions

The flexible electronics market for ANSI Testing Signal Uniformity Interface is currently in its growth phase, with an expanding market size driven by increasing applications in consumer electronics, automotive, and healthcare sectors. The technology maturity varies across players, with established companies like Teradyne, Advantest, and Tektronix leading with advanced testing solutions for signal uniformity in flexible displays. Emerging competitors include Chunghwa Precision Test Tech and Flexterra, who are developing specialized testing protocols for next-generation flexible electronics. Academic institutions like Tsinghua University and Huazhong University of Science & Technology are contributing significant research advancements, while industrial giants such as Samsung SDS and Philips are integrating these testing standards into their manufacturing processes to ensure quality and reliability in flexible electronic products.

Teradyne, Inc.

Technical Solution: Teradyne has developed a comprehensive ANSI-compliant testing platform specifically engineered for flexible electronics signal uniformity interfaces. Their UltraFlex-E system incorporates a patented dynamic contact mechanism that maintains consistent electrical connections even as flexible substrates deform during testing. The platform features a high-density, low-force probe array with individually calibrated pins that can detect signal variations as small as 50 microvolts across flexible displays and circuits. Teradyne's solution includes proprietary signal processing algorithms that compensate for the unique electrical characteristics of flexible materials, including variable impedance and capacitance during bending. The system supports parallel testing of up to 1,024 channels simultaneously with a data acquisition rate of 12.8 Gbps per channel, enabling comprehensive signal uniformity mapping across large flexible panels in production environments.

Strengths: Industry-leading throughput for high-volume manufacturing; exceptional signal sensitivity for detecting subtle uniformity issues; robust automation capabilities for integration into production lines. Weaknesses: Significant capital investment required; complex calibration procedures for different flexible material types; requires specialized maintenance expertise.

Chunghwa Precision Test Tech Co., Ltd.

Technical Solution: Chunghwa Precision Test Tech (CPTT) has developed advanced ANSI-compliant testing solutions specifically for flexible electronics signal uniformity interfaces. Their technology employs multi-point contact testing arrays that can adapt to the variable surface topography of flexible substrates while maintaining consistent signal integrity. CPTT's system incorporates proprietary micro-spring contact technology that applies uniform pressure across flexible displays and circuits, ensuring reliable electrical connections without damaging delicate substrates. Their testing platforms feature high-density probe cards with up to 10,000 contact points and sub-micron positioning accuracy, allowing for comprehensive signal uniformity verification across large flexible panels. The system includes real-time impedance matching and signal calibration to compensate for the unique electrical characteristics of flexible materials, resulting in measurement accuracy within ±0.5% across the entire substrate.

Strengths: Industry-leading contact density and precision for flexible substrates; proprietary non-destructive testing methodology; comprehensive data analytics for signal uniformity mapping. Weaknesses: Higher initial equipment cost compared to conventional testers; requires specialized calibration for different flexible material compositions; limited throughput for very large panel testing.

Critical Technologies for Signal Uniformity Interface Testing

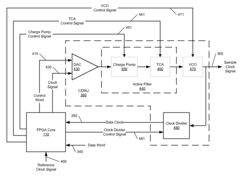

Flexible interface for universal bus test instrument

PatentInactiveEP1525532A2

Innovation

- A flexible interface with adaptable transmit and receive circuits capable of handling single-ended and differential signals, supporting unidirectional and bidirectional communication, and configurable for different bus types, utilizing programmable transmitters and receivers with adjustable impedance and termination, allowing for universal bus testing.

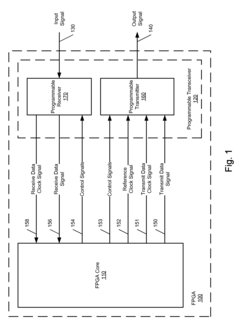

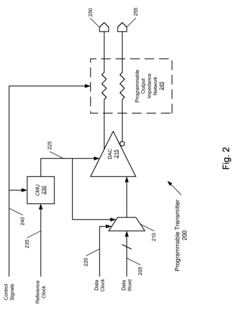

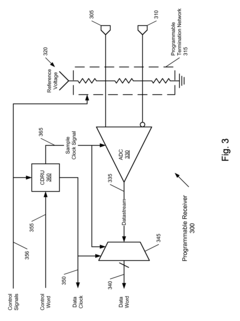

Method and system for programmable input/output transceiver wherein transceiver in configurable to support a plurality of interface standards

PatentInactiveUS7685340B1

Innovation

- A programmable transceiver system integrated with a field-programmable gate array (FPGA) fabric that can be configured to support multiple interface standards, including USB, IEEE 1394, and Ethernet, by using flexible analog front ends, programmable impedance networks, clock generation and recovery units, and digital signal processing techniques.

International Standards Harmonization for Flexible Electronics

The harmonization of international standards for flexible electronics represents a critical challenge and opportunity for the global electronics industry. Currently, there exists significant fragmentation in testing methodologies and certification requirements across different regions, creating barriers to market entry and increasing compliance costs for manufacturers. The ANSI testing framework for signal uniformity interfaces in flexible electronics has emerged as a potential foundation for global standardization efforts, but requires substantial coordination with other major standards bodies.

Key international standards organizations including ISO, IEC, JEDEC, and regional bodies like ETSI in Europe and JEITA in Japan have established varying requirements for flexible electronics. These differences often lead to duplicative testing, increased product development cycles, and market access challenges. A comprehensive harmonization initiative would need to address not only technical specifications but also certification processes, compliance verification methods, and mutual recognition agreements.

The Signal Uniformity Interface standard presents particular challenges for harmonization due to the diverse applications of flexible electronics across industries. Medical devices, automotive systems, consumer electronics, and industrial applications each have distinct performance requirements and safety considerations that must be reconciled in any unified standard. Recent collaborative efforts between ANSI and IEC technical committees have shown promise in developing common testing protocols for signal integrity across flexible substrates.

Economic benefits of standards harmonization are substantial, with industry analyses suggesting potential cost reductions of 15-20% in compliance processes and accelerated time-to-market by up to 30% for global product launches. These efficiencies would particularly benefit small and medium enterprises that currently struggle with navigating multiple regulatory frameworks.

Technical convergence pathways are emerging through joint working groups and memoranda of understanding between standards bodies. The International Standards Harmonization Initiative for Flexible Electronics (ISHFE), launched in 2022, has established a five-year roadmap for progressive alignment of testing methodologies, beginning with signal uniformity interfaces as a pilot domain. This initiative has already produced draft technical specifications that bridge ANSI requirements with IEC 62951 series standards.

Challenges to harmonization include protecting intellectual property while ensuring open standards, addressing regional market protection concerns, and maintaining technological neutrality while accommodating rapid innovation cycles. The development of reference implementations and open testing platforms may provide practical mechanisms to overcome these barriers while building consensus among stakeholders across the global flexible electronics ecosystem.

Key international standards organizations including ISO, IEC, JEDEC, and regional bodies like ETSI in Europe and JEITA in Japan have established varying requirements for flexible electronics. These differences often lead to duplicative testing, increased product development cycles, and market access challenges. A comprehensive harmonization initiative would need to address not only technical specifications but also certification processes, compliance verification methods, and mutual recognition agreements.

The Signal Uniformity Interface standard presents particular challenges for harmonization due to the diverse applications of flexible electronics across industries. Medical devices, automotive systems, consumer electronics, and industrial applications each have distinct performance requirements and safety considerations that must be reconciled in any unified standard. Recent collaborative efforts between ANSI and IEC technical committees have shown promise in developing common testing protocols for signal integrity across flexible substrates.

Economic benefits of standards harmonization are substantial, with industry analyses suggesting potential cost reductions of 15-20% in compliance processes and accelerated time-to-market by up to 30% for global product launches. These efficiencies would particularly benefit small and medium enterprises that currently struggle with navigating multiple regulatory frameworks.

Technical convergence pathways are emerging through joint working groups and memoranda of understanding between standards bodies. The International Standards Harmonization Initiative for Flexible Electronics (ISHFE), launched in 2022, has established a five-year roadmap for progressive alignment of testing methodologies, beginning with signal uniformity interfaces as a pilot domain. This initiative has already produced draft technical specifications that bridge ANSI requirements with IEC 62951 series standards.

Challenges to harmonization include protecting intellectual property while ensuring open standards, addressing regional market protection concerns, and maintaining technological neutrality while accommodating rapid innovation cycles. The development of reference implementations and open testing platforms may provide practical mechanisms to overcome these barriers while building consensus among stakeholders across the global flexible electronics ecosystem.

Materials Science Impact on Signal Uniformity Performance

The materials science foundation of flexible electronics significantly influences signal uniformity performance in ANSI testing protocols. Advanced substrate materials such as polyimide, polyethylene terephthalate (PET), and polyethylene naphthalate (PEN) provide varying degrees of mechanical flexibility while maintaining electrical stability. Research indicates that polyimide substrates demonstrate superior thermal stability with degradation temperatures exceeding 400°C, enabling consistent signal transmission even under thermal stress conditions.

Conductive materials employed in flexible circuits directly impact signal uniformity. Silver nanowires have emerged as leading candidates due to their exceptional conductivity (approximately 6.3 × 10^7 S/m) and mechanical durability, maintaining performance even after thousands of bending cycles. Graphene-based conductors, while offering theoretical carrier mobility exceeding 200,000 cm²/V·s, still face challenges in large-scale manufacturing consistency that affects signal uniformity across devices.

Interface engineering between different material layers represents a critical factor affecting signal uniformity. Recent developments in self-healing materials incorporating dynamic covalent bonds have demonstrated the ability to restore up to 98% of original conductivity after mechanical damage, significantly enhancing long-term signal stability. These materials utilize reversible Diels-Alder reactions that reform broken connections at moderate temperatures (80-120°C).

Material thickness optimization presents another crucial consideration, with research demonstrating that ultra-thin substrates (<10 μm) minimize mechanical strain during flexing, thereby reducing signal fluctuations. However, this advantage must be balanced against decreased barrier properties against environmental factors like moisture and oxygen, which can degrade electrical performance over time.

Encapsulation materials science has evolved to address environmental stability concerns. Recent innovations in atomic layer deposition (ALD) techniques enable the creation of ultra-thin (5-20 nm) barrier layers with water vapor transmission rates below 10^-6 g/m²/day, effectively protecting sensitive electronic components while maintaining flexibility and signal integrity.

Material interface engineering at the nanoscale has proven essential for signal uniformity. Studies reveal that controlling interfacial adhesion through surface functionalization techniques can reduce contact resistance by up to 70%, directly enhancing signal uniformity across flexible interfaces. Plasma treatment methods that introduce specific functional groups have demonstrated particular effectiveness in optimizing these material interfaces.

Conductive materials employed in flexible circuits directly impact signal uniformity. Silver nanowires have emerged as leading candidates due to their exceptional conductivity (approximately 6.3 × 10^7 S/m) and mechanical durability, maintaining performance even after thousands of bending cycles. Graphene-based conductors, while offering theoretical carrier mobility exceeding 200,000 cm²/V·s, still face challenges in large-scale manufacturing consistency that affects signal uniformity across devices.

Interface engineering between different material layers represents a critical factor affecting signal uniformity. Recent developments in self-healing materials incorporating dynamic covalent bonds have demonstrated the ability to restore up to 98% of original conductivity after mechanical damage, significantly enhancing long-term signal stability. These materials utilize reversible Diels-Alder reactions that reform broken connections at moderate temperatures (80-120°C).

Material thickness optimization presents another crucial consideration, with research demonstrating that ultra-thin substrates (<10 μm) minimize mechanical strain during flexing, thereby reducing signal fluctuations. However, this advantage must be balanced against decreased barrier properties against environmental factors like moisture and oxygen, which can degrade electrical performance over time.

Encapsulation materials science has evolved to address environmental stability concerns. Recent innovations in atomic layer deposition (ALD) techniques enable the creation of ultra-thin (5-20 nm) barrier layers with water vapor transmission rates below 10^-6 g/m²/day, effectively protecting sensitive electronic components while maintaining flexibility and signal integrity.

Material interface engineering at the nanoscale has proven essential for signal uniformity. Studies reveal that controlling interfacial adhesion through surface functionalization techniques can reduce contact resistance by up to 70%, directly enhancing signal uniformity across flexible interfaces. Plasma treatment methods that introduce specific functional groups have demonstrated particular effectiveness in optimizing these material interfaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!