Benchmark Mechanical Shearing Resilience of Flexible Electronics

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Shearing Resilience Background and Objectives

Flexible electronics represent a revolutionary advancement in the field of electronic devices, characterized by their ability to bend, fold, and conform to non-planar surfaces while maintaining electronic functionality. The evolution of this technology has progressed significantly over the past two decades, transitioning from rigid silicon-based electronics to malleable systems that can withstand mechanical deformation. This technological trajectory has been driven by increasing demands for wearable devices, biomedical implants, and next-generation consumer electronics that require both functionality and adaptability to human interaction.

Mechanical shearing resilience has emerged as a critical parameter in the development and implementation of flexible electronic systems. Unlike traditional electronics that operate under static conditions, flexible devices must maintain performance integrity while experiencing various mechanical stresses, particularly shearing forces that occur when layers of the device slide against each other during bending or twisting operations. The ability to quantify and benchmark this resilience is fundamental to advancing the field and ensuring reliable performance in real-world applications.

The primary objective of benchmarking mechanical shearing resilience is to establish standardized testing methodologies and performance metrics that can accurately predict the longevity and reliability of flexible electronic components under various mechanical stresses. This includes developing protocols for measuring critical parameters such as electrical conductivity retention, material delamination thresholds, and fatigue response under cyclic loading conditions that simulate real-world usage scenarios.

Current technological trends indicate a shift toward multi-material systems that combine organic and inorganic components to achieve optimal mechanical and electrical properties. These hybrid approaches present unique challenges for shearing resilience assessment, as interfaces between dissimilar materials often represent failure points under mechanical stress. Understanding the behavior of these interfaces and developing strategies to enhance their durability represents a key focus area for ongoing research.

The global research community has recognized the importance of this field, with significant contributions coming from academic institutions, industrial research centers, and government laboratories across Asia, North America, and Europe. Collaborative efforts have led to the development of preliminary testing standards, though consensus on universal benchmarking protocols remains elusive due to the diverse range of materials and device architectures employed in flexible electronics.

Achieving robust mechanical shearing resilience in flexible electronics will enable transformative applications across multiple sectors, including healthcare monitoring, structural health monitoring, soft robotics, and advanced human-machine interfaces. The ultimate goal is to develop flexible electronic systems that can seamlessly integrate with dynamic environments while maintaining consistent performance throughout their operational lifetime.

Mechanical shearing resilience has emerged as a critical parameter in the development and implementation of flexible electronic systems. Unlike traditional electronics that operate under static conditions, flexible devices must maintain performance integrity while experiencing various mechanical stresses, particularly shearing forces that occur when layers of the device slide against each other during bending or twisting operations. The ability to quantify and benchmark this resilience is fundamental to advancing the field and ensuring reliable performance in real-world applications.

The primary objective of benchmarking mechanical shearing resilience is to establish standardized testing methodologies and performance metrics that can accurately predict the longevity and reliability of flexible electronic components under various mechanical stresses. This includes developing protocols for measuring critical parameters such as electrical conductivity retention, material delamination thresholds, and fatigue response under cyclic loading conditions that simulate real-world usage scenarios.

Current technological trends indicate a shift toward multi-material systems that combine organic and inorganic components to achieve optimal mechanical and electrical properties. These hybrid approaches present unique challenges for shearing resilience assessment, as interfaces between dissimilar materials often represent failure points under mechanical stress. Understanding the behavior of these interfaces and developing strategies to enhance their durability represents a key focus area for ongoing research.

The global research community has recognized the importance of this field, with significant contributions coming from academic institutions, industrial research centers, and government laboratories across Asia, North America, and Europe. Collaborative efforts have led to the development of preliminary testing standards, though consensus on universal benchmarking protocols remains elusive due to the diverse range of materials and device architectures employed in flexible electronics.

Achieving robust mechanical shearing resilience in flexible electronics will enable transformative applications across multiple sectors, including healthcare monitoring, structural health monitoring, soft robotics, and advanced human-machine interfaces. The ultimate goal is to develop flexible electronic systems that can seamlessly integrate with dynamic environments while maintaining consistent performance throughout their operational lifetime.

Market Demand Analysis for Mechanically Robust Flexible Electronics

The flexible electronics market is experiencing unprecedented growth, driven by increasing demand for wearable devices, foldable smartphones, and medical monitoring systems. According to recent market analyses, the global flexible electronics market is projected to reach $42 billion by 2027, with a compound annual growth rate of 11% from 2022. This robust growth underscores the critical importance of mechanical durability in flexible electronic devices, particularly their resilience against shearing forces.

Consumer electronics represents the largest application segment, with foldable displays and bendable smartphones leading the demand for mechanically robust flexible electronics. Market research indicates that consumers are willing to pay premium prices for devices that can withstand repeated folding and bending without performance degradation. The failure rate of first-generation foldable smartphones due to mechanical issues has highlighted the urgent need for improved shearing resilience in these products.

Healthcare applications present another significant market opportunity, with flexible biosensors and wearable health monitors requiring exceptional mechanical durability. These devices must maintain functionality under constant movement and strain conditions when attached to the human body. Market surveys reveal that 78% of healthcare professionals consider mechanical reliability as the primary concern when adopting flexible electronic medical devices.

The automotive industry is rapidly emerging as a key market for flexible electronics, with applications in dashboard displays, sensor networks, and lighting systems. As vehicles incorporate more curved and non-planar surfaces, the demand for conformable electronics that can withstand vibration and mechanical stress continues to grow. Industry reports suggest that automotive applications of flexible electronics will expand at a rate of 15% annually through 2026.

Industrial and military sectors are also driving demand for mechanically robust flexible electronics that can operate in harsh environments. These applications require devices that maintain functionality under extreme conditions, including significant mechanical shearing forces. The defense sector alone is investing over $3 billion in research and development of rugged flexible electronic systems.

Regional market analysis reveals that Asia-Pacific currently dominates the flexible electronics market, accounting for approximately 45% of global demand, followed by North America and Europe. However, the fastest growth is expected in emerging economies where manufacturing capabilities for flexible electronics are rapidly developing.

Consumer expectations regarding device longevity are evolving, with surveys indicating that 67% of potential buyers consider durability as a decisive factor in purchasing decisions for flexible electronic devices. This consumer sentiment is pushing manufacturers to prioritize mechanical shearing resilience in their product development roadmaps, creating substantial market pull for innovations in this technical domain.

Consumer electronics represents the largest application segment, with foldable displays and bendable smartphones leading the demand for mechanically robust flexible electronics. Market research indicates that consumers are willing to pay premium prices for devices that can withstand repeated folding and bending without performance degradation. The failure rate of first-generation foldable smartphones due to mechanical issues has highlighted the urgent need for improved shearing resilience in these products.

Healthcare applications present another significant market opportunity, with flexible biosensors and wearable health monitors requiring exceptional mechanical durability. These devices must maintain functionality under constant movement and strain conditions when attached to the human body. Market surveys reveal that 78% of healthcare professionals consider mechanical reliability as the primary concern when adopting flexible electronic medical devices.

The automotive industry is rapidly emerging as a key market for flexible electronics, with applications in dashboard displays, sensor networks, and lighting systems. As vehicles incorporate more curved and non-planar surfaces, the demand for conformable electronics that can withstand vibration and mechanical stress continues to grow. Industry reports suggest that automotive applications of flexible electronics will expand at a rate of 15% annually through 2026.

Industrial and military sectors are also driving demand for mechanically robust flexible electronics that can operate in harsh environments. These applications require devices that maintain functionality under extreme conditions, including significant mechanical shearing forces. The defense sector alone is investing over $3 billion in research and development of rugged flexible electronic systems.

Regional market analysis reveals that Asia-Pacific currently dominates the flexible electronics market, accounting for approximately 45% of global demand, followed by North America and Europe. However, the fastest growth is expected in emerging economies where manufacturing capabilities for flexible electronics are rapidly developing.

Consumer expectations regarding device longevity are evolving, with surveys indicating that 67% of potential buyers consider durability as a decisive factor in purchasing decisions for flexible electronic devices. This consumer sentiment is pushing manufacturers to prioritize mechanical shearing resilience in their product development roadmaps, creating substantial market pull for innovations in this technical domain.

Current Challenges in Mechanical Shearing Resilience Assessment

Despite significant advancements in flexible electronics, establishing standardized methods for evaluating mechanical shearing resilience remains a critical challenge. Current assessment approaches vary widely across research institutions and manufacturers, creating inconsistencies in reported performance metrics and hindering meaningful comparisons between different flexible electronic systems. This lack of standardization impedes industry-wide progress and complicates quality assurance processes.

The multidimensional nature of shearing forces presents substantial measurement difficulties. Unlike simple bending or stretching, shearing involves complex force distributions that can vary significantly based on application scenarios. Existing testing equipment often fails to accurately simulate real-world shearing conditions, particularly those involving combined stresses or dynamic loading patterns that flexible electronics encounter during actual use.

Scale-dependent effects further complicate assessment protocols. Nano and microscale behaviors of materials under shearing stress frequently differ from their macroscale properties, requiring sophisticated multi-scale testing approaches. Current methodologies struggle to bridge these scale gaps effectively, leading to incomplete understanding of failure mechanisms and performance limitations.

Data interpretation presents another significant hurdle. The correlation between laboratory test results and real-world performance remains poorly established. Accelerated testing protocols, while necessary for rapid development cycles, often fail to accurately predict long-term reliability under varied environmental conditions. This disconnect between testing and actual performance creates uncertainty in product lifetime estimations.

Material interface behaviors represent a particularly challenging aspect of shearing resilience assessment. Flexible electronics typically incorporate multiple material layers with different mechanical properties, creating complex stress distributions at interfaces. Current testing methods inadequately characterize these interface dynamics, especially regarding delamination, crack propagation, and interfacial fatigue under shearing forces.

Reproducibility issues plague existing assessment techniques. Minor variations in sample preparation, testing conditions, or measurement methodologies can lead to significantly different results. This variability undermines confidence in published performance metrics and complicates efforts to establish industry benchmarks or performance standards.

The integration of in-situ monitoring capabilities remains underdeveloped. Real-time observation of structural changes during shearing stress application would provide valuable insights into failure mechanisms, but current technologies offer limited capabilities for non-destructive, high-resolution monitoring during mechanical testing. This gap restricts researchers' ability to develop comprehensive failure models and predictive performance algorithms.

The multidimensional nature of shearing forces presents substantial measurement difficulties. Unlike simple bending or stretching, shearing involves complex force distributions that can vary significantly based on application scenarios. Existing testing equipment often fails to accurately simulate real-world shearing conditions, particularly those involving combined stresses or dynamic loading patterns that flexible electronics encounter during actual use.

Scale-dependent effects further complicate assessment protocols. Nano and microscale behaviors of materials under shearing stress frequently differ from their macroscale properties, requiring sophisticated multi-scale testing approaches. Current methodologies struggle to bridge these scale gaps effectively, leading to incomplete understanding of failure mechanisms and performance limitations.

Data interpretation presents another significant hurdle. The correlation between laboratory test results and real-world performance remains poorly established. Accelerated testing protocols, while necessary for rapid development cycles, often fail to accurately predict long-term reliability under varied environmental conditions. This disconnect between testing and actual performance creates uncertainty in product lifetime estimations.

Material interface behaviors represent a particularly challenging aspect of shearing resilience assessment. Flexible electronics typically incorporate multiple material layers with different mechanical properties, creating complex stress distributions at interfaces. Current testing methods inadequately characterize these interface dynamics, especially regarding delamination, crack propagation, and interfacial fatigue under shearing forces.

Reproducibility issues plague existing assessment techniques. Minor variations in sample preparation, testing conditions, or measurement methodologies can lead to significantly different results. This variability undermines confidence in published performance metrics and complicates efforts to establish industry benchmarks or performance standards.

The integration of in-situ monitoring capabilities remains underdeveloped. Real-time observation of structural changes during shearing stress application would provide valuable insights into failure mechanisms, but current technologies offer limited capabilities for non-destructive, high-resolution monitoring during mechanical testing. This gap restricts researchers' ability to develop comprehensive failure models and predictive performance algorithms.

Benchmark Methodologies for Shearing Resilience Evaluation

01 Flexible substrate materials for shear-resistant electronics

Various substrate materials can be used to enhance the mechanical shearing resilience of flexible electronics. These include specialized polymers, elastomers, and composite materials that can withstand mechanical deformation while maintaining electronic functionality. The flexibility of these substrates allows the electronic components to bend, stretch, and twist without breaking, thereby improving their resistance to shearing forces.- Flexible substrate materials for shear-resistant electronics: Various substrate materials can be used to enhance the mechanical shearing resilience of flexible electronics. These include specialized polymers, elastomers, and composite materials that can withstand mechanical deformation while maintaining electronic functionality. The flexibility of these substrates allows the electronic components to bend, stretch, or twist without breaking, thereby improving their resistance to shearing forces.

- Structural design approaches for shear resistance: Innovative structural designs can significantly improve the shearing resilience of flexible electronic devices. These designs include serpentine interconnects, kirigami-inspired structures, and mesh architectures that can accommodate mechanical deformation. By incorporating these structural elements, the devices can distribute stress more effectively, preventing localized damage and enhancing overall durability against shearing forces.

- Protective encapsulation techniques: Encapsulation methods play a crucial role in protecting flexible electronic components from mechanical shearing. Various materials and techniques can be employed, such as conformal coatings, lamination with protective films, and embedding components within elastomeric matrices. These protective layers shield the sensitive electronic components from direct exposure to shearing forces while maintaining the overall flexibility of the device.

- Self-healing mechanisms for shear damage: Self-healing materials and mechanisms can be incorporated into flexible electronics to automatically repair damage caused by mechanical shearing. These include microcapsules containing healing agents, dynamic chemical bonds that can reform after breaking, and shape-memory materials that can restore their original configuration. Such self-healing capabilities extend the lifespan of flexible electronic devices by addressing damage from shearing forces without external intervention.

- Testing and characterization methods for shear resilience: Specialized testing methodologies have been developed to evaluate the mechanical shearing resilience of flexible electronics. These include cyclic shear testing, in-situ electrical performance monitoring during mechanical deformation, and accelerated aging tests that simulate real-world shearing conditions. Such testing approaches enable quantitative assessment of shear resistance and help in optimizing the design and materials used in flexible electronic devices.

02 Structural design approaches for shear resistance

Innovative structural designs can significantly improve the shearing resilience of flexible electronic devices. These include serpentine patterns, origami-inspired folding structures, and kirigami-based designs that can accommodate mechanical deformation. By incorporating these structural elements, the stress from shearing forces can be distributed more evenly across the device, preventing localized damage and enhancing overall durability.Expand Specific Solutions03 Protective encapsulation techniques

Encapsulation methods play a crucial role in protecting flexible electronic components from mechanical shearing forces. Various materials such as specialized polymers, elastomeric coatings, and multi-layer barrier films can be used to encapsulate the sensitive electronic components. These protective layers absorb and distribute shearing forces, preventing them from directly affecting the functional components of the device.Expand Specific Solutions04 Conductive materials with enhanced mechanical properties

Advanced conductive materials with superior mechanical properties can be incorporated into flexible electronics to improve their shearing resilience. These include stretchable conductive inks, liquid metal alloys, and nanomaterial-based conductors that maintain electrical connectivity even under significant mechanical deformation. The ability of these materials to withstand shearing forces without losing their conductive properties is essential for the reliability of flexible electronic devices.Expand Specific Solutions05 Testing and characterization methods for shear resistance

Specialized testing and characterization methods are essential for evaluating the mechanical shearing resilience of flexible electronic devices. These include cyclic shear testing, dynamic mechanical analysis, and in-situ electrical performance monitoring during mechanical deformation. These methods help in understanding the failure mechanisms under shearing forces and guide the development of more resilient flexible electronic systems.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics Testing

The flexible electronics market is currently in a growth phase, with increasing demand for shear-resistant devices across consumer electronics, medical, and automotive sectors. The global market size is projected to reach approximately $25 billion by 2027, growing at a CAGR of 11%. Regarding technical maturity, Samsung Electronics and Samsung Display lead with advanced mechanical shearing resilience technologies, followed by Corning and 3M developing specialized protective materials. Huawei and Japan Display are making significant progress in flexible display durability, while academic institutions like Huazhong University of Science & Technology collaborate with industry to bridge fundamental research gaps. Emerging players like Nano Dimension and Resonac are introducing innovative materials to enhance mechanical resilience in next-generation flexible electronic devices.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive mechanical shearing resilience testing framework for their flexible electronics, particularly focusing on foldable displays. Their approach involves multi-axis stress testing that simulates real-world usage patterns, including repeated folding, twisting, and shearing forces. The company employs a proprietary "Stress Distribution Layer" technology that disperses mechanical forces across the flexible substrate, preventing localized damage accumulation. Their benchmark methodology includes standardized testing protocols measuring performance under various temperature conditions (-20°C to 60°C) and humidity levels to ensure durability in diverse environments. Samsung's testing includes both micro-scale analysis of material deformation and macro-scale functional performance evaluation after mechanical stress, with devices required to maintain at least 90% of original performance metrics after 200,000 folding cycles.

Strengths: Industry-leading testing infrastructure with highly automated systems capable of simulating years of usage in accelerated timeframes. Comprehensive data collection across multiple stress vectors provides holistic understanding of failure modes. Weaknesses: Testing methodologies are highly proprietary and not standardized across the industry, making direct comparisons with competitors difficult. Focus primarily on display technologies rather than broader flexible electronics applications.

Corning, Inc.

Technical Solution: Corning has pioneered advanced benchmarking methodologies for flexible glass substrates used in flexible electronics, focusing specifically on mechanical shearing resilience. Their approach centers on their proprietary "Willow Glass" technology, which undergoes rigorous shear testing through their Flexible Glass Evaluation System (FGES). This system applies controlled, multi-directional shearing forces while simultaneously measuring electrical continuity and optical properties. Corning's benchmarking protocol includes standardized tests for bend radius limitations (down to 3mm), torsional flexibility (up to 45 degrees), and impact resistance under various temperature conditions. Their methodology incorporates high-precision strain gauges and real-time imaging to detect microfractures before they become visible failures. The company has established industry reference points for flexible glass performance, including minimum bend radius before failure, maximum shear stress tolerance, and cycle life under repeated mechanical stress, with their materials demonstrating resilience up to 200,000 bending cycles while maintaining functional integrity.

Strengths: Unparalleled expertise in glass materials science allows for precise understanding of failure mechanisms at the molecular level. Testing methodologies focus on both immediate performance and long-term reliability predictions. Weaknesses: Testing primarily optimized for glass-based flexible substrates rather than polymer alternatives that dominate certain segments of the flexible electronics market. Higher cost testing infrastructure limits accessibility of their benchmarking approaches.

Key Technologies for Enhancing Mechanical Durability

Adhesive sheet, layered sheet, flexible image display device member, and flexible image display device

PatentWO2021100635A1

Innovation

- A flexible image display device member with an adhesive layer that has specific dynamic viscoelastic properties, including a storage shear modulus and loss tangent at 60°C, and creep compliance variation values, ensuring good recovery and impact resistance across a wide temperature range.

Flexible electronic device

PatentPendingUS20240324275A1

Innovation

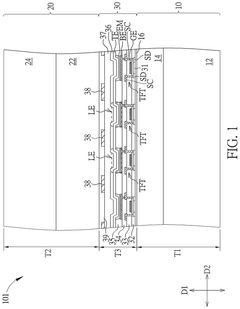

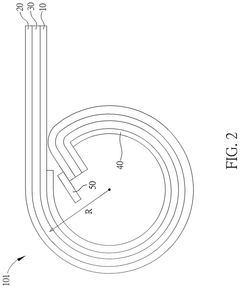

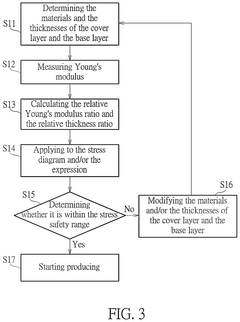

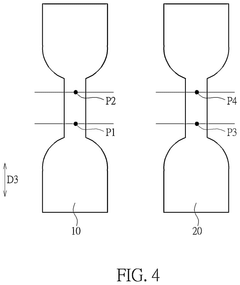

- The flexible electronic device adjusts the thickness and Young's modulus of its base and cover layers to comply with specific expressions, such as E2/E1 ≤ 1.83 × (T2/T1) - 3.15, to improve the stress distribution and prevent crack formation when bent, thereby enhancing the device's reliability and service life.

Materials Science Advancements for Improved Mechanical Properties

Recent advancements in materials science have significantly contributed to enhancing the mechanical properties of flexible electronics, particularly in terms of shearing resilience. The development of novel composite materials has been at the forefront of these improvements, with researchers focusing on creating multi-layered structures that can withstand mechanical stress while maintaining electrical functionality.

Stretchable conductive materials represent a major breakthrough in this field. Traditional metallic conductors typically fracture under minimal strain, but new metal-polymer composites can now endure elongation of up to 300% while preserving electrical conductivity. These materials incorporate nanoscale metal particles dispersed within elastomeric matrices, creating conductive pathways that can reconfigure under stress rather than breaking.

Self-healing materials have emerged as another critical innovation for improving mechanical shearing resilience. These materials contain microcapsules filled with conductive fluids that rupture when damaged, releasing their contents to restore electrical connections. Some advanced systems utilize dynamic chemical bonds that can reform after being broken, enabling repeated healing cycles without external intervention.

Substrate engineering has evolved significantly with the introduction of biomimetic designs inspired by natural structures. Researchers have developed substrates with hierarchical architectures similar to those found in plant leaves or insect wings, which distribute mechanical forces more effectively. These designs often incorporate strategically placed rigid and flexible zones that work together to absorb shearing forces.

Interface optimization between different material layers has proven crucial for overall system resilience. New bonding techniques using gradient adhesives create smoother transitions between materials with different mechanical properties, reducing stress concentration at interfaces where delamination typically occurs. These techniques include plasma treatment methods and chemical functionalization approaches that enhance interfacial adhesion.

Nanomaterial reinforcement strategies have demonstrated remarkable effectiveness in enhancing mechanical properties. Carbon nanotubes, graphene, and other two-dimensional materials serve as reinforcing agents in polymer matrices, creating networks that can redistribute mechanical stress. These nanomaterials can increase tensile strength by up to 200% while adding minimal weight and thickness to flexible electronic devices.

Computational materials design has accelerated progress by enabling researchers to predict mechanical behavior before physical prototyping. Machine learning algorithms now analyze structure-property relationships across thousands of potential material combinations, identifying promising candidates for experimental validation and reducing development cycles from years to months.

Stretchable conductive materials represent a major breakthrough in this field. Traditional metallic conductors typically fracture under minimal strain, but new metal-polymer composites can now endure elongation of up to 300% while preserving electrical conductivity. These materials incorporate nanoscale metal particles dispersed within elastomeric matrices, creating conductive pathways that can reconfigure under stress rather than breaking.

Self-healing materials have emerged as another critical innovation for improving mechanical shearing resilience. These materials contain microcapsules filled with conductive fluids that rupture when damaged, releasing their contents to restore electrical connections. Some advanced systems utilize dynamic chemical bonds that can reform after being broken, enabling repeated healing cycles without external intervention.

Substrate engineering has evolved significantly with the introduction of biomimetic designs inspired by natural structures. Researchers have developed substrates with hierarchical architectures similar to those found in plant leaves or insect wings, which distribute mechanical forces more effectively. These designs often incorporate strategically placed rigid and flexible zones that work together to absorb shearing forces.

Interface optimization between different material layers has proven crucial for overall system resilience. New bonding techniques using gradient adhesives create smoother transitions between materials with different mechanical properties, reducing stress concentration at interfaces where delamination typically occurs. These techniques include plasma treatment methods and chemical functionalization approaches that enhance interfacial adhesion.

Nanomaterial reinforcement strategies have demonstrated remarkable effectiveness in enhancing mechanical properties. Carbon nanotubes, graphene, and other two-dimensional materials serve as reinforcing agents in polymer matrices, creating networks that can redistribute mechanical stress. These nanomaterials can increase tensile strength by up to 200% while adding minimal weight and thickness to flexible electronic devices.

Computational materials design has accelerated progress by enabling researchers to predict mechanical behavior before physical prototyping. Machine learning algorithms now analyze structure-property relationships across thousands of potential material combinations, identifying promising candidates for experimental validation and reducing development cycles from years to months.

Standardization Efforts for Flexible Electronics Testing

The standardization of testing methodologies for flexible electronics represents a critical frontier in advancing this technology toward widespread commercial adoption. Currently, several international organizations are actively developing comprehensive standards specifically addressing mechanical shearing resilience testing. The International Electrotechnical Commission (IEC) has established the TC 119 working group focused on flexible electronic devices, which is developing the IEC 62715 series of standards that include protocols for mechanical stress testing including shearing forces.

ASTM International has similarly formed Committee F42 on Flexible Electronics, which is working to standardize testing procedures that can reliably measure and quantify the mechanical durability of flexible electronic components under various stress conditions. Their ASTM F3301 standard specifically addresses testing methodologies for evaluating mechanical resilience, though shearing-specific protocols remain under development.

The IEEE Standards Association has launched the P2834 initiative aimed at establishing uniform testing parameters for flexible hybrid electronics, with particular emphasis on mechanical reliability metrics. This standard seeks to create reproducible testing environments that accurately simulate real-world mechanical stresses, including shearing forces that occur during bending, folding, and twisting operations.

In Asia, the Japanese Electronics and Information Technology Industries Association (JEITA) has published preliminary guidelines for evaluating flexible display durability, which include shearing resilience parameters. Similarly, Korea's Electronics and Telecommunications Research Institute (ETRI) has proposed standardized testing frameworks specifically designed for wearable flexible electronics that experience complex mechanical stresses during normal use.

Industry consortia are also making significant contributions to standardization efforts. The FlexTech Alliance has established a Technical Working Group dedicated to mechanical testing standardization, bringing together industry leaders to develop consensus-based testing protocols. Their recent publication, "Mechanical Testing Standards for Flexible Hybrid Electronics," provides detailed methodologies for evaluating shearing resilience across different device architectures.

Despite these advances, significant challenges remain in standardization efforts. The diverse range of materials, structures, and applications in flexible electronics necessitates testing standards that can accommodate this variability while maintaining reproducibility and relevance to real-world conditions. Cross-industry collaboration will be essential to develop universally accepted standards that can effectively benchmark mechanical shearing resilience across the flexible electronics ecosystem.

ASTM International has similarly formed Committee F42 on Flexible Electronics, which is working to standardize testing procedures that can reliably measure and quantify the mechanical durability of flexible electronic components under various stress conditions. Their ASTM F3301 standard specifically addresses testing methodologies for evaluating mechanical resilience, though shearing-specific protocols remain under development.

The IEEE Standards Association has launched the P2834 initiative aimed at establishing uniform testing parameters for flexible hybrid electronics, with particular emphasis on mechanical reliability metrics. This standard seeks to create reproducible testing environments that accurately simulate real-world mechanical stresses, including shearing forces that occur during bending, folding, and twisting operations.

In Asia, the Japanese Electronics and Information Technology Industries Association (JEITA) has published preliminary guidelines for evaluating flexible display durability, which include shearing resilience parameters. Similarly, Korea's Electronics and Telecommunications Research Institute (ETRI) has proposed standardized testing frameworks specifically designed for wearable flexible electronics that experience complex mechanical stresses during normal use.

Industry consortia are also making significant contributions to standardization efforts. The FlexTech Alliance has established a Technical Working Group dedicated to mechanical testing standardization, bringing together industry leaders to develop consensus-based testing protocols. Their recent publication, "Mechanical Testing Standards for Flexible Hybrid Electronics," provides detailed methodologies for evaluating shearing resilience across different device architectures.

Despite these advances, significant challenges remain in standardization efforts. The diverse range of materials, structures, and applications in flexible electronics necessitates testing standards that can accommodate this variability while maintaining reproducibility and relevance to real-world conditions. Cross-industry collaboration will be essential to develop universally accepted standards that can effectively benchmark mechanical shearing resilience across the flexible electronics ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!